Abstract

Conception of ball screw, gearbox, pinion and rack are commonly used for linear and rotary axes of machine tools. Issues of these applications are backlash, increased moments of inertia and friction. These disadvantages can be eliminated by using of direct drive motors. In this case, it has to be taken into account that the entire mechanical stiffness of the axis is formed only by closed loop control. Before using of this technology, required properties and behavior of motors has to be practically tested in specific situations on real device. The first goal of this project was design and implementation of unique stand for testing of direct linear and direct torque drive motors in order to use in special-purpose machine tools. The second goal was design and implementation of complete control system for testing of dynamics and position accuracy. Both of the test stand and the control system based on Siemens Simotion C controller were successfully constructed and implemented in accordance with the design. Created solution allows measuring of position accuracy, speed and torque for standardized displacements law and it can be done in manual or automatic mode. It also allows developing and evaluating the quality of the control system. Attention was paid to the new method of transmission data of displacement law from the USB flash memory to the controller based on the Client-Server communication. Result of this project is decision about recommendation of this concept for practical application for special-purpose machine tools.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Demands for linear movement with high dynamic performance and for accuracy and elimination of backlash and increased moments of inertia caused by conventional mechanical conceptions can be solved by usage of linear motor. Linear motors simplify mechanical design, increase affordability and durability and improve handling of the machine by elimination of mechanical transmission elements. Direct torque motor which transfers force not trough gearbox but directly on the workpiece was already successfully used by VÚTS Company for BRV300 radial cam grinder [1]. First issue is if replacement of Mechanical transmission elements by direct servo drives is effective option for particular application of single purpose machine-tools. Second issue is if control system and created application meet demands for dynamics testing of both servo drives. The benefit of this concept is to study and identifying the behavior of electric motors on the real equipment for research in cooperation with the Technical university of Liberec. Tests is already underway feedforward regulation on this machine. Especially, the benefit of using the knowledge from this concept in a dedicated new CNC machine tool with direct drives follow-up to this project. Direct drive components have been designed, engineered and manufactured to order in our research institute. For example a sliding surface of the linear model holding the probe following the cam. This metallic cam has also been produced in VÚTS.

2 Mechanical Part

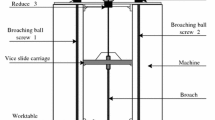

The flywheel has a function of load as well as reduction for cam clamping on Siemens 1FW3150 [2]. Stroke length of the linear motor is 450 mm and is determined by six permanent magnets Siemens 1FN3050. Feedback from absolute encoder by using Heidenhain LC483 is indispensable for closing of control loop [3] (Fig. 1). Measuring probe MSL50.152KA is used for accurate measuring of the length coordinate in short measuring range. Measuring step is 5.0 µm. Siemens Simotion C control system was selected because of this system satisfies demands for controlling of multiaxis systems with possibility of design and modification of displacement laws within program execution. Speed and current loop control are closed here [4]. Specific requirement is controlling of the motors by pendant control station with hand wheel. General safety supplemented by special circuit for safe servo drives switching off by safety integrated. Double motor module uses enable pulse which determines if sequence of functions like timer and OFF3 will be started. Function OFF3 ensures safe stop of servo motor via ramp function.

3 Software Part

Software architecture is decomposed into manual mode, the operator of cam panel and automatic mod. Monitoring of position, speed, positioning, jog, homming, enable axes, synchronization the virtual and the real axis alllows manual mode. Upload displacement law with USB portable memory, display it for inspection and then exported to the memory controller allows cam panel. All synchronization of the three axes are using the gear and cam handles automatic mode. The whole system is controlled by a single virtual axis. Virtual gear rotational axis is attached virtual axis. Displacement law between the rotational axis and a linear is use. First, parameters and hardware configuration were set during program initialization. Then, the stops were solved. Real system contains mechanical stops which are supplemented by virtual ones 10 mm earlier and programmed ones 20 mm before real stop. That means triple protection against collision between linear and torque motor. In the case of program error and moving into virtual stop, motor goes immediately into disable state. Remedy is deleting of position error, putting motor in enable state and leaving the restricted area with negated speed. This information is displayed by LEDs on electrical switchboard and on HMI panel throughout remedy. Errors can be acknowledged on HMI panel. Conventional total stop on electrical switchboard and on pendant control station is supplemented by software stop. The safety integrated function is activated during emergency stop of the motor and it executes delayed switching off. This makes possible to stop motor with defined deceleration.

Visualization and controlling by using Weintek 8070iH HMI and Simotion PLC are based on Client-Server communication. Although these two systems do not support each other, because the motion control system Simotion uses the indirect (symbolic) addressing, bidirectional communication can be established by means of this application. Application of “Client-Server” based on functions in a development environment EasyBuilder and Siemens Scout is described in report Client-Server application for the operator panel Weintek and the control system Siemens Simotion [5].

Source data of displacement law are saved in controller memory. That is standard practice. Large attention is paid to the new method for displacement law data transfer via USB to the Simotion controller memory. This transfer is based on mentioned unique Client-Server communication and on Weintek HMI panel usage. This new technique allows user friendly data transfers from any USB flash memory directly into Simotion memory. Simotion unlike Weintek uses indirect addressing and so this option is not standardly possible. Typical situation for dynamic tests is displacement law modification on system input. Within few seconds, displacement law can be uploaded, displayed for checking and exported into the controller during RUN mode and without any change of programme in the PLC. That is possible thanks to the Client-Server method [5].

Application for the testing stand of the direct linear and the torque servo drives Siemens is divided into the three basic windows: Main panel, Cam panel (Fig. 2) and Control panel. The first window (Main Panel) is responsible for: axes positioning, actual position and speed showing, axes homming, axes enabling, synchronization between three axes and activate of pendant mode. Particular axes, theirs multiple of position, jog and hand wheel are possible to be selected on pendant control station. Because of security, operator has to use both hands and be pushing enable pulse button with defined pressure.

The second window (Cam Panel) is designed to select one of the predefined displacement laws for the electronic cam. Electronic cam is alternate option to the conventional mechanical cams. Quick change of displacement law is one of the biggest advantages of the electronic cam. Solving of cam movement dynamics is on the contrary disadvantage. Periodic type of cam from VDI 2143 standard was used for electronic cams dynamics testing [6]. This cam has high dynamics and interval with constant nonzero speed. Relation between positions of master and slave axes (displacement law) is saved in *.xls format and sampling step of master axis is 0.5°. Therefore, one displacement law in 0–360° range with two axes with mentioned sampling period needs 1440 elements. Data file on USB flash memory has to be in *.emi format and its name has to be in range EM0-EM9. Conversion from *.csv format to *.emi format is done by Recipe Editor [7]. Particular elements of the data field are in float type and the file is saved into root of USB flash memory. After this, the data are ready to be connected into HMI panel. After connection of the flash drive to the panel, this memory is as accessible as inner memory with EM0-EM9 attributes. File saving is done by data transfer function with definition of source (EM0.emi), destination for saving into HMI panel memory registers (LW514), uploaded data size (1440) and mode (touch trigger). Afterwards, the USB flash memory can be removed without losing of data. Rendering of the electronic cam displacement law on the HMI screen is done by plot function with definition of rendered data size. Four bytes are necessary for every position value. Information about displacement law is carried by slave axis so 2880 elements are necessary. Size of the field is always used as a multiple of 512. Here is divided into 6 parts with size of 512 due the limitation of maximal field size during Client-Server communication. Displacement law which is saved in the inner HMI panel registers is saved into field of 3072 size. Afterwards, two times nested for loop is used for sending the packets of 512 Byte size. Communication channel on the 9001 port is reserved for this.

The third window (Control panel) allows showing of actual position and speed of all axes, showing and acknowledging of errors of the axes selected electronic cam type. This window defines the master axis speed set point and active automatic mode and finally switching the main contactor in front of the frequency converter.

This mode is block of instructions that are executed automatically. Initial assumptions are successful enable of the motor with zero errors and activated active line module contactor. Two automatic modes were used in this project. First one tests dynamic parameters of both motors. These parameters are position, speed, torque and position error of standardized VDI 2143 displacement law with 1800 values per one revolution. These points are linearly interpolated. Testing system has virtual master axis. This axis is rotating at a constant speed 125°/s and is synchronized with real torque axis by displacement law. Resulting graph on the Fig. 3 presents displacement law of linear and torque motor.

Second automatic mode simulates machining for measuring the zero position error of the measuring probe. Synchronization of particular axes (real and virtual) is done by displacement law. Whole process is separated into approach, machining simulation and departure. Approach and departure is done by moving at 120°/s into the safe distance. Then the speed is decreased at 3°/s due to the safe movement on required position.

Synchronization of all three axes is realized during this process. Double synchronization is made for machining simulation. Entire system is controlled by master axis speed which revolves real torque axis via gearbox with 1:1 ration. Electronic cam defined by 1800 values is between torque and linear motor. Real steel asymmetric cam was manufactured thanks to known x and y coordinates and it was placed directly on the torque motor. Linear motor was mounted with measuring probe. Torque motor rotates at constant speed 3°/s and linear motor copies contour of the cam.

4 Conclusions

The first goal of the project, assembling of the stand, was successively and completely accomplished. The biggest attention was paid to the perpendicularity of linear rails and to the accuracy of air gap between primary and secondary section in whole range. Concept of contact between measuring probe and cam is area where further development is required. Radial stress acting on measuring probe is bigger than 0.2 N. That can bring difficulties during higher speeds. Solution of this issue can be application of measuring probe with roller, contactless measuring, etc. Nevertheless, the used concept of measuring probe with sphere was fully sufficient for required speeds.

The second goal of the project, design and implementation of complete control system for testing of dynamics and position accuracy, was successfully accomplished. The biggest attention was paid to the safety and to the transmission of displacement law. This new transmission method facilitates and speeds up manufacturing process. Its next application can be transfer via company network from office computer to the production hall using the same principle.

Fulfillment of these goals had allowed testing of dynamic properties of motors in real situations. It also proved that replacement of conventional conception by direct motors is proper solution and that control system fulfills all demands and therefor can be recommended.

References

Jirásko, P.: Metodika aplikací elektronických vaček v pohonech pracovních členů mechanismů výrobních strojů. Liberec (2010). Available from:http://www.fm.tul.cz/files/autoreferat_jirasko.pdf

Souček, P.: Servomechanismy ve výrobních strojích. Vydavatelství ČVUT, Praha (2004). ISBN:80-01-02902-6

Heidenhain: linear encoders for numerically controlled machine tools. Measuring principles [online]. 2016 [cit. 2016-04-18]. Available from: http://www.heidenhain.de/fileadmin/pdb/media/img/571470-28_Linear_Encoders_For_Numerically_Controlled_Machine_Tools.pdf

Lindr, D.: Řízení servopohonů v dynamicky náročných aplikacích. Liberec (2011)

Antos, J., Busek, M.: Client-server application for the operator panel weintek and the control system Siemens Simotion. Mechatronika. VÚTS a.s. Liberec [online]. (2014) [cit. 2016-04-18]. ISBN 978-1-4799-3527-7. Available from: http://ecopyright.ieee.org/xplore/down.html

VDI 2143, Bl. 1: Blatt 2 Motion rules for cam mechanisms; practical application. VDI-Fachbereich Getriebe und Maschinenelemente (2002)

Weintek: Professional in human maschine interface [online] (2012) [cit. 2016-04-18]. Available from:http://www.weintek.com/global/download/Download.aspx?wFun=byM&c=Manuals&S=HMI_0002

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing Switzerland

About this paper

Cite this paper

Antoš, J. (2017). The Testing Stand of the Direct Linear and the Torque Servo Drives Siemens Controlled by the Simotion C. In: Beran, J., Bílek, M., Žabka, P. (eds) Advances in Mechanism Design II. Mechanisms and Machine Science, vol 44. Springer, Cham. https://doi.org/10.1007/978-3-319-44087-3_48

Download citation

DOI: https://doi.org/10.1007/978-3-319-44087-3_48

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-44086-6

Online ISBN: 978-3-319-44087-3

eBook Packages: EngineeringEngineering (R0)