Abstract

The synthesis of porous organic polymer materials with nanoscale range has long been an important science subject and received an increasing level of research interest owing to their essential properties merging both of the porous materials and polymers such as low skeleton density, processability, easy functionality, and diverse synthetic methods. In this chapter, several porous polymer materials including covalent organic frameworks (COFs), hypercrosslinked polymers (HCPs), conjugated microporous polymers (CMPs), polymers of intrinsic microporosity (PIMs), and macroporous polymers from high internal phase emulsions (HIPEs) will be introduced as well as their diversiform synthetic methods and potential applications including gas storage, carbon capture, separation, catalysis, sensing, energy storage and conversion.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Porous Polymer

- Pickering Emulsion

- Macroporous Material

- Sonogashira Coupling

- High Internal Phase Emulsion

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Design, construction, and utilization of advanced functional materials with special porous architectures in micro- and nanoscale range have long been an important science subject. Porous polymers especially have attracted a large amount of research attention owing to their unique characteristics that combine both porous materials and polymers [1]. First of all, porous polymers are able to be designed and prepared with high surface area and well-controlled pore structure [2,3,4]. Secondly, porous polymers are processable due to their polymer chain essence. For instance, they can be easily synthesized with various micromorphology such as hollow nanosphere [5,6,7], thin film [8,9,10], and monolithic form [11,12,13,14,15]. Some kinds of porous polymers may even be dissolved in common organic solvents for further solvent-based process technology, however, without losing their porosity [16,17,18].

Furthermore, a wide range of optional organic building blocks as well as multitudinous synthesis methods enable the resulting porous polymers facile to incorporate multiple chemical functionalities within networks or pore surface which is far different from inorganic porous materials such as zeolite, carbon, and silica [4, 19,20,21,22]. Besides, porous polymer frameworks are composed of light elements which provide a weight advantage in many applications.

For the porous polymers, surface area and pore size are the two most important factors that affect their performance. According to the IUPAC recommendation, pores can be divided into the following three species: micropores with pore size less than 2 nm; mesopores with pore size between 2 and 50 nm; and macropores with pore size larger than 50 nm [23]. Usually, smaller pore size contributes larger adsorption amount of sorbate molecules at lower pressures which results in a higher surface area [24]. To introduce micropore into the polymer matrix, rigid aromatic building blocks are necessary to be adopted directly linking together or by other rigid groups such as alkynes [25] or alkenes [26] in order to construct a fixed rigid structure which prevent the polymer chains from collapsing. After the removal of solvent, the space that solvent filled previously will be permanent pore [27].

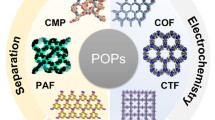

According to the synthetic methods and the chemical structure, microporous organic polymers (MOPs) can be roughly classified as covalent organic frameworks (COFs) [3, 28], hypercrosslinked polymers (HCPs) [29, 30], conjugated microporous polymers (CMPs) [31, 32], polymers of intrinsic microporosity (PIMs) [33, 34], covalent triazine-based frameworks (CTFs) [35, 36], porous aromatic frameworks (PAFs) [2, 37], and so on. Among them, COFs are a class of crystalline networks with well-ordered structures and uniform pore size that related to their monomers. COFs are usually formed via reversible bond-forming chemistry such as boronic acids’ self-condensation or with diols to form bromine rings by which the most thermodynamically stable structure can exist [27].

Some other polymers possess rather amorphous networks with disordered structure and normally a wider pore size range [38]. Amorphous networks always require metal-catalyzed high-yielding reactions to achieve entire condensation as possible. For example, Lewis acid catalytic Friedel–Crafts alkylation reaction is usually for HCPs synthesis [29], and CMPs are prepared by noble metal catalytic Sonographer–Ghaghara coupling, Yamamoto coupling, Suzuki coupling reactions, and so on [32].

In this chapter, we mainly discuss the following microporous organic polymers including covalent organic frameworks, hypercrosslinked polymers, conjugated microporous polymers and polymers of intrinsic microporosity as well as some macroporous polymers based on polymerization of high internal phase emulsions (polyHIPEs). Not only the design and synthetic strategies, but also the potential applications of these porous polymers will be introduced in detail including gas storage, carbon capture, separation, catalysis, sensing, energy storage, and conversion.

2 Covalent Organic Frameworks

Covalent organic frameworks are a new class of porous covalent crystalline organic networks based on dynamic covalent chemistry which leads to the process of forming, broking, and reforming covalent bonds [39]. Generally, linking organic molecules by covalent bonds into extended networks typically generates amorphous, disordered solid materials. The ability to develop strategies for obtaining crystals of such solids is of interest because it opens the way for precise control of the geometry and functionality of the extended structure, and the stereochemical orientation of its constituents. The attainment of crystals is done by several techniques in which a balance is struck between the thermodynamic reversibility of the linking reactions and their kinetics. This success has led to the expansion of COFs including organic units linked by these strong covalent bonds: B–O, C–N, B–N, and B–O–Si. Compared to the amorphous porous organic polymers (PIMs, CMPs, and HCPs), COFs have permanent geometry, and it is possible to predict the structures of the resulting COFs using powder X-ray diffraction (PXRD) techniques. For this advantage, it can be directed to the synthesis of COFs structures by design and for their formation with desired composition, pore size, and aperture, which make COFs an attractive class of new porous materials. In 2005, Yaghi and co-workers demonstrated the utilization of the topological design principle in their synthesis of covalent-linked crystalline porous organic frameworks [28]. Since this seminal work, the chemical synthesis of COFs has progressed significantly, and been used in gas storage, solid supports for catalysis, and optoelectronic devices. In this account, we outline how this chemistry was used to prepare crystalline COFs and highlight their synthesis, characterization, and applications.

2.1 Design and Synthesis

The synthesis of COFs could be designed through the principles of reticular chemistry [40,41,42,43,44]. Normally, the basic concerns for design mainly focus on the porosity and the structural regularity. In this regard, much experience has been obtained from the synthesis of metal-organic frameworks (MOFs). However, the crystalline framework of MOFs via the coordination bonds is much easier formed than to fabricate crystalline COFs via the covalent bonds. In order to form the crystalline solid, the formation of linkages should be well reversible and the reaction rate must be on a timescale that allows for self-correction of defects [45].

2.1.1 Design Principles

Crystalline COFs are synthesized in condensation reactions of organic building blocks, with geometry shape. The structure of the building blocks must meet two requirements: (1) the formation reaction should be reversible, and (2) the geometry of the building blocks should be well preserved in the COFs [46]. Figure 4.1 summarizes the synthetic reactions successfully applied for the COFs synthesis. The reaction A is based on the reversible formation of boronate anhydride from the dehydration of boronic acid. The synthesis of COF-1 was led by Yaghi and co-workers via this reaction [47]. An analogous dehydration reaction (reaction B) between boronic acid and (acetonide-protected) catechol results in the reversible formation of boronate esters by which a series of boron-containing COFs have been successfully obtained [47, 48]. The synthesis of triazine-based frameworks has been prepared via the nitrile cyclotrimerization under ionothermal condition, which represents a unique method (reaction C) [36, 49]. CTFs simultaneously provide high thermal, chemical, and mechanical stabilities along with a high degree of conjugation; however, they typically possess low crystallinity as a result of the poor reversibility of the trimerization reaction. The reactions D and E are based on the imine bonds structure (–C=N–), by which several COFs have been synthesized with the new networks. The dehydration of aldehyde and amine gives rise to the Schiff base-type linkage (reaction D), while the reaction E between aldehyde and hydrazide affords the hydrazine structure.

As mentioned above, the rigid conformation of the building blocks enables the topological design of the COFs. Figure 4.2 summarizes the building units used, the general features of which are rigid in structure and symmetric multiconnective so as to meet the requirement for constructing the regular pores of COFs. For clarity, these building blocks are classified based on functional groups such as (–B(OH)2, –OH, –CHO, –NH2, and –CN). The synthetic strategies for COFs are based on diversity of building blocks, which endows the COFs with high flexibility in their molecular design.

2.1.2 Synthetic Methods

Since Yaghi and co-works exploited the solvothermal method to achieve the first successful COF-1 in order to construct the skeleton of COFs, many research groups have attempted to expand the synthetic possibility in different ways. We summarize the solvothermal, ionothermal, and microwave methods applied for the COFs synthesis below. Compared to bulky methods, surface or film COFs have been developed via reactions on substrates, such as metal surface and graphene sheet.

-

Solvothermal Synthesis

Initial studies were carried out in Pyrex tube via the solvothermal synthesis method which was degassed using several freeze–pump–thaw cycles, sealed, and heated to a desired temperature for 2–9 days. The precipitate was obtained, washed with suitable solvents, and dried under vacuum to yield the COFs powder. Issues such as the solubility, reaction pressure, crystal growth rate, and reversibility are the important points to be considered when selecting the reaction media and conditions. For example, whether fully soluble or completely insoluble building blocks can lead to the synthesis of COFs needs further experimental investigations [50, 51].

Moreover, solvent combination and ratio are the important factors for the highly crystalline COFs synthesis. As an example, Jiang and co-workers discussed the influence of solvents on the crystallinity of COFs [51]. When the ratio of mesitylene and dioxane is 19/1 or 9/1(v/v), COFs with high crystallinity could be obtained. At the same time, a suitable temperature and optimal inside pressure ensure the reversibility of the reaction. Generally, COFs have been prepared at temperatures ranging from 85 to 120 °C which is dependent on the chemical reactivity of the building blocks.

-

Microwave Synthesis

Microware-assisted reactions have been widely adopted in chemistry and material synthesis [52, 53]. 2D COF-5 and 3D COF-102 were obtained via the microwave heating by Cooper and co-workers [54, 55]. Compared to the solvothermal methods, microwave synthesis provides several advantages, such as rapid reaction, without sealed vessel, and more efficient.

-

Ionothermal Synthesis

Thomas and co-workers exploited the ionothermal synthesis method to produce crystalline porous CTFs [36]. Cyclotrimerization of nitrile building units in molten ZnCl2 at 400 °C affords crystalline CTFs. The molten ZnCl2 plays important roles in this system, not only as the solvent and catalyst but also as the template for the reversible cyclotrimerization and crystallization. However, most synthesized CTFs are amorphous materials, a probable reason is that this method seems to be partially reversible [46].

-

Synthesis of Monolayer COFs on Substrates

Forming the monolayer COFs on surface takes a further step for real applications. So far, Ag, highly ordered pyrolytic graphite (HOPG), and graphene have been used to prepare monolayer COFs. Condensation of the building blocks onto a metal surface formed monolayer of COF-1 and COF-5 [5]. The molecular arrays were obtained by the sublimation of 1,4-benzenediboronic acid (BDBA) and 2,3,6,7,10,11-hexahydroxytriphenylene (HHTP) under ultrahigh vacuum (UHV) from two heated molybdenum crucible evaporators onto a clean Ag(111) surface. Images of molecular layers were conducted using scanning tunneling microscopy (STM) at room temperature [56] (Fig. 4.3). The preparation of defect-free monolayer may require fine-tuning reaction conditions, highly purified building blocks, and employing a suitable single-crystal metal substrate to direct the building block alignment.

STM image of the near-complete monolayer of SCOF-1 film synthesized from the deposition of 1 on Ag (111). The inset shows the proposed chemical structure for SCOF-1. Reproduced from Ref. [56] with kind permission of © 2008 American Chemical Society

Subsequently, a HOPG surface was adopted instead of a metal surface to prepare monolayer COFs [57]. In this experiment, biphenyldiboronic acid, 1,4-benzenediboronic acid, and 9,9-dihexylfluorene-2,7-diboronic acid were deposited onto a HOPG surface from their THF solutions, and CuSO4·5H2O as a water “reservoir,” followed by heating in a sealed autoclave at 150 °C for 1 h to form COFs monolayer. Structural analysis of the network showed a uniform pore spacing of 2.3 nm, which was in excellent agreement with the 2.27 nm size predicted by density functional theory (DFT) calculations and thus confirming the covalent formation of boroxine-linked SCOF-1. To achieve the reliable interface of electrodes or incorporate into real devices, Dichtel and co-workers reported the synthesis and characterizations of layered oriented COF-5 films onto single-layer graphene (SLG on SiO2) surface (Fig. 4.4) [58,59,60]. Then, TP-COF, NiPc-COF, HHTP-DPB-COF, and ZnPc-PPE-COF were successfully prepared on graphene surfaces, and their thicknesses can be tuned by controlling the reaction time.

Solvothermal synthesis of HHTP and PBBA on a single-layer graphene surface, affording COF-5 as the film on the graphene surface and as the powder precipitated around the bottom of the tube. Reproduced from Ref. [58] with kind permission of © 2011 The American Association for the Advancement of Science

2.1.3 Structural Studies

Due to the highly crystalline structure, COFs with special architecture can be characterized by PXRD techniques. The structural simulation provides an important tool in revealing COFs’ stacking structures. Besides, the structural regularity, composition, and atomic linkage of the COFs can be characterized by infrared spectroscopy, solid-state NMR spectroscopy, elemental analysis, and X-ray photoelectron spectroscopy. In molecular perspective, COFs can be classified into three categories: boron-containing, triazine-based, and imine-based COFs.

-

Boron-containing COFs

In 2006, COF-1 was synthesized as a crystalline material by the self-condensation of 1,4-phenylenediboronic acid (BDBA) which resulted in a structure consisting of extended layers stacked in staggered form and gave hexagonal pores with 1.5 nm diameter and BET surface area of 711 m2 g−1. It has also been applied for the synthesis of three-dimensional COFs by condensation of molecules with tetrahedral structure, such as tetra(4-dihydroxyborylphenyl)methane (TBPM) and tetra(4-dihydroxyborylphenyl)silane (TBPS) [3]. Subsequently, Lackinger and co-workers used para-diboronic acids, in which the size of the organic backbone varied from phenyl to quaterphenyl incrementally, to synthesize a series of isoreticular 2D COFs [61]. These networks ranged from 1.5 to 3.8 nm, and the corresponding pore sizes increased from 1.0 to 3.2 nm. Scanning tunneling microscopy was employed for structural characterization of the covalent networks as well as non-covalent self-assembled structures that were formed on the surface prior to the thermally activated polycondensation reaction. Recently, Fischer and co-workers developed a novel synthesis strategy for COF-1 at room temperature which was suitable for multigram scale synthesis [62]. This methodology shifts COF synthetic chemistry from sealed tubes to open beakers.

In addition to self-condensation, boronic acids can also react with catechols to form five-membered C2O2B boronate esters. And the mechanistic studies of COF-5 formation have been done from initial homogenous conditions (Fig. 4.5) [63]. The obvious advantage of this co-condensation strategy is the diverse combination of boronic acids and diols as building units, by which a series of COFs could be constructed with different properties and functionalities. For example, via the co-condensation of monomers 2,3,6,7,10,11-hexahydroxytriphenylene (HHTP) and pyrene-2,7-diboronic acid (PDBA), a 2D COF material (TP-COF) was successfully obtained [64]. TP-COF is a highly blue luminescent and electrical conductive material. Moreover, the functionality of COFs could be tailored with more versatile building units. For instance, via the co-condensation of donor and acceptor monomers, COFs with segregated donor–acceptor heterojunctions were synthesized [59, 65, 66]. Meanwhile, photoresponsive structurally dynamic COFs [67], polygonal shape-persistent macrocycles COFs [68], and star-shaped COFs [69] were also successfully synthesized using this strategy.

A comparison of heterogeneous and homogeneous growth conditions for COF-5 and turbidity measurement of COF-5 formation as a function of time (8 mM HHTP, 1.5 equiv of PBBA, 15 equiv of MeOH, 4:1 dioxane/mesitylene, 90 °C). Reproduced from Ref. [63] with kind permission of © 2014 American Chemical Society

Based on the methods above, three-dimensional COFs were synthesized by condensation or co-condensation of molecules with tetrahedral geometry, such as TBPM or TBPS, TBPM, and HHTP [3].

-

Imine-based COFs

Similarly, C=N bond formation reaction has been applied to synthesize COFs with imine linkages [70]. One category is the “Schiff base”-type COFs formed via the co-condensation of aldehydes and amines (reaction D in Fig. 4.1). The first imine-based COF (COF-300) was synthesized via the dehydration reaction of tetra-(4-anily)methane and terephthaldehyde [70]. Subsequently, many scientists involved in this field. Jiang [71,72,73,74,75,76] and Rahul [77,78,79,80,81] are the best of them. Jiang and co-workers used this method mainly to focus on porphyrin-containing COFs synthesis [71, 73, 76]. By tuning the size and length and by introducing specific functional groups of the building blocks, photochemical active COFs [73], chiral COF catalysts, [75], adsorbents [73, 76], and chemical probe [82] can be produced. Rahul and co-workers designed a series of COFs based on the 1,3,5-triformylphloroglucinol (TP) units [77, 79,80,81, 83]. More recently, 3D imine-based COFs were synthesized via the Knoevenagel condensation reaction, showing excellent catalytic activity [84]; the other one was 3D pyrene-based COF, which was constructed through [4+4] imine condensation reactions. The novel 2D COFs with two different pores were recently developed.

Zhao and co-workers designed a dual-pore COF, which possessed both micopores and mesopores (7.1 and 26.9 Å) (Fig. 4.6a) [85]. Zhang and co-workers successfully synthesized two COFs with heterogeneous pore structures through the desymmetrized vertex design strategy [86]. Pore size distribution analysis revealed that two types of micropores (1.06 and 1.96 nm) were incorporated into the resulting COFs (Fig. 4.6b).

a Schematic representation for the synthesis of TpBDH and TfpBDH [one unit of a space filling model of TpBDH and TfpBDH is shown in the inset of the chemical drawing model]; b syntheses of HP-COF-1 and PSDs of HP-COF-1. Reproduced from Ref. [85] with kind permission of © 2014 American Chemical Society, Reproduced from Ref. [86] with kind permission of © 2015 American Chemical Society

Another type of imine-based COFs is hydrazone-linked COFs synthesized by pioneer Yaghi and co-workers via the co-condensation reaction of aldehydes and hydrazides (Fig. 4.7). By employing 2,5-diethoxyterephthalohydrazide and 1,3,5-triformylbenzene or 1,3,5-tris(4-formylphenyl)benzene as the building units, COF-42 and COF-43 were successfully synthesized [87]. The existence of abundant hydrogen bonds within the hydrazone units is beneficial for the formation of the eclipsed structure. More recently, Wang and co-workers designed fluorescent COFs (COF-LZU8) by introducing the thioether groups into COF-42 for efficient detection and removal of Hg2+ ions [88].

Building units and the extended structures of COF-42 and COF-43. Reproduced from Ref. [87] with kind permission of © 2011 American Chemical Society

-

Triazine-based COFs

Covalent triazine-based frameworks were firstly developed by Thomas and co-workers [36]. The CTFs synthesis was based on cyclotrimerization of aromatic nitrile building units in molten ZnCl2 at 400 °C (reaction C in Fig. 4.1). Interestingly, the ratio of ZnCl2 to monomer is the key to the CTFs synthesis. The higher ratio (10:1) would lead to an amorphous polymer but with higher surface area (1123 m2 g−1). Compared to the two types of materials above, the CTFs are usually of lower crystallinity. The reaction for CTFs is partially reversible reaction. To date, only two crystalline CTFs have been successfully synthesized [36, 49].

-

Other COFs

Polyimide-COFs (PI-COFs) were designed by Yan and co-workers using the imidization reaction. The resulting PI-COFs possessed large pore sizes that can be tuned by extending the building units, and in particular, PI-COF-3 displayed the largest size (5.3 nm) among the results reported to date [89]. Subsequently, 3D porous PI-COFs with non- or fourfold-interpenetrated diamond networks were synthesized which represented the first kind of COFs ever to be employed in controlled drug delivery with high loading and good release control [90]. Novel COFs with two types of covalent bonds have been developed using orthogonal reactions. This strategy can be adapted not only in binary systems but also in more complicated systems. For example, the first multiple-component NTU-COF-2 showed both high BET surface area and large H2 uptake capacity [91].

2.2 Application Exploration

The applications of COFs are derived from their porosity and functional unit skeleton. With tunable porous architecture, these COFs are new candidates for further applications, such as gas storage, catalyst, and photoelectric device.

2.2.1 Gas Storage

-

Hydrogen Storage

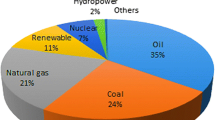

Fossil fuels such as oil, natural gas, and coal contain carbon and produce CO2, CO gases including a higher ratio of nitrogen oxides (NO x ) and sulfur dioxide (SO2) which lead to pollution and global warming. Moreover, coal and fuel oil are available in limited supply. However, hydrogen is a clean, highly abundant, and non-toxic renewable fuel, and it is viewed as a promising clean fuel in the future which only generates water vapor after burning. The major problem with this fuel is its storage since it needs to be stored like other compressed gases. Hydrogen is usually stored in three different ways, viz. compression, liquefaction, and in a solid material [92, 93]. COFs have generated much interest in the study of the hydrogen storage materials.

Normally, COFs with larger surface areas possess higher hydrogen uptake capacities under the same condition. For example, 3D COF-102 with a higher BET surface area of 3620 m2 g−1 showed the highest hydrogen uptake up to 7.2 wt% at 1 bar and 77 K [94]. This capacity is comparable to that of MOF-177 (7.5 wt%, S BET: 4500 m2 g−1) [95], MOF-5 (7.6 wt%, S BET: 3800 m2 g−1) [96], and PAF-1 (7.5 wt%, S BET: 5600 m2 g−1) [2]. For 2D COFs, COF-10 (S BET: 1760 m2 g−1) showed the highest hydrogen uptake of 3.92 wt% at 1 bar and 77 K compared to the other 2D COFs [94]. Recently, Zhao and co-workers developed a high BET surface area (1619 m2 g−1) NTU-COF-2, with two types of covalent bonds using orthogonal reaction. Its hydrogen uptake is 1.55 wt% at 1.0 bar and 77 K [91]. However, the exceptional COF-11 Å with the lower BET surface area (105 m2 g−1) showed hydrogen uptake of 1.22 wt% at 1.0 bar and 77 K [94]. The DOE road map target for hydrogen storage is set to be 9 wt% and 81 kg H2 m−3 at 253–323 K with a pressure of 100 atm by the year 2015. Rooting on this purpose, the practical employment of COFs toward hydrogen uptake seems remoted.

-

Carbon Dioxide Storage

The emission of CO2 due to the combustion of fossil fuels is one of the major sources for the accumulation of CO2 in the atmosphere. To stabilize atmospheric CO2 level, it is necessary to develop CO2 capture and storage/sequestration technologies [94]. The storage of CO2 has been extensively studied using a wide range of porous materials, for example, porous carbons, silicas, and MOFs [42, 97, 98]. Yaghi and co-workers achieved a very high CO2 uptake of COF-102 reaching 120 wt% at 55 bar and 298 K [94]. However, COF-102 showed higher adsorption at low pressures than COF-108 because of their compact atomic packing; on the contrary, at high pressures, higher CO2 uptake value (422.4 wt%) was obtained for COF-108. Compared with other porous materials (for example, ZIFs) [43, 99], COFs via reasonable design might become good candidates for CO2 storage.

-

Methane Storage

Natural gas has been demonstrated to be potential as an alternative fuel for vehicular application due to its abundance and low price. Much effort has been focused on reaching the DOE target (180 cm3) of storing methane at 35 bar, because this is the pressure in natural gas pipelines. Similar to the cases of hydrogen storage, the capability of methane storage is based on surface areas of COFs. The adsorption capacity of methane at 35 bar and 298 K in 3D COF-102 (18.7 wt%, 3620 m2 g−1) is higher than that of 3D COF-103 (17.5 wt%, 3530 m2 g−1) [94]. For 2D COFs, COF-5 has a lower value (8.9 wt%). Although the capacities of methane storage are similar in some COFs, decreasing the costs and efforts in synthesizing COFs still remain a big challenge toward the practical employment.

-

Ammonia Storage

Boron-containing COFs with abundant boron element (electron-deficient element) are useful for adsorbing ammonia. Among the series of boron-containing COFs, COF-10 has the highest ammonia uptake (15 mol kg−1) at 1 bar and 298 K [100]. Moreover, COF-10 has a good circulation property. However, the stability of boron-containing COFs restrains their application.

2.2.2 Heterogeneous Catalysis

Organocatalysis in homogeneous systems is problematic because of the difficulty of separating expensive catalysts for repeated use [101,102,103]. Most heterogeneous organocatalysts are based on linear polymer supports; however, such catalysts exhibit low activity owing to the inefficient access to the catalytic sites. To overcome this issue, crystalline MOF-based organocatalysts have been developed. However, their stability, enantioselectivity, and diastereoselectivity need to be improved [75]. Imine-based COFs, due to containing abundant C=N (basic group), are useful for organic catalysis. Jiang and co-workers developed π-electronic COFs as a new type of metal-free heterogeneous catalyst, which enabled the high-performance catalysis of Diels–Alder reactions in neat water and ambient condition. Meanwhile, they prepared the mesoporous COFs with two distinct chiral segments by post-synthetic functionalization. The resulting crystalline metal-free catalysts displayed high activity, enantioselectivity, and recyclability for Michael reactions. On the other hand, imine-based COFs can incorporate metal ions into its pores via the coordination reaction with nitrogen atoms in the COFs. In 2011, Wang and co-workers realized the first application of metal COFs (Pd/COF-LZU1) for highly efficient Suzuki-Miyaure coupling catalysis reaction [104]. Recently, Vaidhyanathan and co-workers reported an amphiphilic triazine COF and the facile single-step loading of Pd(0) nanoparticles. The 18–20% of nano-Pd loading gave highly active composite working in open air at low concentrations (Conc. Pd(0) < 0.05 mol%, average TON 1500) catalyzing simultaneous multiple site Heck couplings and C–C couplings using “non-boronic acid” substrates, and exhibited good recyclability with no sign of catalyst leaching [105].

2.2.3 Photoelectric Applications

COFs with the photoelectric performance (PPy-COF) were firstly synthesized via the self-condensation of PDBA under solvothermal condition by Jiang and co-workers [106]. Remarkably, PPy-COF possessed 2D eclipsed structures with a higher BET surface area of 868 m2 g−1, and showed a fluorescence shift compared to its monomer PDBA. PPy-COF is electrically conductive, displaying photoconductivity with a quick response to light irradiation, and is capable of repetitive on–off photocurrent switching with a large on–off ratio (Fig. 4.8).

a I–V profile of PPy-COF between two Pt electrodes 10 mm apart (black curve: without PPy-COF; blue curve with PPy-COF; red curve with iodine-doped PPy-COF). b Electric current when the 2 V bias voltage was turned on or off. c I–V profile of PPy-COF between sandwich-type Al/Au electrodes (black curve without light irradiation; red curve upon light irradiation). d Photocurrent when the light was turned on or off. Reproduced from Ref. [106] with kind permission of © 2009 Wiley-VCH (color figure online)

Phthalocyanines (Pcs) have received considerable attentions due to their unique optical and electronic properties which give rise to the application of Pcs in various domains, such as organic field-effect transistor, optical information storage, organic solar cell, photodynamic therapy, and nonlinear optical material. Phthalocyanine-based polymers combine the excellent physical and chemical properties of Pcs as well as good solubility and processability, which are becoming one of the research hot spots. Spitler and Dichtel synthesized an eclipsed 2D COF (PC-PBBA-COF) containing metal-free phthalocyanine groups using phthalocyanine tetra(acetonide) and BDBA [48]. At the same time, Jiang and co-workers synthesized nickel phthalocyanine-based COFs (NiPc COF and 2D-NiPc-BTDA COF) via the boronate esterification reaction of (2,3,9,10,16,17,23,24-octahydroxyphthalocyaninato) nickel(II) with BDBA or benzothiadiazole diboronic acid (BTDADA) [50, 51]. Both NiPc COF and 2D-NiPc-BTDA COF possessed eclipsed structures with BET surface areas of 624 and 877 m2 g−1, respectively. Due to 2D eclipsed structure, NiPc COF showed an enhanced light-harvesting capability in the visible and near-infrared regions. And NiPc COF revealed highly photoconductive property, exhibiting a panchromatic light response and exceptional sensitivity to visible and near-infrared photons. Subsequently, they synthesized 2D tetragonal metallophthalocyanine by introducing electron-withdrawing blocks at the edges of n-channel 2D COFs. 2D-NiPc-BTDA COF turned to be an n-type semiconductor and exhibited great changes in the carrier transport mode with a broad and enhanced absorbance of light up to 1000 nm. Moreover, this COF exhibited panchromatic photoconductivity and was highly sensitive to near-infrared lights. Recently, they developed a new donor–acceptor strategy to construct COFs with various skeletons and pore for charge separation and photoenergy conversion. For example, using a three-component topological design diagram in conjunction with click chemistry, they developed a method for converting the open lattice of COFs into photoelectric structures. Most recently, they reported the design and synthesis of a photoresponsive COF with anthracene units as the photoresponsive π-building blocks. The COF is switchable upon photoirradiation to yield a concavo-convex polygon skeleton through the interlayer[4p+4p] cycloaddition of anthracene units stacked in the π-columns [67].

Porphyrins possess extensive π-conjugated systems which contribute to electron transfer from donor unit to acceptor unit, and high molar absorption coefficient in light absorption, and their properties can be easily tuned via synthetic modifications for the periphery or by metal insertion into the cavity of porphyrin. In recent years, porphyrins have been applied in the synthesis of porous materials such as MOFs [47, 107, 108], CMPs [109], and COFs [76]. Jiang and co-workers reported the porphyrin-based COF (ZnP-COF) constructed via the boronate esterification reaction of zinc(II) 5,10,15,20-tetrakis(4-(dihydroxyboryl)phenyl) porphyrin and 1,2,4,5-tetra-hydroxybenzene. ZnP-COF revealed a tetragonal 2D eclipsed structure with a large BET surface area of 1742 m2 g−1 and an average pore size of 2.5 nm. Subsequently, the photoelectronic properties of ZnP-COF and other two porphyrin-based COFs (H2-COF and CuP-COF) have been studied [46]. Compared to H2-COF, ZnP-COF and CuP-COF showed high-rate ambipolar and electron conduction, respectively. CuP-COFs have been investigated in a recent work, in which fluoro-substituted and non-substituted arenes at different molar ratios were integrated into the edge units that stack to trigger self-complementary π-electronic interactions in the COFs. These interactions also showed a prominent effect on changing the π-electron distribution in the framework and lowering the HOMO-LUMO gap (Fig. 4.9) [71].

Schematic representation of the synthesis of COFs integrated with self-complementary π-electronic interactions (CuP-TFPhX, X = 25, 50, and 75 mol%) and the CuP-Ph and CuP-TFPh Controls. Reproduced from Ref. [71] with kind permission of © 2013 American Chemical Society

2.3 Summary

COFs have emerged as an important class of materials because their backbone is built entirely from light elements (thus far, C, N, O, B, Si) held together by strong covalent bonds (B–O, C–N, B–N, and B–O–Si) to make robust porous materials including the advantages of predictable structures and tunable pore functionality and metrics. The crystallization problem has been overcome in COF chemistry except CTFs, and a large variety of COF structures have been made and will continue to evolve in their diversity and complexity. However, the development of new synthetic methods is the key to broaden the COFs family. Formability is another important issue for the practical application of COFs. Finally, both the introduction of functional groups and post-modification are the critical subjects according to the practical application of COFs.

3 Hypercrosslinked Polymers

Hypercrosslinked polymers represent a novel class of porous polymer materials containing abundant microporous structure [29, 30]. These polymers are mainly prepared by the Friedel–Crafts chemistry and developed by taking the concepts of “crosslinking” which, however, is further extended [110]. The obtained polymer networks are usually cross-linked with highly rigidity linkages which prevent the polymer chains from collapsing. Therefore, these resulting polymer materials contain permanent micropore, high surface area, and large pore volume. According to the difference between the synthetic methods, hypercrosslinked polymers are mainly prepared by the following three approaches: (1) post-crosslinking polymer precursors, (2) direct one-step polycondensation of functional monomers, and (3) knitting rigid aromatic building blocks with external crosslinker. In this part, we will introduce the development of hypercrosslinked polymers in detail as well as compare the merits between various synthetic methods. Networks with specific functionalities and controlled micromorphology which can be applied in broad practical and potential applications such as gas storage, adsorption, separation, catalysis, sensing are also discussed.

3.1 Post-crosslinking Procedure

“Davankov-type” resins are commonly regarded as the first category of hypercrosslinked polymers which were initially discovered and investigated in the early 1970s [111]. These hypercrosslinked polymeric networks can be generated by further crosslinking of either dissolved linear polystyrene or swollen gel-type styrene-divinylbenzene copolymer precursors [112]. The representative reaction scheme is provided in Fig. 4.10. The polymer precursors are dissolved or swollen in solvents which separate the polymer chains, and then, a crosslinking step was carried out immediately to lock these chains forming a rigid intensive network. After removing the solvent, the rigid linkage units prevent the chains from collapsing thus resulting in interconnected pores in the polymer matrix [113].

Scheme of the representative hypercrosslinking reaction. Reproduced from Ref. [113] with kind permission of © 2007 Royal Society of Chemistry

As pioneers in this field, Davankov with his colleagues has done a large amount of research in preparing various kinds of hypercrosslinked materials as well as exploring the reaction conditions [110, 112, 114,115,116]. An intermolecular hypercrosslinked soluble material was obtained from the linear polystyrene using monochlorodimethyl ether (MCDE) as the crosslinking agent in the presence of SnCl4 catalyst [114]. A series of surface areas up to 680–1000 m2 g−1 can be obtained with materials showing potential applications in chromatography, separation of contaminants from liquid solutions, and adsorption of organic vapors.

Low-cost CCl4 is a good crosslinker with less toxicity compared with monochlorodimethyl ether. By post-crosslinking styrene-divinylbenzene copolymer precursors, a series of 1000 m2 g−1 surface area hypercrosslinked resins were produced via Friedel–Crafts reaction with CCl4 as the crosslinker as well as aluminum or ferric chloride as the catalyst [117].

With similar linear structure as polystyrene, polyDVB-VBC (which is short for polydivinylbenzene-co-vinylbenzyl chloride) can be efficient precursors for hypercrosslinking which convert the chloromethyl groups into methylene bridges thus creating stronger crosslinking linkages (Fig. 4.11) [118, 119]. Sherrington and co-workers [119] synthesized a variety of hypercrosslinked polymers based on polyDVB-VBC precursors and investigated the porosity discrepancy affected by different synthetic conditions including the monomer ratio, solvent, catalyst, and reaction time. The resulting surface areas ranged from 300 to 2000 m2 g−1 of different precursors with tiny structure variation using Lewis acid catalysts. For example, a gel-type precursor containing 2 mol% DVB yielded a surface area of ~1200 m2 g−1 within only 15 min initiating crosslinking which rose steadily to 2090 m2 g−1 after 18 h.

Post-hypercrosslinking of DVB-VBC polymer precursors. Reproduced from Ref. [119] with kind permission of © 2006 American Chemical Society

Despite various synthetic strategies, hypercrosslinked polymers with controllable pore size and size distribution were also studied. Tan group [120] chose the typical poly(DVB-VBC) copolymer as the precursor to investigate the influence of the precursor structure on porosity. By increasing the DVB content, the pore size of the obtained hypercrosslinked poly(divinylbenzene-co-vinylbenzyl chloride) (HCP-DVB-VBC) can be efficiently adjusted from macropore to micropore size showing a more uniform and narrower microporous structure. When the DVB concentration is higher than 7%, a typical type I nitrogen adsorption/desorption isotherm was observed indicating a pure microporous polymer network. Gas adsorption properties of these materials were also investigated indicating that the smaller micropore size and higher microporous volume are beneficial for H2 and CO2 uptakes.

Recently, polystyrene-base block copolymers exhibited attractive advantages in designing microporous materials with hollow structure [121, 122]. By adopting the self-assembly of PMMA-b-PS copolymer, Wu et al. [122] synthesized uniform PMMA@PS core–shell micelles in a selected mixed solvents, followed by hypercrosslinking to produce microporous hollow spheres. Precise control over the nanostructures can be achieved by the variation of the molecular composition of PMMA-b-PS. After carbonization into carbon hollow spheres, these as-prepared nanoscale materials showed good CO2 capture and supercapacitance properties.

3.2 Direct One-Step Self-polycondensation

In recent years, “Davankov-type” resins displayed a rapid development in the synthetic strategies. However, their post-crosslinking essences resulted in limited applications because of the tedious reaction process as well as restricted optional precursors. What if hypercrosslinked polymer synthesized directly from small molecule monomers which contain functional groups such as chloromethyl group? Early researches were started by Cooper and co-workers [123]. Via a simple one-step condensation polymerization process, three kinds of bis(chloromethyl) aromatic monomers (Fig. 4.12) including dichloroxylene (DCX), bis(chloromethyl)biphenyl (BCMBP), and bis(chloromethyl) anthracene (BCMA) linked together with the elimination of functional groups and formed a highly crosslinked network. By changing the monomer ratio among the monomers as well as Lewis acid catalyst amount, surface area and porous structure of the resulting materials can be easily tuned. According to the N2 adsorption/desorption analysis, these materials were predominantly microporous and exhibited apparent highest BET surface areas of up to 1904 m2 g−1. Owing to their high surface area and permanent microporosity, these materials also showed outstanding performance in hydrogen adsorption [123], methane storage [13], and CO2 capture [124] indicating their potential applications in energy and environment field.

Three typical monomers used in self-condensation polymerization. Reproduced from Ref. [123] with kind permission of © 2007 American Chemical Society

This one-step condensation polymerization of small monomers highly extended the range of optional building blocks. Moreover, multifunctional polymer materials can be easily obtained by a simple copolymerization with other functional monomers.

Yang et al. [125] synthesized a series of microporous copolymers from triphenylamine and p-DCX using FeCl3- promoted oxidative polymerization and Friedel–Crafts alkylation. The BET specific surface areas ranging from 318 to 1530 m2 g−1 were obtained with the increasing content of p-DCX. These nitrogen-functionalized materials exhibited an enhanced CO2 uptake of 4.60 mmol g−1, which was comparable with the best reported results for MOPs, activated carbon, and MOFs under the same conditions. Following investigation about hydrocarbons/water separation properties was also made using BCMCP as the crosslinker [126]. By changing the monomer ratio, hypercrosslinked polymers with apparent BET surface areas of 1362 and 1338 m2 g−1 were obtained which showed benzene/water vapor selectivity as high as 53.5 and 63.6, respectively. Moreover, a monolithic polymer was also prepared to show potential application in oil spill cleanup.

Except for the traditional chloromethyl groups, Tan group [127] has explored two kinds of aromatic hydroxymethyl monomers such as 1,4-benzenedimethanol (BDM) and benzyl alcohol (BA) that can also be prepared into self-condensation microporous polymers (Fig. 4.13). N2 adsorption/desorption isotherms of the polymers indicated a predominantly microporous network with high surface areas of up to 847 and 742 m2 g−1, respectively. Polymer networks based on BA monomers can store a significant amount of CO2 up to 8.46 wt% at 273 K/1 bar and H2 up to 0.97 wt% at 77.3 K/1 bar. This research has enlarged the optional building blocks that even monofunctional compounds can be involved in the construction of hypercrosslinked polymers.

Synthesis route of HCP-BDM and HCP-BA. Reproduced from Ref. [127] with kind permission of © 2013 American Chemical Society

Following this study, Tan group [21] has recently demonstrated that rigid aromatic monomers and derivatives can also be utilized for a novel one-step self-polycondensation reaction (Fig. 4.14). This strategy is based on the Lewis acid catalytic Scholl reaction [128], which involves the elimination of aryl-bound hydrogen atoms accompanied by the formation of new aryl-aryl bonds. Due to the universality of this strategy, a wide variety of monomers are suitable including monomers with both high or low electron density, acidic or alkaline functional group containing monomers, aryl or fused ring-based monomers, as well as heterocyclic ring containing monomers. A series of microporous organic polymers with surface areas ranging from 636 to 1421 m2 g−1 were synthesized according to the N2 sorption analysis. Moreover, the porous structure and functionalities of the resulting networks can be easily modulated by adopting different functional building blocks indicating potential applications in gas storage, catalyst, optoelectronic sensing, and semi-conducting.

a Typical Scholl reaction, b polymer networks form 1,3,5-triphenyl benzene, c other monomers. Reproduced from Ref. [21] with kind permission of © 2014 Royal Society of Chemistry

Zhu group [129] introduced several three-dimensional monomers such as triphenylamine, tetraphenylmethane, tetraphenylsilane, and tetraphenylgermane for the construction of spatial hypercrossslinked networks via the Scholl coupling reaction. With moderate surface areas reaching up to 1119 m2 g−1, the resulting polymer networks exhibited relatively high CH4 and CO2 sorption capacity of 1.04 and 3.52 mmol g−1, respectively (at 273 K/1.13 bar).

3.3 External Crosslinking Strategy

Although this one-step self-polycondensation strategy has extended the optional building blocks boundary, there are still limitations for the synthetic routes. For example, the preparation of functional group containing monomers like chloromethyl group or hydroxymethyl group is difficult and is of high cost. Moreover, the hydrogen chloride generated from chloromethyl group also will do damage to fabrication facilities in large-scale industrial production and the environmental issues also need to be considered.

Considering these problems, a new strategy was proposed by Tan group [130] that using formaldehyde dimethyl acetal (FDA) external crosslinker to knit low functionality rigid aromatics via a simple Friedel–Crafts reaction in which anhydrous FeCl3 acts as catalyst. This strategy is gentle, facile, flexible, and is of low cost that a wide variety of building blocks can be involved resulting in materials with predominantly microporous structure and high surface area (Fig. 4.15). By adjusting the ratio of monomer and the crosslinker, surface areas as well as the porous structure of the resulting networks can be roughly controlled and a high BET surface area of 1391 m2 g−1 was obtained for benzene-based network. In addition, the functionality of the polymer networks can be easily modulated by introducing functional monomers. This knitting strategy demonstrated evident advantages compared with previous methods: (1) a large amount of monomers can be adopted even without specific functional groups, (2) facile synthesis conditions and low cost are easy to scale up, (3) result in materials with abundant microporosity and high surface area, and (4) modulation of microporous structure and functionality networks is simple, thus providing a novel pathway for the construction of functional polymers or materials with unique micromorphology.

Knitting rigid aromatic building blocks with FDA crosslinker. Reproduced from Ref. [130] with kind permission of © 2011 American Chemical Society

The environmental issues are always the human concerns. The change in a global climate caused by excessive CO2 emissions has attracted widespread public attention in recent years [131]. CO2 capture and storage (CCS) technology is a promising method using MOPs as physical adsorption material in which high adsorption capacity should be the key factor [132]. Enormous research has shown that the introduction of functional groups such as carboxyl and amine may enhance the CO2 adsorption and selectivity for CO2/N2 by increasing the interactions between adsorbent and adsorbate [133,134,135].

Prof. Cooper thought highly of this strategy which extended the approach to a wide range of low functionality aromatic monomers, and these materials possessed more promising CO2 uptakes at the higher pressures that are relevant to precombustion CCS [136]. By employing this knitting method, firstly they successfully synthesized a series of amino group containing polymer networks by the copolymerization of aniline and benzene [137]. Varying the monomer ratio leaded to a highest BET surface area of up to 1100 m2 g−1 as well as an improved CO2/N2 selectivity up to 49.2; however, the entire benzene network only showed a CO2/N2 selectivity of 15.9. Polymerization of alcohol-containing monomers using knitting process produced microporous networks with surface areas of up to 1015 m2 g−1 [138]. Moreover, synthesis of chiral networks without any complex monomer involvement is also successful. The investigation of CO2 adsorption performance for these materials in “wet” condition showed that hydrophobicity endures a much smaller drop in CO2 capacity which could be an important point to consider in the future design of sorbents for CO2 capture. To move forward one step, they tested the CO2 adsorption behaviors for several different kinds of microporous materials including carbon, zeolite 13x, ZIF-8, HKUST-1, and FDA knitting polymers [136]. The results showed that unlike other polar adsorbents, the hydrophobic FDA knitting polymers are hardly affected by the water vapors and adsorb CO2 in a different way by physical swelling thus giving rise to a higher CO2 capacity and much better CO2 selectivity. As a result, these knitting polymers have superior function as a selective gas adsorbent as would be required for materials preparation on the large industrial scale required for carbon capture.

By adopting this knitting method, some other researches focus on the development of constructing polymer networks using novel building blocks with special functional groups such as amino, hydroxyl, carbazole, and triptycene.

Zhu group [139] successfully prepared highly porous materials derived from amino and hydroxyl containing tetrahedral monomers with apparent surface areas up to 1230 and 1608 m2 g−1, respectively. According to their functionality, the corresponding polymer networks revealed enhanced CO2 adsorption capacities and higher heats of adsorption than the non-functionalized materials.

Dai and co-workers produced triazine- and carbazole-bifunctionalized task-specific porous polymers via the Friedel–Crafts reaction with surface areas of 563 and 913 m2 g−1, respectively [22]. The resultant porous framework exhibits a comparable 18 wt% CO2 uptake (273 K, 1 bar) and 38 selectivity for CO2 over N2. In addition, a series of novel carbohydrate-based microporous polymers were synthesized by knitting various hydroxyl-functionalized carbohydrate monomers [140]. BET surface areas around 800 m2 g−1 were obtained as well as a considerable amount of CO2 adsorption of 12 wt% with a 42 CO2/N2 selectivity at 273 K. Several factors including the quantity and reactivity of hydroxyl groups and the structure of the carbohydrate monomers that contributed to CO2 adsorption were discussed indicating these microporous polymers’ promising applications in carbon capture.

Han group [141] also selected two carbazole-based building blocks for constructing knitting porous materials via FeCl3-promoted one-step oxidative coupling and Friedel–Crafts reaction. N2 adsorption analysis confirmed that these networks were permanently microporous with BET specific surface areas around 1190 m2 g−1. Besides the H2 and CO2 storage, these microporous networks also exhibited potential application in eliminating harmful small molecules from the environment such as toluene and formaldehyde.

Jiang group reported several kinds of knitting microporous organic polymers synthesized from a series of functional monomers containing hydroxyl, carbazole, and silole. The polymer networks based on tetraphenylethylene (TPE) and/or 1,1,2,2-tetraphenylethane-1,2-diol (TPD) [20] displayed surface areas ranging from 1980 to 618 m2 g−1 with a decrease in CO2 adsorption capacities. However, the CO2/N2 selectivity enhanced to the highest 119 with the TPD content increase. The carbazole-based knitting polymers [142] showed a comparatively performance in CO2 storage and separation with 1845 m2 g−1 high surface area. Novel silole-containing monomers were also used for building knitting aromatic polymers with similar surface areas around 1200 m2 g−1 [143]. The introduction of silicon atom enhanced the binding affinity between the adsorbent and CO2 molecules, thus resulting in a slight higher CO2/N2 selectivity compared with other non-functionalized MOPs. The activated carbon materials with high surface area of 2065 m2 g−1 were obtained directly by potassium hydroxide-activated carbonization of a nitrogen-rich knitting polymer based on N,N,N′,N′-tetraphenylbiphenyl-4,4′-diamine (DTPA) monomer [144]. An extreme high CO2 uptake up to 6.51 mmolg−1 (1.13 bar/273 K) was obtained with a comparable 57 CO2/N2 selectivity. Considering the high surface area and good gas sorption performance, these knitting polymers are promising for CO2 capture industrial applications.

Triptycene and its derivatives have earned a large amount of attention in supramolecular chemistry and materials science fields due to their specific three-dimensional rigid structure and easy functionalization. Zhang group has synthesized two series of triptycene-based knitting microporous polymers from hexaphenylbenzene-based triptycene [145] and tricarbazolyltriptycene building blocks [146]. According to the N2 adsorption/desorption analysis, the obtained surface areas were 569 and 893 m2 g−1, respectively. With high thermal stability and comparable high surface area, these porous polymers are promising candidates for H2 storage and carbon capture. In addition, triptycene monomer can be knitted with FDA crosslinker directly which resulted in high surface area reaching 1426 m2 g−1 [147]. With hierarchical porosity, this kind of knitting polymer could be used as adsorbent for organic solvents and dyes in water treatment application.

The knitting strategy can also be directly used for crosslinking heterocyclic aromatic building blocks. Tan group [148] synthesized heteroatom-decorated knitting polymers using three typical heterocyclic molecules pyrrole, thiophene, and furan as monomers (Fig. 4.16). The BET surface areas were about 437–726 m2 g−1 which were much lower compared to the benzene-knitted polymer network. However, the introduced heteroatoms provided excess lone electron pairs on the network skeleton which enhanced the binding affinity to CO2 molecules by dipole–dipole interaction. As a result, Py-1 shows an extraordinarily high selectivity of CO2/N2 about 117 at 273 K which was the highest among all the microporous materials reported at that time.

Synthesis of aromatic heterocyclic microporous polymers via the knitting strategy. Reproduced from Ref. [148] with kind permission of © 2012 Wiley-VCH

Saleh et al. [149] explored more heterocyclic monomers including indole (IN), benzothiophene (BT), benzofuran (BF), carbazole (CBZ), dibenzofuran (DBF), and dibenzothiophene (DBT) for the construction of heteroatom-functionalized knitting polymers. Based on the N2 sorption analysis, the synthesized polymer networks showed diversified surface areas in the range of 391–1022 m2 g−1. By attributing to their electron-rich electronic essence, these materials not only displayed high selective adsorption of CO2/N2 but also exhibited stable selective adsorption of CO2/CH4.

For organic chemistry field, the cheap and renewable CO2 is an ideal carbon source. As a result, the incorporation of CO2 capture and storage as well as the CO2 utilization is an attractive potential application. In this respect, functionalized porous materials with both adsorption property and catalytic sites for CO2 conversion could be promising materials.

Zhang et al. [150] developed a novel series of knitting porous polymers with phosphonium salt incorporated into the networks. By copolymerization triphenylphosphane (PPh3) salts with benzene monomer, high surface area of 1168 m2 g−1 was obtained with a moderate CO2 uptake. These knitting microporous polymers can be used as catalysts for the conversion of CO2 with propylene oxide into propylene carbonate which revealed a higher catalytic activity than the PS-supported phosphonium catalyst.

As is mentioned above, this knitting strategy via the Friedel–Crafts alkylation reaction proposed a simple and efficient synthetic route forming cost-effective porous materials with special functionality which can be promising solid sorbents for practical application in CCS technologies.

Moreover, the knitting strategy was also adopted for the preparation of heterogeneous catalyst [151,152,153,154,155]. Tan group [154] synthesized a phosphorus-decorated knitting polymers by crosslinking PPh3 with benzene and then Pd was banded with PPh3 groups to form KAPs(Ph–PPh3)–Pd catalyst. The BET surface area was found to be 1036 m2 g−1 for the knitting polymer network, which however showed no obvious decrease after binding with Pd (1025 m2 g−1). The resulting networks showed a uniform dispersion of Pd nanoparticle owing to their refined microporous structure, and the heterogeneous nature improved the reactant diffusion of small molecules. As a result, the KAPs (Ph–PPh3)–Pd exhibited excellent activity and selectivity for the Suzuki-Miyaura cross-coupling reaction of aryl chlorides in an aqueous ethanol solution under mild conditions. Following this study, three N-heterocyclic carbenes were successfully integrated into the skeleton of the knitting polymer for Pd loading [155]. BET surface area as high as 1229 m2 g−1 was achieved. Due to the substantial porosity and individual pore structure, the catalyst afforded rapid conversion for the Suzuki-Miyaura cross-coupling reactions including various aryl halides and arylboronic acids in aqueous media. In particular, it can be used for 5 times without obvious inactivation.

The knitting methods can also be used for the synthesis of metal-free heterogeneous photocatalysts which contain photoactive-conjugated organic semiconductor units such as 4,7-diphenylbenzo [1, 2, 5] and thiadiazole (BT-Ph2) [156]. The resulting photocatalysts were directly employed for a visible light-promoted, highly selective bromination reaction using HBr as a bromine source and molecular oxygen as a clean oxidant, however, without transition metal. High catalytic efficiency and good reusability were observed within the materials. The utilization of the simply prepared knitting microporous polymer photocatalyst opens new opportunities toward a sustainable and efficient material design.

The knitting microporous polymers were also prepared into electron sensor devices. Zhang et al. [157, 158] investigated the humidity sensing properties of the 3-hydroxybenzoic acid monomer-based knitting porous polymers. After loading LiCl salt [157], the sensors revealed good humidity sensing properties that the impedances dropped with the increase of relative humidity which is attributed to the interaction between the loaded LiCl and water molecules. In addition, the enhanced humidity sensing properties can be obtained when the knitting materials were loaded with lithium hydroxide [158]. Therefore, the lithium-modified knitting polymers could be a new category of humidity-sensitive materials.

In general, the utilization of this simple and efficient knitting strategy has greatly expanded the variety of hypercrosslinked polymers as well as application range by incorporating different functional monomers. In addition, this strategy was also adopted for the preparation of microporous materials with precisely controlled micromorphology such as nanoparticles [159], hollow microcapsules [5,6,7], two-dimensional polymeric membranes [8, 9, 160], and monolithic blocks [14, 15].

Hollow microporous organic capsules (HMOCs) combining the advantages of microporosity and nanocapsule were fabricated via the hard templating methods in which nano-SiO2 was used as core template (Fig. 4.17) [7]. SiO2@PS-DVB precursors with core–shell structure were prepared via a simple traditional emulsion polymerization process. After the knitting and etching approach, the HMOCs were obtained with specific hollow morphology and high surface areas up to 1129 m2 g−1. By adjusting the DVB concentration, the resulting surface areas can be easily controlled which revealed a decreasing trend with the increasing DVB content. With hollow cavity inside, these HOMCs showed a much higher ibuprofen adsorption compared with the solid nanoparticles. Moreover, the controlled microporous structure made HOMCs to possess zero-order drug release kinetics demonstrating their attractive applications in medical field.

Preparation of hollow microporous organic capsules. Reproduced from Ref. [7] with kind permission of © 2013 Macmillan Publishers Limited

Compared to hollow capsule model, two-dimensional polymeric membranes have greater superiority for molecular level separation applications in industrial-scale chemistry, energy, and environment fields. Dai and co-workers [9] developed a facile one-pot approach for the synthesis of polymeric molecular sieve membranes by using non-porous polystyrene membrane as precursor via an in situ knitting process (Fig. 4.18). The resulting knitting polymeric membrane showed a sandwich porous structure comprising a dense microporous layer with an inner macroporous core and outer mesoporous surface formed by small polymer particles. N2 sorption analysis demonstrated the hierarchical porous structure showing type 1 reversible sorption isotherms with a slight hysteresis loop at relative high pressures. The BET surface areas varied from 218 to 618 m2 g−1 with the crosslinking time increasing, while the CO2 permeability increased from 222.2 to 5261 barrer. On the contrary, the CO2/N2 selectivity decreased to 18.5 from 30. The high permeability and good selectivity indicated the promising potential applications in gas separation.

a Synthesis of knitting microporous polystyrene membranes, b Mechanism for the formation of hierarchical porous structure. Reproduced from Ref. [9] with kind permission of © 2014 Macmillan Publishers Limited

Based on this novel in situ concept, Kim et al. synthesized the knitting microporous polystyrene ionic liquid membranes via an in situ crosslinking of polystyrene membrane precursors [8, 160]. The 1-allyl-3-methylpyridinium bromide ionic liquid was incorporated into polymer matrix directly by dissolving in DMF solvent with polystyrene. Followed by a casting process, the polystyrene ionic liquid membranes were obtained. After coordinating with ferric [8] and nickel salts [160], these membranes were applied for the catalysis of H2 generation from sodium borohydride and 4-nitrophenol reduction, respectively.

Compared with other specific micromorphology, three-dimensional macroscopic hierarchical porous monolith forms have attracted significant attention due to the rapid mass transport driven by convection through the internal connecting pores. Svec and co-workers reported the preparation of porous polymer monoliths by knitting styrene-type polymers involving three external crosslinkers BCMBP, DCX, and FDA [15]. Polymeric monoliths with surface areas reaching up to 900 m2 g−1 were obtained using BCMBP as crosslinker in only 2.5 h knitting process. Owing to the high surface area and interconnecting hierarchical porous structure, the monoliths as the stationary phase for liquid chromatography delivered a significant improvement in efficiency in the reversed phase separation of small molecules. Tan group [14] also synthesized hierarchical porous polystyrene monoliths by knitting poly(styrene-divinylbenzene) high internal phase emulsions. BET surface areas of 196–595 m2 g−1 were obtained by N2 sorption analysis with interconnecting well-defined macroporous, mesoporous, and permanent microporous structure. Owing to the interconnected cellular structure as well as the hydrophobicity in the skeleton, these monoliths exhibited a fast equilibrium and high adsorption capacity for organic solvents.

In summary, the knitting strategy using FDA as external crosslinker has become a very practical method for the preparation of hypercrosslinked polymer with multifunctionality and special micromorphology, while the surge to expand the synthesis strategy never stops.

3.4 Summary

Hypercrosslinked polymers have experienced an extended exploration in the design, synthetic strategy and potential applications since the discovery by Davankov. According to the development, there are mainly three synthetic routes: (1) post-crosslinking polymer precursors, (2) direct one-step polycondensation of functional monomers, and (3) knitting rigid aromatic building blocks with external crosslinker. Among them, the external knitting strategy has been proved to be a facile and efficient method and widely adopted for the synthesis of functional polymers or materials with unique micromorphology.

Even though, there also exists some challenges for developing HCPs. For example, the polymer networks of HCPs are highly irregular due to their fast dynamical character of the Lewis acid catalytic reaction. The huge amount heats generated by hypercrosslinking and hydrogen chloride released from unavoidable catalyst hydrolysis are also intractable problems for large-scale industrial production. Looking for new synthetic approaches for higher surface area HCPs which can be more than 3000 m2 g−1 is always highly desired. HCPs with controllable structure and new function will be a prolonged research hot spot with broad applications in photoelectricity, sensors, and semi-conducting devices.

4 Conjugated Microporous Polymers

CMPs, firstly reported in 2007 [25], are a class of microporous organic polymers consisting of π-conjugated segments totally bonded by covalent bonds, which inherently combine π-conjugated skeleton with microporous structure.

Porous architecture of CMPs can be controlled by molecular design, for instance, the surface areas and pore volumes can be easily tuned by using different monomers with various molecular lengths. Moreover, employment of diverse functional modules is feasible to construct CMPs. By selecting proper monomers, CMPs usually can be synthesized by conventional metal-catalyzed reactions, such as Sonogashira–Hagihara coupling [161], Suzuki coupling [162], Yamamoto couplings [163], oxidative polymerizations [164], and Schiff base reaction [165]. CMPs materials are always prepared by irreversible reactions, so they are usually amorphous and show short range of structural order. The pores are accessible to various guest molecules and metal ions, which allow the construction of supramolecular structures and organic–inorganic hybrids. Compared with crystalline COFs and MOFs, amorphous CMPs can be synthesized more easily by linking the appropriate organic building units to achieve functionalization and the functional groups can be fully exposed. The incorporation of new functional groups into CMPs has generated numerous new functional materials.

Although most of the works focus on developing new strategies, tuning the pore size distribution and surface area of CMPs, some efforts have already been made to control morphology, such as quasi-zero-dimensional (0D) microspheres [162], one-dimensional (1D) nanofibers and nanotubes [166], two-dimensional (2D) nanosheet structures [167], as well as three-dimensional (3D) monoliths [168]. What’s more, the development of soluble CMPs also remains to be well explored [169].

CMPs have attracted tremendous attention and become one of the fastest developing types of porous materials. These kinds of material allow the complementary utilization of π-conjugation and porosity, which are unique and usually not available in other porous materials. Such structural features bring CMPs a large number of exciting properties and potential applications, such as gas storage [170], catalysis [171], sensors [163], and anode materials [172].

4.1 Synthesis and Modification

Typically, linear polymers are created with two end groups monomers (A2 + B2). As for three-dimensional CMPs, one or more monomers with more than two end groups (A x + B y , x > 2, y > 2) are needed.

4.1.1 Synthesis Method

Laybourn et al. [173] studied the framework formation mechanism of CMPs. The results showed that monomer concentration, solvent, temperature, and building block structure would affect the network formation in complex situations (Fig. 4.19). Firstly, oligomers are formed in solution, which resulted in clusters. And then, these clusters precipitate from solution and continue to react in solid state by crosslinking, which lead to the formation of CMPs frameworks at last. The initial precipitated material exhibits a low degree of microporosity and significant interparticulate mesoporosity; true microporous materials are only formed at longer time upon fusion of the clusters and further crosslinking within the particles. Xu et al. [174] disclosed that the linkage geometry plays a vital role in the control over the porosity, gas adsorption, π-conjugation, exciton migration, and luminescence of CMPs. Works from Dawson et al. [175] and Tan et al. [176] showed that the choice of the reaction solvent is also important.

Proposed reaction mechanism for the formation of CMP networks. Reproduced from Ref. [173] with kind permission of © 2014 American Chemical Society

Many CMPs have been synthesized with miscellaneous polymerization, including Suzuki coupling reactions [177], Sonogashira coupling [25], Yamamoto coupling reaction [178], oxidative coupling polymerization [179], Schiff base chemistry [180], and electropolymerization (EP) [181] etc.

Suzuki cross-coupling reaction is one of the most powerful one-step pathways for the formation of carbon-carbon bonds [162] (Fig. 4.20a). Typically, Suzuki coupling reactions are performed under homogeneous conditions using a variety of phosphine ligand/palladium catalytic complexes. However, oxygen will cause the formation of homocoupling and deboronation by-products. Consequently, the Suzuki reaction often needs to be performed under highly oxygen free condition. Sonogashira coupling reaction which introduces acetylenyl groups in CMP frameworks is one of the most studied reactions among all the synthetic methods for the fabrication of CMPs [161] (Fig. 4.20b). Moreover, triple bonds may lead to a more rigid and extended network structure and can be used to adjust the porosity [182], and pore size and surface area [183]. At the same time, the final properties of CMPs can also be affected by the reaction conditions. Yamamoto coupling reaction is a C–C coupling of aryl-halogenide compounds mediated by transition metal complexes [163] (Fig. 4.20c). Only halogen-functionalized monomers are involved, while on the other hand, stoichiometric quantities of the nickel complexes are also important. Oxidative coupling polymerization has cost-effective advantages in the preparation of CMPs. CMPs materials can be prepared in large scales by oxidative coupling polymerization which shows advantages of adopting cheap catalyst, with low room temperature and only need single monomers [164] (Fig. 4.20d). Catalyst can be completely removed by easy purification [184]. Schiff base chemistry is a novel synthetic strategy for CMPs, which is a catalyst-free and one-pot reaction. Schiff base chemistry can build nitrogen-rich CMPs networks with high surface areas [165] (Fig. 4.20e). Buchwald–Hartwig (BH) coupling is utilized for the generation of C–N bonds via the palladium-catalyzed cross-coupling of amines with aryl halides [185] (Fig. 4.20f). The BH coupling approach allows the expansion of repertoire of possible C–N bond formation through the facile synthesis of aromatic amines. This useful method also provides a simple route to nitrogen-containing redox-active systems.

Direct arylation polymerization is a new method for synthesizing CMPs [186]. However, CMPs synthesized by direct arylation polycondensation are only limited to monomers containing two-arm fluoroarenes and nitrogen-free tri- or tetra-bromoarenes (Fig. 4.21).

Direct arylation polycondensation of fluoroarene monomers with TAz into CMPs. Reproduced from Ref. [186] with kind permission of © 2016 Elsevier

Electropolymerization has been proven to be a useful method for fabricating electroactive CMPs films, which is an in situ polymerization of CMPs precursors or monomers [197]. The precursors are dissolved at first, and then, the coupling reaction occurs on the electrode surface. At last, the CMPs films depose on the electrode (Fig. 4.22). This strategy is of low cost, without catalyst, and controlled thickness of the film can be obtained.

Setup of the three-electrode electrochemical cell for the polymerization of monomers and the deposition of CMPs films on ITO. Reproduced from Ref. [197] with kind permission of © 2015 Wiley-VCH

4.1.2 Modification

The incorporation of metal sites into CMPs opens up the second-generation porous materials. Porphyrin which possesses macrocyclic cavity basic pyrroles is widely used in CMPs to form modified CMPs. Some metal-porphyrin CMPs using metal-porphyrin (metal: Zn, Co, Cu, Fe, Ni, etc.) as monomer have shown combined chemical and physical properties for applications in catalysis [187,188,189,190], supercapacitor [191], photosensitizer [192], and adsorption [89]. Metal ions (Fe and Al) can also be introduced into porphyrin-based CMPs and show good performance in adsorption [184] and CO2 capture [193]. Some other methods are also used to introduce metals into CMPs framework. Jiang et al. [194] prepared MO-CMP by two methods: post-treating bipyridine-functionalized CMPs with metal complexes (Re, Rh, and Ir) and the direct Sonogashira–Hagihara cross-coupling of halogenated metal-organic monomers. Fischer et al. [195] copolymerized Li[B(C6F4Br)4] with 1,3,5-triethynylbenzene using Sonogashira coupling [MnII(bpy)]2+ complex and then immobilized in the CMP networks which is a promising catalyst for the aerobic oxidation of alkenes. Xie et al. [196] reported a class of Co/Al-coordinated CMPs which exhibit outstanding CO2 capture comparable to MOFs.

Lee et al. [198] prepared CMPs by Sonogashira coupling and then prepared CMP-Co3O4 composites via organometallic complexation of cobalt carbonyl with microporous organic networks (MONs) and the successive oxidation. The materials showed the enhanced stability as anode materials.

Some organic molecules are also used as modifiers. For example, thiolyne can be introduced into CMPs networks [199,200,201]. Ratvijitvech et al. [202] reported the post-synthetic modification of amine-functionalized CMPs by anhydrides to build a series of amide-functionalized networks.

4.2 Control of Morphology

Morphology is an important factor in CMPs properties. Many efforts have been focused on the morphology control. Normally, template strategy and stepwise method have been used to control CMPs morphology.

4.2.1 Template Strategy

Template strategy is a straightforward method to build CMPs with specific morphology similar to the template. Zhuang et al. [203] reported a graphene-inspired synthetic approach for the preparation of sandwich-like CMP. Furthermore, they demonstrated a series of heterostructures CMPs with 0D, 1D, or 2D morphology, by using bromo-functionalized carbon nanospheres (0D CSs), single-walled carbon nanotubes (1D SWNTs), and reduced graphene oxide (2D RGO) as templates. The resulting CMPs showed nanosphere, nanotube, and nanosheet morphologies, and then carbonized. They found that the performance of these nanocarbon-based zinc-air batteries using nanocarbon as air electrode was affected by morphology (2D > 1D > 0D) [204]. Son group studied the synthesis of new functional MONs based on Sonogashira coupling by template strategy. SiO2 [205, 206], Fe3O4 [187, 207], zeolites [208], and MOF [209] were used as templates, and the resulting materials showed good performances as catalysts [187, 206], precursor of inorganic materials [205, 207], and adsorbents [208, 209]. Tan et al. [210] reported a one-step synthesis of nanoscale CMP (NCMP) capsules by using PMAA microspheres as self-sacrificial templates. The morphology, nanostructure, and shell thickness can be precisely controlled.

4.2.2 Stepwise Method

By controlling reaction conditions, CMPs with different morphology can be obtained. Tan et al. [176, 211] found that reaction solvents and the structure of monomers would influence the morphologies of the polymers (sphere, tubular, and plate). Ma et al. [212] illustrated the design principle and the synthesis of CMPs nanoparticle (Fig. 4.23).

Synthetic route to CMP NPs via (A3 + B2)-type Suzuki-Miyaura or Sonogashira–Hagihara cross-coupling polycondensation reactions in an oil-in-water miniemulsion system. Reproduced from Ref. [212] with kind permission of © 2015 Royal Society of Chemistry