Abstract

This chapter addresses ADCs for IoT nodes, which are needed to digitize sensor information before processing, storage or wireless transmission. ADCs are also required for the radio communication channel. This chapter focusses on successive approximation (SAR) ADCs, a popular architecture for IoT thanks to their high power-efficiency. After deriving requirements for IoT, the design basics of SAR ADCs are discussed, followed by various design examples to illustrate key enabling techniques.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

This chapter addresses ADCs for IoT nodes, which are needed to digitize sensor information before processing, storage or wireless transmission. ADCs are also required for the radio communication channel. This chapter focusses on successive approximation (SAR) ADCs, a popular architecture for IoT thanks to their high power-efficiency. After deriving requirements for IoT, the design basics of SAR ADCs are discussed, followed by various design examples to illustrate key enabling techniques.

13.1 ADC Requirements for IoT

This section first reviews basic ADC definitions, and then discusses ADC requirements in the context of IoT nodes. State-of-the-art ADCs are highlighted and the SAR architecture is selected for further elaboration in this chapter thanks to its suitability for IoT.

The function of an Analog-to-Digital Converter (ADC) is to convert analog information into the digital domain. The three most important performance metrics of ADCs are accuracy, speed and power consumption. While the ADC’s accuracy can be expressed in different ways, a common way is to use SNDR (Signal-to-Noise-and-Distortion-Ratio), i.e., the ratio between signal power and power caused by all forms of noise and distortion (Pelgrom 2017). The SNDR can also be recalculated to ENOB (Effective-Number-Of-Bits) with equation (13.1). Note that an ideal Nyquist-rate ADC with N-bit output codes will have an ENOB equal to N. From this, the maximum theoretical SNDR of such an ADC can be determined as well. In reality, ENOB and SNDR will be lower than this theoretical upper bound.

In terms of speed, two metrics are relevant: the sample rate fs of the ADC and the signal bandwidth (BW) that can be converted. For a Nyquist rate ADC, fs will be twice the value of BW to satisfy the Nyquist criterion. Oversampled ADCs have an fs that is much higher than BW to allow for instance noise-shaping techniques. In this chapter, fs,Nyq denotes the equivalent Nyquist sample-rate of an ADC, which is thus twice BW. The last performance parameter of an ADC is its power consumption, here denoted with P. Combining the above three metrics, different Figure-Of-Merits can be calculated to evaluate the overall performance with a single number. Two commonly used FOMs are the FOMW and FOMS as shown in equations (13.2) and (13.3), respectively. Both FOMs show the trade-off between power, accuracy, and speed, albeit with different weighting functions.

Inside IoT nodes, data converters are generally found in two locations (Fig. 13.1): inside the baseband of the wireless receiver and as the final stage of the sensor interface. Due to energy constraints, ADCs in early-generation IoT nodes are typically optimized for low power consumption by reducing accuracy and speed down to the minimum acceptable performance. For instance, 8/9-bit ADCs with up to a few MS/s sample rate are used in low-power proprietary standard ISM-band radios (Vidojkovic et al. 2011) or in standard compliant BLE (Bluetooth Low Energy) radios (Liu et al. 2015; Prummel et al. 2015; Sano et al. 2015). For sensor interfaces, traditional high-precision applications typically use ADCs with 12 to 16-bit resolution (Makinwa et al. 2015), but IoT systems have sacrificed precision to achieve power reduction. For instance, 7 to 10-bit performance was proposed in systems used for IoT and wearable sensing applications (Harpe et al. 2015; Yip et al. 2011). With the progress of technology, a trend towards higher resolutions like 10 to 12-bit can be seen more recently (Konijnenburg et al. 2016). The required speed of IoT ADCs strongly depends on the application. In wireless communication, this depends on the signal bandwidth which is typically in the kHz or low-MHz range, requiring up to a few MS/s of sample rate from the ADC. For sensors, some applications require only quasi-static conversion, for instance in case of temperature, pressure, light, or humidity monitoring. Many other sensors have relatively low speed of operation and require ADCs up to a few kS/s, for instance in case of bio-potential recording, accelerometers, or gyroscopes. Lastly, some particular sensors, such as image sensors, could require a very high conversion bandwidth.

In summary, most IoT applications can be covered with ADCs with relatively low speed (DC up to a few MS/s) and moderate resolution (ENOB around 7 to 12-bit). With today’s CMOS technology, such speed of operation is straightforward to achieve, and hence the focus in design can be mostly on power efficiency.

Figure 13.2 gives an overview of state-of-the-art ADCs (1997–2016, (Murmann 2016)) in terms of efficiency (energy consumption per sample) versus SNDR. It can be seen that for the resolutions of interest, Successive Approximation Register (SAR) ADCs are the most power efficient solution. Therefore, the remainder of this chapter focusses on SAR ADCs.

State-of-the-art ADC power-efficiency versus SNDR, data from (Murmann 1997)

As stated before, IoT nodes have minimized ADC accuracy and speed to save power. However, this could for instance reduce the interference tolerance of the radio, or it may give suboptimal sensor performance. For those reasons, higher performance ADCs are demanded. Fortunately, technology scaling and design techniques enable this demand. As shown in Fig. 13.3, it can be observed that the power-efficiency of ADCs has been improving steadily over the last decades, reaching more than a factor 1000 of power reduction in 20 years. Thanks to this trend, future IoT nodes will either benefit from lower power consumption or improved precision/speed.

Improvement of ADC power-efficiency over time, data from (Murmann 1997)

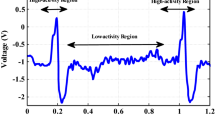

Besides the critical trade-off between power, precision, and speed, that lead to the selection of the SAR architecture, there are several other aspects that are relevant in the context of IoT. First, IoT nodes are often operated on-demand, implying that the node is inactive for a long time, and only operational in short bursts. For this reason, ADCs with low standby consumption and instantaneous operation are preferred. SAR ADCs suit well in this context, because they can be made without static bias currents, allowing automatic power-down in standby phases. Moreover, as they are Nyquist converters, a single conversion can be made instantaneously (as opposed to oversampled converters that could suffer from memory or start-up effects). Reconfigurability, i.e., the ability to operate efficiently at different speeds and resolutions, is another key parameter that is favorable for IoT. For instance, this allows to digitize signals with a variable speed or resolution, dependent on the activity, application, or environmental conditions.

In the remainder of this chapter, Sect. 13.2 describes the general design aspects of low-power SAR ADCs. The main requirements of IoT are discussed by means of design examples, namely: low power consumption and duty cycling (Sect. 13.3), developments towards higher precision (Sect. 13.4), and reconfigurability (Sect. 13.5). Section 13.6 elaborates on voltage references that are needed for the ADC, and Sect. 13.7 discusses perspectives and trends in the field of ADCs for IoT.

13.2 Basics of SAR ADC Design

In this section, the basics of low-power SAR ADC design are discussed, addressing all major components in the system.

13.2.1 SAR Principle of Operation

Figure 13.4 shows the topology and timing diagram of a SAR ADC where an analog input voltage Vin is first sampled at the sample clock fs using a Track & Hold (T&H). Next, the SAR logic performs a binary search algorithm to find the N-bit output code Dout that matches the sampled input voltage. This is done by comparing VDAC, the voltage corresponding to the estimated output code, to the sampled voltage Vs. After N cycles of approximation, VDAC will be very close to Vs, implying that Dout is the output code describing the sampled input Vin. As shown in the timing diagram, sampling takes place in a first clock cycle, after which there are N clock cycles to determine the N bits. After this, the final code is obtained and the operation repeats for the next input sample. In order to implement this ADC, a T&H, comparator, logic and DAC are needed. These components will be described in the following paragraphs.

13.2.2 Track&Hold

The basic T&H topology that is often used in SAR ADCs is shown in Fig. 13.5a. Vin is sampled on capacitor Cs at the sampling rate fs. When the control signal is high, the output tracks in the input signal; when the control signal is low, the signal is held on the capacitor. Crucial for the T&H performance is the implementation of the switch. The most straightforward way is to use an NMOS (or PMOS) device as switch (Fig. 13.5b). However, assuming the control signal going to the gate of the NMOS is limited by the supply voltage, this NMOS device cannot conduct for rail-to-rail input signals: the NMOS only conducts when Vin < VDD−Vtn, where VDD is the supply voltage and Vtn the threshold voltage of the NMOS. Similarly, a PMOS only conducts when Vin > |Vtp|, where Vtp is the PMOS threshold voltage.

A conventional solution to this problem is to use a CMOS switch, where an NMOS and PMOS device are connected in parallel. In this way, as long as |Vtp| + Vtn < VDD, a rail-to-rail input swing can be supported. Unfortunately, VDD tends to scale down faster than the threshold voltages in advanced processes, making it more and more difficult to satisfy this requirement. Moreover, IoT nodes may prefer to use a reduced supply voltage to save power, making it even harder to reach this requirement.

Due to the above issues, techniques such as clock boosting (Cho and Gray 1995) and bootstrapping (Abo and Gray 1999) are often used. Both techniques essentially use the circuit of Fig. 13.5b with an NMOS only, but they control the gate with a voltage beyond VDD to allow a rail-to-rail input swing and a better switch conductivity. In clock boosting, a fixed voltage multiplier is used to increase the gate voltage from VDD to kVDD, where k is typically between 1.5 and 2x of gain. In bootstrapping, a level-shifter is used to lift the gate voltage to VDD + Vin, making the gate-source voltage always equal to VDD. A limitation of boosting and bootstrapped techniques is that they rely on a charge pump. For ADCs operating at extremely low speed or on-demand (which could be the case in IoT nodes), these charge pumps could fail to operate properly due to charge leakage. In such cases, a CMOS switch could be preferable.

Having discussed the basic topologies of the T&H, the most important imperfections are discussed next, namely: sampling noise, on-resistance, charge injection, leakage and capacitive coupling.

At the moment the switch samples the input voltage on capacitor Cs, the thermal noise produced by the transistor will also be sampled on the capacitor. This leads to an output noise power Pnth of kT/Cs, where k is the Boltzmann constant and T the temperature. For ADCs with higher SNDR, a lower Pnth can be tolerated, implying that they will need a larger Cs. Typical low-power SAR ADCs can have a Cs in the order of 0.3–1 pF (Harpe et al. 2013, 2015).

Two important imperfections causing distortion are the finite on-resistance and the charge injection of the sampling switch (Pelgrom 2017). However, as the speed and resolution requirements are relatively mild in IoT nodes, boosted or bootstrapped switches can usually achieve sufficient linearity. In some cases, a CMOS switch might also be adequate. Only if the supply voltage is scaled down too much, the above problems become a limiting factor. As example of what is feasible, the T&H in Harpe et al. (2014) achieves a linearity well above 80 dB for a signal bandwidth of 16 kHz using a 0.8 V supply, a 65 nm technology and a clock-boosted switch.

The last two problems, leakage and capacitive coupling, occur when the T&H is in the hold mode. Ideally there should an infinite impedance between the input and output node of the switch during hold mode. However, there might be drain-to-source leakage from the transistor (modeled by a resistance Rleak) and capacitive coupling from the layout (modeled by Cds), as shown in Fig. 13.6. As a result, the output voltage is not completely isolated from the input signal during the conversion, which can cause distortion in the output code (Harpe et al. 2011). In particular in advanced CMOS nodes, it can be important to simulate these effects to verify the impact on the performance.

13.2.3 DAC

In this subsection, the design of the feedback DAC is discussed. While there are various possible implementations, the most typical solution is a capacitive charge-redistribution DAC, using voltage-mode operation. In the context of IoT, one important advantage of a switched-capacitor DAC is that its power consumption is fully dynamic. It thus scales intrinsically with the sampling rate and it allows on-demand operation and standby, simply by enabling/disabling the control signals. Figure 13.7a shows a single-ended 3-bit example of such a DAC. It is composed of binary-scaled capacitors Ci, controlled by a digital binary code d2:0. The digital control can switch the bottom plate of each capacitor between various reference voltages, in this example GND and VREF. If code di switches capacitor Ci from GND to VREF, an output voltage step ΔVDAC of Ci/CS∙VREF is induced, where Cs is the sum of all capacitors (8Ci in this example). Based on superposition, the overall DAC voltage is hence proportional to the value of the binary code:

Note that the DAC is shown here as a stand-alone component. However, as will be explained in Sect. 13.3, the DAC often acts as sampling capacitance of the T&H as well, such that a dedicated CS (as in Fig. 13.5) is not needed anymore.

The above circuit shows only one example of a 3-bit DAC that creates a transfer function as in equation (13.4). In reality, different topologies with different switching schemes can achieve the same transfer function while saving power or resources by using for instance multiple references, semi-differential switching schemes, split capacitors, or charge recycling schemes. Without being complete, a few examples are: (Ginsburg et al. 2006; Hariprasath et al. 2010; Liu et al. 2010; Liou et al. 2013; Liu et al. 2016b; Tai et al. 2014; Zhu et al. 2010). These schemes can save a substantial amount of power, and are thus very relevant to IoT nodes.

In terms of reference voltages, a trend is to use only voltages close (or equal) to the supply and ground levels, as this simplifies the design of the switches in Fig. 13.7a. At reduced supplies it is particularly difficult to make a well-conducting switch for signal levels in the middle between supply and ground. On the other hand, the ground level can be easily switched with an NMOS while the supply level can be easily switched with a PMOS device. By doing so, the switching network simplifies to a digital-style inverter, where the control signal is applied to the input of the inverter, and the reference voltage VREF (often equal to VDD) is the supply of the inverter (Fig. 13.7b).

The selection of the value of the unit capacitor (C0), implying a total DAC capacitance CS equal to 2N∙C0, is the most critical decision in the DAC design process. In the following, the various considerations are discussed.

In terms of noise, the DAC has several contributions. First, when the DAC is reused as sampling capacitor, it will exhibit kT/C-noise as explained in Sect. 13.2.2. Furthermore, noise from the reference voltages and noise from the DAC switches contribute additional noise to the DAC’s output. In terms of linearity, the ideal transfer function is given in equation (13.4), but this is only valid if the capacitors Ci are perfectly binary scaled. In reality, each capacitor element C0 will experience a random mismatch σ0, causing the function to become non-linear and thus introducing INL/DNL errors and loss of SNDR. Generally speaking, a larger value of CS is required to suppress noise and mismatch.

As opposed to the above, power consumption and chip area benefit from using smaller capacitors. To first order, both power and chip area are linearly related to the total capacitance CS, suggesting one should reduce its value as much as possible down to noise and linearity limitations. In practice, the smallest possible element can be dictated by the minimum element available from the foundry’s library. A solution to that is to develop custom designed sub-fF capacitors (Harpe et al. 2011) which can save power, while having relatively good matching (given the capacitor value), and a small form-factor layout. However, the chip area will also be related to the number of interconnections and spacing requirements, which will be proportional to the number of control signals (N), or the number of elements (2N). As such, for higher resolution ADCs, the area might be dictated by the large number of units (2N). This can be reduced by using a split-capacitor array (Agnes et al. 2008) or by using multiple layout units (Harpe et al. 2014).

13.2.4 Comparator

In this subsection, the design of the comparator is discussed. Conceptually, in a single-ended case, the comparator compares the sampled input voltage VS against the DAC voltage VDAC, as illustrated in Fig. 13.8a. Comparators in SAR ADCs are usually dynamic, i.e., they perform a comparison and a reset for each clock period fcmp. Similar to the DAC, this allows convenient power scaling dependent on the sample rate. In most practical implementations, the signals VS and VDAC are differential. To avoid a 4-input comparator, VDAC is usually subtracted from VS prior to the comparator. Then, a 2-input comparator can simply decide the sign of VS−VDAC as shown in Fig 13.8b to obtain the required information. An advantage of doing so is that the input common mode of the comparator can become signal-independent and remain around mid-supply.

The most important non-idealities of the comparator are its input-referred noise, offset and decision time. Comparator noise can lead to decision errors once the input signal magnitude is similar to the noise level. For that reason, comparator noise is as important as T&H noise and quantization noise. As the comparator is often critical for the overall ADC’s power consumption, the power-efficiency is a particular point of attention. Fundamentally, each 6 dB noise improvement costs a factor of four in power consumption. However, several strategies can be employed to optimize the efficiency. For instance, the dynamic topology in van Elzakker et al. (2010) achieves relatively good efficiency, which is further improved by biasing the critical devices in sub-threshold. A further enhancement of the above circuit is made in Liu et al. (2016) where a factor of two in power is saved by using both phases for amplification rather than wasting one for reset. Another approach is to minimize the supply voltage, as the power of a dynamic circuit scales with the square of the supply. Besides circuit innovations, system-level solutions such as in Harpe et al. (2012, 2013) have helped to reduce the comparator power consumption by using adaptive performance during the conversion.

A second imperfection of the comparator is its input-referred offset. Fortunately, the comparator’s offset is equivalent to an ADC input-referred offset and does not introduce distortion. For IoT applications where the signal being converted is not containing DC information, this input-referred offset might be ignored. For applications where the offset is critical, for instance an offset calibration could be performed, or a system-level chopping technique could be applied to cancel the ADC’s offset (Harpe et al. 2014).

The third consideration for the comparator is it speed. As soon as the comparator is triggered by the clock signal, it still takes a certain delay until the comparator reaches its decision. This delay depends on the input signal magnitude and increases for smaller input signals (Pelgrom 2017). The clock signal should thus allow sufficient time to reach a decision. Moreover, the comparator also needs a sufficiently long reset phase to reset the comparator to the initial condition. If this time is too short, the next decision can be affected by the previous one, causing signal dependency and hence non-linearity. While IoT applications are not very demanding in terms of speed, the comparator delay will increase substantially when lowering the supply voltage. Moreover, when operating in sub-threshold, the delay can also be severely affected over PVT variations, thus requiring sufficient design margin with respect to the timing. As discussed in the next paragraph, asynchronous timing can alleviate the comparator delay variation to some extent.

13.2.5 Logic

The logic in a SAR ADC is conventionally build around two strings of flip-flops (Fig. 13.9a). A first string (or register) is acting as a thermometer counter to memorize in which phase of the conversion process the SAR ADC is. Assuming that the ADC uses N + 1 clock cycles (1 for tracking and N for the N-bit SAR conversion), the thermometer counter will count from 0 up to N. A second register contains the actual DAC code that will ultimately compose the ADC output code at the end of the conversion. Besides these two registers, additional combinational logic needs to be added to generate various internal signals to control the comparator, T&H and DAC, based on the state of the registers. For simplification this is not shown.

The basic operation of the registers is shown in the timing diagram of Fig. 13.9b. The external clock fclk, at N + 1 times the sample rate fs, drives the thermometer counter, thus creating N + 1 counter values from 0 to N. Combinational logic will combine fclk with the counter value to generate a sampling clock fs in the first counter cycle (counter = 0) and to generate N comparator clock cycles (fcmp) in the other counter cycles. The incrementing counter also strobes the data register, addressing each bit one by one (starting with the MSB down to the LSB), to store the comparator output in the correct data bit. The data register drives the DAC, but some additional combinational logic might be needed, dependent on the switching scheme used in the DAC.

The above solution has two drawbacks. First, the logic requires an external clock which is N + 1 times faster than the actual sample rate. The higher speed could increase system-level power consumption, but it also complicates duty-cycled operation as one has to keep track of the number of cycles of fclk. A second disadvantage is in terms of comparator metastability handling. As explained in Sect. 13.2.4, the comparator decision time depends on the signal magnitude applied to the comparator. Ultimately, when the signal becomes very small, the comparator is close to metastability where the decision can take a long time. During the N cycles of the SAR conversion, the input signal to the comparator will vary substantially. As a result, the comparator decision time varies significantly from cycle to cycle. However, with a fixed fclk rate, the maximum fclk is limited by the slowest decision time of the comparator. Since in most cases the comparator is much faster, this implies that time is wasted in the other cycles.

A solution to the above problems is to use asynchronous timing inside the SAR ADC. In this case, as sketched in Fig. 13.10, only an external clock at the sample rate fs is provided. The comparator clock fcmp is internally generated, usually by means of a feedback loop that automatically produces N comparator cycles. The actual cycle time can be made variable by waiting exactly until the comparator decision has been made. As a result, some cycles will be faster and others slower, to accommodate the timing variation of the comparator without wasting time. By doing so, the average clock cycle is now set by the average delay of the comparator rather than the worst-case delay, hence improving speed and improving the ability to deal with metastability issues. This also simplifies the system-level design, as a single clock pulse on fs is now sufficient to perform a single (on-demand) conversion. Examples of asynchronous timing are for instance given in Chen and Brodersen (2006), Harpe et al. (2011, 2013), and detailed logic implementations are described in Harpe et al. (2011, 2012).

13.3 An Ultra-Low Power SAR ADC

This section discusses a design example of an ultra-low power SAR ADC with 10 bit resolution and a variable sampling rate from DC to 100kS/s, consuming down to 0.15 nW of power (Harpe et al. 2015, 2016). While originally developed for low-power bio-potential recording, the specifications are suitable for versatile sensing applications where especially the power consumption is critical. Thanks to nW-level operation, this ADC allows extremely small form-factor devices powered by energy harvesting or tiny batteries.

The topology of the ADC, which is rather standard, is shown in Fig. 13.11. To save power, the nominal supply is reduced to 0.6 V, well below the regular 1.2 V supply of the applied 65 nm CMOS technology. At the same time, the supply of 0.6 V is still sufficiently high such that conventional circuits can operate correctly. The sampling switches are clock-boosted to achieve sufficient linearity (Cho and Gray 1995). As mentioned earlier, the T&H has no explicit sampling capacitance, but the input signal is sampled directly on the DAC capacitor array instead. Because all circuits are dynamically biased, the power scales inherently with the sample frequency. To reduce the leakage power consumption, high threshold-voltage transistors are used.

The ADC only requires a single external clock at the sample rate fs. An internal loop around the comparator creates the clock that is needed for the comparator and logic. As shown in the timing diagram in Fig. 13.12, a rising edge of the external ADC clock initiates a complete conversion. The logic enables the feedback loop around the comparator (Fig. 13.11): this loop will start the comparator clock first. As soon as the comparator has resolved a decision, its Ready output will be engaged. By means of the inverted delay, this Ready signal will disable the comparator clock. As a result, the comparator is reset and its Ready will switch off again. As the Ready turns off, this will initiate a next comparison clock cycle. In this way, the consecutive bit cycles are generated until all 10 bits are resolved. At that point, the logic disables the feedback loop, produces an ADC output code, returns the DAC to tracking mode, and then places the ADC into standby. As the timing diagram shows, the entire conversion takes approximately 5 μs, after which the ADC returns to sleep. Since the ADC only requires a single rising clock-edge on its external clock to trigger a conversion, the ADC is very suitable for on-demand operation.

The implementation of the capacitive DAC is shown in Fig. 13.13a. The differential DAC is implemented by two identical single-ended structures. Normally, a 10-bit binary scaled array would be needed. In this case, the 10 bit is segmented in 3 MSBs and 7 LSBs. The LSBs are binary coded and controlled by code B<6:0>, the 3 MSBs are thermometer encoded and therefore control 7 identically sized capacitors, controlled by thermometer code T<6:0>. Using thermometric coding has two advantages: it saves switching energy in the DAC and it reduces the maximum DNL error as the worst-case number of switching elements is reduced (Harpe et al. 2013).

To maximize the dynamic range and to simplify the ADC system integration, the DAC only uses ground and VDD as its reference voltages, as explained before in Fig. 13.7b. Because of that, the ADC requires only a single supply voltage that is used by all components.

To save power in the DAC, as well as in the (external) reference buffer and in the analog buffer driving the ADC, the capacitance of the DAC is minimized as much as possible by developing custom designed fringing capacitors. Similar to Harpe et al. (2011), this work uses capacitive elements as shown in Fig 13.13b with a unit value of 0.25fF. To improve capacitor density, two metal layers (6 and 7) are stacked. The lower layers (1 to 5) are not used, because they would increase the parasitic capacitance to the substrate, causing an attenuation of the signal range. By using these small capacitors, the total input capacitance of the DAC is only 0.3 pF, which leads to a kT/C-limited SNR of approximately 66 dB, which is still sufficient for a 10 bit ADC.

Figure 13.14 presents the die photo of the ADC, implemented in a 65 nm CMOS process and occupying 180 μm∙80 μm. The chip area is mostly dominated by the capacitive DAC. However, a large part of the DAC area (~75 %) is due to interconnections that were not really optimized for chip area, while the capacitors only take <20 % of the total DAC area.

The precision of the ADC is verified by measuring the INL, DNL and ENOB. The INL and DNL are shown in Fig. 13.15. Both parameters remain within 1LSB. As expected, the largest DNL errors (and thus the largest discontinuities in the INL) happen at the thermometer code transitions.

The ENOB, measured as a function of the input signal frequency at a sample rate of 100 kS/s is given in Fig. 13.16. The performance is constant over the entire Nyquist zone, showing the ADC has sufficient bandwidth despite the reduced supply voltage.

Lastly, Fig. 13.17 displays the measured power consumption versus sampling rate together with the simulated power breakdown at 1 kS/s. It can be seen that the power scales proportional to the sample rate. Due to limitations of the measurement setup, the lowest frequency measured is around 0.2kS/s. A standby leakage of 0.15 nW is measured by disabling the clock altogether and measuring the supply current. From the simulated breakdown (post-layout), it is clear that the comparator contributes most to the overall power. The DAC contribution is small thanks to the small unit capacitors, even though the DAC switching scheme was not optimized.

Table 13.1 shows a performance summary and comparison to prior-art. The efficiency is comparable to state-of-the-art, but not as good as (Tai et al. 2014). However, as can be seen from Fig. 13.2, this is still one of the few ADCs under the indicated FOMW trend line of 2 fJ/conversion-step. Another advantage of the proposed ADC is that it has the lowest leakage power, allowing to maintain power efficiency even when the sample rate is reduced to well below 1 kS/s.

This section described a 10-bit ADC with a versatile sampling rate. As shown, the architecture and implementation are relatively basic. Thanks to technology scaling, the simple architecture and circuits, the small unit capacitors, and a reduced supply voltage, this still allows to achieve state-of-the-art power efficiency. Moreover, by using only a single supply and a single clock-edge for triggering conversion, the ADC is simple to integrate and use in an IoT system.

13.4 A High-Precision SAR ADC

The previous section described a SAR ADC with 10 bit resolution. While this can be sufficient for basic sensing applications, other applications could demand higher precision. Therefore, this section describes a SAR ADC with a relatively high precision, selectable from 67.8 dB up to 79.1 dB of SNDR (Harpe et al. 2014).

In order to increase a SAR ADC’s SNDR, the main challenge is to reduce noise and distortion contributions while maintaining power-efficiency. In this design, a combination of oversampling, chopping, dithering and data-driven noise-reduction is applied to achieve this. These techniques will be described one by one.

Oversampling is a known technique to improve the SNR (Signal-to-Noise-Ratio) in a signal band of interest by sampling faster than the Nyquist rate. Given that the sampling rate is increased with a certain oversampling ratio (OSR), the in-band noise power will be reduced by the same factor:

This implies that every factor 4 of oversampling reduces the in-band noise by 6 dB, thus improving the SNR by 6 dB at the cost of 4x higher speed and power. Oversampling allows to mitigate all random noise contributions of a SAR ADC while maintaining a constant FOMS. However, correlated errors (such as distortion and 1/f noise) cannot be solved by oversampling.

The second technique being applied is system-level chopping. Chopping is a known technique to mitigate offset and 1/f noise problems of amplifiers, and can be applied likewise to an ADC. Figure 13.18 shows a simplified explanation of an ADC converting an analog input X to a digital code Y. As shown in the upper graph, the ADC might add signal-dependent harmonic distortion (HD(X)), offset (O) and 1/f noise (1/f). In the second graph, system-level chopping is applied to this ADC. The input signal is modulated with a chopping clock (fc) before the conversion, and demodulated by the same clock at the output of the ADC. If fc is set to half of fs, this means that the system is transparent in the odd clock cycles, while the input and output signals are inverted in the even clock cycles. The equations in Fig. 13.18 show how the output codes in the two phases (Y1 and Y2) depend on the input and various imperfections.

Next, the harmonic distortion is separated in two components, namely the even-order and the odd-order distortion components, denoted by HDe(X) and HDo(X), respectively. This means that the relations in equations (13.6) and (13.7) hold.

As a final step, the average value of Y1 and Y2 can be determined, which yields the result in equation (13.8). The result shows that chopping removes offset, 1/f noise and even-order distortion when looking to the average of codes (or in reality: when looking to the low-frequency part of the spectrum). In fact, these imperfections are not removed, but modulated to the chopping frequency. If oversampling is applied together with chopping, this implies that offset, 1/f noise and even-order distortion will be moved out of band, hence allowing to improve the SNDR of a SAR ADC.

The third technique used to improve linearity is dithering. It can be observed (for instance in Fig. 13.15) that the ADC distortion is often rather irregular due to capacitor mismatch, causing strong local variations. Dithering aims to smooth out these irregularities by adding an amount of dither to the input signal before conversion. In this way, the local irregularities can be averaged, causing an improvement of local linearity. However, it should be noted that since the dither is limited in amplitude, it cannot solve global non-linearities.

Figure 13.19a shows the implementation of the ADC including the chopping and dithering techniques. It supports a native resolution of 12 or 14-bit. To integrate chopping, there are two sets of sampling switches, allowing to sample the input signal alternatingly in the normal way (φ1) or with inverted polarity (φ2). The second chopper, which is in the digital domain, simply needs to forward the output bits in one clock cycle, and invert the output bits in the next clock cycle.

The dithering technique is implemented inside the DAC, as illustrated in Fig. 13.19b. The actual circuit is differential, but only one half is shown here. Similar to the ADC design discussed in Sect. 13.3, the lower bits (9 down to 0) are binary encoded, while the upper 4 bits are unary encoded (requiring 15 identical-sized capacitors). The dither signal can be injected with a capacitive network connected to the DAC. In time, the input signal is first sampled on the top plates of all the capacitors. Then, the delayed sample clock will switch the dither capacitors, causing a dither value to be added to the sampled input signal. After that, the normal conversion starts, such that the ADC converts the dithered input signal. Additional details on this technique are explained in Harpe et al. (2014).

The implementation of the DAC capacitors leads to a practical challenge. Since the ADC has 14-bit of resolution, it theoretically needs 214 = 16,384 capacitive elements, which is unpractical. A split capacitor array (Agnes et al. 2008) could reduce this, but may lead to additional non-linearities. In this case, the number of units is reduced by using multiple layout units, of respectively 8.8, 4.4, 2.2 and 1.1fF. Table 13.2 gives an overview of how the DAC capacitors are composed. The largest capacitors (for the thermometer bits and the binary bits 9 down to 4) are composed of 8.8fF layout elements to reduce the number of devices. The lower bits (bit 3, 2, and 1) use the down-scaled layout elements of 4.4, 2.2 and 1.1fF. Lastly, bit 0 effectively uses half a unit of 1.1fF. This is done by placing a capacitor of 1.1fF on the positive side of the DAC array, and no capacitor on the negative side of the differential topology. In this way, the effective value is 0.55fF when looking to the differential operation. The slight common-mode imbalance is irrelevant as this is very small. From Table 13.2 it is clear that the number of units is reduced to 1027 in this way, saving almost a factor of 16 in the number of devices and thus making the layout more simple and compact. The total DAC capacitance is 9 pF, which leads to about 85 dB of kT/C-related SNR at 0.8 V supply.

The last technique applied in this design is Data-Driven Noise-Reduction (DDNR). Its goal is to improve the comparator noise level in a more efficient way than by simple analog circuit scaling which costs 4x in power for a 6 dB better SNR. This is critical in low-power ADCs, as the comparator can dominate the overall ADC power consumption (e.g., 57 % in Fig. 13.17). When looking to Fig. 13.20a, it can be observed that during the SAR conversion, the input signal magnitude applied to the comparator is often large, and only in a few cycles it will be small (in the order of an LSB). Comparator noise can cause decision errors, but this will only happen if the input signal is in the same order of magnitude as the noise. For those cycles where the input is very large, the comparator noise is in fact not critical at all. Thus, rather than using a comparator with a fixed noise level, DDNR saves power by modifying the comparator noise level on-the-fly for each cycle, dependent on the input signal magnitude: for large signals a high noise level is tolerated to save power, and for small signals the noise level is reduced to achieve better precision. In order to implement this concept, two components are needed: (1) it should be detected (within each cycle) whether the input signal magnitude is large or small; (2) the noise-level of the comparator should be tunable instantaneously during the conversion process.

To address the first problem, recall that the comparator decision time is related to the input signal magnitude: smaller signals lead to a longer decision time (Sect. 13.2.4). Thus, by observing the decision time, the input signal magnitude can be classified. As shown in Fig. 13.20b, a tunable delay cell is triggered together with the comparator. By comparing the delay of the comparator (τdelay) against this reference delay (τref), it can be decided whether the input signal was large or small. In practice, by tuning the reference delay cell by means of feedback, the reference delay τref can be stabilized to a desired value regardless of PVT variations (Harpe et al. 2014).

The second problem is to tune the noise-level of the comparator dynamically. While this could be done by tuning the analog circuit, this is cumbersome and could induce new errors (such as offset variations). Therefore, a digitally-intensive solution is applied by majority voting on a repeated set of comparator decisions to enhance the effective noise level. For instance, when the same comparator decision is repeated five times, and the majority vote of those five decisions is used as final output, this effectively reduces the input-referred noise by 6 dB, as shown in the presentation of Harpe et al. (2013). In fact, this is a bit similar to oversampling, where a higher sample rate is used to reduce in-band noise.

Combining the above two components, the overall approach is as follows: each SAR cycle starts with a single comparison. If the decision time is faster than the reference delay, this decision is immediately forwarded to the SAR logic and the SAR continues with the next bit cycle. However, if the decision was slower than the reference delay, four additional comparisons are performed on the same input signal. The majority vote on five decisions is taken and forwarded to the SAR logic. Only then will the SAR logic proceed to the next bit cycle.

A die photo of the implemented ADC is shown in Fig. 13.21. The largest portion of the indicated area is occupied by supply decoupling capacitors and the DAC. The ADC operates at a nominal supply of 0.8 V, and can work either in 12 bit or 14 bit Nyquist mode, or in oversampling modes. 12 bit resolution is simply implemented by skipping the last 2 conversion cycles and by disabling majority voting to save power. When oversampling is enabled, the chopping and dithering techniques can be turned on to improve the in-band SNDR.

Figure 13.22 shows an example of a measured output spectrum, in this case in 14 bit 16x oversampling mode with 128kS/s sampling rate. The in-band SNDR is 80.0 dB while the linearity reaches 87.5 dB and the ENOB is 13 bit. In this mode, the power breakdown (based on post-layout simulations) is as follows: DAC 51 %, comparator 40 %, logic 4 %, chopped T&H 3 %, dithering 2 %. Figure 13.23 shows the SNDR of this ADC in different modes of operation (12 bit/14 bit, Nyquist and oversampling), and an overall performance summary is given in Table 13.3. Compared to prior-art (Fig. 13.2), this work achieves state-of-the-art power-efficiency (FOMS from 173.8 to 176.8 dB) and also enables a relatively high SNDR up to 79.1 dB.

The SAR ADC presented in this section shows several simple features that enhance the SNDR while maintaining state-of-the-art power-efficiency. Also, the ADC can cover different performance settings (67.8 dB to 79.1 dB of SNDR) to allow a flexible trade-off between performance and power.

13.5 A Reconfigurable SAR ADC

The design examples of the previous sections are mostly relevant for sensor interfaces because of their sample rates in the kHz range. However, similar SAR topologies can be used easily to operate in the MHz range, allowing to re-use the converter in low power radios. In this section, a SAR ADC with flexible resolution (7, 8, 9, or 10 bit) and a variable speed (DC to 2 MS/s) is described, allowing to re-use the design for either low-power sensing or low-power narrow-band communication (Harpe et al. 2012).

Figure 13.24 shows the architecture of the reconfigurable SAR ADC. The basic architecture is similar to the previous design examples, using asynchronous clocking and a single supply for all components (including the DAC reference voltage). In order to make the sample rate reconfigurable, the ADC is implemented with dynamic circuits, similar to the examples discussed earlier. Therefore, the main attention in this section is on how to reconfigure the ADC resolution while maintaining power-efficiency.

For the digital logic inside a SAR ADC, the complexity and power consumption theoretically scale linear with the resolution N, as can be seen from the diagram in Fig. 13.9. To implement reconfigurable logic where the resolution can be adapted on-the-fly is straightforward: for instance, if 10 registers are implemented, up to 10 bit ADC resolution can be supported. If only 7 out of the 10 registers are activated, the ADC resolution is effectively reduced from 10 to 7 bit, while the power is scaled down proportionally as well, following the expected linear trend with N. Since the ideal power-scaling trend can be achieved with this reconfigurable implementation, the power efficiency is maintained for the logic.

As opposed to the power consumption of the digital part, the power consumption of the comparator and DAC should theoretically scale exponentially with N, because these blocks are limited by physical constraints such as noise and matching. To maintain the best possible ADC efficiency throughout a reconfigurable range of resolutions, these analog blocks need to be reconfigured in such a way that they achieve exponential power scaling with N.

Figure 13.25 shows the implementation of the reconfigurable DAC. First, it is assumed that the reconfiguration switch is permanently connected. In this case, the DAC has a resolution of N bit, and the power consumption is proportional to the total capacitance CS, which is equal to 2N∙C0. To reduce the DAC’s resolution, the reconfiguration switch can be disconnected. In this situation, the largest two capacitors (CN−1 and CN−2) are permanently disconnected and do not contribute to the DAC’s resolution or power consumption. Thus, the DAC has now N−2 bit of resolution, while the effective capacitance is reduced to 2N−2∙C0. This implies that the power consumption is exponentially scaled down with a factor 22, following the exponential scaling requirement in N.

In theory, it would be possible to add 3 reconfiguration switches, such that DAC resolutions of 7, 8, 9, and 10 bit can be implemented with a relative power consumption of 100 %, 50 %, 25 % and 12.5 %, respectively. However, for sake of simplicity, the implementation is limited to have only 2 modes of operation as shown in the graph, with a factor of 4 in power scaling. The DAC is set to 8-bit mode to support ADC resolutions of 7 and 8 bit, and it is set to 10-bit mode to support ADC resolutions of 9 and 10 bit. The unit capacitance (C0) is 0.6fF and implemented similar to Fig. 13.13b. Note that the proposed technique manages to scale the DAC power with 2N, which achieves constant-FOMW scaling. However, the scaling is still not optimal, as the DAC’s noise limit would theoretically allow scaling with 4N.

For the comparator, the design is based on the dynamic two-stage topology proposed in van Elzakker et al. (2010). In that design, a first stage acts as a dynamic pre-amplifier, while the second stage implements a latch. As the first stage contributes most of the comparator noise, it also dominates the total power consumption. Hence, it is sufficient to reconfigure the dynamic pre-amplifier only. The pre-amplifier (Fig. 13.26) is enabled when the CLK signal is turned on: a current will start to flow through the tail transistor. Dependent on the differential input signal, the differential pair will generate a differential output current that will be integrated on the load capacitors, thus creating a dynamically amplified output voltage. As analyzed in van Elzakker et al. (2010), the effective input-referred noise voltage of this stage is inversely proportional to √C, while the power consumption is given by 2∙C∙VDD2. As 1 bit additional resolution requires a 6 dB better SNR, this can be achieved by including a 4x larger C. In this way, the capacitor size and power consumption scale with 4N, following the ideal noise-power trade-off. The implemented pre-amplifier has therefore a programmable load capacitance. This is done by adding a small array of capacitors and switches such that the value can be programmed digitally. Four different noise/power settings are supported, with which the power can be scaled almost by 4x while the noise voltage scales about 2x. A wider scaling range would be preferable, but is hard to achieve: further down-scaling of C hardly helps, because by then the power is dominated by other components. Further up-scaling of C also has a limited impact, because by then the noise is dominated by other contributors.

So far, the reconfigurability of logic, DAC and comparator has been explained. A last feature integrated in this ADC is redundancy in order to save power. Rather than using a binary-scaled DAC which requires N cycles to find the N-bit output code, this ADC uses N + 1 cycles and a non-binary DAC. This redundancy allows to relax precision requirements in the early conversion cycles, as the redundancy can solve errors in the later conversion cycles. As shown in Giannini et al. (2008), this can be exploited to save power: Giannini et al. (2008) uses a noisy low-power comparator in the first SAR cycles to save power, and a precise higher-power comparator in the last few cycles to obtain the required precision. While (Giannini et al. 2008) required two separate comparators, this work can achieve the same result by simply reconfiguring the load capacitance of the comparator during the conversion process. More details can be found in Harpe et al. (2012).

The ADC was implemented in a 90 nm CMOS technology (Fig. 13.27) and operates from a 0.7 V supply. Figure 13.28 shows the measured ENOB as function of the input frequency, while operating at 2 MS/s. The ENOB for the different resolutions (7, 8, 9, and 10 bit) varies from 6.94 to 9.30 bit.

Figure 13.29 shows the measured power consumption versus sampling rate for the different resolutions. The power scales linear with the sample rate. The minimum power is 2 nW, caused by leakage. The power also scales with resolution, but this is not very well visible due to the logarithmic axis in the graph. At 2 MS/s, the power scales from 1.61 up to 3.56 μW when the resolution is changed from 7 to 10 bit.

A summary of the performance is given in Table 13.4. The ADC achieves good power efficiency for all resolutions and covers a useful resolution and speed range for IoT. For instance, for biopotential or environmental monitoring, the ADC could operate at 10 bit resolution and 1kS/s, where it consumes only 4nW. For a low-power radio, it could work at 8 bit resolution and 2MS/s where it consumes 1.61 μW. To expand the application range, it would be interesting for future work to include higher resolutions for more precise sensing and higher speeds to support more advanced wireless communication standards.

13.6 On-Chip Voltage References

The previous sections described low-power ADCs. To use such ADCs, analog signal conditioning (discussed in Chap. 12) and references are also required. As seen from the basic topology (Sect. 13.2), the SAR ADC usually only requires a voltage reference for the DAC that sets the full-scale range of the ADC (equation (13.4)). Moreover, as can be observed from the design examples (Sects. 13.3–13.5), this DAC reference voltage is often equal to the VDD of the other circuit blocks. Therefore, this section focusses on Reference Voltage Generators (RVG) and their application to ADCs for IoT.

The reference voltage provided to the DAC can experience several different types of imperfections, here classified as random variations and systematic variations. Random variations happen for instance due to thermal noise, or due to incidental glitches/disturbances. Since these effects are directly seen by the DAC, they will immediately modulate with the signal being digitized. However, if the problem is truly random, it can be filtered out either by filtering the reference with a by-pass capacitor, or by filtering the digitized samples in the digital domain. Systematic variations of the reference voltage could happen due to gradual temperature, process or supply voltage variations. These errors might drift over time but are usually strongly correlated from sample to sample. As such, they cannot be filtered out. However, it depends on the application if these errors are a problem or not. For instance, ratio-metric measurements can be insensitive to the precise reference voltage. Or, in case of a wireless link, the absolute amplitude of a received signal does not matter in itself. Communication can still be reliable if the reference is unprecise, as long as it is stable during the time of a transmission. However, for applications where the absolute voltage of the sensed signal is relevant, the reference voltage needs to be tightly controlled.

In case a reference voltage needs to be generated, several requirements of IoT should be noted. Low power consumption is mandatory. To save further power, low-voltage operation and the ability for duty-cycling are preferred as well. Lastly, to integrate the references together with the rest of the IoT system, technology portability to scaled CMOS nodes is also relevant. Table 13.5 shows several state-of-the-art examples of low-power voltage references. They all manage to achieve pW to nW levels of power consumption, albeit with different performance characteristics. The line sensitivity and PSRR describe how sensitive the generated reference is with respect to variations or disturbances of the input voltage. The temperature coefficient describes the sensitivity to temperature variations in the indicated temperature range. Most designs, except (Dong et al. 2016), can operate at sub-1 V supplies. Liu et al. (2016) is the only design in this list that is integrated in an advanced CMOS node, and the only one that includes duty-cycling ability. On the other hand, the power consumption of the other designs is so low that duty-cycling is not even necessary. In Magnelli et al. (2011), the generated reference is determined by the threshold voltage of a single MOS transistor. In Dong et al. (2016), Liu et al. (2016), Seok et al. (2012) the generated reference is dependent on the threshold voltage difference between two MOS transistors. However, their actual principles and circuit implementations are very different. Seok et al. (2012) uses the threshold difference between a native and a thick-oxide device, Dong et al. (2016) uses the difference caused by the body bias effect, and Liu et al. (2016) uses the difference based on different ion implant levels in two thin-oxide transistors. While these designs prove that low-power reference generation is feasible, these circuits have a very high output impedance and are thus not able to directly drive the DAC, as the DAC requires substantial power from the reference. For that reason, a buffer or low-drop-out regulator (LDO) is still required to connect the RVG to the ADC.

A complete system example, published in Liu et al. (2016), is shown in Fig. 13.30. Here, the RVG provides a reference voltage to an LDO. The LDO multiplies the reference and powers the entire 10bit ADC. A raw supply of at least 0.8 V is needed to generate a reference voltage of 0.4 V and an ADC supply of 0.6 V. To save reference power, the RVG can be duty-cycled. A S&H at the RVG output is included so that the generated reference is continuously available for the LDO even when the RVG is powered down.

The overall system was measured while the RVG was duty-cycled at 10 %. Table 13.6 shows the measured performance and compares it against the very similar 10 bit ADC that was discussed in Sect. 13.3. The ENOB of both designs is similar, while the FOMW increased from 1.5 to 2.4fJ/conversion-step. The increase of FOMW is because this design includes the power of the RVG and LDO, and it uses a higher supply voltage. Nonetheless, this example shows that an ADC including reference generation can be power-efficient. It also confirms that the ADC is still dominant over the RVG and LDO in terms of power consumption.

13.7 Perspectives and Trends

In this chapter, ADCs for IoT nodes were discussed. The SAR ADC is a suitable solution in this context, allowing very low power consumption with suitable speed and precision for most applications. Several examples described techniques to achieve state-of-the-art in terms of efficiency and precision. As also shown, the SAR ADC can deal well with modern technologies, and allows operation at low supply levels. The dynamic power consumption of SAR ADCs and the Nyquist operation enable automatic power scaling with the sample rate and on-demand operation. Techniques to implement versatility in the ADC’s resolution to expand the application range of a single design were also introduced.

In the future, the ongoing improvement of ADC power-efficiency (illustrated in Fig. 13.3) will enable further benefits for IoT. Either power could be saved, or advantage can be taken from improved speed and precision at existing power levels. However, due to technology scaling, leakage starts to dominate the overall power consumption for ADCs that are heavily duty-cycled. For instance for quasi-static monitoring, the leakage power will be higher than the active power, requiring leakage mitigation techniques to maintain efficiency.

Present state-of-the-art ADCs for IoT can be so power-efficient, that the bottleneck in terms of power is usually not inside the ADC anymore, but in the components that surround the ADC. For instance the reference voltage generation, the analog input buffer, or the anti-aliasing filter could consume similar or more power than the ADC itself. This is particularly true in on-demand sensing applications as the ADC can be duty-cycled easily but the other analog blocks often experience static consumption that does not scale down with the activity. Hence, research is needed in those circuits to take full advantage of low-power ADCs at the system level.

Lastly, while the simple SAR architecture suits well to IoT requirements, other topologies should not be discarded. Hybrid architectures are becoming more and more popular in recent years. For instance, Shu et al. (2016) combines a SAR structure with noise-shaping and mismatch-shaping techniques, allowing to reach a far greater SNDR (101 dB) than typical SAR ADCs with state-of-the-art power-efficiency (FOMS = 180 dB). The power-efficiency of Sigma-Delta Modulators is also improving, such as Billa et al. (2016) which achieves an SNDR of 98.5 dB for 24 kHz signal bandwidth with a FOMS of 177.8 dB. Hybrid and Sigma-Delta converters especially stand out for high-precision applications that cannot be covered easily with pure SAR ADCs.

References

A.M. Abo, P.R. Gray, A 1.5-V, 10-bit, 14.3-MS/s CMOS pipeline analog-to-digital converter. IEEE J. Solid-State Circuits 34(5), 599–606 (1999)

A. Agnes, E. Bonizzoni, P. Malcovati, F. Maloberti, A 9.4-ENOB 1V 3.8 μW 100kS/s SAR ADC with time-domain comparator. ISSCC Dig. Tech. Papers (Feb. 2008), pp. 246–247

S. Billa, A. Sukumaran, S. Pavan, A 280 μW 24 kHz-BW 98.5 dB-SNDR chopped single-bit CT ΔΣM achieving <10Hz 1/f noise corner without chopping artifacts. ISSCC Dig. Tech. Papers (Feb. 2016), pp. 276–277

S.-W.M. Chen, R.W. Brodersen, A 6-bit 600-MS/s 5.3-mW asynchronous ADC in 0.13-μm CMOS. IEEE J. Solid-State Circuits 41(12), 2669–2680 (2006)

T.B. Cho, P.R. Gray, A 10 b, 20 M sample/s, 35 mW pipeline A/D converter. IEEE J. Solid-State Circuits 30(3), 166–172 (1995)

Q. Dong, K. Yang, D. Blaauw, D. Sylvester, A 114‐pW PMOS‐only, trim‐free voltage reference with 0.26% within‐wafer inaccuracy for nW systems, in IEEE Symposium on VLSI Circuits (June 2016)

V. Giannini, P. Nuzzo, V. Chironi et al., An 820μW 9b 40MS/s noise–tolerant dynamic-SAR ADC in 90 nm digital CMOS. ISSCC Dig. Tech. Papers (Feb. 2008), pp. 238–239

B.P. Ginsburg, A.P. Chandrakasan, A 500 MS/s 5b ADC in 65 nm CMOS. in IEEE Symposium on VLSI Circuits (June 2006), pp. 140–141

V. Hariprasath, J. Guerber, S.-H. Lee, U.-K. Moon, Merged capacitor switching based SAR ADC with highest switching energy-efficiency. IET Electron. Lett. 46(9), 620–621 (2010)

P. Harpe, C. Zhou, Y. Bi et al., A 26 μW 8 bit 10 MS/s asynchronous SAR ADC for low energy radios. IEEE J. Solid-State Circuits 46(7), 1585–1595 (2011)

P. Harpe, G. Dolmans, K. Philips, H. de Groot, A 0.7 V 7-to-10 bit 0-to-2 MS/s flexible SAR ADC for ultra low-power wireless sensor nodes. in European Solid-State Circuits Conference (Sep. 2012), pp. 373–376

P. Harpe, E. Cantatore, A. van Roermund, A 2.2/2.7fJ/conversion-step 10/12b 40kS/s SAR ADC with data-driven noise reduction. ISSCC Dig. Tech. Papers (Feb. 2013), pp. 270–271

P. Harpe, E. Cantatore, A. van Roermund, An oversampled 12/14b SAR ADC with noise reduction and linearity enhancements achieving up to 79.1dB SNDR. ISSCC Dig. Tech. Papers (Feb. 2014), pp. 194–195

P. Harpe, H. Gao, R. van Dommele, E. Cantatore, A. van Roermund, A 3 nW signal-acquisition IC integrating an amplifier with 2.1 NEF and a 1.5fJ/conv-step ADC. ISSCC Dig. Tech. Papers (Feb. 2015), pp. 382–383

P. Harpe, H. Gao, R. van Dommele, E. Cantatore, A.H.M. van Roermund, A 0.20 mm2 3 nW signal acquisition IC for miniature sensor nodes in 65 nm CMOS. IEEE J. Solid-State Circuits 51(1), 240–248 (2016)

M. Konijnenburg, S. Stanzione, L. Yan et al., A battery-powered efficient multi-sensor acquisition system with simultaneous ECG, BIO-Z, GSR, and PPG. ISSCC Dig. Tech. Papers (Feb. 2016), pp. 480–481

C.-Y. Liou, C.-C. Hsieh, A 2.4-to-5.2fJ/conversion-step 10b 0.5-to-4MS/s SAR ADC with Charge-Average Switching DAC in 90 nm CMOS, in ISSCC Dig. Tech. Papers (Feb. 2013), pp. 280–281

C.-C. Liu, S.-J. Chang, G.-Y. Huang, Y.-Z. Lin, A 10-bit 50-MS/s SAR ADC with a monotonic capacitor switching procedure. IEEE J. Solid-State Circuits 45(4), 731–740 (2010)

Y.-H. Liu, C. Bachmann, X. Wang et al., A 3.7 mW-RX 4.4 mW-TX fully integrated bluetooth-low-energy/IEEE802.15.4/proprietary SoC with an ADPLL-based fast frequency offset compensation in 40 nm CMOS. ISSCC Dig. Tech. Papers (Feb. 2015), pp. 236–237

M. Liu, K. Pelzers, R. van Dommele, A. van Roermund, P. Harpe, A 106nW 10 b 80 kS/s SAR ADC with duty-cycled reference generation in 65 nm CMOS. IEEE J. Solid State Circuits 51(10), 2435–2445 (2016a)

M. Liu, A. van Roermund, P. Harpe, A 7.1fJ/conv.-step 88dB-SFDR 12b SAR ADC with energy-efficient swap-to-reset, in European Solid-State Circuits Conference (Sep. 2016b), pp. 409–412

L. Magnelli, F. Crupi, P. Corsonello, C. Pace, G. Iannaccone, A 2.6 nW, 0.45 V temperature-compensated subthreshold CMOS voltage reference. IEEE J. Solid-State Circuits 46(2), 465–474 (2011)

K.A.A. Makinwa, A. Baschirotto, P. Harpe (eds.), Efficient Sensor Interfaces, Advanced Amplifiers and Low Power RF Systems—Advances in Analog Circuit Design 2015 (Springer, Berlin, 2016), ISBN 978-3-319-21184-8

B. Murmann, ADC Performance Survey 1997–2016. http://web.stanford.edu/~murmann/adcsurvey.html

M. Pelgrom, Analog-to-Digital Conversion (Springer, Berlin, 2017) ISBN 978-3-319-44970-8

J. Prummel, M. Papamichail, M. Ancis, A 10mW bluetooth low-energy transceiver with on-chip matching, in ISSCC Dig. Tech. Papers (Feb. 2015), pp. 238–239

T. Sano, M. Mizokami, H. Matsui, A 6.3mW BLE transceiver embedded RX image-rejection filter and TX harmonic-suppression filter reusing on-chip matching network, in ISSCC Dig. Tech. Papers (Feb. 2015), pp. 240–241

M. Seok, G. Kim, D. Blaauw, D. Sylvester, A portable 2-transistor picowatt temperature-compensated voltage reference operating at 0.5 V. IEEE J. Solid-State Circuits 47(10), 2534–2545 (2012)

Y.-S. Shu, L.-T. Kuo, T.-Y. Lo, An oversampling SAR ADC with DAC mismatch error shaping achieving 105dB SFDR and 101dB SNDR over 1 kHz BW in 55 nm CMOS, in ISSCC Dig. Tech. Papers (Feb. 2016), pp. 458–459

H.-Y. Tai, Y.-S. Hu, H.-W. Chen, H.-S. Chen, A 0.85fJ/conversion-step 10b 200kS/s subranging SAR ADC in 40 nm CMOS, in ISSCC Dig. Tech. Papers (Feb. 2014), pp. 196–197

M. van Elzakker, E. van Tuijl, P. Geraedts et al., A 10-bit charge-redistribution ADC consuming 1.9 μW at 1 MS/s. IEEE J. Solid-State Circuits 45(5), 1007–1015 (2010)

M. Vidojkovic, X. Huang, P. Harpe et al., A 2.4 GHz ULP OOK single-chip transceiver for healthcare applications, in ISSCC Dig. Tech. Papers (Feb. 2011), pp. 458–459

M. Yip, A.P. Chandrakasan, A resolution-reconfigurable 5-to-10b 0.4-to-1V power scalable SAR ADC, in ISSCC Dig. Tech. Papers (Feb. 2011), pp. 190–191

D. Zhang, A. Alvandpour, A 3-nW 9.1-ENOB SAR ADC at 0.7 V and 1 kS/s, in European Solid-State Circuits Conference (Sep. 2012), pp. 369–372

Y. Zhu, C.-H. Chan, U.-F. Chio et al., A 10-bit 100-MS/s reference-free SAR ADC in 90 nm CMOS. IEEE J. Solid-State Circuits 45(6), 1111–1121 (2010)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Harpe, P. (2017). Ultra-Low Power Analog-Digital Converters for IoT. In: Alioto, M. (eds) Enabling the Internet of Things. Springer, Cham. https://doi.org/10.1007/978-3-319-51482-6_13

Download citation

DOI: https://doi.org/10.1007/978-3-319-51482-6_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-51480-2

Online ISBN: 978-3-319-51482-6

eBook Packages: EngineeringEngineering (R0)