Abstract

Mössbauer studies of PbFe0.5Nb0.5O3 samples prepared by mechanical activation of PbO, Fe2O3 and Nb2O5 mixture and subsequent sintering at various temperatures T S were performed. The room temperature Mössbauer spectra consist of two doublets (D1 and D2) for the samples with T S < 800 °C and one doublet (D1) for the samples with T S > 800 °C. The parameters of the doublet D1 correspond to Fe3+ in the octahedron environment. Doublet D2 has a lower isomer shift corresponding to Fe3+ with the coordination number 5 that indicates the presence of oxygen vacancies. Dependence of the temperature T N of magnetic phase transition on T S has a maximum at T S ≈ 700 °C. The effect of Fe3+/Nb5+ ordering degree and oxygen deficiency on T N is discussed.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

1 Introduction

Ternary perovskite oxide PbFe0.5Nb0.5O3 and its solid solutions exhibit high dielectric, piezoelectric, pyroelectric, electrostrictive responses [1,2,3,4]. Ceramics of these materials may be sintered at rather low temperatures (1050–1100 °C), and are prospective for many applications. As PFN contains a magnetic ion (Fe3+) it belongs to the currently very actively studied family of multiferroics . These materials possess simultaneously ferroelectric and magnetic orders [5,6,7]. On cooling PFN undergoes phase transitions from a cubic paraelectric phase to a tetragonal ferroelectric phase at T CT ≈ 380 K, then to a rhombohedral [8] (or monoclinic [9, 10]) ferroelectric phase at T TR ≈ 360 K and finally to a G-type antiferromagnetic (AFM) phase at T N ≈ 150 K [5, 6, 10]. In several works, magnetization loops were reported for ceramics and thin films of PFN and its analog PbFe0.5Ta0.5O3 (PFT) as well as for their solid solutions with PZT [7, 11, 12]. As the T N values of PFN, PFT and their solid solutions with PbTiO3 (PT) and PbZrO3 (PZ) are well below the room temperature [13,14,15,16] a possible origin of these room-temperature magnetic properties was supposed to be the formation of super-paramagnetic clusters [6, 7] and/or Fe spin clustering [11]. However in PFN-PT single crystals the super-antiferromagnetic and/or super-paramagnetic clusters were observed up to rather high temperatures well above the T N , while the magnetization loops were observed only below ≈50 K [13]. Another possible explanation of these room-temperature magnetic properties is the presence of some small admixture of the ferromagnetic or ferrimagnetic phase, e.g. PbFe12O19, however its amount is below the detection limit of X-ray diffraction and Mössbauer spectroscopy [16, 17].

Until recently, there had been a belief that Fe and Nb in PFN are distributed over the lattice in a random fashion, but several observations now indicate that the Fe ions might segregate at the nanoscale level. Studies of 57Fe Mössbauer spectra [18], as well as 93Nb and 17O NMR spectra [19] and magnetization [6] have led to the conclusion that PFN is a chemically inhomogeneous system and that long range AFM order forms in Fe-rich-Nb-poor regions while, a magnetic relaxor spin-glass like state below T ≈ 20 K can arise from the Fe-poor-Nb-rich regions [6, 19]. These data are reinforced by the results of first principles calculations showing that Fe3+ and Nb5+ ions are distributed in the PFN lattice not randomly, but that they exhibit clustering [18]. Such clustering is actually a sort of local ordering changing the number of the nearest-neighbor Fe3+ ions and this fact, in particular, explains why the experimental values of T N , for both PFN and PFT (≈150 K) are much lower than the calculated values of T N for the case of random distribution of Fe3+ and Nb5+ (Ta5+) ions in the lattice (T N ≈ 300 K) [20].

Such self-organization would be of great interest for applications if one could control it. Previously Li- doping was successfully used to change the compositional ordering degree of B-site cations in \( {\text{Pb}}B_{0.5}^{3 + } B_{0.5}^{3 + } {\text{O}}_{3} \) perovskites with B 3+ = Sc, Yb; B 5+ = Nb, Ta, [21]. Such ordering should decrease T N as the number of the nearest-neighbor Fe3+ ions decreases. Indeed Li-doping was reported to decrease T N value of PFN and PFT ceramics by ≈50 K [22].

However much more important is to increase T N values, preferably up to room temperatures. Though linear-quadratic paramagnetoelectric effect in PFN ceramics is observed at room temperature and up to the ferroelectric Curie temperature T CT ≈ 380 K, the value of this effect is several orders of magnitude lower that in the magnetic phase [23].

Some years ago there appeared a report that T N value of the epitaxial PFN nanofilm is more than 50 K higher than that of the bulk samples [12]. Moreover in this film a remnant magnetization was observed up to room temperature, while in the bulk PFN single crystals it vanishes above ≈10–15 K [13]. These intriguing properties of PFN nanofilms seem to be due to the effect of epitaxial strain on the degree of Fe3+ and Nb5+ ions ordering. First-principles calculations support such possibility [24].

Recently we found out that T N values of both PFN and PFT powders can be increased by 50–70 K by means of high-energy mechanical activation [25,26,27]. Such treatment is known to increase disorder of B-site cations in \( PbB_{0.5}^{3 + } B_{0.5}^{5 + } O_{3} \) perovskites [28]. However the origin of the observed increase of T N in mechanically activated multiferroics is not well understood yet.

The aim of the present study was a thorough study of Mössbauer spectra of mechanically activated PFN powders annealed at different temperatures in order to elucidate a correlation between T N values and the environment of magnetic Fe3+ ions.

2 Experimental

PFN samples were fabricated from a stoichiometric mixture of high purity PbO, Fe2O3 and Nb2O5 powders. Mechanical activation was carried out using the high-energy planetary-centrifugal ball mill AGO-2 under a ball acceleration of 40 g. A mixture of powdered reagents (10 g) was placed into a steel cylinder together with 200 grams of steel balls, 8 mm in diameter. Activation was carried out for 15 min. After each five minutes of activation, the mill was stopped, the cylinders were opened, the powder was taken out and mixed, then it was put back into the cylinders for further mechanical activation. Besides the described above one-stage activation, the second batch of the powders was prepared by two-stage activation. At the first stage only Fe2O3 and Nb2O5 powders were activated for 15 min. At the second stage PbO was added and the resulting mixture was activated for 15 min. The samples for subsequent sintering were pressed at 1000 kg/cm2 without a plasticizer. Sintering of the samples, placed into a closed alumina crucible, was carried out in an electric oven at different temperatures for 2 h. X-ray diffraction (XRD) studies were performed using DRON-3 diffractometer and Cu-Kα radiation. Transmission Mössbauer spectra of 57Fe were measured with the aid of MS-1104EM rapid spectrometer and analyzed using the computer program SpectrRelax [29]. Mössbauer studies were carried out in the 12–320 К range using the closed-cycle helium cryostat-refrigerator Janis Ccs-850 (Cryogenics).

3 Results and Discussion

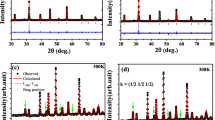

Figure 14.1 shows XRD patterns of mechanically activated stoichiometric mixture of PbO, Fe2O3 and Nb2O5 just after one-stage (a) and two-stage (b) activation. XRD patterns of both samples are very similar. One can see that using of AGO-2 high-energy planetary-centrifugal ball mill enables one to obtain practically pure perovskite phase of PFN after only 15 min of activation. It is worth noting that in the case of usual planetary or vibrating mills pure perovskite phase of PFN forms only after 20–30 h of activation [28, 30]. The diffraction reflexes of as-synthesized PFN are somewhat diffused, which seems to be caused by the small size of the particles formed. The mean size D of X-ray coherent scattering blocks, estimated using the Scherrer formula, appeared to be about 15–20 nm. Increase of the sintering temperature T S leads to the sharpening of the diffraction reflexes (Fig. 14.1a, b, curves 2). This sharpening correlates with the increase of the D values up to ≈40 nm at T S = 800 °C and 50–55 nm at higher sintering temperatures. However in the sample obtained by one-stage activation and sintered at 800 °C there is a substantial admixture of the parasitic pyrochlore phase (Fig. 14.1a, curve 2).

Figure 14.2 shows Mössbauer spectra of the same two samples. Both spectra are superposition of doublet and sextet. The doublet and sextet parameters are listed in Table 14.1. Parameters of sextet correspond to α-Fe2O3. The doublet is related to perovskite phase of PFN with admixture of FeNbO4. The areas of doublet and sextet give the concentration of Fe ions in corresponding phases. Thus 25% of Fe3+ ions are related to PFN/FeNbO4 phase in the sample (A). Similar ratio of the Fe2O3 and PFN/FeNbO4 phases was reported for the stoichiometric mixture of PbO, Fe2O3 and Nb2O5 activated in SPEX 8000D vibrating mill for 20 h [30]. The doublet isomer shifts value correspond to Fe3+ state with coordination number 5 [31] and is lower than that for PFN single crystal (0.4 mm/s) [32]. The coordination number of Fe3+ ions in perovskites is 6. The reduction of coordination number is probably related to oxygen vacancies, which appear during mechanical activation . In addition, the quadrupole splitting value is higher than that for PFN single crystal (0.4 mm/s) because of high dispersion of the investigated mixture [33]. The doublet isomer shift value of the sample (B) is close to that for PFN single crystal and also corresponds to Fe3+ ions in the octahedron. The doublet quadrupole splitting value for sample (B) is lower than that for the sample (A). This fact may indicate the increase of the particle size. For further studies, the samples sintered from the powders fabricated by two-stage mechanical activation were used.

Mössbauer spectra of PFN samples sintered at different temperatures T S from mechanically activated powders are present in Fig. 14.3. The spectra consist of one or two paramagnetic doublets. Their parameters are listed in Table 14.2. For some spectra, a Zeeman sextet is observed as well. The sextet parameters correspond to α-Fe2O3 admixture.

The spectra of the samples with T S = 400–700 °C are a superposition of two doublets D1 and D2. The D1 parametres correspond to Fe3+ ions in octahedron and are close to parametres of PFN synthesized by conventional solid-phase reactions route [18]. The doublet D1 is present in the spectra of all the samples. The quadruple splitting is a consequence of the composition disorder in B-sublattice of PFN. In contrast to this, Mössbauer spectrum of the highly ordered (in the rock-salt manner) PbFe1/2Sb1/2O3 perovskite appears to be a singlet at room temperature [34]. The second doublet D2 has an isomer shift value ≈0.36–0.37 mm/s that is lower than that for D1. The reduction of the isomer shift value indicates the lowering of coordination number due to the presence of oxygen vacancies. The doublet D2 quadruple splitting value is higher than that of D1, showing the presence of large crystallographic distortions in close environment of Fe3+ ions. The oxygen vacancies and distortions are probably related to the appearance of crystallographic shear planes during mechanical activation . The line broadening of D2 may be also due to the inhomogeneity of the environment of Fe3+ ions.

Figure 14.4 shows the dependence of the Mössbauer spectra component’s area on T S . The D2 area decreases as T S grows. Thus the oxygen vacancies concentration decreases with the increase of T S . In addition, the α-Fe2O3 impurity disappears when T S exceeds 700 °C. The isomer shift and quadrupole splitting dependencies on T S are present in Figs. 14.5 and 14.6. One can see that the isomer shift does not change as T S increases. The quadrupole splitting of D2 increases with T S indicating the growth of crystallography distortions around Fe3+ ions corresponding to D2.

For estimation of magnetic phase transition temperature T N , the method of temperature scanning was used. The essence of temperature scanning is measuring of Mössbauer spectrum line intensity in the course of sequential decreasing of the temperature. When magnetic ordering appears, the paramagnetic doublet transforms into Zeeman sextet, which is accompanied by a dramatic decrease of the line intensity. The temperature dependencies of Mössbauer spectrum intensity η, related to its value at 300 K for PFN ceramic samples, sintered at different temperatures from mechanically activated powders, are present in Fig. 14.7a. The abrupt drop of η(T) curve corresponds to T N value.

a Temperature dependencies of η-maximal intensity of doublet in Mössbauer spectrum related to its value at 300 K for PFN samples, sintered from mechanically activated powders at different temperatures T S ; b magnetic phase transition temperature dependence on T S for PFN samples sintered from mechanically activated powders at different temperatures T S

One can see from Fig. 14.7a that the samples sintered at T s = 400–600 °C have diffused magnetic phase transitions in a wide temperature range. For the samples sintered at higher T S , magnetic phase transitions temperature range is much more narrower. This may come from the lowering of inhomogeneity in the environment of Fe3+ ions and growth of grain size. Figure 14.7b shows the T N versus T S dependence for PFN samples studied. The T N value grows up to ≈220 K as T S increases from 400 up to 700 °C and on further increase of sintering temperature T N gradually lowers down to ≈150 K, i.e. to the value typical of PFN single crystal . The uprising part of T N (T S ) dependence corresponds to T S range, where the D2 area decreases.

The magnetic structure in perovskites comes from 180° superexchange between Fe3+ ions. So the T N value is determined by the number of Fe3+–O2–Fe3+ links [35]. This number depends on the degree of compositional ordering of Fe3+ and Nb5+ ions. Namely, the Fe3+–O2–Fe3+ links number increases, when the compositional ordering degree lowers. In addition, oxygen vacancies also reduce the number of Fe3+–O2–Fe3+ links. Thus, the T N growth with T S in the 400–600 °C range coincides with decrease of oxygen vacancies’ concentration . The largest values of T N in the samples sintered in the 650–800 °C range are probably explained by growing of grain size as well as by compositional disorder stimulated by mechanical activation . Decrease of T N values in the samples sintered at T S > 800 °C comes from appearing of the regions with local compositional ordering of Fe3+ and Nb5+.

4 Summary

In PFN ceramics sintered from mechanically activated powders dependence of the temperature T N of magnetic phase transition on sintering temperature T S has a maximum at T S ≈ 700 °C. The low T N value of the samples having lower T S is likely to be connected with a small size of PbFe0.5Nb0.5O3 particles, presence of FeNbO4 admixture as well as with oxygen deficiency. In the samples, sintered at 600–700 °C, T N achieves the maximal value and slowly decreases to 150 K in the samples with higher T S. . The T N value in oxides depends on the number of Fe–O–Fe links, which in turn correlates with Fe3+/Nb5+ cation ordering degree and oxygen deficiency. Thus, it seems that in the samples with T S ≤ 700 °C, the clusters with low cation ordering degree are present. The oxygen deficiency in such samples is probably related to the appearance of crystallographic shear planes during mechanical activation.

References

I.P. Raevskii, S.T. Kirillov, M.A. Malitskaya, V.P. Filippenko, S.M. Zaitsev, L.G. Kolomin, Inorg. Mater. 24, 217 (1988)

YuN Zakharov, S.I. Raevskaya, A.G. Lutokhin, V.V. Titov, I.P. Raevski, V.G. Smotrakov, V.V. Eremkin, A.S. Emelyanov, A.A. Pavelko, Ferroelectrics 399, 20 (2010)

D. Bochenek, P. Kruk, R. Skulski, P. Wawrzała, J. Electroceram. 26, 8 (2011)

E.I. Sitalo, I.P. Raevski, A.G. Lutokhin, A.V. Blazhevich, S.P. Kubrin, S.I. Raevskaya, Y.N. Zakharov, M.A. Malitskaya, V.V. Titov, I.N. Zakharchenko, IEEE Trans. Ultrason. Ferroelectr. Freq. Contr. 58, 1914 (2011)

D.I. Khomskii, J. Magn. Magn. Mater. 306, 1 (2006)

W. Kleemann, V.V. Shvartsman, P. Borisov, A. Kania, Phys. Rev. Lett. 105, 257202 (2010)

R. Blinc, P. Cevc, A. Zorko, J. Holc, M. Kosec, Z. Trontelj, J. Pirnat, N. Dalal, V. Ramachandran, J. Krzystek, J. Appl. Phys. 101, 033901 (2007)

K.H. Ehses, H.Z. Schmid, Kristallography 162, 64 (1983)

W. Bonny, M. Bonin, Ph Sciau, K.J. Schenk, G. Chapuis, Solid State Commun. 102, 347 (1997)

S.P. Singh, S.M. Yusuf, S. Yoon, S. Baik, N. Shin, D. Pandey, Acta Mater. 58, 5381 (2010)

D.A. Sanchez, N. Ortega, A. Kumar, G. Sreenivasulu, R.S. Katiyar, J.F. Scott, D.M. Evans, M. Arredondo-Arechavala, A. Schilling, J.M. Gregg, J. Appl. Phys. 113, 074105 (2013)

W. Peng, N. Lemee, M. Karkut, B. Dkhil, V. Shvartsman, P. Borisov, W. Kleemann, J. Holc, M. Kosec, R. Blinc, Appl. Phys. Lett. 94, 012509 (2009)

V.V. Laguta, M.D. Glinchuk, M. Maryško, R.O. Kuzian, S.A. Prosandeev, S.I. Raevskaya, V.G. Smotrakov, V.V. Eremkin, I.P. Raevski, Phys. Rev. B. 87, 064403 (2013)

I.P. Raevski, S.P. Kubrin, S.I. Raevskaya, S.A. Prosandeev, M.A. Malitskaya, V.V. Titov, D.A. Sarychev, A.V. Blazhevich, I.N. Zakharchenko, IEEE Trans. Ultrason. Ferroelectr. Freq. Contr. 59, 1872 (2012)

I.P. Raevski, S.P. Kubrin, V.V. Laguta, M. Marysko, H. Chen, S.I. Raevskaya, V.V. Titov, C.-C. Chou, A.V. Blazhevich, E.I. Sitalo, D.A. Sarychev, T.A. Minasyan, A.G. Lutokhin, YuN Zakharov, L.E. Pustovaya, I.N. Zakharchenko, M.A. Malitskaya, Ferroelectrics 475, 20 (2015)

I.P. Raevski, V.V. Titov, M.A. Malitskaya, E.V. Eremin, S.P. Kubrin, A.V. Blazhevich, H. Chen, C.-C. Chou, S.I. Raevskaya, I.N. Zakharchenko, D.A. Sarychev, S.I. Shevtsova, J. Mater. Sci. 49, 6459 (2014)

A.A. Gusev, S.I. Raevskaya, V.V. Titov, V.P. Isupov, E.G. Avvakumov, I.P. Raevski, H. Chen, C.-C. Chou, S.P. Kubrin, S.V. Titov, M.A. Malitskaya, D.A. Sarychev, V.V. Stashenko, S.I. Shevtsova, Ferroelectrics 496, 231 (2016)

I.P. Raevski, S.P. Kubrin, S.I. Raevskaya, D.A. Sarychev, S.A. Prosandeev, M.A. Malitskaya, Phys. Rev. B. 85, 224412 (2012)

V.V. Laguta, J. Rosa, L. Jastrabik, R. Blinc, P. Cevc, M. Zalar, B. Remskar, S.I. Raevskaya, I.P. Raevski, Mater. Res. Bull. 45, 1720 (2010)

S. Nomura, H. Takabayashi, T. Nakagawa, Jpn. J. Appl. Phys. 7, 600 (1968)

I.P. Raevski, VYu. Shonov, M.A. Malitskaya, E.S. Gagarina, V.G. Smotrakov, V.V. Eremkin, Ferroelectrics 235, 205 (1999)

I.P. Raevski, S.P. Kubrin, S.I. Raevskaya, V.V. Stashenko, D.A. Sarychev, M.A. Malitskaya, M.A. Seredkina, V.G. Smotrakov, I.N. Zakharchenko, V.V. Eremkin, Ferroelectrics 373, 121 (2008)

V.V. Laguta, A.N. Morozovska, E.I. Eliseev, I.P. Raevski, S.I. Raevskaya, E.I. Sitalo, S.A. Prosandeev, L. Bellaiche, J. Mater. Sci. 51, 5330 (2016)

S.A. Prosandeev, I.P. Raevski, S.I. Raevskaya, H. Chen, Phys. Rev. B. 92, 220419(R) (2015)

A.A. Gusev, S.I. Raevskaya, V.V. Titov, E.G. Avvakumov, V.P. Isupov, I.P. Raevski, H. Chen, C.-C. Chou, S.P. Kubrin, S.V. Titov, M.A. Malitskaya, A.V. Blazhevich, D.A. Sarychev, V.V. Stashenko, S.I. Shevtsova, Ferroelectrics 475, 41 (2015)

A.A. Gusev, S.I. Raevskaya, V.V. Titov, V.P. Isupov, E.G. Avvakumov, I.P. Raevski, H. Chen, C.-C. Chou, S.P. Kubrin, S.V. Titov, M.A. Malitskaya, D.A. Sarychev, V.V. Stashenko, S.I. Shevtsova, Ferroelectrics 496, 231 (2016)

A.A. Gusev, S.I. Raevskaya, I.P. Raevski, V.P. Isupov, E.G. Avvakumov, S.P. Kubrin, H. Chen, V.V. Titov, T.A. Minasyan, C.-C. Chou, S.V. Titov, M.A. Malitskaya, Ferroelectrics 496, 250 (2016)

X. Gao, J. Xue, J. Wang, Mater. Sci. Eng. B 99, 63 (2003)

M.E. Matsnev, V.S. Rusakov, AIP Conf. Proc. 1489, 178 (2012)

D. Bochenek, G. Dercz, D. Oleszak, Arch. Metall. Mater. A. 56, 1015 (2011)

F. Menil, J. Phys. Chem. Solids 46, 763 (1985)

S.P. Kubrin, S.I. Raevskaya, S.A. Kuropatkina, D.A. Sarychev, I.P. Raevski, Ferroelectrics 340, 155 (2006)

W. Kundig, H. Bommel, G. Constabaris, R.H. Lindquist, Phys. Rev. 142, 327 (1966)

I.P. Raevski, N.M. Olekhnovich, A.V. Pushkarev, Y.V. Radyush, S.P. Kubrin, S.I. Raevskaya, M.A. Malitskaya, V.V. Titov, V.V. Stashenko, Ferroelectrics 444, 47 (2013)

J.B. Goodenough, Magnetism and Chemical Bond. (Interscience Publisher, a division of Wiley, New York, London, 1963), 393 pp

Acknowledgements

This work was partially supported by Ministry of Education and Science of the Russian Federation (Research project No. 3.5346.2017/BP), Russian Foundation for Basic Research (project 17–03–01293_a) and Research Committee of the University of Macau under Research & Development Grant for Chair Professor No RDG007/FST-CHD/2012.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Kubrin, S.P. et al. (2017). Mössbauer Study of the Effect of Mechanical Activation on the Magnetic Properties of PbFe0.5Nb0.5O3 . In: Parinov, I., Chang, SH., Jani, M. (eds) Advanced Materials. Springer Proceedings in Physics, vol 193. Springer, Cham. https://doi.org/10.1007/978-3-319-56062-5_14

Download citation

DOI: https://doi.org/10.1007/978-3-319-56062-5_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-56061-8

Online ISBN: 978-3-319-56062-5

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)