Abstract

A demonstration of the feasibility of application of iron phosphate (vivianite) nanoparticle techniques, coupled with phytoremediation, for remediation of heavy metal contaminated soil and water resources is proposed for urban and peri-urban areas of Ulaanbaatar and also developing mining regions of Mongolia. The work will be followed by more wide spread application of the remediation technique and strengthening of the environmental assessment and analytical capacity of government public health and environmental management agencies. Remediation of metal contaminated soils due to anthropogenic inputs from urban development and mining activity in Mongolia is considered an important issue by the World Health Organization and the Mongolian Government. Such remediation is urgently required within Ulaanbaatar and at sites such in the Zaamar district, Tuv Province, downstream in marshes and mires of the Tuul River and also in the Boroo River catchment. Silt, mud and metals have contaminated large areas as a consequence of large multi-national mining operation, widespread artisanal mining and other unregulated mining activities. The current situation and approaches to be taken are considered.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

8.1 Introduction

Remediation of metal contaminated soils and water resources, due to urbanisation and mining activity in Mongolia, is considered an important issue by the World Health Organization and the Mongolian Government. The problem of heavy metal contamination has been reported both in the capital city, Ulaanbaatar with a population of approximately 1.4 million, and also in many regional areas of Mongolia (Chung and Chon 2014; Murao et al. 2006; Tumenbayar 2003; World Bank 2006). The body burden and human health impact resulting from the use of mercury in artisanal gold mining is high not only in the miners themselves, an increased mercury hazard was also found for inhabitants of mining areas who were not actively involved in mining (Steckling et al. 2011).

8.2 The Situation

Ulaanbaatar, the capital city of Mongolia in the central Asia (Fig. 8.1), is reliant on a coal-based fuel–energy complex which is one of the major sources of environmental pollution. The city has three coal-fired thermal power plants and about 100,000 dwellings using coal for their heating and cooking. About half of the city inhabitants live in apartments and the other half in traditional tents (gers) and small individual houses. About 80 % of inhabitants living in apartments use central heating and hot water from the three thermal power plants which are located in the city center, and the rest of the inhabitants of apartments use heating boilers and individual stoves. Their basic fuel is brown coal of the Baga Nur, Nalaikh, and Chulut deposits, which are enriched in Pb, As, and Mo. Control or reduction of coal combustion emissions is uncommon. Gasoline in the country is treated with tetraethyl lead and catalytic converters are rarely present or functional. These conditions have resulted in poor air quality, soil and water pollution with contaminants including Hg, As, Zn, Cu, Cr, Cd, Mo and Pb (Kasimov et al. 2011).

In recent years, artisanal gold mining (digging and smelting by individuals, usually unregulated) is increasingly gaining momentum in developing countries as a subsistence activity. In Mongolia, it is largely practiced in rural areas by unemployed or struggling herder populations who lack the requisite education, training, management skills and equipment required to carry-out such activities in an environmentally sustainable fashion. It is estimated that the total number of artisanal miners in Mongolia is about 50,000, including approximately 25,000–35,000 artisanal miners who are panning placer gold in the North Khentei gold belt. Contamination from their activities includes elemental Hg waste, tailings, silt and mud runoff containing Hg, Pb and other metals. These workers are called “Ninja” miners because their clandestine activity in narrow, irregular, mining excavations reminds people of historical Japanese secret service mercenaries, Ninja. (Murao et al. 2006).

Silt, mud and metals have contaminated large riverine, wetland and mire areas as a consequence of widespread artisanal mining and other mining activities (Figs. 8.2 and 8.3). It has been reported that placer gold mining (mining of stream bed or alluvial deposits) at the Zaamar site has increased the total riverine mass flows of Al, As, Cu, Fe, Mn, Pb and Zn by 44.300, 30.1, 65.7, 47.800, 1.480, 76.0 and 65.0 tonnes per year, respectively (Thorslund et al. 2012). Remediation is urgently required at sites within Ulaanbaatar and in the Zaamar district, Tuv Province, downstream in marshes and mires of the Tuul River and in the Borro River catchment. The importance of wetland nutrient transformation has been noted in Mongolia, however, the potential of wetland systems for heavy metal and sediment management has not been recognized (Itoh et al. 2011). The above contaminated areas are within an approximate 200–300 km radius of Ulaanbaatar (Fig. 8.4), predominantly in the NW and NE sectors.

Unlike many other developing countries, artisanal mining is not part of traditional subsistence economy in Mongolia. It is suggested that the initiation of artisanal mining and its dramatic growth over the past decade, particularly in terms of organizational structure, is an outcome of poverty-driven self-help efforts to reduce some of the more insidious effects of developing a market economy, including job loss, declining real incomes, decline in rural services, and the difficulty all governments face in providing a rural safety net particularly in the face of natural disasters and climate change (World Bank 2006).

8.3 Remediation Options and Recommendations

A number of remediation approaches have been used to diminish toxic effects of metals in the environment. Remediation of metal contaminated soil and sediment may involve separation, excavation, thermal extraction, stabilisation or biological methods. Physical separation processes are used to reduce the volume of metal contamination in size or type for further treatment. Excavation of contaminated soils and impoundment in landfill is a conventional method in developing counties (Figs. 8.5 and 8.6). However, this technique is environmentally disruptive and can result in an increased risk of heavy metal leaching (Mulligan et al. 2001).

Schematic representation of river diversion, dredging and overburden placement as used in mining operations at Zaamar, Tuv province, Mongolia. The technique results in major ecosystem disruption, sediment discharge, downstream metal contamination and is often left with no rehabilitation, resulting in further erosion and sediment discharge. The sequence could be modified with wetland creation to minimize sediment inputs to downstream waters and erosion of diversion channels

Prevention of pollution is always preferable to follow-on remediation. It is important to emphasise that mining, industrial and agricultural activities should always use environmentally sustainable and responsible methodologies. As such practices are commonly not rigorously followed in both developed and developing countries, metal contamination is a difficult and wide spread issue in many parts of the world. Heavy metal remediation techniques such as excavation and disposal or physical separation of contaminants from polluted sites are often inappropriate to apply in large and heavily contaminated areas due to economic, site social and ecosystem disruption and energy constraints. It is suggested that immobilization techniques, coupled with phytoremediation options, are more feasible and economical approaches in situations such as are present in Mongolia.

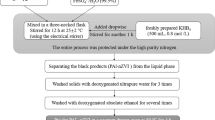

Previous studies have investigated the feasibility of iron phosphate (vivianite) nanoparticles for stabilisation of heavy metals in wetland sediments. Plant species such as Helianthus annuus were also used to phytoremediate the stabilised heavy metals. The effectiveness of the treatment was verified by examining nanoparticle sequestered metal leachability (Fig. 8.7), bioavailability and speciation in sediments using a Toxicity Characteristic Leaching Procedure, Physiologically Based Extraction Test and Sequential Extraction Procedures, respectively (Bavor and Shinen 2015; Rauret 1998; Ruby et al. 1999; USEPA 1992). These studies focussed on Cu and Zn, however, a number of researchers have reported significant immobilisation/phytoremediation , using similar approaches for As, Pb and Hg (Almaroaia et al. 2014; Cabrejo and Phillips 2010; Ferreyroa et al. 2014; Goldowitz 2006).

Toxicity Characteristic Leaching Procedure (TCLP) showing reduction in Cu and Zn leachability in untreated and nanoparticle (VPN) amended sediment. Leaching solution consisted of glacial acetic acid & sodium hydroxide (USEPA Method 1311, 1992). Total reduction of leachability was 22 % for Cu, 69 % for Zn

A demonstration program for the feasibility of application of iron phosphate (vivianite) nanoparticle techniques, coupled with phytoremediation , for remediation of heavy metal contaminated soil and wetland linked water resources is recommended for establishment in selected contaminated sites within Ulaanbaatar and at sites such in the Zaamar district catchment area, Tuv Province, downstream in marshes and mires of the Tuul River and also in the Boroo River catchment.

The program should include the following components in an integrated remediation approach:

-

Strengthen laboratory capability and field monitoring skills.

-

Staff training.

-

Infrastructure development – equipment, reagents and standards for sediment, plant biomass and water analysis.

-

Characterize concentration, form and distribution of metals at selected site(s).

-

Establish objectives and linkages with local stake holders.

-

Establishment of small scale demonstration site(s) to verify remediation technique, linking immobilisation and phytoremediation techniques.

-

Up-scale application of selected technique protocols to large field site.

-

Monitoring to manage and confirm efficacy of remediation.

-

Consideration of more wide-scale application of remediation.

8.4 Conclusions

Pollutant inputs from increased urbanisation and both regulated and unregulated expansion of the mining activities in Mongolia have resulted in an urgent need for heavy metal remediation of soil and water resources in urban and peri-urban areas of Ulaanbaatar and also in contaminated mining-activity regions of Mongolia.

A number of studies have investigated nanoparticle and phytoremediation technologies for the stabilisation of heavy metals. The studies support the establishment of an integrated feasibility program to demonstrate of use of wetland-linked nanoparticle and phytoremediation technology for stabilisation/removal of heavy metals in contaminated sediments and water resources. Experimental data indicates that stabilised nanoparticles can effectively decrease the leachability and bioimpact of heavy metals. Further, the approach has been estimated to be economical and have ancillary ecosystem benefits. Such a program would require a government multi-agency approach and, given the developing country status of Mongolia, mining industry and/or international funding assistance would be needed.

References

Almaroaia, Y.A., Vithanagec, M., Rajapakshaa, A.U., Leea, S.S., Doud, X., Han Leee, Y., Sungf, J., & Sik Oka, Y. (2014). Natural and synthesised iron-rich amendments for As and Pb immobilisation in agricultural soil. Chemistry and Ecology, 30(3), 267–279.

Bavor, H.J., & Shinen, B. (2015). Assessment of immobilization and biological availability of iron phosphate nanoparticle-treated metals in wetland sediments. In: J. Vymazal (Ed.), The role of natural and constructed wetlands in nutrient cycling and retention on the landscape (pp. 33–40). Cham: Springer International Publishing Switzerland.

Cabrejo, E., & Phillips, E. (2010). In situ remediation and stabilization technologies for mercury in clay soils. U.S. Department of Energy -FIU Science & Technology Workforce Development Program. Report ARC-2007-D2540-032-04. https://clu-in.org/download/contaminantfocus/mercury/Mercury-Cabrejo-2010.pdf. Assessed 24 Mar 2015.

Chung, S., & Chon, H. (2014). Assessment of the level of mercury contamination from some anthropogenic sources in Ulaanbaatar, Mongolia. Journal of Geochemical Exploration, 147, 237–244.

Ferreyroa, G.V., Montenegro, A.C., Tudino, M.B., Lavado, R.S., Molina, F.V. (2014). Time evolution of Pb(II) speciation in Pampa soil fractions. Chemical Speciation and Bioavailability, 26(4), 210–218.

Goldowitz, I., & Goldowitz, J. (2006) Phytoremediation of lead contaminated soil in the urban environment using seed mustard. In: E. J. Calabrese, P. T. Kostecki, J. Dragun (Eds.), Contaminated soils, sediments and water volume 10: Successes and challenges (pp. 271–276). New York: Springer Science-Business Media, Inc.

Itoh, M., Takemon, Y., Makabe, A., Yoshimizu, C., Kohzu, A., Ohte, N., Tumurskh, D., Tayasu, D., Yoshida, N., Nagata, T. (2011). Evaluation of wastewater nitrogen transformation in a natural wetland (Ulaanbaatar, Mongolia) using dual-isotope analysis of nitrate. Science of the Total Environment, 409, 1530–1538.

Kasimov, N.S., Kosheleva, N.E., Sorokina, O.I., Bazha, S.N., Gunin, P.D., Amgalan, S.E. (2011). Ecological–Geochemical state of soils in Ulaanbaatar (Mongolia). Eurasian Soil Science, 44(7), 709–721.

Mulligan, C.N., Yong, R.N., Gibbs, B.F. (2001). Remediation technologies for metal-contaminated soils and groundwater: An evaluation. Engineering Geology, 60, 193–207.

Murao, S., Naito, K., Dejidmaa, G., Sie, S.H. (2006). Mercury content in electrum from artisanal mining site of Mongolia. Nuclear Instruments and Methods in Physics Research B 249, 556–560.

Rauret, G. (1998). Extraction procedures for the determination of heavy metals in contaminated soil and sediment. Talanta, 46, 449–455.

Ruby, M.V., Schoof, R., Brattin, W., Goldade, M., Post, G., Harnois, M., Mosby, D.E., Casteel, S.W., Berti, W., Carpenter, M., Edwards D., Cragin, D., Chappell, W. (1999). Advances in evaluating the oral bioavailability of inorganics in soil for use in human health risk assessment. Environmental Science and Technology, 33, 3697–3705.

Steckling, N., Boese-O’Reilly, S., Gradel, C., Gutschmidt, K., Shinee, E., Altangerel, E., Badrakh, B., Bonduush, I., Surenjav, U., Ferstl, P., Roider, G., Sakamoto, M., Sepai, O., Drasch, O., Lettmeier, B., Morton, J., Jones, K., Siebert, U., Hornberg, C. (2011). Mercury exposure in female artisanal small-scale gold miners (ASGM) in Mongolia: An analysis of human biomonitoring (HBM) data from 2008. Science of the Total Environment, 409, 994–1000.

Thorslund, J., Jarsjo, J., Chalov, S,R., Belozerova, E.B. (2012). Gold mining impact on riverine heavy metal transport in a sparsely monitored region: The upper Lake Baikal Basin case. Journal of Environmental Monitoring, 14, 2780–2792.

Tumenbayar, B. (2003). Action research on mercury pollution in Boroo area Mongolia (pp. 77). Ulaanbaatar: JICA Mongolia Office.

USEPA (1992). US EPA method 1311. Washington, DC: Environmental Protection Agency.

World Bank. (2006). Mongolia: A review of environmental and social impacts in the mining sector. East Asia and Pacific Region-The World Bank. http://www.worldbank.org/eapenvironment. Accessed 24 Mar 2015.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Bavor, H.J., Shinen, B. (2016). Application of Vivianite Nanoparticle Technology for Management of Heavy Metal Contamination in Wetland and Linked Mining Systems in Mongolia. In: Vymazal, J. (eds) Natural and Constructed Wetlands. Springer, Cham. https://doi.org/10.1007/978-3-319-38927-1_8

Download citation

DOI: https://doi.org/10.1007/978-3-319-38927-1_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-38926-4

Online ISBN: 978-3-319-38927-1

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)