Abstract

Silk is a protein-based material which is predominantly produced by insects and spiders. Hundreds of millions of years of evolution have enabled these animals to utilize different, highly adapted silk types in a broad variety of applications. Silk occurs in several morphologies, such as sticky glue or in the shape of fibers and can, depending on the application by the respective animal, dissipate a high mechanical energy, resist heat and radiation, maintain functionality when submerged in water and withstand microbial settling. Hence, it’s unsurprising that silk piqued human interest a long time ago, which catalyzed the domestication of silkworms for the production of silk to be used in textiles. Recently, scientific progress has enabled the development of analytic tools to gain profound insights into the characteristics of silk proteins. Based on these investigations, the biotechnological production of artificial and engineered silk has been accomplished, which allows the production of a sufficient amount of silk materials for several industrial applications. This chapter provides a review on the biotechnological production of various silk proteins from different species, as well as on the processing techniques to fabricate application-oriented material morphologies.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

16.1 Introduction

Silk is a highly fascinating natural material. It has inspired humans throughout history and has been exploited for many purposes. Precious cloths of silky shine have been produced from the silk of the silkworm Bombyx mori for millennia. Domestication of the silk moth over 5000 years ago together with improvements in processing of raw silk, e.g. removal of the glue proteins coating the natural silk fiber, gave rise to a huge and economically important textile industry (Sun et al. 2012). Silks have further attracted much attention, as some silk fibers exhibit extraordinary properties, such as great strength and extensibility, resulting in a great toughness in combination with good biocompatibility, making silks promising candidates for many applications in the biomedical field, but also a favorable material for technical applications (Vollrath 2000; Vollrath and Knight 2001).

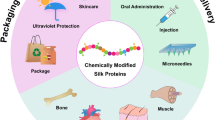

Ancient Romans and Greeks already made use of the low immunogenicity of silk and used spider silk webs to stop bleedings and to cover wounds (Scheibel 2004). As a result of biocompatibility and strength, silk has also been used as suture material. The extraordinary mechanical properties of silk have further been exploited to string branches with spider silk in order to create a tear resistant dip net for fishing or for the construction of thin and therefore precise as well as durable crosshairs for the military (Heim et al. 2009). Even violin strings have been produced from spider silk (Osaki 2012). Due to their enormous diversity and due to the fact that all silks have been the object of an evolutionary optimization process, they might provide a basis for the development of a plethora of future materials. Great efforts have been made to investigate silks, to produce the underlying proteins recombinantly and to process the proteins into different morphologies to exploit the beneficial properties of silks in various applications (Fig. 16.1).

Silks have evolved several times among arthropods and are as such a generally diverse material. They function as protein-based extracorporeal structural materials which are produced by a wide range of insects and spiders for numerous purposes, e.g. to capture prey, for adhesion, to build cocoons for pupation or to serve as egg stalks to just name a few examples (Craig 1997; Sutherland et al. 2010). Generally, silk proteins are secreted into a silk gland and stored there as a highly concentrated spinning dope, which is further treated in a fiber spinning process to create insoluble fibers from the liquid dope (Neuenfeldt and Scheibel 2014). The best studied silks are cocoon silk produced by caterpillars of silk moths and webs of orb-weaving spiders (Zhou et al. 2001; Vepari and Kaplan 2007; Heim et al. 2010). Despite their evolutionary distance, the silk proteins of insects and spiders share several properties: they are often large proteins with molecular weights of over 150 kDa, they possess a repetitive core domain, where long hydrophobic blocks are alternated with short hydrophilic regions, and the core domain is flanked by hydrophilic, non-repetitive termini (Bini et al. 2004). The amino acid composition of silk proteins reveals a high level of alanine, serine and glycine residues (Garb et al. 2010; Lintz and Scheibel 2013) and accounts for both the stability of the spinning dope as well as for the defined secondary structure upon transition of the solution into an insoluble thread, which in large parts determines the mechanical properties of the fiber.

But, since the diversity is high, other silk concepts have also evolved. The larvae of honeybees produce a silk that consists of much smaller (~30 kDa) and less repetitive silk proteins, which are assembled into α-helical coiled coil structures, in the rather hydrophobic waxen environments of the beehive (Sutherland et al. 2006). Lacewing egg stalks are another example admired for their bending stiffness, which is caused by a cross-β structure (Weisman et al. 2009). In contrast to terrestrial silks, the larvae of caddisflies, as a representative of aquatic silk producers, have developed an underwater-adhesive silk to adhere sand grains and branchlets to their body or their retreat tube (Ashton et al. 2013). The enormous diversity in silks leads to the different mechanical properties of the different silk fibers (Table 16.1).

Recombinant protein production is one key technology towards the employment of silk materials (other than silkworm silk) on an industrial scale. The natural availability of silk proteins – with the exception of Bombyx mori silk – is fairly low, and, if harvested from the respective organisms, proteins vary in molecular weight, amount and quality. For instance, attempts to farm spiders failed due to their territorial and cannibalistic behavior (Vendrely and Scheibel 2007). Instead, recombinant production of silk proteins allows silk protein production at large scale with constant quality and furthermore facilitates genetic engineering of the coding gene sequence, allowing the production of tailored proteins for respective applications (Vendrely and Scheibel 2007). Due to the great availability of different engineered strains, as well as the huge number of suitable expression plasmids, E. coli is by far the most used host organism for heterologous protein production (Rosano and Ceccarelli 2014). Nevertheless, during the production of (large) silk proteins in bacterial hosts, problems such as low yield, truncated proteins, and aggregation of proteins in inclusion bodies have been encountered (Vendrely and Scheibel 2007; Scheibel 2004; Heidebrecht and Scheibel 2013). To circumvent these obstacles, the nucleotide sequence encoding silk proteins can be engineered with regard to the host’s codon usage or limitations in the size of expressible genes. For the expression of original (partial) silk gene sequences, expression hosts other than E. coli, e.g. yeast, insect cells, mammalian cell lines, even transgenic animals and plants have been tested (Vendrely and Scheibel 2007).

As well as silk protein production and protein purification from the expression host, another key step is the processing of the obtained recombinant silk proteins. Besides fibers, which are typically found in nature, many other morphologies, e.g. nonwoven mats, particles, capsules, hydrogels, foams or coatings, are feasible and, therefore, allow diverse applications of silk materials. Fibers spun into nonwoven mats can improve filter systems by an excellent filter efficiency and much better air permeability than comparable materials (Lang et al. 2013). The excellent mechanical properties of spider silk fibers could improve textiles such as bullet-proof vests or other textiles where extensibility combined with tensile strength and light weight are in demand. Even electronic devices could benefit from elaborated silk protein processing. Silks cannot only serve as a passive substrate in bio-integrated electronics, but can also be used as active elements, e.g. as transistors or memristive devices (Zhu et al. 2015). Due to their good biocompatibility, silks have many applications in biomedicine, e.g. in tissue engineering. Cell-seeded three-dimensional constructs have good prospects for in vitro-cultured replacements of tissues, in which the biodegradable silk scaffold degrades at the rate the body accepts and integrates the material. Biodegradable silk particles or capsules can be used as mobile drug carriers, whereas other morphologies mentioned above can be employed as stationary drug delivery platforms, e.g. to achieve constant drug levels over time through sustained drug release (Blüm and Scheibel 2012). Silk-coatings of implants can improve the biocompatibility of the material and thereby reduce unwanted reactions like fibrosis (Zeplin et al. 2014b; Borkner et al. 2014).

16.2 Biotechnological Production of Silk

For the recombinant production of proteins, usually the desired genetic information encoding the protein is cloned into an appropriate vector from which the gene can be expressed in a suitable expression host. Nevertheless, for many silk proteins, the gene encoding the silk protein is unknown or not fully known and, therefore, has to be identified prior to recombinant production. As an example, the identification of four honeybee silk genes is depicted here. The silk gene expression is highly regulated in honey bee. Since only final instar larvae produce silk in their modified salivary glands (Sutherland et al. 2006), samples were taken from these glands and analyzed with regard to gene expression, i.e. mRNAs were analyzed by creation of a cDNA library (Fig. 16.2). As RNA is prone to degradation, reverse transcriptase is used to transcribe mRNA into cDNA. As most eukaryotic RNA is poly-adenylated, the poly(A) tails of the 3′ ends allow easy transcription by use of oligo(dT) primers. The RNA moiety can then be degraded by RNase H, and after a PCR-amplification cycle double-stranded cDNA emerges. Terminal transferase subsequently adds several Cs to the terminal parts of the cDNA, which allow poly(G) primers to be used for the amplification of the constructs. Cohesive ends can then be added to the DNA strands, enabling ligation into a plasmid with complementary ends. This enables efficient sequencing of the unknown nucleotide sequences as the sequence of the vector is well-known and, therefore, allows precise design of sequencing primers. The ligated vectors are transformed into suitable expression hosts, e.g. E. coli, supporting plasmid propagation and facilitating plasmid preparation at reasonable quantities. As this process is carried out with all mRNAs present in the sample, a so-called cDNA library emerges. Thus, the cDNA library represents the population of mRNAs present in the cell at a certain time point and, remarkably, only contains exons of a gene.

In the case of the honey bee silk proteins, the proteins present in the gland were purified and analyzed by mass spectrometry after tryptic digestion. These fragments were matched with the predicted protein sizes (after tryptic digestion) of the transcriptome obtained from the generated cDNA library of the analyzed silk gland tissue and further matched with predictions obtained from genomic information. Taken together, six silk-encoding genes could be identified. Further analysis of the encoded proteins revealed that four genes encoded fibrous silk proteins of 30–34 kDa (termed Apis mellifera fibroin 1–4), whereas the remaining two proteins were classified as silk-associated proteins, with one small gene encoding a possible glue protein and the second one a high molecular weight protein with a yet unknown function (Sutherland et al. 2006).

Once a silk gene is identified it is cloned into an expression vector and transformed into the respective expression host to produce the recombinant protein. While this works perfectly well for smaller proteins with less repetitive sequences, such as honey bee silk proteins, the production of larger proteins with highly repetitive sequences, such as silkworm silk or spider silk proteins, often suffers from low yields of recombinant (full-length) protein. The underlying silk genes can have a size of up to 15 Mbp which conflicts with the limited size of well-expressible genes in e.g. the preferred bacterial expression host E. coli. Premature termination of the transcriptional and/or translational process together with depletion of specific tRNAs caused by differences in codon usage of the expression host often lead to fragmented silk proteins. Furthermore, the repetitive sequences can undergo homologous recombination, thereby shortening the genetic information (Vendrely and Scheibel 2007; Arcidiacono et al. 1998). Therefore, either a suitable expression host has to be chosen for the expression of original silk genes or synthetic silk-like genes with adopted codon usage and gene length have to be created (Fig. 16.3).

Cloning strategies for recombinant silk production. For the production of original (partial) silk fragments, appropriate hosts have to be chosen, while for the production of large silk proteins in bacterial hosts such as E. coli synthetic silk genes have to be designed to facilitate reasonable protein production rates

16.2.1 Examples of Biotechnologically Produced Silk Proteins: Honey Bee Silk

16.2.1.1 Natural Honey Bee Silk

Honey bees produce silk in their larval stage (Sutherland et al. 2006). Like many other holometabolous insects, the final instar larvae of honey bees of the species Apis mellifera produce a silken cocoon to undergo metamorphosis inside their sealed brood comb cells (Sutherland et al. 2006). The deposition of silk has beneficial effects on the hive in general as it increases its thermal stability and its mechanical strength, probably by creating a structure similar to a modern fiber-reinforced composite (Zhang et al. 2010; Weisman et al. 2010). The larvae attach a silken layer to the waxen walls of the brood comb cells prior to pupation, and from one generation to the next the proportion of silk accumulates and can increase up to 40 % of the total nest mass (Hepburn and Kurstjens 1988). Mechanical tests revealed that old combs are much stronger and stiffer, and especially at temperatures above 40 °C the composite material of silk and wax is up to one order of magnitude stronger than wax alone (Hepburn and Kurstjens 1988;Zhang et al. 2010). Little is known about the mechanical properties of the plain larval silks of the Vespoidea and Apoidea, the latter including honey bee silk, due to the difficulties in obtaining appropriate material from living organisms (Sutherland et al. 2012). Hand-drawn fibers of honey bee larvae revealed a breaking stress of 132 MPa and a breaking strain of 204 % at a relative humidity of 65 % (Hepburn et al. 1979). They have a greater extensibility and toughness compared to silkworm silk but lower tensile strength (Hepburn et al. 1979). Honeybee silk is a very interesting material, as it is very extensible and also tough and keeps its properties when wet (Hepburn et al. 1979).

Honey bee larvae produce silk from modified salivary glands (labial glands), a feature they share with silkworm silk (Sutherland et al. 2006). The silk forming mechanism of Apis mellifera in the labial glands was reported to be similar to that of Lepidoptera. Within the gland, the silk proteins assemble into cigar-shaped bodies (Weisman et al. 2010). Subsequent to polymerization of the proteins in the lumen of the gland into so-called tactoids, a gradual dehydration during the extrusion process along the gland leads to the formation of a well-organized, insoluble, silk filament (Silva-Zacarin et al. 2003). However, the primary and secondary structure of honey bee silk is very different to that of most other silks. Honey bee silk comprises comparatively low levels of glycine residues whereas levels of alanine, serine, aspartic and glutamic acids are elevated (Lucas and Rudall 1968). While extensive β-sheet strands make up the main part of silkworm silk and spider silks, honey bee silk shows mainly α-helical character. The helices are assembled into a coiled coil structure running parallel to the fiber axis. One further study indicated the presence of tetrameric coiled coils (Atkins 1967;Fig. 16.4). Coiled coils are a widely distributed structural motif in which multiple α-helices with a characteristic seven-residue periodicity wind around each other to prevent hydration of hydrophobic residues buried in the core of the structure (Woolfson 2005). These heptad repeat sequences are generally denoted as (abcdefg)n. Large hydrophobic residues occupy positions a and d, whereas the more polar and charged residues reside in the other positions (Woolfson 2005).

The tetrameric coiled coil structure of honeybee silk. (a) The primary structure of honeybee silk consists of heptad repeats, where the positions a, d and e (grey) are occupied by predominantly hydrophobic amino acid residues. (b) Arranged into α-helical structure, the residues a, d and e point into similar directions. (c) Assembled into antiparallel tetrameric configuration, the hydrophobic residues are buried in the core

Comparison of several coiled coil fibroin proteins revealed a low degree of sequence identity among different species and no extensive repeats, while, in contrast, the repetitive primary sequence of silk proteins creating β-sheet silk is rather conserved. The sequence diversity might be a result of repeated amino acid substitutions with amino acids possessing similar properties during evolution. The exact sequence seems less important than the conservation of the character of the side chains in special heptad positions (Sutherland et al. 2007). As the four identified silk genes (see above) are expressed at similar rates in the larvae, it is highly probable that all four proteins are involved in the four strands of the predicted coiled coil structure (Weisman et al. 2010). Interestingly, relatively large amounts of alanine are found in the honey bee silk a and d position although alanine is a less favored residue in this position. Alanine alone is classified as not hydrophobic enough to stabilize the coiled coil conformation, indicating the influence of further factors on secondary structure formation (Sutherland et al. 2006). Interestingly, no cysteines are present in honey bee silks. The relatively high abundance of alanine among polar and charged residues in the remaining positions might be interpreted as an adaption of honey bee silk to the waxen environment in the hive. While many other coiled coil structures are found in an aqueous environment, honey bee silk is used in a highly hydrophobic one (Sutherland et al. 2006).

16.2.1.2 Recombinant Honey Bee Silk Production

Honey bee silk proteins are suitable for recombinant expression in E. coli as these proteins generally do not comprise highly repetitive sequences and they have a small molecular weight of ~30–45 kDa (Sutherland et al. 2012; Weisman et al. 2010). The proteins consist of extensive coiled coil regions flanked by short termini. The hydrophilic termini might increase the solubility of the silk proteins in the gland prior to spinning and might therefore have a similar function as the terminal regions of β-sheet silks (Sutherland et al. 2007), which will be discussed below in detail.

The silk proteins of the honey bee Apis mellifera are encoded by four small (~ 1 kb each) and non-repetitive genes (Weisman et al. 2010; Sutherland et al. 2006). For recombinant protein production, the four genes have been cloned from the cDNA clones into pET expression vectors without their signal peptides, and E. coli Rosetta 2 (DE3) served as expression host. The bacteria were cultured to an optical density at 600 nm (OD600) of ~20, and gene expression was induced for further ~24 hours. As an example, AmelF3 could be purified from inclusion bodies at a yield of 2.5 g per liter. Also AmelF1, 2 and 4 could be produced recombinantly and purified at yields of 0.2, 1.5 and 1.9 g per liter, respectively (Weisman et al. 2010). Studies revealed that solutions of one protein alone were less stable than solutions of equimolar mixtures of all four proteins. Fibers hand-drawn from the mixture were comparatively extensible but had lower tensile strength in comparison to natural honey bee fibers. The fibers were not birefringent suggesting that the proteins were not aligned. Post-stretching of the fibers in methanol leads to birefringence similar to native fibers indicating the alignment of the proteins within the fiber, and, though extensibility was reduced, the tensile strength of native fibers could be mimicked (Weisman et al. 2010).

Due to the knowledge of the A. melliferis silk genes, homologous genes could be identified in the Asiatic honey bee Apis cerana (Shi et al. 2008 ). With 289 to 321 amino acid residues, these proteins exhibit a similar size compared to that of the European honey bee. For recombinant protein production, the respective four DNA fragments encoding the Asiatic honey bee silk proteins 1–4 (ABS1–4) were used as a template for amplification by PCR. The primers were designed to amplify the genetic sequence of the silk proteins without their signal peptides. Resulting PCR products were cloned into pET expression vectors providing His-tags to the proteins. E. coli strain BL21 (DE3) served as an expression host. Bacteria were cultivated to an OD600 of 0.7, and gene expression was induced for three hours. The soluble protein was purified by affinity chromatography at yields of 30, 30, 10 and 60 mg/ml, respectively. The work of this group could in the first instance not confirm the expected coiled coil structure. In contrast, in aqueous solution, mainly a random coil conformation was reported (Shi et al. 2008). Further research has to reveal if this is an effect of sequence changes between European and Asiatic honey bee silk or if it might be attributed to the influence of the His-tag or processing conditions.

The recombinant production of four silk proteins of the giant honey bee Apis dorsata further shed light on the folding behavior of the silk proteins (Maitip et al. 2015). Recombinantly produced, His-tagged AdorF1-4 silk proteins were found to be soluble without the addition of SDS or other detergents. This allowed more precise investigations of the folding behavior of these silk proteins. The proteins were of similar size and amino acid composition as the recombinant proteins mentioned above. Interestingly, the folding behavior was different for equimolar mixtures of all four proteins compared to individual silk solutions. The CD (circular dichroism) spectra revealed that proteins were structured as coiled coils above concentrations of 3 mg/ml. At lower concentrations, solutions of individual proteins started to dissociate into unassociated α-helices, whereas the mixed solution retained the coiled coil structure (Maitip et al. 2015). Tetrameric coiled coils are therefore more stable than homomeric coiled coils, indicating that the four proteins probably are not functionally redundant, but each have a critical role.

16.2.2 Examples of Biotechnologically Produced Silk Proteins: Lacewing Silk

16.2.2.1 Natural Lacewing Silk

The coiled coil motif in silk has evolved convergently in at least five insect lineages - the stinging hymenopterans (ants, bees, hornets), sawflies, fleas, praying mantises and lacewings (Sutherland et al. 2014; Kameda et al. 2014). Larvae of the green lacewing (Mallada signata) produce a cocoon silk protein in their Malpighian tubules that is 49 kDa in size and rich in alanines (Weisman et al. 2008). The final instar lacewing larvae of both sexes spin a loosely woven silk cocoon to pupate inside (Weisman et al. 2008). The outer silk layers attach the construct to a substrate and also provide a sticky surface to attach debris or leaves to it in order to disguise the cocoon from predators, while the inner layer serves as a scaffold for lipid coverage (Kameda et al. 2014). Although experimental data on the cocoon silk’s secondary structure are poor and rather indicate unassociated α-helical structures, bioinformatics analysis provided evidence for the presence of heptad repeats supporting the coiled coil structure, although the close proximity of lipids in the composite material could lead to a destabilization of coiled coils in the hydrophobic environment (Weisman et al. 2008).

Interestingly, in the adult live stage, lacewings produce a completely different, unrelated silk. Although adult insects in general hardly produce silk, female lacewings produce egg stalk silk from collateral glands (Rudall and Kenchington 1971). In order to protect the eggs from predation, lacewings place their eggs underneath leaves or other kind of shelter. The female secrets a drop of silk dope onto a surface (e.g. of a leaf) and dips in an egg. By pulling the abdomen away, it creates the thin egg stalk on top of which the egg resides. The egg stalk hardens within few seconds, and the egg is released completely. Already in 1957 a structural peculiarity had been published. In contrast to spider silk or silkworm silk which consists in parts of parallel β-sheet structures, cross-β-structures with individual β-strands aligned perpendicular to the fiber axis were reported in lacewing egg stalks (Parker and Rudall 1957). This secondary structure arrangement leads to comparably high bending stiffness of the stalks and makes them particularly resistant to transversal forces. Egg stalks of M. signata exhibit a bending modulus nearly three times higher than that of silkworm fibers (Weisman et al. 2009). The extensibility of egg stalks is highly humidity-dependent: while an extensibility of up to 600 % is reported at high humidity, at a relative humidity of 30 % only values of around 5 % are achieved (Weisman et al. 2009; Bauer and Scheibel 2012).

Based on the secondary structure of lacewing silk, a model has been proposed to explain the humidity-dependent performance of the material (Bauer et al. 2012). The effects were mainly ascribed to the transition from cross-β-structures to parallel β-sheets based on the interplay of disulfide bridges crosslinking protein molecules of different β-strands and the variable strength of stabilizing hydrogen bonds in the presence or absence of water. At low humidity, the disulfide bonds break up already at low strain as the strength of the hydrogen bonds in total is higher than the strength of the disulfides, and the stalk can take up only little energy. At high humidity, residual water molecules function as new hydrogen bond donors/acceptors competing with the hydrogen bonds between β-sheets and weakening the cohesion of the β-sheets via hydrogen bonds. In this situation, the disulfides are comparatively strong, and, upon extension of the stalk, breakage of hydrogen bonds between the β-sheets allows an irreversible rearrangement of the cross-β-structure into parallel β-sheets, followed by a significant increase of extensibility of the stalk and thus the ability to absorb much more energy (Bauer et al. 2012).

The fascinating properties of natural lacewing egg stalks encouraged further research (albeit not promoted at the pace of research on silkworm silk or spider silk) on the underlying proteins (Lintz and Scheibel 2013). The silk dope of Chrysopa carnea has been shown to consist of five proteins. In the species Mallada signata two egg stalk proteins, namely MalXB1 (86 kDa) and MalXB2 (55.5 kDa) have been identified (Weisman et al. 2009). These serine- and glycine-rich proteins consist of 51 or 29 repeats of a 16 amino acid long motif, respectively, which are flanked by non-repetitive terminal domains. Additionally, MalXB1 has a non-repetitive region in the middle of the protein. MalXB1 contains seven, MalXB2 five cysteine residues found predominantly in the terminal domains (Weisman et al. 2009).

16.2.2.2 Recombinant Lacewing Silk

A 48 amino acid long consensus motif of the core domain of MalXB2, named [AS], was selected to be recombinantly produced in E. coli (Bauer and Scheibel 2012) (Fig. 16.5). The DNA encoding this motif was multimerized eight times and fused to the genetic sequence encoding the natural amino (N) and carboxy (C) terminal domains. The recombinant 53 kDa protein N[AS]8C was purified from E. coli and analyzed regarding its assembly properties. Post-treated N[AS]8C fibers showed very similar secondary structures compared to natural egg stalks as measured by FTIR spectroscopy.

16.2.3 Examples of Biotechnologically Produced Silk Proteins: Caddisfly Silk

16.2.3.1 Natural Caddisfly Silk

Caddisflies (order Trichoptera) are a large group of (partially) aquatic insects with over 12,000 species (Wiggins 2004). The larvae spend their lives in freshwater streams and lakes where they feed, mature and pupate under water (Bai et al. 2015; Ashton et al. 2013). After several larval stages the larvae undergo complete metamorphosis inside their underwater cocoon before hatching as a short-lived, winged adult to leave the water for terrestrial mating (Ashton et al. 2013; Stewart and Wang 2010).

Caddisflies are closely related to Lepidoptera, an order including silk-spinning terrestrial moths and butterflies (Ashton et al. 2013; Morse 1997). They diverged from a common ancestor and successfully penetrated diverse aquatic habitats largely owing to the development of adhesive underwater silk fibers (Ashton et al. 2013; Stewart and Wang 2010). In order to provide shelter for their soft bodies, casemaker larvae use their silk like an adhesive tape to gather organic material, e.g. debris, small stones or sand grains, twigs and leaves to build a protective case, while retreat builders create stationary composite retreats attached to firm ground in streaming water which can additionally be equipped with silk nets to catch prey (Ashton et al. 2013; Bai et al. 2015).

Regarding the exceptional ability of this silk to stick to any surface underwater, it could serve as a natural blueprint for biocompatible water-borne adhesives (Stewart 2011; Brubaker and Messersmith 2012). Obtaining this sticky silk on an industrial scale would be highly interesting for biomedical as well as technical applications (Brubaker and Messersmith 2012). Efficient adhesion under wet conditions is required in many fields, including surgery when repairing living wet tissue (e.g. gluing tissues or bones together) or in dentistry, but also for the replacement for any technical glue which has to be used in wet or aquatic environment. Until now, most commercially available glues fail to perform in wet environments. Therefore, caddisfly silk has attracted researchers’ interest as a model for a biopolymeric glue.

Similar to Bombyx mori silkworm silk (see below), caddisfly silk is spun in a pair of modified salivary glands as fused fibers (Tsukada et al. 2010). In both orders, the silk is mainly made up from H- and L-fibroins (heavy and light chain fibroins) with a molecular weight of more than 300 kDa and roughly 25 kDa, respectively (Ashton et al. 2013). The H-fibroins comprise a long, repetitive core region which is flanked by short non-repetitive termini (Ashton et al. 2013). The highly conserved cysteine residues might be a hint for covalent linkage of the two proteins in a stoichiometric manner (Ashton et al. 2013). Despite these similarities, distinct molecular adaptation of the dry silk was necessary to create underwater adhesives. Comparing the primary structure of terrestrial silks to that of caddisfly silk reveals the accumulation of basic residues, especially arginine, which has been attributed to the adaption of caddisfly silk to aquatic systems (Stewart and Wang 2010). Further characterization showed that these silks lack the abundant poly(A) and poly(GAGAGS) domains seen in silkworm and spider silk, which form rigid β-sheet structures and contribute to the mechanical properties (Marsh et al. 1955; Holland et al. 2008). Instead, extensive (SX)n repeats were found in the sequence of H-fibroin with S indicating serine, X an aliphatic amino acid, often valine or isoleucine (which both are known to play a role in β-sheet formation (Johansson et al. 2010)) and n numbers from 2 to 6 (Yonemura et al. 2006; Wang et al. 2010; Ashton et al. 2013). These (SX)n stretches are hypothesized to account for the β-sheet structure of caddisfly silk. Moreover, in proximity to these (SX)n structures, conserved proline-glycine (PG) motifs are found which can also be seen in β-turns (Jenkins et al. 2010). This is in accordance with the observation that X-ray diffraction studies revealed a three-sheet ordered structure in the absence of poly(A) stretches (Engster 1976). It has been estimated that more than half of the serines are phosphorylated (Stewart and Wang 2010). The phosphorylations are mainly found in the prevalent (SX)4 repeats. Together with the relatively high levels of multivalent cations such as Ca2+, Mg2+ and Fe3+ detected in caddisfly silk, a model was developed with alternate phosphorylated serine residues interacting with these divalent cations to form the observed β-sheet structure (Stewart and Wang 2010; Addison et al. 2014;Fig. 16.6).

Caddisfly silk. (a) Caddisfly larvae with a silk case and attached debris. (b) SEM micrograph of caddisfly silk. (c) Model for the structural motif of phosphorylated (SX)4 repeat regions, in which divalent cations Ca 2+ and Mg 2+ (green and blue dots) complex with negatively charged phosphoserine residues (Reprinted and adapted with permission from (Addison et al. 2013). Copyright (2013) American Chemical Society)

It is assumed that dehydration of the predominantly hydrophilic silk is achieved by crosslinking of phosphoserine-rich domains with metal-ions (predominantly Ca2+) when silk is submerged in water, since the solubility of these ions is low at neutral pH (Addison et al. 2013). This hypothesis is confirmed by a decrease in β-structures upon depletion of Ca2+-ions with EDTA (Ashton et al. 2013). Stress-strain-profiles confirmed a loss of toughness and a dramatically reduced young’s modulus upon the addition of EDTA to natural silk fibers. An additional adaptation of caddisfly silk can be seen in the substantial hysteresis effect. Controlled cylindrical strains were applied to caddisfly silk fibers, and their stress response revealed normal loading profiles. But interestingly, the unloading profile showed nearly full recovery of the initial modulus and yield point, although the strain was beyond the (pseudo)yield point. This fact indicated that the deformation was reversible, while the strain energy dissipated as heat (Ashton et al. 2013). Such a self-tensioning effect might be very helpful for the larvae to keep stones and twigs tightly assembled on their body. The viscoelasticity of caddisfly silk has been attributed to two independent Ca2+ networks: in addition to Ca2+-stabilized phosphoserines of H fibroins, Ca2+-complexed carboxylate groups were found in the amino terminal region (Ashton and Stewart 2015).

16.2.3.2 Recombinant Caddisfly Silk

Biotechnologically, it is difficult to produce caddisfly silk proteins. More generally, the recombinant production of protein-based adhesives has shown only limited success (Stewart 2011). For efficient adherence to underwater substrates, many aquatic organisms need to extensively post-translationally modify their amino acid residues. For example, mussel foot proteins 3 and 5 (mfp-3 and -5) contain more than 20 % of hydroxylated tyrosines (Papov et al. 1995). For caddisfly silk, massive phosphorylation of serines has been shown (Stewart and Wang 2010). Generally, polymeric phosphates are well-known adhesion promotors and are already applied in dental treatments and in the coating industry (Stewart and Wang 2010). If these bio-adhesive proteins are produced by bacterial hosts such as E. coli, no substantial post-translational modifications (PTMs) occur.

In order to circumvent the obstacles of heterologous protein production, some effort has been made on the approach to engineer proteins and polymers to imitate properties of underwater adhesives and transfer these properties of the natural system to polymers (Stewart 2011). Just recently, the viscoelastic, tough and self-strengthening properties of caddisfly silk have served as a model to toughen synthetic polymeric hydrogels. To mimic its H-fibroin, a phosphate-graft-methacrylate pre-polymer was copolymerized with polyacrylamide. If a critical phosphate side chain density was reached, equilibration with Ca2+ led to an increased initial stiffness, and a 100-fold increased work-to-fracture was needed compared to hydrogels equilibrated with other cations such as Na+ or Mg2+. This finding was generally assigned to the energy-dissipating, reversible unfolding of phosphate-metal ion crosslinks (Lane et al. 2015). Caddisfly silk-inspired toughening of hydrogels provides a simple model for further structure-function investigations and perhaps allows the development of synthetic soft materials which exceed the mechanical properties of natural materials (Lane et al. 2015; Ashton and Stewart 2015).

Just recently four major S. marmorata silk proteins (Smsps 1–4) have successfully been identified and recombinantly produced in E. coli. Analysis of the amino acid sequence of these proteins revealed the presence of a new GYD-rich motif which could play an important role for the mechanical properties of caddisfly silk (Bai et al. 2015), since di-tyrosine crosslinking has already been reported for the underwater adhesive silk of H. occidentalis (Wang et al. 2014 ).

16.2.4 Examples of Biotechnologically Produced Silk Proteins: Silkworm Silk

16.2.4.1 Natural Silkworm Silk

Silk from silkworm has been used since ancient times and is still used today (e.g. to manufacture cloth). Silkworms, the larvae of the holometabolous silk moths, undergo several molts during their life cycle before they pupate inside their silken cocoon. Upon completion of metamorphosis, the release of proteolytic enzymes leads to the partial destruction of the cocoon and allows the adult insect to escape. Originally, silk was harvested from collected cocoons of wild silk moths, but the silk of these cocoons generally varied in color and structure, and availability was low. Upon breeding, the domesticated silkmoth Bombyx mori emerged; the larvae of this moth produce large amounts of silk within their silk glands (Tomita 2011; Xu 2014).

Silk from the silkworm B. mori has not only been used for textile production but has also been used as a biomaterial. Owing to its extraordinary mechanical properties and biocompatibility, it has been used in biomedical applications, e.g. as suture material, for centuries (Altman et al. 2003). Even though some biocompatibility problems have been reported, this finding is likely attributable to the incomplete or omitted removal of sericin, as affirmed by studies on silkworm fibroins indicating a biocompatibility of silkworm fibroin comparable to that of other biomaterials, such as polylactic acid or collagen (Altman et al. 2003). However, biocompatibility alone is not sufficient for successful application of silkworm silk in e.g. tissue engineering.

Silkworms produce their silk from a pair of labial glands from where the silk emerges as a double thread. The silk is mainly composed of fibroin coated with sericin, a family of glue-like glycoproteins. Silk fibroin consists of heavy (H)-chain fibroin, a hydrophobic protein with a molecular weight of 350 kDa which forms a complex with the relatively hydrophilic 25 kDa fibroin light (L)-chain (Yamaguchi et al. 1989) via a disulfide bridge (Tanaka et al. 1999b). P25, a 30 kDa glycoprotein (Tanaka et al. 1999a) associates non-covalently with the disulfide-linked fibroin complex mainly driven by hydrophobic interactions with the H-chain (Tanaka et al. 1999a, 1993). Quantitatively, the ratio of heavy chain, light chain and P25 is 6:6:1 (Inoue et al. 2000). In the caterpillar, the fibroins are mainly secreted into the lumen of the posterior silk gland from where they are transported to the middle silk gland to add sericin and further towards the anterior silk gland where the silk is spun into fibers (Inoue et al. 2000).

16.2.4.2 Recombinant Silkworm Silk

Despite the natural availability of silkworm silk, B. mori silk fibroins have also been produced recombinantly in expression hosts, such as E. coli (Ohshima and Suzuki 1977 ). Full-length as well as partial silk genes were transformed into E. coli and analyzed. Due to the size of the silk proteins massive deletions were found in the repetitive domain. Later on, synthetic proteins based on specific motifs of silkworm silk were produced in E. coli. Even hybrid proteins were designed where a sequence derived from the crystalline domain (GAGAGS)n of Bombyx mori silk fibroin was fused to the cell-adhesive sequence TGRGDSPA originating from fibronectin and additionally fused to the sequence (GVPGV)n from elastin to tailor properties of fibers spun therefrom (Yang et al. 2008).

Interestingly, good expression of modified silkworm genes was shown using silkworms as expression systems. Silkworms have been used to produce foreign proteins already in 1985, when a B. mori nucleopolyhedrovirus (BmNPV) expression system enabled the heterologous production of human α-interferon in silkworm larvae (Maeda et al. 1985). However, this transient expression system is limited to one generation, and, therefore, the infection with this particular virus has to be carried out repeatedly.

Great progress in recombinant protein production in silkworm silk glands has been made upon the development of a stable germline transformation system for B. mori. A vector derived from a lepidopteran transposon, piggyBac, was shown to be able to transpose genetic information into the silkworm’s chromosome, thereby generating stable germline transformations (Tamura et al. 2000). Genetic sequences encoding peptides from collagen or fibronectin were fused to the B. mori L-chain fibroin gene and introduced into B. mori using the piggyBac transposon (Yanagisawa et al. 2007). The first peptide, called Coll-F, consisted of a consensus sequence derived from collagen [GERGDLGPQGIAGQRGVV(GER)3GAS]8 fused to the crosslinking sequence GPPGPCCGGG derived from collagen III to promote triple helix formation through disulfide bonds formed between the chains (Yao et al. 2004). Another peptide, abbreviated RGD, with the sequence [TGRGDSPAS]8 was derived from fibronectin. The transformation vectors pigFiLpColl-FGFP/3xP3DsRed for the production of fibroin containing the genetic information for L-chain, Coll-F and GFP was constructed as well as the construct containing the RGD sequence. For both constructs, a transgenic silkworm line could be established, and the recombinant silk could be analyzed concerning cell adhesion of mouse fibroblasts. Surprisingly, the recombinant proteins were not only found in the fibroin but also in the sericin layer.

Another example of engineered silkworm silk is the production of chimeric silkworm/spider silk fibers for improved mechanical properties. A spider silk derived protein called A2S814 comprised a (GPGGA)8 sequence and a poly-alanine sequence (linker-alanine8). The encoding gene was cloned into a piggyBac vector further containing the B. mori fibroin heavy chain promoter to target protein secretion into the posterior silk gland, as this promotor is active in this part of the gland (Sehnal and Akai 1990). The sequence encoding the synthetic spider silk protein (78 kDa or 106 kDa when fused to GFP) was cloned between the amino and carboxy terminal domains of the B. mori fhc protein and finally, transgenic silkworms could be established and their silk analyzed with regard to the mechanical properties.

16.2.5 Examples of Biotechnologically Produced Silk Proteins: Spider Silk

16.2.5.1 Natural Spider Silk

Arthropods have evolved a huge variety of different silks. Besides the insect silks mentioned above, spiders (Araneae) are prominent producers of silks. Spiders produce silks for a great variety of purposes, such as to catch prey, to wrap it afterwards, to protect their offspring or as a lifeline. Interestingly, not all spiders produce spider silk webs to catch prey; among all known spider species only some do so (Römer and Scheibel 2008). Evolution has brought a plethora of different web shapes, with orb webs being the best studied ones (Römer and Scheibel 2008). Female orb weaving spiders can produce up to seven different silk types from separate glands, all adapted and evolutionarily optimized to fulfill their respective tasks in the web (Vollrath 2000;Fig. 16.7). The outer frame and the radii of an orb web are constructed from a silk type with high tensile strength (Blackledge et al. 2005; Gosline et al. 1984; Vollrath and Porter 2006). This silk is mainly made of two types of silk proteins originating from the major ampullate gland, therefore the fiber is called major ampullate silk. This silk also functions as an always-ready lifeline which is dragged behind to facilitate rapid escape from predators and therefore has the by-name “dragline silk”. In contrast, the capture spiral of the web is made of highly elastic flagelliform silk (produced in the flagelliform gland) to absorb and dissipate the enormous kinetic impact on the web if prey is caught in mid-flight (Becker et al. 2003; Dicko et al. 2004). Silk proteins produced from the minor ampullate silk gland are used in auxiliary fibers during construction of the web (Dicko et al. 2004; Riekel and Vollrath 2001). Proteins from the piriform silk gland provide a sophisticated cement to attach both, fibers to each other and the web to a substrate (Hajer and Rehakova 2003). Aciniform silk and cylindrical silk protect the eggs (Garb and Hayashi 2005; Hayashi et al. 2004). And, finally, aggregate silk serves as a sticky coating on the capture spiral (Vollrath 2006; Hu et al. 2007).

Among the orb weaving spider silks, draglines of Nephila clavipes and Araneus diadematus are the best studied ones (Scheibel 2004). On a weight-to-weight basis, the tensile strength of some silk fibers is comparable to that of steel, and the elasticity of others comparable to rubber (Römer and Scheibel 2008). Remarkably, spider dragline silk is classified as the toughest natural fiber and thus superior to other biological materials, such as silkworm silk, and even superior to man-made high-performance fibers, such as Nylon or the aramid-based fiber Kevlar (Liu et al. 2005; Omenetto and Kaplan 2010; Porter et al. 2013; Tokareva et al. 2013). Especially, the combination of elasticity and strength and low weight of the fiber at the same time has attracted researcher’s interest and prompted extensive investigation on structure-function relationships, as the mechanical properties of different silks can be ascribed to the underlying amino acid sequence.

Generally, spider silk proteins comprise three domains: a large, highly repetitive core domain flanked by non-repetitive amino and carboxy terminal domains (Huemmerich et al. 2004a). The repetitive sequences are composed of up to over 100 repeats of short polypeptide stretches of a length of up to 60 amino acids and account for up to 90 % of the protein (Huemmerich et al. 2004a; Guerette et al. 1996). Spider silk proteins are large proteins with a size in the range of 250–320 kDa (Ayoub et al. 2007; Sponner et al. 2005). Typical motifs seen in dragline silk are blocks of alanines, which assemble into crystalline β-sheet stacks and account for the strength of the fiber (Hijirida et al. 1996; Parkhe et al. 1997), whereas glycine-rich motifs such as GGX or GPGXX confer elasticity to the fiber through adopting 310-helical structures or β-turn spirals, respectively (Van Beek et al. 2002;Hijirida et al. 1996). The primary structure of spider silk protein core domains characteristically comprises alternating patterns of hydrophilic and hydrophobic blocks (Römer and Scheibel 2008). While the core domain determines the macromolecular properties of the resulting protein fiber and, therefore, is more variable between silk types and spider species, the terminal domains are highly conserved and consist of 100–200 amino acids with α-helical structures in a five helix bundle (Rising et al. 2006; Challis et al. 2006). The terminal domains play a key role in storage and fiber assembly (Askarieh et al. 2010; Hagn et al. 2010, 2011).

16.2.5.2 Recombinant Spider Silk

Spider silks are interesting candidates for many technical as well as biomedical applications. In contrast to silkworms like Bombyx mori, farming of spiders as a living source of silk is impeded by their aggressive territorial and cannibalistic nature. In addition, silk from spiders kept in captivity fluctuates in quality, i.e. the nutrition as well as the general condition of the animal has significant influence thereon (Madsen et al. 1999). Recombinant production of spider silk proteins allows the production of large amounts of protein with constant quality, and additionally facilitates genetic modifications of the proteins.

First attempts to express native spider silk genes in E. coli have had only limited success (Arcidiacono et al. 1998). The repetitive sequences and high G C content made manipulation of the genes difficult, and exemplarily silk genes of Nephila clavipes of a size larger than 2.5 kb exhibited genetic instability and underwent recombination (Arcidiacono et al. 1998). Therefore, synthetic silk-like genes were developed (Prince et al. 1995; Lewis et al. 1996). One of the first approaches to produce spider silk proteins in E. coli was reported in 1995 (Prince et al. 1995). Consensus motifs were derived from the available cDNA sequences of N. clavipes and back-translated into the respective DNA sequences regarding the respective codon usage of the desired expression host E. coli. Exemplarily, the consensus sequence GGAGQGGYGGLGSQGAGRGGLGGQGAG was multimerized with a sequence of ten alanine residues in between each block to mimic the character of spider silk proteins. As, at that time, synthesis of entire genes was not far advanced, the sequence coding for the consensus motif had to be assembled from four separate oligonucleotides by utilizing 5′-Nhe I and 3′-Spe I ends. Finally, the sequences were sub-cloned from the cloning vector pUC18 into pQE-9 or pET-21a expression vectors, and the gene expression was induced in E. coli bacteria transformed with this vector upon the addition of IPTG. Multimers of 4, 7, 10, and 13 repeats were successfully purified, but the protein yield after purification was as little as 2–15 mg per liter. Later on a plethora of partial spidroins as well as spider silk-derived proteins were successfully produced in E. coli (Heidebrecht and Scheibel 2013; Tokareva et al. 2013). Limitations such as low yields, truncated proteins due to premature translation termination e.g. as a result of tRNA depletion due to G and C rich genes or the accumulation of silk proteins in inclusion bodies had to be managed (Vendrely and Scheibel 2007). A large proportion of recombinant proteins have been in the range of 10–100 kDa, which seems to give good results concerning protein quality and yield. However, the size of a silk protein is suspected to have an influence on the mechanical properties of silk fibers spun therefrom. In 2010, the recombinant production of a native-sized Nephila clavipes silk protein was reported in metabolically engineered E. coli (Xia et al. 2010). The partial cDNA sequence of Major ampullate spidroin I (MaSp1) of N. clavipes was the basis for the consensus motif SGRGGLGGQGAGMAAAAAMGGAGQGGYGGL GSQGT.Mulitmerization of the module by the “head-to-tail” strategy created constructs with 32–96 repeats of the module resulting in a predicted molecular weight from 100.7 to 284.9 kDa (including a His-tag and S-tag at the amino terminus). In a preliminary experiment, an upregulation of a glycine biosynthetic pathway was seen as a stress response in E. coli bacteria upon the production of recombinant silk proteins. In order to eliminate this putative bottleneck of insufficient provision of glycine during translation, the bacteria were equipped with a compatible plasmid allowing the expression of tRNAs recognizing two glycine codons GGU and GGC. To additionally increase the protein production, the bacteria were engineered to overexpress serine hydroxymethyltransferase. Among the investigated proteins, these engineering strategies especially increased the protein production of the larger sized proteins, i.e. a 64mer, 80mer and 96mer, and enabled a 10 to 35-fold increased protein production. The bacteria were cultivated under high cell density conditions, and protein yields were calculated to be 1.2 g per liter (Xia et al. 2010).

The limitations of recombinant spider silk protein production seen in E. coli have prompted research on expression hosts other than E. coli to attain improvements concerning yield, quality and availability. Other bacterial hosts such as Salmonella typhimurium have been exploited to produce silk proteins due to their ability to secrete proteins to the extracellular environment (Lee et al. 2006; Widmaier et al. 2009). Therefore, a type III secretion system (T3SS) encoded within the Salmonella Pathogenicity Island 1 has been utilized and genetically manipulated to secrete monomers of Araneus diadematus spidroins ADF-1, -2 and-3 (Widmaier et al. 2009).

Yeasts, such as the Pichia pastoris, are auspicious alternatives for the production of spider silk proteins as they are able to synthesize and secrete large proteins (Cereghino et al. 2002; Cregg et al. 1993). Synthetic spider silk genes were expressed under control of the methanol-inducible AOX1 promoter at high levels, but while proteins encoded by genes with up to 3000 codons were produced successfully, increasing size led to significantly decreased yields, and the size of the proteins varied from the expected ones (Fahnestock and Bedzyk 1997).

Insect cells have been tested for recombinant spider silk production as insects and spiders are from the same phylum (Arthropoda), and, therefore, insect cells are very close phylogenetic relatives compared to other frequently used expression hosts (Huemmerich et al. 2004a). Araneus diadematus spidroins ADF3 and ADF4 have been successfully produced in a fall armyworm Spodoptera frugiperda derived cell line, Sf9, infected with baculoviruses containing the respective partial cDNA sequences (Huemmerich et al. 2004b). While ADF4 assembled into fibrils in the cytoplasm, ADF3 remained in the soluble state, which was mainly attributed to the differences in hydropathicity. Further, a N. clavipes flagelliform silk protein was recombinantly produced in a B. mori cell line using a Bombyx mori nuclear polyhedrosis virus baculovirus expression system (Miao et al. 2005). The reported yield of the purified 37 kDa protein was 0.08 mg per 6 ml of cell suspension.

Spider silk proteins have also been produced in mammalian cells. These cells are able to produce large proteins and can also secrete the produced protein. Two cell lines, namely bovine mammary epithelial alveolar cells (Kamenskiy et al. 2014) and baby hamster kidney (BHK) cells, have been used for the production of partial dragline silk proteins ADF3 of Araneus diadematus and MaSpI and MaSpII of Nephila clavipes. Analysis of the medium of stable transfectants of all constructs revealed the successful production and secretion of silk proteins by these cell lines. Nevertheless, multimerization of the ~60 kDa constructs leading to larger protein sizes up to 140 Da was accompanied by much lower yields (Lazaris et al. 2002).

A genetic sequence encoding a part of the major ampullate spidroin 1 from the African spider Euprosthenops sp. was cloned into an expression vector suitable for transient transfection of mammalian COS-1 cells, a cell-line derived from monkey kidney (Grip et al. 2006). The constructs contained a carboxy terminal poly-histidine tag to allow affinity purification, and some transformants contained an additional amino terminal leader sequence for protein secretion. Although, successful transient production of the 22.5 kDa and 24.9 kDa constructs could be demonstrated, the expression rate was low, suggesting these cells would encounter similar problems as bacterial expression hosts, such as obstacles with efficient transcription and translation of repetitive sequences (Grip et al. 2006).

Transgenic animals and plants have been created to test them as hosts for recombinant spider silk production. Plants were discovered as promising expression hosts as they offer a plethora of expression loci, e.g. roots, leaves, seeds or fruits (Scheller and Conrad 2005). Transgenic tobacco and potato plants have been investigated concerning the expression of synthetic MaSp1 genes of Nephila clavipes of 420 to 3600 bp in size (Scheller et al. 2001). The proteins were produced in the endoplasmatic reticulum of tobacco and potato leaves and potato tubers and were found to represent up to 2 % of the soluble protein, thereby showing that the production of spider silk proteins of up to 100 kDa is feasible. Arabidopsis thaliana and somatic soybean embryos served as an expression host of an N. clavipes MaSp1-derived gene in the leaves and seeds (Barr et al. 2004). While smaller silk-like proteins were produced efficiently, production of larger proteins of 127 kDa led to the additional production of smaller protein fragments. In another approach, a native sized flagelliform protein of N. clavipes has been produced in the endoplasmic reticulum of tobacco leaves (Hauptmann et al. 2013). Exploiting an intein-based posttranslational protein fusion technology, silk protein multimers larger than 250 kDa were formed subsequent to ligation of monomers. This method copes with highly repetitive genes and, therefore, might lead to reduced genetic instability. In further work, intein-based trans-splicing led to seed-specific production of synthetic flagelliform silk proteins (Weichert et al. 2016). The seed-specific expression was driven by the unknown seed protein (USP) promoter, and multimers larger than 460 kDa have been reported, which are stable when storing the seeds up to 1 year under ambient conditions.

Also, genetically modified silkworms (B. mori) were established using a Bac-to-Bac/BmNPV baculovirus expression system to produce the dragline silk protein MaSp1 of Nephila clavata (Zhang et al. 2008). The genetic fragment encoding a 70 kDa protein was fused to an EGFP sequence. In a larva, approximately 6 mg of fusion protein was detected, but 60 % of the recombinant protein was insoluble. In another experiment, a partial cDNA encoding an 83 kDa MaSp1 protein of Nephila clavata was cloned into a piggyBac vector, and eggs of silkworms were transformed with this vector to generate germline-transgenic silkworms (Wen et al. 2010). The silken pupation cocoons were harvested and analyzed with regard to their design and properties. The silk proteins were located in the sericin layer of the silkworm silk. Mechanical tests revealed a slight improvement of transgenic silkworm silk compared to unmodified silkworm silk, but the mechanical properties did not reach the extraordinary properties of the natural blueprint.

Production of spider silk proteins in transgenic animals has been tested in mammary glands of mice and goats. Based on the partial cDNA of MaSp1 and MaSp2 of N. clavipes an artificial gene construct was cloned into the pBC1 vector and microinjected into the pronuclei of fertilized Kunming White eggs. The protein yield from milk was demonstrated to be up to 11.7 mg per liter, but protein size varied (Xu et al. 2007). Moreover, genetically engineered goats were generated to produce recombinant spider silk proteins based on MaSp1 and MaSp2 of N. clavipes (Lazaris et al. 2002). Although, spider silk proteins could be produced successfully, these expression systems showed several drawbacks as the generation of transgenic animals is difficult, the generation time is very long and separation of silk proteins from milk caseins is another hurdle for efficient silk protein production (Xu et al. 2007; Heim et al. 2009).

16.3 Processing and Properties of Silk Proteins

In general, there are two possibilities for processing polymeric materials – from the melt or from solution. Silk proteins have exclusively been processed from solution due to their physicochemical properties. The thermal behavior of silk materials has been investigated by differential scanning calorimetry (DSC) and thermogravimetric (TGA) analysis. The results of these observations indicate a bimodal melting and thermal decomposition of silk proteins due to the narrow temperature range in which melting and decomposition occur (Spiess et al. 2011; Vasconcelos et al. 2008; Gotoh et al. 1997). Though it has been shown that, under extreme heating and cooling rates of 2000 K/s, reversible melting and crystallization of silk proteins is possible preventing thermal decomposition (Cebe et al. 2013), it is questionable if such parameters are applicable for established processing procedures. Consequently, the following methods are all solvent based upon dissolution of the proteins in aqueous or organic solvents.

16.3.1 Fibers and Nonwoven Mats

In principle, polymer fibers can be produced by wet spinning, dry spinning, melt spinning, melt blowing, rotational spinning or electrospinning. In the case of silk protein solutions, the most commonly performed methods are wet spinning and electrospinning. However, microfluidic spinning has also been investigated to mimic properties as obtained in natural silk glands (Fig. 16.8).

Wet Spinning

The most commonly used method to produce artificial silk fibers with diameters in the micrometer range is wet spinning. Wet spinning is conducted by extruding an aqueous or organic protein solution into a coagulation bath. Solvents which can be used for coagulation baths are polar organic solvents such as methanol, ethanol, acetone, propanol or isopropanol (Chen et al. 2012), as well as aqueous solutions of cosmotropic salts (e.g. potassium phosphate) (Rammensee et al. 2008). In wet spinning, the main objective is the production of fibers with optimal mechanical properties, making wet spinning a highly attractive method for producing silk fibers. Various studies have shown that the mechanical potential of artificial silk fibers can only be approached by mimicking the naturally occurring structure based on high molecular weight proteins, which display small aligned crystals in an amorphous matrix.

The crucial role of the primary structure is exemplified by the wet spinning of recombinant N. clavipes Flag-like silk proteins with compositional variation of the motifs (GPGGX, GGX and a non-iterated spacer) dominating the repetitive core domain of natural N. clavipes Flag proteins (Adrianos et al. 2013). Fibers were wet spun by extrusion of the protein solutions (15 % w/v in 1,1,1,3,3,3-hexafluoro-2-propanol (HFIP), subsequent addition of 5 % v/v toluene) into pure 2-propanol, and tensile testing was performed. In the presence of the non-iterated spacer, fiber toughness was significantly improved by a factor of ~5.

Additionally, the impact of naturally occurring non-repetitive termini on the mechanics of wet spun spider silk fibers has been examined (Heidebrecht et al. 2015). It was shown that the presence of terminal domains is crucial for silk pre-assembly in the spinning dope. During fiber formation, terminal domains trigger dimerization and are essential to obtain a stable intermolecular protein network. In fact, the effects of this molecular self-assembly of the spidroins enhances toughness even more significantly than increasing the protein’s molecular weight (An et al. 2011; Xia et al. 2010; Heidebrecht et al. 2015). However, the most significant factor in the wet-spinning process is post-stretching of the as-spun fibers. Post-stretching is usually performed in alcohol/water mixtures with water acting as a plasticizer allowing the mobilization of glycine-rich regions and therefore promoting conformational switching and chain orientation (Seidel et al. 2000; Lazaris et al. 2002). The significance of post-stretching is exemplified in recent publications (Table 16.2). In all cases, the tensile strength and extensibility are considerably enhanced upon post-stretching, leading to a significant increase of the resulting toughness. Furthermore, it can be seen that the toughest fibers are generated by wet spinning proteins with non-repetitive terminal domains from aqueous solution (Heidebrecht et al. 2015). Unlike solutions with strong denaturants like HFIP, which prevent protein assembly, this approach allows for the biomimetic preassembly of an intermolecular network during wet spinning, which is then further stabilized by molecular alignment during post-stretching.

Microfluidic Spinning

Wet spinning approaches have indicated that the performance of artificial silk fibers can be significantly improved by introduction of biomimetic factors (terminal domains, aqueous solutions, induced phase-separation, post-stretching). Hence, another step towards the technical transfer of the natural spinning process is to mimic the geometry of silk glands, as well as the flow profile, and thus to spin fibers with diameters in the range of the natural blueprint. Therefore, a microfluidic device was designed based upon the dimensions of spider silk glands, which allowed for a precise control of chemical and mechanical properties (Rammensee et al. 2008). These outcomes were controlled by altering the elongational flow conditions as well as by introducing two laminar buffer streams, which could be used to induce protein assembly by diffusive ion-exchange and pH-drop. Such a system allowed for a carefully orchestrated interplay of ion-exchange, pH and shear forces. However, a drawback of this system is that it does not allow for dehydration and ion extraction as it is taking place in the natural spinning duct. Microfluidic spinning from aqueous solution (solely triggered by natural assembly mechanisms upon simultaneous fiber formation and stretching) has so far been the closest spinning approach compared with the natural system.

In another approach, a pH-buffered poly(ethylene oxide) solution was used as a shell stream in a microfluidic device to match the viscosity of a regenerated B. mori-fibroin solution in water and to mimic the pH-drop in B. mori silkworm glands (Kinahan et al. 2011). The device was submerged in a methanol bath, inducing subsequent dehydration and thus further strengthening the silk fibers. Due to the precise parametric control, this system was capable of producing functional silk fibers with tunable properties such as Young’s modulus and fiber diameter. However, due to the lack of control over shear stress, post-stretching in alcohol was still necessary to improve mechanical properties and tune fiber diameters. This was also the case in a microfluidic dry spinning setup, where a highly concentrated silk solution (pH 4.8) was pumped through a single channel microchip to create biomimetic shear and elongation conditions (Luo et al. 2014). This data confirmed the dominating influence of post-stretching on the mechanical properties.

Electrospinning

Electrospinning is an electrostatically-driven process allowing the production of fibers with diameters ranging from micrometers down to a few nanometers (Sundaray et al. 2004). The basic setup comprises a needle which is charged (0–30 kV) and through which a protein/polymer solution is extruded (Garg and Bowlin 2011). The strong electric field induces electrostatic repulsion at the surface of an extruded droplet and causes Coulombic forces, which ultimately leads to the formation of a Taylor cone. If the electrostatic forces overcome the surface tension, and the molecular cohesion and chain entanglement in the protein/polymer solution is sufficiently high, the droplet is not ejected as a spray, but a jet is formed. At a certain point this jet experiences whipping instabilities, and is thenceforth stretched and dries on its way to an oppositely charged collector plate on which the fibers are deposited as a nonwoven mesh (Reneker and Yarin 2008). The diameters of fibers produced by electrospinning can be well-controlled by adaption of the spinning dope properties (protein/polymer concentration, viscosity, conductivity, volatility and surface tension of the solvent) and process parameters (voltage, distance to counter electrode, flow rate, temperature, humidity) (Greiner and Wendorff 2007). Considering the number of parameters involved in electrospinning, predictions of the resulting fiber diameters are only possible within one protein/solvent system and under highly defined spinning conditions. Variations in the resulting fiber diameters are demonstrated in Table 16.3 giving a few examples of different electrospun protein/solvent systems.

Allowing the production of fibers with diameters in the range of e.g. collagen fibrils (40–150 nm) (Pilotto and Filosi 1977) in combination with a high degree of biocompatibility of the underlying proteins, electrospinning of artificial silk proteins has gained rising interest for a range of applications. With regards to applications, electrospun engineered A. diadematus fibroin 4 (eADF4) fibers were tested as a filter material for air filtration devices, and the results showed high filter efficiencies whilst using small material amounts (Lang et al. 2013). A crucial argument for the use of silk proteins for such applications is that fragmented submicron- or nanofibers can be respirable and harmful if they are bio-persistent. Consisting of biodegradable amino acid chains, silk proteins are assumed to be uncritical upon inhalation. Furthermore, due to their mechanical properties (predominantly soft when exposed to water), different studies have examined the suitability of electrospun recombinant silk proteins as substrates for soft-tissue cells such as fibroblasts. Engineered A. diadematus fibroin 4 (eADF4) proteins were electrospun using different protein concentrations in HFIP to create non-woven meshes with controllable fiber diameters in the range of 150–680 nm (Leal-Egana et al. 2012), which allowed controlling cell behavior; there was a strong correlation between the fiber diameter and the ability of mouse fibroblasts to adhere and proliferate.

Fibroblast growth was also tested on fibers made of silk-elastin-like proteins (SELPs) (70 kDa) electrospun from formic acid (15 and 20 % w/v) (Qiu et al. 2010). After posttreatment with methanol and/or glutaraldehyde vapor, water stable non-woven meshes with fiber diameters of 50–200 nm were seeded with fibroblasts. The cells adhered to and spread on the scaffolds, maintaining high viability and proliferation rates (similar to the positive control on treated cell culture plates). Approaches to electrospin aqueous solutions were performed successfully by adding PEO and SDS to the aqueous silk-elastin like protein (70 kDa) solution, forming a polymer-micelle complex which decreases the surface tension, increases solution conductivity and retards the gelation process of SELP in water (Nagarajan et al. 2007). Furthermore, SELP-fibers could also be electrospun from pure aqueous solution at concentrations of 5–13 %w/v, though the resultant fiber mats were not as homogeneous in fiber diameter and shape as fibers electrospun from formic acid (Machado et al. 2013). Efficient cell adhesion and proliferation was also observed on electrospun fiber mats made of a recombinant honey bee larva cocoon silk protein AmelF3 (34 kDa) (Weisman et al. 2010), which was spun from aqueous solution (12.5 % w/v) (Wittmer et al. 2011). Electrospinning of 12.5 % aqueous silk solution was only possible upon the addition of 0.67 or 1.0 % w/v polyethylene oxide (PEO) and resulted in fibers with a diameter of 200nm. Post-treatment by annealing in methanol or water caused an increase in β-sheet content and simultaneously washing out of PEO.

To further enhance their suitability for tissue engineering, recombinant silk proteins with cell binding motifs were electrospun, such as an RGD-modified N. clavipes MaSp 1 protein (Bini et al. 2006) or a recombinant silk-like polymer with fibronectin functionality (Anderson et al. 1994). The generated porous films showed enhanced biocompatibility based on structural gradients and controlled morphology (Buchko et al. 1999).

16.3.2 Particles and Capsules

Particles

To produce particles from silk proteins, different procedures have been successfully applied. One strategy is to trigger self-assembly of the silk proteins, which has been demonstrated with an engineered MaSp 1 spidroin (model: N. clavipes) (Rabotyagova et al. 2009). Upon variation of the number of hydrophobic (alanine-rich) blocks the assembly behavior was determined by the size of the hydrophobic domain and its interaction with the solvent system. Particle formation predominantly occurred with smaller proteins in water, while micelles were formed by increasing the number of hydrophobic blocks and using isopropanol as a solvent. Furthermore, recombinant A. trifasciata aciniform spidroin 1 can also assemble into nanoparticles in the presence of low concentrations (near-physiological) of cosmotropic anions such as phosphate (Xu et al. 2013). This effect is likely based on the amphiphilic character of silk proteins, leading to formation of spherical structures upon reaching a critical concentration. Another approach is to ‘salt-out’ the proteins. This sort of protocol was applied to produce particles of an engineered A. diadematus fibroin 4 (eADF4) (Slotta et al. 2008). Above a critical potassium phosphate concentration, particles occurred as a result of the structural transition from random coils to β-sheets. The mechanism behind this change in structure was determined to be a liquid-liquid phase separation where there is a dense protein phase in which formation and growth of nuclei takes place. Spherical growth stagnates as the protein concentration in the protein-rich phase falls below a critical number. To control particle size, protein concentration and mixing conditions were determined as effective parameters, and particles could be produced covering a range of 250 nm- 2.1 μm (Lammel et al. 2008). In further studies, these microspheres were shown to be promising drug delivery vehicles. eADF4(C16)-particles could be efficiently loaded (almost 100 %) with lysozyme due to electrostatic interactions between the negatively charged silk proteins and positively charged lysozyme molecules (Hofer et al. 2012). Subsequent drug release could be triggered by pH and ionic strength of the release medium. Similar results were obtained with a variety of small molecular weight model drugs predominantly positively charged at pH 7 (Lammel et al. 2011). To further allow loading with negatively charged substances, a positively charged analogue of eADF4(C16), namely eADF4(κ16), was processed into particles, and high-molecular-weight substances as well as low-molecular-weight substances could be efficiently loaded (Doblhofer and Scheibel 2015). Additionally, eADF4 proteins have been used for colloidal stabilization of hydrophobic particles in an aqueous environment (Liebmann et al. 2008). Unlike the aforementioned approaches, instead of adding the model compound (β-carotene) to the finished particles, it was added to an aqueous eADF4-solution, and subsequent salting-out was performed. It was shown that, in solution, hydrophobic regions of eADF4 interact with the hydrophobic model compound leading to a stable suspension. Salting-out resulted in co-precipitation of β-carotene encapsulated in eADF4 particles, and subsequent release could be induced by proteolytic degradation. Resistance of eADF4 particles in gastric fluids and digestion in intestinal fluids renders this drug carrier system highly interesting in the field of food and pharma formulations.

To produce particles from natural B. mori fibroin fibers without the use of additional chemicals as required for salting out (Lammel et al. 2010), a wet milling-spray drying process was applied (Rajkhowa et al. 2012). This top down process resulted in highly porous particles with an average diameter of 5 μm and a high surface area. Furthermore, it was shown, that milling induced breaking of stacked β-sheets within silk crystallites leading to a significant increase of enzymatic hydrolysis compared to that of fibers. Such tuning of the degradation behavior of porous silk particles can be attractive in developing targeted biomedical applications.

Capsules

Formation of a continuous protein membrane is a prerequisite to produce capsules, and there are different strategies to obtain capsules of proteins. Self-assembly of amphiphilic proteins and surfactant peptides has been shown to be sufficient for smaller molecules (Park and Champion 2014; Vauthey et al. 2002; Santoso et al. 2002), but is likely unsuitable for more complex larger proteins with more functionalities such as silk proteins (Hermanson et al. 2007b). Other approaches apply micro-spherical templates providing interfaces at which protein layers can form either by electrostatic deposition (Du et al. 2014; Zhao and Li 2008; Li et al. 2005) or by adsorption of amphiphilic protein chains due to hydrophobic interactions (Horinek et al. 2008; Geisler et al. 2008).

Regenerated B. mori silk fibroin has been processed into microcapsules by electrostatically driven layer-by-layer deposition on polystyrene particles as a sacrificial template (Li et al. 2014). The particles were first coated with polyethylenimine to render their surface positively charged and subsequently coated with up to 10 silk fibroin layers. The polystyrene cores were dissolved in tetrahydrofuran to obtain microcapsules that could be shown to be potentially suitable as carriers for controlled, localized gene delivery. Alternatively, silica particles can be coated with aqueous silk solution and subsequently removed by dissolution in 8 % hydrogen fluoride (Shchepelina et al. 2011). The resulting capsules could potentially be applied as bio-sensing materials.