Abstract

Poor bioavailability associated with poorly water-soluble compounds remains a challenging issue in drug development. Particle engineering may be used to improve the physicochemical properties of poorly water-soluble compounds, thereby enhancing the bioavailability. Cryogenic technologies, including spray freeze drying (SFD), spray freezing into liquid (SFL), and thin film freezing (TFF), are “bottom-up” precipitation processes to generate amorphous nanostructured aggregates with significantly enlarged surface area, higher dissolution rates, and supersaturation, via rapidly inducing nucleation followed by particle growth arrest through stabilization via polymers and solidification of the solvent. This chapter provides detailed description of each cryogenic process, formulation guidelines, and characterization analyses. Finally, examples of cryogenically engineered drug compositions with improved in vitro and in vivo macroscopic performance are provided to illustrate the potential benefits of cryogenic technologies, especially TFF. The current authors would like to thank and acknowledge the significant contribution of the previous authors of this chapter from the first edition. This current second edition chapter is a revision and update of the original authors’ work.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Particle engineering

- Spray freeze drying (SFD)

- Spray freezing into liquid (SFL)

- Thin film freezing (TFF)

- Amorphous nanostructures

- Dissolution rates

- Supersaturation

- Nucleation

- Particle growth arrest

- Polymers

- Solvents

- Dry powder inhalation

11.1 Introduction

11.1.1 Therapeutic Shortfalls of Poorly Water-Soluble Drugs

In modern drug discovery processes , routine use of high-throughput screening, combinatorial chemistry, and computer-aided drug design appear to result in a higher prevalence of lead compounds of increased molecular weight and lipophilicity, despite the high efficiency of the automated processes. About 60 % of these drug candidates exhibit poor aqueous and nonaqueous solubility (Gao et al. 2008). Among which, for those with high permeability through biomembranes, classified as Biopharmaceutical Classification System (BCS) Class II drugs , the poor dissolution rate limits drug molecules released into biological fluid contacting the absorbing mucosa (Rasenack and Muller 2002). Basically, it is in the form of an aqueous solution that a drug can be absorbed into the systemic circulation and exert its therapeutic effect. Consequently, the poorly water-soluble drugs often result in low and highly variable bioavailability, and sub-optimal therapeutic effects in patients, particularly when delivered via the oral administration (Muller et al. 2001; Patravale et al. 2004).

11.1.2 Solid Dispersion/Solution , Supersaturation

To improve the bioavailability of poorly water-soluble drugs, defined as the rate and extent of the drug that reaches systemic circulation, new technologies and innovative formulations and drug delivery systems were explored to improve dissolution properties of poorly water-soluble drugs throughout the past decade. These include more conventional techniques such as the use of surfactants, cyclodextrin inclusion complexation, emulsification processes, co-solvency, salt formation, powder milling, and spray drying. However, these attempts have been of limited success, and each was found with inherent problems of their efficacy or stability of the final product.

The increased amount of excipients required to formulate the poorly water-soluble drugs may potentially increase side effects, resulting in low patient compliance. Alternatively, invasive dosage forms such as parenteral formulations have to be developed to address the challenges being presented. However, with even less pharmaceutically acceptable excipient options, solubilization of drug is practically limited (Liu 2000).

Salt formation is one of the commonly used means to increase aqueous solubility of poorly water-soluble drugs. Despite the unionized form being much less soluble than its salt, of further interest, therapeutically, it is the unionized form that more readily penetrates biological membranes to exert therapeutic effects (Martin et al. 1993). Salt forms can improve wettability and bioavailability of drugs. For example, albendazole salts exhibited better wettability due to the hydrophilic and ionic nature of their crystals. Microenvironmental pH changes also affect the solubility of the salt forms therefore some salt forms are superior to others. Particle size reduction typically helps increase solubility of the drug. However, in some cases, this is not possible due to the poor wettability (Paulekuhn et al. 2013).

Mechanical milling was generally used to reduce particle size. However, it generates particles with irregular shape and a wide range of size distribution. Moreover, thermo-degradation is another issue associated with milling process. Spray drying is also not an ideal method of choice due to only 50 % dry product recovery (Esclusa-Diaz et al. 1996). Leleux and Williams (2014) recently reviewed mechanical reduction methods regarding particulate systems. There are various bottom-up and top-down techniques utilized to produce crystalline drugs in the micron size range. The pros and cons of both approaches were discussed in terms of their contribution to the pharmaceutical field. However, the top-down methods have demonstrated greater efficiency in the industrial scale. The authors stated that micronization of some extremely low solubility drugs did not have a substantial impact on their solubility. However, size reduction to the nanoscale particle size range was possibly an effective method to enhance solubility of poorly soluble drugs.

To overcome these shortcomings, novel technologies such as hot-melt extrusion, particle engineering by use of supercritical fluid, nanomilling, and solution-based micro-/nanoparticle precipitation (Betageri and Makarla 1995; Mawson et al. 1997; Rogers et al. 2001; Sarkari et al. 2002; Hu et al. 2004b; Matteucci et al. 2007) have been developed to enhance saturation solubility of poorly water-soluble drugs. It may be practical to increase apparent solubility and/or the dissolution rate via alteration of the solid-state form.

Solid dispersion typically refers to systems in which drug particles are homogeneously distributed throughout a solid matrix of excipient(s). This system provides the possibility of reducing the particle size of drugs to nearly a molecular level in order to transform the drug from the crystalline to partially amorphous morphology. A solid solution results when the drug is molecularly dispersed throughout a solid matrix, i.e., complete amorphous morphology (Kapsi and Ayres 2001), in which the particle size of the drug has been reduced to its absolute minimum without any crystalline drug domains (Leuner and Dressman 2000). The amorphous form of a drug has a higher thermodynamic chemical potential than its crystalline counterpart.

Additionally, exposure area of drug to the dissolution media was also greatly enhanced due to significantly increased surface areas of drug compositions obtained in this way. Therefore, poorly water-soluble drugs in the solid solution/dispersion exhibit higher dissolution rates and higher saturation concentration than their intrinsic solubility of crystalline form of drug, i.e., they can produce supersaturated solutions (Betageri and Makarla 1995). Generation of supersaturation provides higher number of free drug molecules in the solution available for absorption, thereby leading to enhanced bioavailability.

11.1.3 Solubility Advantage of Nanoparticles

Production of drug-loaded nanoparticles for the poorly water-soluble drugs is an alternative and promising approach to overcome their low aqueous solubilities and the consequential low bioavailabilities (Muller et al. 2001). Nanoparticles are currently defined as single particles with a diameter less than 100 nm. Agglomerates of nanoparticles can be larger than 100 nm in diameter but may be de-agglomerated either with weak mechanical forces or by dispersing in a solvent.

Although micronization can increase dissolution rate of the poorly water-soluble drugs by reduction of particle size and thereby increased surface area, it does not increase equilibrium solubility. Often, for drugs with very low aqueous solubility, the achieved increase in dissolution rate is limited and insufficient to provide significant enhancement of bioavailability (Muller et al. 2001). However, when the drug particle sizes were deducted in the 100-nm range, they dissolve more quickly and achieve supersaturation versus the micronized drug particles, as described by the Noyes–Whitney and Ostwald–Freundlich equations (Grant and Brittian 1995). Both particle dissolution kinetics and solubility are size dependent. Thus, the dissolution of drug nanoparticles in vivo is usually accompanied by an increase in bioavailability (Hintz and Johnson 1989; Borm et al. 2006).

Furthermore, novel investigation of supersaturation levels of drug nanoparticles in aqueous media demonstrated significantly higher values than the much larger microparticles of drug composition, which have the potential to crystallize during slow dissolution (Matteucci et al. 2007). Amorphous nanostructured formulations of poorly water-soluble drugs have also been developed to enhance therapeutic effectiveness (Yang et al. 2008a).

An emulsion-freeze-drying technique was used to prepare nanoparticles of poorly water-soluble drugs. In situ formation of poorly water-soluble drug nanoparticles within a porous hydrophilic polymer (PVA) scaffold by freeze-drying o/w emulsions has been accomplished. The pore structure maintained the drug nanoparticles and prevented agglomeration. The nanoparticles of the model poorly water-soluble drug loaded in porous polymer rapidly dissolved in water (Grant and Zhang 2011).

He et al. (2013) reported that the dissolution of a model poorly water-soluble drug, indomethacin, was significantly improved due to the resulting nanoparticles prepared by a cryogenic technique. However, preventing nanoparticles from aggregation and agglomeration is also challenging. Nanosuspensions of indomethacin with food proteins as novel stabilizers were prepared by a nanoprecipitation–ultrasonication method following by freeze drying. The nanosuspensions were lyophilized, and the original particle size and particle-size distribution were maintained. The protein stabilizers physically stabilized indomethacin nanosuspensions via a combination of two mechanisms: electrostatic repulsion and steric stabilization.

Published literature reviews have discussed nanoparticle technologies. For example, a review of nanoparticle engineering processes for the enhancement of dissolution rates of poorly water soluble drugs was published by Hu et al. (2004b, c). This overview focused on the commercially viable nanoparticle engineering processes available for increasing the dissolution properties of poorly water-soluble drugs. Cryogenic spray processes and spray freezing into liquid (SFL) were proposed as alternative approaches to prepare nanoparticles of poorly water-soluble drugs. Examples using these techniques were also included. Besides, bottom-up technologies utilized to prepare nanosuspensions of poorly water soluble drugs were recently reviewed by Du et al. (2015). Spray freeze drying and freeze drying were used as the “solidification methods for the nanosuspension prepared by the bottom-up approach”. The article included other solidification techniques, advantages, manufacturing processes, the corresponding characterization methods, drug dosage forms, and limitations of commercial drug products.

11.1.4 Overview of Cryogenic Technologies

Cryogenic particle engineering technologies were developed to improve the solubility and dissolution properties by creating nanostructured amorphous particles with dramatically enlarged surface area at very low temperature conditions, in contrast to micronized crystalline form of poorly water-soluble drugs (Hu et al. 2002, 2004a, b, c; Rogers et al. 2003a; Overhoff et al. 2007a). Cryogenic technologies basically can be categorized into micro-/nanoparticle precipitation technologies or the so-called “bottom-up” particle engineering technologies , with the mechanism of inducing a rapid change in solute solubility to generate solid particles.

Another example of novel bottom-up process using freeze drying to improve the dissolution behavior of poorly water soluble drugs was reported by De Waard et al. (2008). Nanocrystalline particles of fenofibrate produced by the “controlled crystallization during freeze drying” process significantly increased dissolution of the drug compared to tablets containing the physical mixture. The freeze-dried formulation contained fenofibrate, a drug with low Tg, and mannitol as a carrier since it crystallizes. Freezing rate and the ratio of water-to-tertiary butyl alcohol (TBA) affected the nucleation rate that controlled the size of crystals and dissolution performance. The challenge is how to apply the process to high Tg drugs.

There are some recently reported examples of the bottom-up particle engineering based upon cryogenic technologies. For example, Yasmin et al. (2014) successfully utilized lyophilization to prepare silica–lipid hybrid (SLH) microparticles from submicron o/w emulsions stabilized by silica nanoparticles. The authors reported that the performance of microparticles fabricated from this technique were comparable to those produced using spry drying. Hence this technology is another alternative method to manufacture SLH formulations of poorly water-soluble drugs which are thermally labile and also other challenging drugs to process through spray drying.

To the contrary, a comparison of two processing approaches (spray- and freeze-drying) to manufacture solid phospholipid nanoparticles of celecoxib, a BCS Class II drug, was reported. Celecoxib with phospholipid E80 and trehalose was formulated in various drug-to-excipients ratios. Spherically shaped, amorphous nanoparticles (average diameters <1 μm) were produced by spray-drying; while larger particles of the matrix-like structure of solid amorphous phospholipid dispersion were prepared by freeze-drying. Both products significantly improved the dissolution of the drug. The apparent and molecular solubility of the drug from the spray-dried formulation in phosphate buffer (pH 6.5) and in biorelevant fasted state simulated intestinal fluid (pH 6.5) were considerably higher than the freeze-dried powder. This probably resulted from the difference in particle size and surface morphology (Fong et al. 2015).

As well known, solubility is largely determined by the bonding interactions between the solute and solvent on a molecular level; it is also heavily influenced by external factors including temperature, pressure, polarity of the solvent, and pH. Sudden shift of one of these factors can generate strong driving forces to induce nucleation leading to particle formation. Cryogenic technologies utilize cryogens, such as liquid nitrogen, to induce abrupt temperature change of a system containing solubilized poorly water-soluble drug molecules alone or along with excipient molecules. The rapid cooling rates of up to 1.0 × 106 K/s may produce stable amorphous nanostructured particles with significantly enlarged surface areas to facilitate rapid and higher-level dissolution in biological fluids, thereby enhancing bioavailability.

Generally, cryogenic technologies involve the rapid freezing of single solvent or co-solvent-based solution containing drug alone or alone with stabilizer or solubility enhancer. The generated frozen material is then lyophilized to remove the solvent by sublimation like traditional lyophilization and atmospheric freeze drying (ATMFD) (Derle et al. 2010), thus yielding a dry powder of high surface area. Cryogenic processes are defined by the type of injection device (capillary, rotary, pneumatic, and ultrasonic nozzle), location of nozzle (spraying onto or into a cryogenic liquid, or applying the solution onto a cryogenic substrate), and the composition of cryogenic liquid, such as liquid hydrofluoroalkanes, liquid nitrogen, liquid argon, compressed fluid carbon dioxide, and organic solvents.

In this chapter, spray freeze drying (SFD), SFL, and thin film freezing (TFF) cryogenic technologies for pharmaceutical applications will be discussed in detail. Examples of recent studies using the cryogenic technologies with step-by-step procedures to engineer poorly water-soluble drugs for improved in vitro and in vivo performance will be provided and analyzed. It can be readily recognized that applications of these cryogenic technologies may be applied to other freezing processes.

11.1.5 Commonly Used Cryogens

The most commonly used cryogen in cryogenic processes is liquid nitrogen . Liquid nitrogen is a colorless, odorless, and nonflammable liquid that boils at a temperature of approximately −195 °C. Due to its natural abundance in the atmosphere, liquid nitrogen is relatively cheap and is readily available in large quantities throughout the world. Compared to other liquid cryogens, it is relatively safe and is already accepted for use in certain medical applications. The primary disadvantages of liquid nitrogen are that it can pose a safety hazard as an asphyxiant and it also exhibits a behavior known as the Leidenfrost effect, which in some instances may actually result in decreased freezing rates for droplets that come into contact with the liquid nitrogen reservoir but are shielded by a vapor layer for some amount of time before direct contact can be made with the liquid nitrogen.

Liquid argon is the most common alternative to liquid nitrogen for use in SFD. It has many of the same advantages as liquid nitrogen and also suffers from some of the same disadvantages such as being an asphyxiating agent. It boils at nearly the same temperature as liquid nitrogen at −185 °C; however, it is typically more expensive than liquid nitrogen and less widely available.

Another group of alternatives are liquid hydrocarbons such as liquid propane, pentane, and hexane. They have relatively higher boiling point and wider availability than liquid argon. However, these systems are considerably more dangerous to work with due to their extreme combustibility. Additionally, these materials have not been accepted or tested in use with pharmaceutical products and could be a potential source of contamination when brought into direct contact with drug products.

11.2 Cryogenic Technologies

11.2.1 Spray Freeze Drying (SFD)

SFD has been used in pharmaceutical research for over 60 years and is likely the oldest of the cryogenic pharmaceutical processing technologies. One of the first published papers in the literature describing this technique was in 1948, which was used as a means to produce protein powders with varying surface areas for subsequent absorption isothermal analysis (Benson and Ellis 1948). SFD has historically been used as a method to process thermally labile compounds such as proteins and peptides as well as even larger biological molecules in both the pharmaceutical and food industries (Costantino et al. 2000, 2002; Anandharamakrishnan et al. 2010; Ishwarya et al. 2015) because, unlike spray drying, no heat is required to obtain the final powder formulation. In addition to proteins and peptides, SFD has also been applied to different poorly water soluble drugs in order to enhance their solubility and non-pharmaceutical applications such as food processing (Mumenthalera and Leuenberger 1991; Zijlstra et al. 2007; Tong et al. 2011; Niwa et al. 2012, Niwa and Danjo 2013; Wanning et al. 2015)

Spray-freeze drying was applied to fabricate kinetically stable, amorphous solid dispersions. Compared to the commercial tablet, the kinetically stable, amorphous solid dispersions of the BCS Class IV compound, oleanolic acid, with a stabilizer, a wetting agent and a penetration enhancer produced by SFD technique was superior in terms of in vitro dissolution and uniform absorption. Inter-individual variability in oral absorption is common for the BSC Class IV drugs. This SFD-processed formulation not only improved drug absorption but also reduced the large variability of intestinal permeability, which is the critical problem of the compounds in this class (Tong et al. 2011).

A solution of the poorly water soluble drug, cyclosporine, with mannitol was processed through SFD technique to prepare a dry powder inhaler (DPI). Drug was in the amorphous state while mannitol crystallized during the freeze drying process. The hydrophilic property of mannitol promoted dissolution of the drug. Moreover, drug-mannitol co-formulation exhibited better aerosol dispersion since mannitol successfully improved adhesive and cohesive behavior between the drug particles (Niwa et al. 2012).

Niwa and Danjo (2013) also developed a method combining the wet milling and the SFD techniques to generate a novel product for poorly water-soluble drugs. The suspension was prepared by wet milling of drug in an aqueous medium of polymer as a dispersing agent and then sprayed via SFD to yield a dry nanosized powder. The drug in the porous network structure spontaneously released into the nano-scale suspension and rapidly dissolved in both acidic and neutral media. The SFD formulation exhibited a better dipersability and more efficient dispersing into a nanosuspension compared with the product prepared by spray drying (Niwa and Danjo 2013).

The formation of inhalable micronized porous particles containing the poorly water-soluble corticosteroid, budesonide, and mannitol using SFD technique was investigated. The excipients, hydroxypropyl beta-cyclodextrine and/or l-leucine, were used in the formulation. The results demonstrated that both excipients at a suitable ratio influenced the particle shape and morphology as well as improved aerosol performance and dissolution of the particles (Parsian et al. 2014).

Wanning et al. (2015) recently reviewed pharmaceutical SFDs. SFD not only enhanced solubility of poorly water soluble drugs but also exhibited advantages for pulmonary delivery , intradermal ballistic administration and vaccine delivery to the nasal mucosa as well. The authors summarized different studies using SFD technique to prepare both small molecules and biological products for various routes of administration.

11.2.1.1 Process of SFD

SFD is generally described as a three-step process involving the atomization of a drug feed solution or suspension, freezing the atomized droplets, and removal of solvent from the frozen material to obtain a final, typically amorphous, dry powder composition. The equipment and experimental set-up used in SFD are fairly straightforward; however, there are a few choices to consider at each of the three steps of the process.

In the first step of SFD, solutions or suspensions of drug alone or along with excipient(s) are prepared and atomized into small droplets using specialized fluid nozzles or vibrating orifice droplet generators, over a cryogenic vapor to achieve rapid freezing. The primary aspect to consider is the type of nozzle and atomization parameters utilized. To achieve atomization, one of three different types of atomizing nozzles is typically used, including a two-fluid nozzle, an ultrasound or vibration nozzle, and a monodisperse droplet generator. The primary trade-off in these nozzles is particle-size control versus liquid processing rate.

The two-fluid nozzle allows for the highest processing rates up to 15 L/min, but the particle-size distribution created by these nozzles can easily span several orders of magnitude. The particle-size distribution of a given spray created using a two-fluid nozzle is primarily controlled by the properties of the liquid formulation (i.e., the surface tension and viscosity), nozzle geometry, and the flow rate of the liquid and atomizing gas. Two-fluid nozzles are preferred when fast processing is required but droplet-size distribution, hence final particle-size distribution, is not critical. Another disadvantage of the two-fluid nozzle system is that the large volume of atomizing gas utilized by the nozzle can decrease the efficiency and effectiveness of the cryogenic vapor into which the droplets and atomizing gas are being sprayed. This can increase the cost of the overall process and the rate at which cryogen is consumed.

Ultrasonic nozzles allow for relatively high processing rates, potentially up to 100 mL/min, with a better control of particle-size distribution and more importantly do not utilize large volumes of atomizing gas to generate droplets. The particle-size distribution of a spray created using these nozzles is primarily controlled by the properties of the liquid formulation, the properties of nozzle (i.e., orifice size and atomizing surface area), and the frequency of nozzle vibration. Ultrasonic nozzles are preferred for applications where both control of particle size and reasonably high processing rates are needed.

Monodisperse droplet generators are used when extremely precise controls of droplet and particle-size distributions are required. These systems utilize the same technology present in ink jet printing systems to create a controlled monodisperse droplet size; however, the primary disadvantage of these systems is that they have very low processing rates of about 0.1 mL/min. In addition to slow processing rates, these systems are also more prone to clogging and can process only very low viscosity solutions.

The second step in SFD is the freezing of the atomized droplets of drug solution using a cryogenic vapor . In many cases, the cryogenic vapor is created over a cryogenic liquid reservoir. When the atomized droplets fall through the vapor phase, they then encounter the cryogenic liquid reservoir, which can further ensure that the freezing process is completed. The most commonly used cryogen in SFD is liquid nitrogen vapor. When processing poorly water-soluble drugs using SFD, organic solvents are typically used to prepare the drug in solution/suspension. Very low vapor temperatures are therefore required to ensure the freezing point of the solvents reached.

Once the droplets of drug in solution/suspension have been frozen, the final step is removal of the solvents by sublimation to obtain dry powder form of the engineered drug composition. Traditional lyophilization or ATMFD is typically employed to sublime the frozen solvents. In either case, process conditions during sublimation must be controlled precisely to ensure that no melting occurs, which could potentially undo any advantageous physical properties imparted during the rapid freezing of SFD process.

11.2.1.2 Conventional Lyophilization

Conventional lyophilization is conducted at reduced pressure with vacuum level of few hundred millitorr and low shelf temperature to maintain the frozen SFD-processed material. The lyophilization is broken into two stages known as the primary and secondary drying stages. During primary drying, the temperature and pressure inside the lyophilizer are typically kept below that of the triple point of the solvent. This promotes the sublimation of the frozen solvent from the solid phase directly to the gaseous phase, without allowing any melting. After all or the majority of the bulk solvent has been removed, the process is then shifted to the secondary drying stage, where the shelf temperature is typically brought up to room temperature or higher to remove the molecularly bounded solvent. In most cases, convention lyophilization is utilized as it is well studied and accepted for pharmaceutical process.

The enhancement of dissolution rate and oral bioavailability of solid dispersions of valsartan, a poorly water-soluble drug, prepared by a freeze-drying technique was reported. The alkaline solution without organic solvent containing the API, hydrophilic polymers, an alkalizer, and a surfactant was lyophilized. Hydrogen bonds between drug and polymer were detected by FTIR. The resulting amorphous solid dispersions showed greater dissolution rate and significantly higher oral bioavailability as compared with the bulk drug substance (Xu et al. 2014).

11.2.1.3 Atmospheric Freeze Drying (ATMFD)

ATMFD is conducted at atmospheric pressure conditions and thus does not require a vacuum system. In this case, a cold desiccated gas (typically air or nitrogen) is circulated in and around a mass of frozen product in a fluid-bed-style configuration. For these systems to work properly, the circulation gas needs to be colder than the melting point of the solvent to ensure that no melting occurs. Besides low temperature, the circulation gas needs to have a very low partial pressure of the solvent vapor so that a mass transfer driving force is available to allow for sublimation of the frozen solvent. ATMFD has been utilized and well studied in the food industry (Meryman 1959; Boeh-Ocansey 1983; Rahman and Mujumdar 2012) but only recently, in the past 15–20 years, it has begun to gain some traction in the pharmaceutical literature (Mumenthalera and Leuenberger 1991; Rogers et al. 2003a). Its use in the food industry has been entirely focused on the removal of water as a solvent and for this process it has shown great promise. In specific cases, especially with freezing processes that result in more porous or discrete ice chips/particles (e.g., SFD, SFL, and TFF), ATMFD has actually been proven to be a much faster and more energy-efficient sublimation process due to the vastly increased heat and mass transfer afforded by the use of a fluid-bed configuration (Mumenthalera and Leuenberger 1991). However, in the case of poorly soluble compounds, the process is complicated by the use of cosolvent systems. As with traditional lyophilization techniques, cosolvent systems using organic solvents with lower melting points may prove to be problematic due to the low processing temperatures required as well as the large volumes of gas separation that may be required. When removing water as a solvent, standard refrigeration techniques can be used on the large scale to dry and recirculate desiccated air to ensure that the partial pressure of water vapor in the air is low, but when the solvent phase is something other than water it may be more difficult to remove these vapors from the recirculated dry gas. Theoretically, it should be possible to utilize ATMFD for the sublimation and drying of drug products created using cosolvent systems, but currently very little research exists on this topic.)

Rahman and Mujumdar (2012) reported advantages and limitations of the ATMFD process, a comparison between vacuum freeze drying and ATMFD, a novel approach to ATMFD, types of ATMFD and their applications. In addition, mathematical models for ATMFD process optimization were also presented. The models were related to energy, heat and mass transfer of the drying process. Studies of the drying process sought to overcome the limitations of ATMFD.

11.2.1.4 Pros of SFD Process

One potential advantage of SFD over other cryogenic processes is that it typically results in the highest rate of freezing at around 106 K/s when appropriately small droplet sizes are prepared (Engstrom et al. 2007b). This rapid freezing can be useful when working with poorly water-soluble drugs that may have very rapid rates of recrystallization, or when very high surface area powders are needed.

The most common usage of SFD to date has been in the area of the preparation of proteins and peptides for inhalation as a competing and gentler alternative to traditional spray-drying approaches. In contrast to spray drying, SFD process lacks the usage of high and potentially damaging heat to dry powders, and provides very high production yields of more than 95 % versus about 50 % for spray drying (Maa et al. 1999).

Additionally, the SFD process allows for independent control over both the aerodynamic and geometric particle size of prepared powders, which are critical parameters in the development of formulations for inhalation delivery. This enhanced control is due to the fact that geometric particle size is fixed during droplet formation and subsequent freezing so that a specific final particle size can be selected by controlling the size of droplet that is produced during atomization, whereas with spray drying significant droplet shrinkage and deformation occur due to surface-tension forces imparted as the droplet dries. Aerodynamic diameter, on the other hand, is a function of both geometric particle size and density and, in this case, density can also be controlled independently from geometric size by controlling the solids loading and formulation parameters used to prepare the drug solution that is subsequently processed via SFD (Maa et al. 2004).

11.2.1.5 Cons of SFD Process

Compared to other cryogenic techniques such as slow freeze drying in a vial, SFL, and TFF, SFD process can potentially lower biological activity in cases where pure biological compounds without added excipients. SFL and TFF actually result in even higher level of biological activity, because the large droplets used in these processes have relatively less air–water interface. Whereas SFD utilizes atomized fine droplets, a larger air–water interfacial region is created where absorption and denaturation of proteins can occur. However, several recent studies have shown that this effect can be minimized with the incorporation of excipient(s) (stabilizer, complexing agents, cryoprotectants, and surfactants) (Maa et al. 1999; Costantino et al. 2000, 2002; Yu et al. 2006).

11.2.2 Spray Freezing into Liquid (SFL)

SFL, one of the novel cryogenic particle engineering technologies, was developed and patented (Williams et al. 2003) and subsequently commercialized by The Dow Chemical Company.

11.2.2.1 Process of SFL

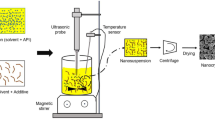

The SFL process involves preparation of a feed liquid, such as an aqueous, organic, or aqueous–organic cosolvent solution, aqueous–organic emulsion, or suspension containing a drug along with pharmaceutical excipient(s) or drug alone: Spray the drug feed liquid under pressure through a small diameter insulating nozzle directly into a liquid cryogen, such as compressed fluid carbon dioxide, helium, propane, ethane, liquid nitrogen, liquid argon, or hydrofluoroethers (Williams et al. 2003). The rapid cooling leads to immediate freezing of the atomized droplets of feed liquid upon contacting the cryogen. A schematic diagram of SFL process is shown in Fig. 11.1. Then the produced frozen materials were collected and subsequently dried by lyophilization or ATMFD as depicted above, to obtain dry and flowable powders of drug compositions.

Schematic diagram of spray freezing into liquid (SFL) process. Reproduced from Rogers et al. (2002b) with permission from Elsevier

The SFL-processed drug powders were generally characterized by micronized structure with amorphous morphology, high surface area, and improved wettability in aqueous media, indicating enhanced dissolution properties of the poorly water-soluble drugs (Hu et al. 2002, 2003; Rogers et al. 2003a, b).

The benefits of SFL process result from intense atomization in conjunction with high freezing rates. Liquid nitrogen has been typically employed as the cryogenic liquid due to nearly instantaneous freezing of the atomized feed liquid resulting from the low boiling point of liquid nitrogen. The nozzle that used to spray feed liquid in SFL process is composed of an insulating material such as poly-ether-ether-ketone (PEEK) tubing to prevent premature freezing of the feed liquid. As the liquid exits the nozzle, liquid–liquid impingement occurs between the pressurized feed liquid exiting the nozzle and the cryogenic liquid, such as liquid nitrogen. The estimated cooling rates are strongly related to droplet particle size of feed liquid, with higher freezing rates observed with smaller droplet sizes due to higher surface area available for heat transfer (Maa and Prestrelski 2000; Engstrom et al. 2007a, b). The cooling rates of SFL process for two different cryogens, iso-pentane and liquid nitrogen, were calculated to be 8.9 × 106 and 1.1 × 105 K/s, respectively (Engstrom et al. 2007a, b). SFL into iso-pentane produced faster cooling rates despite having a higher temperature (−160 °C) compared to liquid nitrogen (−196 °C). This was attributed to the boiling of liquid nitrogen around the inserted spray nozzle and/or sprayed feed fluid formed an insulating layer, known as the Leidenfrost effect (Sitte et al. 1987).

11.2.2.2 Pros of SFL Process

The advantages of the SFL process result from intense atomization of drug feed liquid and the high freezing rates. SFL process used liquid nitrogen nearly exclusively as the cryogen. A very high degree of atomization is achieved by spraying directly into the cryogenic liquid as in contrast to spraying into the vapor phase above the cryogenic liquid, because liquid–liquid impingement occurs between the pressurized feed solution exiting the nozzle and the cryogenic liquid (Rogers et al. 2002b). Thus, high freezing rates can be achieved in SFL process due to the low intrinsic temperature of liquid nitrogen and the high surface area of atomized droplets of the drug feed liquid.

Consequently, amorphous morphology of drug compositions can be formed by SFL process, as a result of the ultra-rapid freezing-induced simultaneous vitrification of the feed solution. The high degree of atomization and ultra-rapid freezing (URF) rates led to the formation of amorphous highly porous nanostructured particles (Hu et al. 2002).

Moreover, it is advantageous to use SFL process to make stable submicron protein drug particles. As discussed previously, SFD has the potential to cause protein aggregation due to the large gas–liquid interface in the spraying step. On the other hand, slow cooling by lyophilization (about 1 K/min) can produce stable protein particles; however, the particle size was found to be a minimum of a few microns in diameter with surface areas less than 1 m2/g. The SFL process can minimize exposure to the gas–liquid interface of droplets containing protein, as the spray nozzle was immersed under the surface of the cryogenic liquid. Thus, the SFL process can reduce protein adsorption, denaturation, and aggregation, and, consequently, lead to higher enzymatic activities than that processed by SFD (Yu et al. 2006; Engstrom et al. 2007a, b). Although the cooling rate in SFL is about 103 K/s, three orders of magnitude less than that in SFD, it is sufficiently fast to arrest the growth of submicron protein particles (Engstrom et al. 2009).

11.2.2.3 Cons of SFL Process

Increase in the drug/excipient(s) concentrations of feed liquid normally leads to increases in viscosity of the feed liquid. The relatively high viscosity of the feed liquid can limit the application of SFL, as it can inhibit liquid jet breakup, resulting in slower cooling rates and larger particle sizes and eventually fibers (Barron et al. 2003).

Moreover, removal of solvent from the collected frozen materials by lyophilization is costly for the equipment (lyophilizers) and is a time- and energy-intensive process that could take days or even weeks to finish (Franks 1992).

11.2.3 Thin Film Freezing (TFF)

TFF, also known as cold metal block freezing, initially was used to cool approximately 100-μm-thick tissue samples at rates between 100 and 10,000 K/s (Gilkey and Staehelin 1986) for nonpharmaceutical application. Impingement and solidification of liquefied droplets onto a cold solid surface have also been used in the electrical and semi-conductor industries to add thin layers of frozen material onto a surface. TFF was also referred as ultra-rapid freezing (URF), spray forming, thermal spray coating, splat cooling, slat quenching solidification, plasma or powder spray deposition, etc. (Overhoff et al. 2009). Recently, TFF has been used as a particle engineering technique to improve the dissolution profiles of poorly water-soluble drugs.

11.2.3.1 TFF Process

In a similar manner to the SFD and SFL processes , the first step in TFF process is preparation of a feed liquid containing a drug along with pharmaceutical excipient(s) or drug alone. Then, droplets of the feed liquid that released from a funnel or a pump/dripper system with a controlled flow rate fall from a given height and impact, spread, and freeze on a cooled surface of a cryogenic substrate, as depicted in a schematic diagram in Fig. 11.2. A cryogenic substrate is selected commonly from materials with a thermal conductivity k between 10 and 20 W/(m K). A rotating cylindrical stainless-steel drum approximately 17 cm in length and 12 cm in diameter with mirror-polished surface was employed to serve as the cryogenic substrate. The drum is hollow with 0.7-cm-thick walls and was filled with cryogen such as dry ice or liquid nitrogen on the inside. As a result of thermal conductivity through the steel, the equilibrium drum surface temperatures were measured to be 223 K or 133 K for dry ice and liquid nitrogen, respectively (Engstrom et al. 2009). The exposure of the cold drum to the atmosphere allowed a thin layer of ice to condense on the drum surface, which may affect the conductivity of the cryogenic substrate, and consequently may affect the freezing rates of the droplets fallen on the drum. To minimize the formation of water-vapor condensation and ice on the steel surface, it is better to place the TFF apparatus in a dry box or humidity-controlled environment with relative humidity less than 15 %. Moreover, a blade made by stainless steel or Teflon is mounted along the rotating drum surface to remove the ice immediately before the droplets of feed liquid impacting the drum.

Schematic diagram of thin film freezing (TFF) process. Reproduced from Overhoff et al. (2007a) with permission from Elsevier

The surface temperature of the drum can be monitored by using a surface moving probe thermocouple attachment. When the temperature on the steel surface reached a proper level, various feed liquids can be applied to the rotating steel drum drop-wise from a height of approximately 10 cm. Upon impacting on the cryogenic surface, the feed liquid droplets (about 2–4 mm in diameter) deformed into thin films (about 100–400 μm in thickness) of disk shape and rapidly cooled until frozen on timescales of 70–1000 ms, which corresponds to a cooling rate of about 102 K/s (Fukai et al. 2000; Pasandideh-Fard et al. 2002), as illustrated in Fig. 11.3 (Engstrom et al. 2009). The frozen disk is scraped off the stainless-steel surface with a blade prior to one full revolution and falls in a collecting pan that filled with dry ice or liquid nitrogen to maintain the frozen disk. After processing a batch, the collecting pan containing the frozen disk is transferred to a lyophilizer where the solvent is removed by sublimation (Overhoff et al. 2007a). The cooling rates in TFF and SFL processes are comparable. Because of rapid conductive heat transfer, resulting in high supersaturation and nucleation rates, TFF process can create powders with high surface area and enhanced dissolution properties, similar to those produced by other rapid freezing technologies. As in other freezing technologies, the rapid freezing of the feed liquid is critical in preventing phase separation of solute and solvent during freezing, allowing for the compositions to molecularly disperse with each other.

Diagram of the thin film freezing process displaying the falling droplet (a), spreading after impact on the stainless-steel surface (b), and during cooling and freezing as a thin film (c) (drawn to scale). Reproduced from Engstrom et al. (2008) with permission from Springer

To tailor the respirable brittle matrix powder, the processing parameters must be taken into consideration. The processing parameters used in the TFF process potentially affected the physicochemical and aerodynamic properties of the resulting matrix powders. Product with improved properties (greater specific surface area, higher porosity and lower density) was prepared at a higher freezing rate by controlling the cryogenic surface temperature. Besides, the lower initial solids content formulation gave the better FPF result possibly due to the increased fragility (Wang et al. (2014a)).

A combination of TFF and another technique (i.e., template emulsion technique) was also used to produce amorphous form of poorly water-soluble drug. The hydrophobic drug was encapsulated into the internal phase of the emulsion through the template emulsion method before rapid freezing through TFF process. Formulation prepared using the TFF-template emulsion technology showed significant improvement of wetting and dissolution properties of the drug (Lang et al. 2014).

11.2.3.2 Advantages of TFF Process

Although the cooling rate in TFF (102 K/s) is lower, compared to those of SFD (106 K/s) and SFL (103 K/s), it is still sufficient to produce rapid nucleation and to prevent significant particle growth during freezing. In TFF process, the size of the unfrozen channels was sufficiently thin and the increase in the viscosity of the unfrozen solution was sufficiently fast to be able to achieve similar particle sizes and morphologies as for the moderately faster process, SFL, and the much faster process, SFD (Engstrom et al. 2008).

TFF on a cold metal surface bypasses the need to maintain aseptic conditions of a liquid cryogen, for example, liquid nitrogen (Gosselin et al. 2003). The cooling rate of the thin films in TFF may be controlled readily by varying the temperature of the metal surface. Also, the surface temperature of the cryogenic substrate may be measured directly. For SFL and SFD, the complex geometry of the turbulent spray in the liquid nitrogen combined with the Leidenfrost effect can be somewhat difficult to control and monitor (Sitte et al. 1987). In TFF, more concentrated and thus more viscous solutions may be processed, as the droplets are not atomized. However, the thickness profile of the film along the radius of the frozen disk may change with viscosity (Overhoff et al. 2009).

TFF process can provide a high yield of products. In TFF, collection of the frozen thin films of the feed liquid droplets leads to nearly 100 % yields, whereas in SFD process yields were about 80 % because of the result of entrainment of uncaptured particles in the atomized aqueous stream, particles attaching to the walls of collection vessels, and inefficient separation of the cryogen from the 10–100-μm frozen particles (Johnson 1997; Overhoff et al. 2009).

TFF process offers flexibility of the amount of drugs to be processed. By using TFF, it is feasible to accommodate either small quantities (<1 mL) of drug feed solution due to the high efficiency in collection of frozen films or large-scale production by adding multiple drippers to make droplets in parallel and increasing the length of the drum. The rotating drum of TFF apparatus offers scale-up advantages over other cryogenic particle engineering technologies by becoming more of a continuous freezing process. Thus, TFF process is not limited by the amount of drug to be processed. It is feasible from the early-stage screening of drug in milligram quantity to commercial product manufacturing at a scale of kilograms to tons.

In addition to the advantage of being a simple, efficient, and robust process for freezing, TFF also renders improvement in the stability of the protein product due to the minimized gas–liquid interface of the feed liquid, in comparison to SFD and SFL. It was found that minimizing gas–liquid interface can improve protein stability by limiting the amount of protein that can absorb to the interface. The surface area to volume ratio of the gas–liquid interface in TFF was 2 orders of magnitude lower than in SFD, leading to much less protein adsorption and aggregation (Engstrom et al. 2008).

11.2.3.3 Disadvantages of TFF Process

First, maintenance of a low humidity for TFF process increases costs for facility design, equipment, and operation, especially for commercial productions.

Second, with all freezing processes, the quantities and quality of cryogen required for manufacturing production-scale batch sizes could also add to production costs. To date, it is not sure which of the aforementioned cryogenic processes is the most cryogenically efficient (Overhoff et al. 2009).

Additionally, similar to the SFL process, removal of solvent from the collected frozen films by lyophilization is costly, for both equipment (lyophilizers) and energy consumption.

11.2.4 Storage of Dried Powders

If the frozen materials were dried by lyophilization, after the lyophilization cycle was complete, the lyophilizer was filled with dried nitrogen gas upon releasing the vacuum to reduce the exposure of the lyophilized powders to moisture in the ambient air before transfer to packaging area, where the humidity is controlled, commonly to less than 15 % RH. The obtained dry powders of the cryogenically processed drug compositions were packaged into hermetically sealed glass containers under dry nitrogen.

11.2.5 Mechanism of Rapid Freezing-Induced Particle Formation

Solubility is heavily influenced by external properties, including temperature, pH, polarity of the solvent, and pressure. Sudden shift of one of these properties can induce nucleation, leading to particle formation. Nanoparticles may be formed by maximizing the supersaturation to induce precipitation instantaneously and then arresting growth (Matteucci et al. 2007). Generally, faster nucleation relative to particle growth leads to a smaller median particle size and more uniform particle-size distribution.

Rapid freezing can be categorized as a precipitation technology, where most of the solvent is separated from the solutes to form ice and the solute phase becomes highly concentrated. Upon initiation of freezing a homogeneous solution, the formation of frozen solvent particles and a drug/polymer-rich phase begin to appear (Tang and Pikal 2004). The rate of cooling in conjunction with other factors, such as solute concentration, plays a key role in determining the final particle size and structure of the solid powders (Overhoff et al. 2007a). The rate of growth and number of solvent crystals in a freezing solution are determined by the degree of supercooling. Higher supercooling results in more/smaller ice crystals and larger ice-specific surface area (Jiang and Nail 1998). As different freezing methods can produce different supercooling effects, freezing with liquid nitrogen basically can provide the highest supercooling, while solutions subjected to slow cooling rates, for example, freezing with the precooled shelf method, give the lowest supercooling. The solvent in the supercooled solution nucleates and forms crystalline solvent particles which grow during freezing. Increased supercooling, in turn, increases the nucleation rate of frozen solvent particles while minimizing the time for frozen solvent particle growth. When the supercooling is extremely high (rapid freezing rate), the formation of a vitrified solution may occur in which the nucleation of crystals may be minimized or fully prevented, leading to an amorphous material (Yu 2001; Overhoff et al. 2009).

During freezing, the supersaturation of the solute in the unfrozen domains as a function of the phase diagram establishes a driving force for precipitation to occur. Particle growth under this condition can occur through condensation of individual molecules onto a growing nucleus, coagulation of two growing particles, or Ostwald ripening, which is the growth of larger structures at the expense of smaller structures (van de Witte et al. 1996). Rapid nucleation at high supersaturation all at one time period will produce uniformly sized particles and lower Ostwald ripening (Overhoff et al. 2009).

As depicted in Fig. 11.4, a greater rapid cooling rate will produce a larger number of nuclei and more solid particles separated by thinner ice domains than in the case of slow cooling and slow nucleation. As the cooling domains vitrify, the high viscosity inhibits the further growth of the particles (Engstrom et al. 2007a, b).

Frozen morphologies of dilute solution with high supercooling (a), concentrated solution with high supercooling (b), dilute solution with low supercooling (c), and concentrated solution with low supercooling (d). Amorphous ice particles are represented as white domains and solute precipitate as solid dots or gray regions. Reproduced from Engstrom et al. (2007b) with permission from Elsevier

11.3 General Guidelines for Cryogenic Technology

11.3.1 Selection of Solvent/Cosolvent Systems for Cryogenic Processes

The first step in the cryogenic processes is to make feed liquids. Despite the diversity of feed liquids (solution, suspension, and emulsion) that can be employed for the cryogenic processes, a complete solution of poorly water-soluble drug alone or along with pharmaceutical excipient(s) was mostly reported.

11.3.1.1 Solubility

Solubility may be defined as the maximum concentration of a substance that may be completely dissolved in a given solvent at a given temperature and pressure. Solute molecules are held together by certain intermolecular forces (dipole–dipole, induced dipole–induced dipole, ion–ion, etc.), as are the molecules of the solvent. In order for dissolution to occur, these cohesive forces of like molecules must be broken and adhesive forces between solute and solvent must be formed. The dissolution process of solids in liquids involves three steps: (1) the removal of a molecule from the solute; (2) creation of a hole in the solvent; and (3) insertion of the solute molecule into the solvent (i.e., solute–solvent interaction) (Hildebrand and Scott 1950). This interaction between the solute and the solvent is obviously dependent on the physical and chemical nature of the participating molecules. The dissolution of hydrophobic materials, which can dissolve readily in nonpolar organic solvents, differs from that of hydrophilic excipient(s) which tend to dissolve in polar aqueous phase.

Generally, hydrophilic excipient(s) would be incorporated into compositions containing poorly water-soluble drug to improve its wettability. To make a feed solution accommodating both hydrophobic API and hydrophilic excipient molecules in a fully dissolved state, it is critical to choose a proper solvent system. One approach is to mix solvents of different polarities to form a solvent system of optimum polarity to dissolve the solutes of different polarities. This method is referred to as solvent blending or cosolvency. When talking about liquids, the term miscibility rather than solubility may be used to describe the affinity between the liquids (Conventional 2000). Liquids that form a homogenous system when mixed in any proportion are said to be miscible (e.g., water and ethanol). Those in which only certain volume ratios produce homogenous mixtures are said to be miscible in certain proportions (e.g., water and chloroform). Immiscible liquids will not produce a homogenous solution in any proportion (e.g., water and olive oil). For the cosolvent used to make feed solution, the solvents must, obviously, be miscible. For example, tetrahydrofuran/water co-solvent was used to form feed solutions for SFL process, because of the ability to dissolve both a poorly water-soluble drug and hydrophilic excipients (Hu et al. 2002; Rogers et al. 2002b). Some poorly water-soluble drugs have relatively low solubility in the tetrahydrofuran/water co-solvent; later on, acetonitrile, acetone, methanol, methylene chloride, 1,3-dioxolane, tert-butanol, and 1,4-dioxane were used to greatly increase the solubility of drugs. However, the percentage of methylene chloride in cosolvent should be less than 1 % to be miscible. Worthy to note is that for the use of low-melting-point solvents, a liquid nitrogen cold trap is necessary to capture the solvent vapor before sucked into vacuum pump during lyophilization.

11.3.1.2 Fluid Dynamics

For SFL process, viscosity of the solvent is an important factor that needs to be considered for preparation of the feed solution to be sprayed through the nozzle into liquid cryogens. Additionally, the melting point of the solvent(s) used in SFL process is better not higher than 0 °C; otherwise, the feed solution may freeze prematurely within the atomizing nozzle before sprayed into cryogens. Examples of case are tert-butanol and 1,4-dioxane, in which many poorly water-soluble drugs show good solubility. However, due to their relatively high viscosity, 3.62 and 1.54 cP, respectively, compared to other organic solvents, and high melting point for liquid, 25 and 12 °C, respectively (see Table 11.1), they are not proper candidates for SFL. Because the TFF technology applies the droplets directly onto the cryogenic substrate, premature freezing is not a concern and solvents with high melting point may be used.

Nevertheless, TFF process also requires consideration of the fluid dynamics for the solvent during spreading and freezing. The ability of an impinging droplet on the cryogenic substrate to spread into a thin large-diameter disk prior to freezing influences the cooling rate of the thin disk. Danazol/polyvinylpyrrolidone (PVP) powders were produced under the same TFF process except for using acetonitrile and tert-butanol, respectively, as the solvent. It was observed that the powder from acetonitrile solution exhibited more uniform nanostructured surface morphology compared to the powder from tert-butanol solution. The morphological difference was attributed to the cooling rate of the two solvents (Overhoff et al. 2007a, 2009). Moreover, solvents of the feed solution with greater thermal diffusivities are more desirable for rapid heat transfer. The rapid heat transfer in TFF process is the result of intimate contact between the solution and cryogenic substrate.

11.3.1.3 Ease of Lyophilization

Freeze drying, i.e., lyophilization , is the commonly used means to obtain dry powder from the cryogenically generated materials by removing the solvent(s). The ideal solvent for freeze drying has the following properties: a high vapor pressure, a melting point either below or slightly above room temperature, a high viscosity, and a low toxicity. It must provide a stable environment for freeze drying and be rapidly and completely removed to produce dry material (Ni et al. 2001).

A variety of different types of organic solvents were used in cryogenic processes, as mentioned in Table 11.1. Most of these water-miscible organic solvents have freezing points below −75 °C. The frozen disk made by the low-melting-point solvents tends to melt during lyophilization and it makes a very challenging task for the lyophilizer condenser to catch the sublimed vapor of these solvents. A cold trap between lyophilizer sample chamber and vacuum pump is necessitated to prevent the solvent vapor from being sucked into the vacuum pump.

Accordingly, organic solvents with higher melting point are of great interest for selecting proper solvent for cryogenic process. Acetonitrile, having a melting point of −45 °C, viscosity of 0.34 cP, good heat transfer, and the unique ability to dissolve both a hydrophobic drug and hydrophilic excipient(s), was widely employed for many compositions containing poorly water-soluble drug in both SFL and TFF processes to increase drug loading with reduced risk of liquid–liquid phase separation. More importantly, the high vapor pressure of 73 mmHg at 25 °C eases the removal of the solvent by lyophilization.

Subsequently, high-melting-point solvents 1,4-dioxane and tert-butanol were often employed in studies of TFF process, which has less concern of premature freezing compared to SFL. Tert-butanol was often used in combination with low-melting-point solvent system for its easy-to-freeze and good lyophilization characteristics. As a result of its high vapor pressure (Table 11.1) and its crystal morphology, the sublimation rate of tert-butanol is greater than 2.5 times that of water. 1,4-dioxane/water co-solvent was extensively used to make feed solutions for TFF process (Overhoff et al. 2007a, b; DiNunzio et al. 2008; Yang et al. 2008a, b), mainly due to its relatively high freezing point and vapor pressure which make the freezing and lyophilization processes easily manageable. These solvents prove beneficial by reducing the lyophilization time (Ni et al. 2001) or eliminating the solvent-removal process altogether as some of these solvents sublime at ambient conditions or higher (Tesconi et al. 1999). Moreover, they have low biological toxicity and basically no harmful impact to the environment.

According to these criteria, a solvent with these ideal properties may not exist for cryogenic processes.

Formation of co-solvent systems can mitigate limitations of certain solvents (solubility) while maintaining some of the ideal fluid dynamics and lyophilization characteristics. Combinations of 1,3-dioxolane (solubility enhancer) and tert-butanol (ideal freezing and lyophilization properties), tetrahydrofuran and water (both are solubility enhancers), acetonitrile (solubility enhancer and freezing and lyophilization properties) and water, and 1,4-dioxane (solubility enhancer and freezing and lyophilization properties) and water have been used to generate nanostructured poorly water-soluble drug compositions using cryogenic technologies.

11.3.2 Selection of Excipients , Concentrations for Drug Formulations Using Cryogenic Processes

The ultimate goal of cryogenic particle engineering technologies is to improve the dissolution properties of poorly water-soluble drug by making an amorphous nanoparticulate form of the drug. However, a primary concern of the formed amorphous material is the inherent instability, due to the higher energy state. Amorphous material may automatically convert back to a low-energy crystalline state. Recrystallization of the amorphous drug may be avoided by inclusion of stabilizing hydrophilic excipients in the composition. Principally, stabilizing excipients combat recrystallization of amorphous drug particles by steric hindrance and/or the formation of hydrogen bonds with drug molecules (Khougaz and Clas 2000; Vasanthavada et al. 2005). These stabilizing excipients must be hydrophilic for improving the wetting properties of drug particles; however, the hydrophilic excipients should not be hygroscopic. Otherwise, they absorb moisture easily when exposed to ambient environment, which can lead to morphological instability of the excipient-stabilized amorphous drug particles by either displacing drug molecules from hydrogen-bonding sites or plasticizing polymeric stabilizers (Forster et al. 2001; Vasanthavada et al. 2004).

As morphological instability and poor wettability are the substantial limitations to particle engineering of poorly water-soluble drugs, concessions need to be made in selecting appropriate stabilizing excipient(s), with respect to rigidity for steric hindrance or hydrophilicity. Many readily soluble and/or wettable excipients do not provide adequate steric hindrance of recrystallization due to low melting points or glass transition temperature (T g). On the contrary, excipients with high melting points or T g’s typically have relatively poor wetting properties. Therefore, polymers with high glass transition temperature (T g) and hydrophilicity, such as PVP and hydroxypropylmethylcellulose (HPMC), are popular candidates to formulate poorly water-soluble drugs for improved aqueous dissolution. To expand the choices of polymers, combinations of rigid and malleable excipients such as surfactants (e.g., poloxamer, sodium dodecyl sulfate, and Tween 80) often can be used to achieve reasonable stability and wettability. Other commonly used polymers include polyvinyl pyrrolidone-covinyl acetate (PVP/VA), hydroxypropylmethylcellulose acetate succinate (HPMCAS), high-molecular-weight polyethylene glycol (PEG), polyvinyl alcohol (PVA), polylactic acids (PLA) and polylactic-co-glycolic acid (PLGA), etc. Catalytic pretreated softwood cellulose (CPSC) isolated from pine wood (Pinus sylvestris) was recently used as a stabilizing carrier polymer of the cryogenic co-ground spray-dried formulation of poorly water-soluble drug (Penkina et al. 2015).

Besides polymers, nonpolymeric natural products (e.g., lecithin) and small-molecule hydrophilic excipients (e.g., sugars) can also be employed to enhance wettability and solubility of poorly water-soluble drugs, with better safety profiles. Sugars such as lactose, sucrose, trehalose, and, recently, fructose oligomer inulin were frequently used as an excipient to stabilize amorphous drugs, peptides, and proteins during drying and subsequent storage (Davies and Feddah 2003; Van Drooge et al. 2004). The addition of sugars has been shown to extend the shelf life of amorphous systems by preventing crystallization (Eriksson et al. 2003).

On the contrary, drugs with low Tg were important for freeze-drying of poorly soluble drugs. To fabricate nanocrystals, fenofibrate, a low Tg, poorly water soluble drug, was mixed with mannitol. Excipient such as mannitol was selected for this process since it was susceptible to crystallize. The produced nanocrystalline particles of poorly water soluble drug also drastically enhanced dissolution of the poorly water-soluble drugs (De Waard et al. 2008).

Worthy to note is that excipient to drug ratio is also an important consideration in formulation design. First, excipient to drug ratio may affect the morphology of the engineered drug composition. The T g of the overall drug composition is a function of the fraction of each component. If there is more amorphous material present in the drug composition, more stabilizing polymer would be needed to be present; otherwise, it may lead to a greater risk of recrystallization. Second, excipient to drug ratio affects hydrophilicity of the engineered drug compositions. It has been demonstrated that as the potency of a poorly water-soluble drug composition increased, the wettability is often decreased, particularly for the matrix system of a drug composition where drug and excipient molecules distribute randomly. Hydrophilic excipients act at the surface of drug composition particles to reduce the solid–liquid interfacial tension between the hydrophobic drug and aqueous media (Sinswat et al. 2005). As potency is increased, a greater proportion of the particle surface area is occupied by drug molecules; hence, the surface is rendered more hydrophobic, i.e., less wettable. Thus, it is often difficult to achieve high-potency drug particles with acceptable wetting properties. However, by carefully selecting excipient(s) and controlling the proportions of drug and excipient(s) in the cryogenically processed drug compositions, it was also possible to achieve high-potency drug compositions with improved wettable surface and high stability against recrystallization. An SFL-processed danazol/PVP K-15 composition with high potency of 91 % was reportedly maintained in its amorphous structure and rapid dissolution characteristics after 1 month of cycled stability conditions (−5 to 40 °C every 3 h) (Hu et al. 2004a, b, c).

In addition to the considerations for characteristics and stability of drug composition, formulation design also needs to comply with regulatory requirements for final dosage forms. It is important to judiciously select excipients that have been accepted/approved by FDA for specific administration routes. Especially for parenteral and pulmonary deliveries, only very limited excipients are approved for use, mainly including biocompatible and biodegradable materials.

Moreover, the total solid loading (drug plus excipients), particularly the excipient to drug ratio in the feed solution for cryogenic processes, affects morphology and surface area of the cryogenically engineered drug compositions. Typically, a higher solid loading infers denser engineered drug composition powder, accordingly, the lower the surface areas of the powder. Itraconazole and hydroxypropylmethyl cellulose phthalate (HP-55) at 2.0 % solid loading demonstrated a porous matrix structure as seen from Fig. 11.5a, b, while decreasing the solid loading to 0.2 % formed discrete nanoparticles, as shown in Fig. 11.5c, d. At 0.2 % solid loading, low polymer loading showed amorphous string-like structures (Fig. 11.5c), whereas increasing the polymer ratio resulted in more spherical nanoparticles (Fig. 11.5d), indicating that the surface morphologies are strongly influenced by the percentage of polymer in the composition. By manipulating the solid loading and polymer portion in the feed solution for cryogenic processes, drug compositions with desired characteristics may be tailored. For example, low-density powders of drug compositions intended for pulmonary delivery can be produced from a feed solution with drug loading commonly in the range of 0.5–1 % (w/v). To make drug composition powders to be further processed into tablets or capsule dosage forms, the feed solution may be made to above 5 % (w/v) if solubility permitted, so that much denser powders can be obtained to press into tablets or fill into capsules.

Scanning electron micrographs of TFF-processed powders containing ITZ and hydroxypropylmethyl cellulose phthalate (HP-55) at various solid loading and drug polymer ratios: (a) 4:1HP55 (2 %), (b) 1:4HP55 (2 %), (c) 4:1HP55 (0.2 %), (d) 1:4HP55 (0.2 %). Reproduced from Overhoff et al. (2007b) with permission from Elsevier

11.3.3 Properties of Pharmaceutical Powders Made by Cryogenic Processes

11.3.3.1 Engineered High Surface Area Powder for Oral Drug Delivery

Based on the extensive studies of the cryogenic particle engineering technologies, drug compositions processed by these technologies have been shown to create nanostructured amorphous particles with dramatically enlarged surface area and improved dissolution properties, in contrast to crystalline bulk drug. Additionally, these processes allow molecular incorporation of hydrophilic pharmaceutical excipient(s) to drug compositions, leading to improvement of the wetting characteristics of the bulk poorly water-soluble drug powder (Hu et al. 2002, 2004a, b; Rogers et al. 2003a, b; ; Overhoff et al. 2007a; Purvis et al. 2007; Yang et al. 2008b). The cryogenic technologies are primarily precipitation, i.e., “bottom-up,” processes, allowing for a reduction in the particle size of drug particles without degradation that induced by heating or mechanical process. As discussed in Sect. 12.2.5 amorphous morphology and uniform small particle size result from the very rapid freezing rates of these processes. Both the spray of drug feed solutions to produce tiny droplets and impinging of the feed solution drop on a solid substrate to form a spreaded very thin layer of liquid enable dramatic enlargement of surface area, which, in turn, enhance the rapid freezing process. According to the Noise–Whitney equation

where dM/dt is the rate of dissolution, A is the surface area available for dissolution, D is the diffusion coefficient of the compound, C s is the solubility of the compound in the dissolution medium, C is the concentration of drug in the medium at time t, and h is the thickness of the diffusion boundary layer. With dramatically increased surface area and decreased particle size, the dissolution rate can be increased. Furthermore, the formation of metastable amorphous form yields higher energy states for the drug and thus a greater thermodynamic driving force for dissolution. Therefore, both dissolution rate and the extent of dissolution are improved, i.e., achieved supersaturation of the drug.

The very rapid freezing of the cryogenic processes enables production of amorphous nanostructured pharmaceutical powders with relatively small amounts of excipient(s) to achieve high drug loadings of commonly 50–86 % drug/total solids, while maintaining high dissolution rates.

Besides the excellent performance of the cryogenically engineered pharmaceutical powders in pulmonary delivery, rapid-release tablet formulation containing SFL-processed danazol micronized compositions by direct compression was also reported (Hu et al. 2004a, b, c). The high surface area, high porosity, and amorphous structure of the SFL-processed danazol compositions contribute to their significantly enhanced dissolution profiles. However, these properties may be changed during the process of incorporation of other tablet excipients and tableting compression. By selection of suitable excipients and direct compression without involving water in the tableting, it was found that over 90 % of danazol released in only 10 min from tablets containing SFL-processed danazol composition (danazol/PVP K-15/SLS = 4:1:1), similar to the dissolution profiles of the SFL composition itself. The amorphous morphology was also maintained. Utilizing high T g excipient in the SFL-processed composition was contributed to prevent recrystallization of the SFL-processed danazol during the tableting process.

An alternative means is to fill the cryogenically engineered pharmaceutical powders into capsules for oral delivery. A solid solution of itraconazole (ITZ) and enteric polymer cellulose acetate phthalate (CAP) (ITZ:CAP = 1:2, w/w) was created by TFF process (DiNunzio, Miller et al. 2008). In vitro supersaturated dissolution results demonstrated significantly lower levels of supersaturation in acidic media and greater extents of supersaturation in neutral media compared to Sporanox pellets, the marketed product of itraconazole. Both the ITZ:CAP = 1:2 and Sporanox pellets were filled into size-9 capsules and dosed to rats. The pharmacokinetics study indicated that ITZ:CAP = 1:2 achieved 2 times higher oral bioavailability and more rapid onset of action versus Sporanox® pellets. The amorphous nature of TFF-engineered ITZ:CAP = 1:2, the intestinal targeting, and the increased durations of supersaturation rendered by enteric polymers were needed to contribute to the improved bioavailability.

A novel way recently patented is utilization of hot-melt extrusion process to prepare extrudates employing relatively low-melting/softening-temperature polymer or a blend of polymers as carrier and cryogenically engineered pharmaceutical powders (Miller et al. 2008). It is critical to conduct the extrusion at a temperature approximating or above the softening or melting temperature of the carrier polymer and below the point of solubilization of drug-containing particles in the carrier system, and below the recrystallization point of amorphous drug in the drug-containing particles. Therefore, high T g excipient(s) need to be employed in the preparation of cryogenically engineered pharmaceutical powders. The obtained extrudate containing the cryogenically engineered pharmaceutical powder particles can be milled for further tableting or capsule filling for oral administration.

Compared to the conventional dosage forms, the lower amount of excipients and drug in cryogenically processed drug compositions to be delivered to patients can provide increased patient compliance, safety, and therapeutic efficacy of the poorly water-soluble drugs (Yang et al. 2008b).

11.3.3.2 Brittle Matrix Powder for Pulmonary Drug Delivery

In addition, cryogenically engineered pharmaceutical powders with the properties described above also offer the versatility of being further assembled into diverse dosage forms for application, such as oral, parenteral and pulmonary delivery. The most extensively explored application is pulmonary delivery, including application of the engineered pharmaceutical powders directly in powder form to various dry powder inhaler (DPI) devices, making aqueous dispersion of the pharmaceutical powder for nebulizers, and dispersing the pharmaceutical powders in propellants such as hydrofluoroalkanes (HFA) for pressurized metered dose inhalers (pMDI).

Pulmonary drug delivery is of great interest due to its targeted delivery of drug to the pathological sites. However, for inhalation delivery, particle-size distribution and morphology of the drug-containing particles have pronounced effects on drug deposition in the respiratory tract and therapeutic effects. There are some drawbacks of nebulization of tacrolimus such as reconstitution, long dosing times, and inefficiently targets the lung. Moreover, drug lost during patient exhalation of more than 50 % resulted in a low efficient therapeutic of drug delivery via vibrating mesh nebulizer and lead to the development of dry powder inhalation formulation (Watts et al. 2013). Unpublished data from our laboratory showed that TFF-engineered dry powders containing tacrolimus and nonpolymer excipient (e.g., sugars) featured with low-density (0.01–0.03 g/mL), high-surface-area amorphous brittle matrices composed of sub-500-nm primary structures. The aerodynamic profiles of the tacrolimus dry powders indicated that they are suitable for deep lung delivery by filling the powders into size-3 capsules and used in Handihaler® and Easyhaler® DPI devices. Shear stress from the Handihaler® DPI device affected the diameter of the respirable brittle powders.

The brittle matrix powders for pulmonary drug delivery of various drugs were prepared using TFF. Formation of the tremendously low-density (<0.01 g/cm3) microparticles of tacrolimus were generated by in situ high shear velocity in a passive commercial pMDI device. The formed particles were delivered to the deep lung.

Lactose and raffinose exhibited better properties than mannitol which showed similar performance to the pure drug formulation. However, both saccharides were hygroscopic materials so, the formulations required a moisture barrier package. On the other hand, mannitol based formulation was less sensitive to humidity (Watts et al. 2013).

The in vitro and in vivo performance the TFF brittle powder and crystalline micronized formulations of tacrolimus were reported by Wang et al. (2014b). Miat® monodose inhaler was used to deliver the low-density particles of tacrolimus to the deep lung. The mass median aerodynamic diameter (MMAD) of 2.26 μm and a fine particle fraction (FPF) of 83.3 % were achieved. Pharmacokinetic results revealed that the brittle powder exhibited higher pulmonary bioavailability but lower systemic concentration than the crystalline dry powder formulation. Moreover, perhaps due to the decreased clearance, the TFF powder retained in the lung longer than the other.