Abstract

Over the recent years, addressing solar energy utilization for different applications has grabbed attention of many research groups around the world. From the past few decades, scientists had made progress in innovating new devices and methods for harnessing solar energy. In this respect, they developed new materials to improve energy efficiency as one of the major focal domain. During twentieth century, scientists engineered the application of nanotechnology in various domains including solar thermal conversion devices. Nanofluids, a homogeneous dispersion and stable suspension of nanoparticles in the base fluids, have made possible progress to achieve higher thermal properties at the smallest possible concentrations. This chapter intends to summarize the research done on the nanofluid applications in different solar thermal conversion systems. This chapter includes comprehensive information about thermophysical properties of nanofluids, the design of solar thermal system at optimum conditions, and the applications of solar collector with nanofluid. Also, challenges and opportunities for future research are identified and reported as well.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Utilization of different energy resources is done in a poor manner, i.e., to satisfy critical domestic and industrial needs, and harnessing energy in a clean and efficient way is still a continuing quest. In more practical terms, sustainable energy is the need for the day, especially for the industrial sector. Rapid industrialization led to a tremendous impact on the environment that resulted in the rise of global surface temperatures. Energy generation through fossil fuels has been identified as one of the primary reasons for environmental pollution. Since the production of electrical power form fossil fuel resources is in the verge of extinct and the global population growth rate is exponential, the solar thermal conversion is acquiring worldwide attention and undoubtedly an alternative source which is entirely eco-friendly. Hence, to combat climate change, clean and sustainable energy resources need to be developed to meet the current and future energy demands. In this aspect, solar thermal energy is a better alternative in spite of its higher capital cost.

At early twentieth century, the first installation of solar thermal energy conversion devices happened in the Sahara desert where sunlight operated a steam engine. Solar thermal conversion system suffers from low efficiency; hence, harvesting solar energy with high efficiency is primary conquering quest. In this paper, applications of nanotechnology in terms of nanofluid (nanoparticle) analysis in solar thermal conversion and devices have been carried both experimentally and numerically.

Nanotechnology in the broad term is used to describe materials and phenomenon at the nanoscale, i.e., 1 × 10−9 m. The benefits of exploiting nanotechnology are going into depth of theoretical understanding of storage and conversion phenomena at the nanoscale. Improvements in the nanoscale characterization of electronic properties and developments enable economical nanomanufacturing of robust devices. Nanotechnology leads to the application of nanofluid and nanomaterial in an innovative form of heat transfer in solar thermal conversion devices. Nanotechnology finds its applications in various fields of solar energy such as in direct solar absorber systems—flat plate collectors, concentrating collectors—solar cells, photovoltaic thermal devices, and desalination. It has the potential to reduce the impact of energy usage during production, storage, and other processes significantly. The applications of nanotechnology aim for improvement in power, efficiency, and reduction of costs and are found in process industries with the aim of both increasing and decreasing the temperature working fluid (Norton and Brian 2013). Most of the conventional fluid such as water, ethylene glycol, or oil has lower thermal conductivity, and alternate methods to improve the properties for effective utilization in thermal conversion devices are necessary. Many experimental investigations in the field of solar energy using nanofluids have were performed (Mahian et al. 2013). Theoretical and experimental studies lead to enhanced solar energy generation, high performance in terms of improved lifetime, power, and large storage capacity, respectively, using nanotechnology.

1.1 Nanofluids

Nanofluid is a fluid containing a particle of nanometer- sized, called nanoparticles with various volume concentrations and size used in heat transfer applications. They provide better efficiency compared to the conventional fluid employed in the present scenario and are also environmentally friendly. These fluids are colloidal suspensions of nanoparticles in a base fluid. The various nanoparticles used in nanofluids are typically made up of metals, oxides, carbides, or carbon nanotubes (CNTs), graphene nanoflakes, and ceramic particles that combined with base fluids such as water, ethylene glycol, and oil (Dharmalingama et al. 2014). The enhanced thermal conductivity and the convective heat transfer coefficient were first investigated by Choi et al. in (1995) using nanofluid. Their rheological behavior of nanofluids is found to be very critical in deciding their suitability for convective heat transfer applications. It led to enormous potential in heat transfer rate in various domains of the area such as in industry, thermal generation, transportation, and microelectronics.

Nanofluids are synthesized by two methods, i.e., one-step and two-step methods. The most extensively used method for mass production of nanofluid is two-step technique. Nanoparticles, nanofibers, nanotubes, or other nanomaterials were utilized in this process. Initial method for preparation was dry powders by chemical or physical methods. One-step method is used to minimize the agglomeration of nanoparticles, and the stability of fluid is increased (Li et al. 2009). The nanoparticles prepared by this method exhibit morphological shapes such as a needle, polygonal, square, and circular. This method avoids the undesired particle aggregation; in addition, they cannot manufacture nanofluids in large scale, and the cost is also high.

Many researchers, for the past two decades, have investigated the heat transfer enhancement using nanofluids both experimentally and theoretically. Wong and De Leon (2009) carried out a review of research detailing the current and future applications of nanofluids. Lee et al. (1999) reported that the addition of nanoparticles such as Cu, Al2O3, and CuO to base fluids of water and ethylene glycol resulted in an increase of thermal conductivity. The thermal conductivity of CNT–water nanofluid was higher than conventional liquid studied by Choi and Eastman in (2004). Due to the properties of the base fluid, the geometry of CNT, and volume fraction, a wide range of enhancement has been reported in the literature. For example, with 1 % volumetric fraction of multi-walled carbon nanotubes (MWCNTs) into the base fluid, the thermal conductivity of the medium was enhanced by ~40 %. Keblinski et al. (2002) observed an enhancement of thermal conductivity of about 60 % for water-based nanofluid. Many experimental observations on the characteristics of nanofluids such as nucleate pool boiling and critical heat flux (CHF) have been carried out. Das et al. (2003) presented the pool boiling characteristics of Al2O3–water nanofluid on smooth and roughened heating surface for different particle concentrations. It showed that nanoparticle degraded the boiling performance with an increase in particle concentration. Wen and Ding (2005) demonstrated that alumina nanofluids of particle size 10–15 nm can significantly enhance boiling heat transfer. Their studies have shown an enhancement in boiling heat transfer coefficient with increasing particle concentrations by 40 %, at a loading rate of 1.25 % by weight.

The effect of nanoparticle size and volume fraction also plays a role in the enhancement of the heat transfer characteristics (Xuan et al. 2000). Arun et al. (2015) conducted study upon nanofluids such as CeO2/water, Al2O3/water, TiO2/water, and SiO2/water with volume concentrations of 0.75, 1, 0.75, and 1.25 % for a flow rate of 3 L/min. It was reported that a maximum heat transfer enhancement of about 35.9, 26.3, 24.1, and 13.9 % was observed, respectively. Wongcharee et al. (2011) studied about CuO–water nanofluid with volume fractions of 0.3, 0.5, and 0.7 % for a laminar regime. They reported an improvement in Nusselt number as nanofluid concentration rose. Kulkarni et al. (2008) investigated heat transfer and fluid dynamic performance of nanofluids. Silicon dioxide (SiO2) nanoparticles suspended in ethylene glycol and water (EG/water) mixture in 60:40 % by weight were used. They observed an enhancement in heat transfer coefficient due to nanofluids for different volume concentrations and pressure drop obtained with increasing nanoparticle volume concentration in the base fluid. Sharma et al. (2009) experimentally studied the heat transfer coefficient and friction factor for transitional flow in a tube with twisted tape inserts using Al2O3 nanofluid. They reported that by using twisted tape in the flow path gives higher heat transfer rates compared to flow in a plain tube, and the heat transfer coefficient with 0.1 % volume concentration was 23.7 % higher compared with water.

Nanofluid is used as a coolant in many conversion devices. Jang and Choi (2006) designed a new cooler, combined microchannel heat sink with nanofluid. They obtained higher cooling performance when compared to the instrument using pure water as working medium. It reduces both the thermal resistance and the temperature difference between the heated microchannel wall and the coolant. In another experiment (Selvakumar and Suresh 2012) on CuO–water nanofluid in an electronic heat sink, the result exhibited an improvement in thermal conductivity compared to base fluid.

2 Solar Collector

Solar collectors are devices that convert the absorbed incident solar radiation to heat. The working fluid converts the generated heat for different applications. Solar collectors were classified into two types, non-concentrating and concentrating collectors (Kalogirou 2004). Non-concentrating solar collectors are usually used for low- and medium-temperature applications such as space heating/cooling, water heating, and desalination, whereas concentrating solar collectors are exploited in high-temperature applications such as electricity generation. Therefore, these systems are acquiring more and more attention, prevailing to low efficiency which is still a major concern. These nanofluids have the ability for enhancing the efficiency of solar systems. In this paper, the research over employing nanofluid in solar collectors is reported.

2.1 Flat Plate Solar Collector

Yousefi et al. (2012) experimentally investigated the efficiency of a flat plate solar collector with Al2O3/water nanofluid used as working fluid as shown in Fig. 1. The effectiveness of Al2O3 nanofluid used as working fluid with and without surfactant on the solar collector has studied. They considered nanoparticles of diameter 15 nm having two different weight fractions of 0.2 and 0.4 % for preparation of the nanofluid. The effect of mass flow rate 1, 2, 3 L/min on efficiency is also considered for experimentation. With 0.2 % weight fraction of Al2O3 nanofluid, the efficiency of the solar collector was 28.3 % higher compared with the water. Efficiency of collector was observed to change with surfactant Triton X-100. The ASHRAE standard was used to calculate the efficiency. They reported enhancement in efficiency of collector with nanofluids as a working fluid, compared to water as the absorption medium. Also, addition of surfactant has shown increase in heat transfer. The maximum enhanced efficiency was 15.63 % in the presence of the surfactant.

Experimental setup (Yousefi et al. 2012)

Yousefi et al. (2012) also demonstrated experimentally the effect of efficiency of the flat plate collector when water–MWCNT nanofluid was used as working fluid. In this study also, they used Triton X-100 as surfactant and prepared working fluid samples with and without surfactant. The effect of different weight fractions of nanoparticles in the nanofluid having particle diameter range from 10 to 30 nm, and the impact of mass flow rate was also taken into consideration. An increase in the efficiency was observed by increasing the weight fraction from 0.2 to 0.4 % and also by the addition of surfactants. The rise in the efficiency of collector depends on the ratio of temperature difference between inlet and ambient to the input solar flux. However, the collector efficiency when 0.4 wt% MWCNT nanofluid without addition of surfactant is used as working fluid is higher as shown in Fig. 2. It was reported that the efficiency can be also increased by increasing the mass flow rate for subtle values of reduced temperature difference parameter, and beyond these small values, the efficiency exhibits a reversed trend.

Efficiency of solar collector for MWCNT nanofluid without surfactant and for water in the same mass flow rate (Yousefi et al. 2012)

In another similar kind experiment conducted by Yousefi et al. (2012), they verified the effect of pH for MWCNT–H2O nanofluid on the efficiency of a flat plate solar collector. The experimental work was carried out by 0.2 % weight fraction under different pH values from acidic to base range, i.e., 3.5, 6.5, and 9.5. They again considered Triton X-100 as surfactant and undertaken the study at a mass flow rate of 0.0333 kg/s. They observed that the efficiency for pH = 3.5 was greater than that for pH = 9.5, if the temperature differences were higher than the mean temperature difference. Larger differences between the pH of nanofluids to that of isoelectric point (pH = 7.5) increase the efficiency of the collector as shown in Fig. 3. Therefore, the positive effect of nanofluids on the efficiency of flat plate solar collector becomes higher as the nanofluids become more acidic than basic.

Chougule et al. (2012) fabricated the experimental set up of flat plate collectors using heat pipes. The effects of nanofluids as working fluid using the solar tracker on solar heat pipe collector were analyzed. In this three identical wickless copper, heat pipes with a length of 620 mm and an outer diameter of 18 mm were fabricated. The nanoparticles used were CNTs 10–12 nm in diameter, and the concentration of nanoparticles used in the preparation of nanofluid was 0.15 % by volume. Nanofluids increase the average efficiency of the solar heat pipe collector irrespective of change in tilt angle. Nanofluids with solar heat pipe collector gives better performance at a higher tilt angle. This solar tracking system provides an add-on advantage to improve the efficiency in both water and nanoworking fluid solar heat pipe collector at each tilt angles for the solar heat pipe collector. They show better performance during winter; that is, solar heat pipe collector should be used in cold climatic conditions. They concluded that at 50° tilt angle working fluid gave better performance as compared to standard average angle in both conditions, i.e., fixed and tracking. Nasrin et al. (2013) numerically studied the influence of Prandtl (Pr) number on free convection in a solar collector filled with nanofluid. Here, the working fluid used is water–Al2O3 nanofluid. By using finite element method, the governing differential equations are solved numerically. The influence of Pr number was taken into consideration for the temperature and flow fields as well as the radiative and convective heat transfer rates, while Rayleigh number (Ra), volume fraction (Ø), and emissivity (ε) are fixed at 104, 5 %, and 0.9, respectively. They observed that the structure of the fluid streamlines and isotherms within the solar collector is found to dependent upon the Pr number. They found that the Al2O3 nanoparticles with the highest Pr were found to be most effective in increasing the performance of heat transfer rate than base fluid. Average heat transfer is obtained higher for convection than radiation. Mean temperature diminishes for both fluids with rising mentioned parameter. Average velocity field increases due to falling Pr. They concluded that analysis highlighted the operating range in which water–Al2O3 nanofluid can effectively utilized for high level of heat transfer augmentation. Faizal et al. (2013) presented a comprehensive overview of the energy and economic and environmental analysis of metal oxides nanofluid for a flat plate solar collector. For a solar thermal conversion system, increasing the heat transfer area can lead to increasing the output temperature of the system. So this study is focussed on potential size reduction and its associated energy saving of flat plate solar collectors when applying Al2O3, SiO2, TiO2, and CuO nanofluid that can produce the same desired output temperature. They found out that the higher density and lower specific heat of nanoparticles lead to greater thermal efficiency and CuO nanofluids have the highest value compared to other three nanofluids. 25.6, 21.6, 22.1, and 21.5 % solar collector area reduction has been achieved using CuO, SiO2, TiO2, and Al2O3, respectively. It is estimated that 10,239, 8625, 8857, and 8618 kg total weight for 1000 units of solar collector can be saved using CuO, SiO2, TiO2, and Al2O3 nanofluid. The payback period and emissions of the nanofluid-based solar collector is 2.4 years and 170 kg less CO2 emissions compared to the conventional solar collector. Environmental damage cost is lower with the nanofluid-based solar collector.

Said et al. (2013) experimentally investigated the effect of density, thermal conductivity, and viscosity of alumina nanofluid (0.05 % < ϕ < 0.1 %) using water and EG/water mixture (60:40 by mass). They studied the effect of pressure drop and pumping power for a flat plate solar collector at a temperature ranging from 25 to 80 °C. It was observed that nanofluid containing nanoparticles had enhanced thermal conductivity compared to that of base fluid. Here, the viscosity of nanofluids increases with increase in nanoparticle volume concentration. Also, the viscosity of alumina nanofluids decreases exponentially with a rise in temperature. Water-based alumina nanofluid of 0.05 % volume concentration exhibits Newtonian behavior at below 40 °C temperature, whereas it behaves as non-Newtonian fluid for all other higher concentration at any temperature. The effect of pumping power and pressure drop noticed for low concentration nanofluids is found to have negligible effect. Raja Sekhar et al. (2013) conducted an experimental simulation of convective heat transfer analysis for a horizontal circular pipe with fluid in mixed laminar flow range under constant heat flux. Here, the variation of heat transfer coefficient and pressure drop in the pipe flow for water and water-based Al2O3 nanofluids at a different volume concentration and twisted tapes was studied and compared. They found that with the increase in heat transfer coefficient in a plain tube with the use of nanofluids is 8–12 % greater compared to the flow of water in the plain tube. The nanofluid of 0.5 % particle concentration has higher friction factor compared to water. Friction factor and Nusselt number increase with the rise of particle concentration. They reported that the use of twisted tape in heat flow of pipes and the energy gained in the heat exchanger was more than energy spent on pumping power. From the results, it was concluded that the heat transfer enhancement in a horizontal tube increases with Reynolds number of flow and nanoparticle concentration. Tiwari et al. (2013) presented a comprehensive overview of the thermal performance of solar flat plate collector for water heating using different nanofluids. The effect of using the Al2O3 nanofluid as an absorbing medium in a flat plate solar collector was investigated. The impact of mass flow rate and particle volume fraction on the efficiency of the collector was studied. They reported that by using an optimum particle volume fraction of 1.5 % Al2O3 nanoparticles, increase in thermal efficiency was 31.64 % as well as saving in kg of CO2 emissions per unit kWh energy generated by solar collector. Chaji et al. (2013) experimentally investigated the thermal efficiency of flat plate solar collector (FPSC) using TiO2/water nanofluid. They evaluated the effect of nanofluid on solar collector efficiency for different mass flow rates and with three levels of nanoparticles concentrations without using a surfactant. They observed an increase of mass flow rates of base fluid inside the solar collector that enhanced the index of total collector efficiency area curve up to 15.7 %. Also, adding the nanoparticles to water improved the ratio of collector efficiency area under the curve between 2.6 and 7 % about base fluid at the same flow rate. Amirhossein et al. (2014) experimental investigated the performance effect of Cu nanoparticle on the efficiency of a flat plate solar collector. The nanoparticles having an average diameter of 10 nm, with a weight fraction of 0.2 and 0.3 % of the nanofluid, were used. A one-step method was used to prepare copper nanofluid with ethylene glycol as the base fluid. The experiments were performed at different volume flow rates of the nanofluid from 0.016 to 0.050 kg/s, and the ASHRAE 93 standard was used to test the solar collector’s performance. From experiment, solar collector efficiency decreased with decreasing the volume flow rate, and the highest F R(Ϯἀ)n value was obtained for 1 L/min. They found that by increasing the nanoparticle weight fraction, the improved efficiency of the collector had observed. Optimum point for solar collector efficiency is observed for 0.3 wt% Cu/EG nanofluid at 1.5 L/min. Said et al. (2014) theoretically examined the entropy generated, heat transfer enhancement capabilities, and pressure drop for a flat plate solar collector operated with single-walled carbon nanotube (SWCNT)-based nanofluids as an absorbing medium. Specific heat (Cp) and density of nanofluid were measured using a PerkinElmer DSC 4000 and density meter. They found out that SWCNT-based nanofluids have better thermal properties, and this consequently leads to better thermal and exegetic efficiencies compared to the metal oxide nanofluids. Analytical outcomes also revealed that SWCNT nanofluid could reduce the entropy generation and enhance heat transfer coefficient by 4.34 and 15.33 % theoretically compared to water as an absorbing fluid. Moghadam et al. (2014) experimentally investigated the efficiency of a flat plate solar collector using CuO–H2O nanofluid as a working fluid. The efficiency of two working fluids was compared. The volume fraction of nanoparticle was taken as 0.4 %, the mean particle dimension is kept constant at 40 nm, and the mass flow rate is varied from 1 to 3 kg/min. They found out that under optimum mass flow rate, solar collector efficiency increases by 16.7 % with that of water. They also observed that highest heat absorption by collector occurred at a different mass flow rate for water and nanofluid, and optimum mass flow rate depends on the working fluid thermal characteristics. Omid et al. (2014) have done a comprehensive investigation on heat transfer and entropy generation of Al2O3/water nanofluids in a flat plate solar collector. They considered the effects of tube roughness and nanoparticle size where the mass flow rather is deemed to be constant ranging from 0.1 to 0.8 kg/s. The impact of different thermophysical models, solar radiation, and ambient temperature on entropy generation was evaluated for the turbulent flow regime. There finding shows that with an increase in the volume fraction of nanofluid, the outlet temperature increases, while with increasing in nanoparticle size, very insignificant decrease had observed in the outlet temperature. They found that change in the outlet temperature was exactly opposite to Nusselt number trend. The effect is more visible at high mass flow rates, and the impact of uncertainties in thermophysical models on entropy generation is not significant in any of volume fraction and mass flow rate. They observed the effect of roughness on entropy generation was more important when the solar radiation and ambient temperature decrease.

Rehena et al. (2014) numerically investigated the impact of forced convection flow by four different nanofluids inside a flat plate solar collector. They examined the temperature, heat function, the rate of heat transfer, mean temperature, the percentage of collector efficiency, and temperature of fluid along the mid-height of the rise pipe. They found out that equation of the temperature and heat function through the riser is found to be significantly dependent upon the performance of nanofluid. The Ag nanoparticle with 5 % solid volume fraction has the highest rate of heat transfer. They found that collector efficiency improved from 65 to 85 % using Cu–water nanofluid. It was reported that as the volume fraction increased from 0 to 5 %, the temperature of water–Cu nanofluid increases steadily while passing through the pipe. Omid et al. (2014) experimentally and numerically evaluate the first- and second-law analyses of a flat plate mini channel-based solar collector. The effect of nanoparticle shape, the impact of tube material on the heat transfer, and entropy generated are evaluated using boehmite alumina nanoparticles in a mixture of water and ethylene glycol. Volume concentrations up to 4 % in turbulent flow conditions are utilized in this study. Four different shapes of nanoparticles included are platelets, blades, cylinders, and brick, and tube and absorber plate are made up of copper and steel. They found that the platelet-shaped nanoparticles showed the lowest heat transfer coefficient and the brick displayed the highest heat transfer coefficient at the maximum volume fraction, i.e., 4 %. They concluded that the entropy generation rate of copper was minimized by using brick-shaped particles with the volume fraction of 2 %, while using steel tubes, minimum entropy generation is achieved by using blade-shaped particles. And also reported that when the mass flow rate is 0.5 kg, the entropy generation rate for steel tubes is found to be 11 % higher than that of copper tubes. Omid et al. (2014) analytically analyzed the performance of four different nanofluids including Cu/water, Al2O3/water, TiO2/water, and SiO2/water in a mini channel flat plate solar collector. Pressure drop was also taken into account for the entropy generation analysis. The analysis of the first law of thermodynamics shows that Al2O3/water nanofluids have the highest heat transfer coefficient, while the lowest value belongs to SiO2/water nanofluids. The higher outlet temperature was provided by Cu/water nanofluids followed by TiO2/water, Al2O3/water, and SiO2/water nanofluids. The results of second-law analysis determine that Cu/water nanofluid produces the lowest entropy generated among the nanofluids. The Nusselt number is also lowest for Cu/water nanofluid, while SiO2/water nanofluid provides the highest value of Nusselt number. They reported that the pressure drop of nanofluids decreases with volume fraction, expect for SiO2/water nanofluids in low mass flow rate. For SiO2/water nanofluids, it was found that when the mass flow rate is 0.1 kg/s, the entropy generation increases because SiO2 nanoparticles have the lowest density of nanoparticles. Goudarzi et al. (2014) experimentally investigated the effect of the pH variation on the efficiency of a new cylindrical solar collector using two different nanofluids, Al2O3–H2O and CuO–H2O. The experimental setup consists of a cylindrical glass tube with the helical pipe as the receiver of the solar energy. The experiments were performed using 0.1 wt% CuO and 0.2 wt% Al2O3 nanofluid with different pH values and tested based on ASHRAE standard. They found that the differences between the pH of nanofluid and the pH of isoelectric point (IEP) caused an increase in the thermal efficiency of the solar collector. It was also observed that for the acidic condition (pH = 3), of CuO nanofluid (pHIEP = 9.5), the efficiency increased by 52 % compared to nanofluid at pH 10.5. For Al2O3 nanofluid (pHIEP = 7.4) at basic condition (pH = 10.5), the efficiency of the collector is obtained to be 64.5 % greater than that of the nanofluid at pH = 9.2. They concluded that the effectiveness of the solar collector with Al2O3 nanofluid at the primary condition and far from the isoelectric point was higher than that with CuO nanofluid. Saleh et al. (2015) experimentally investigated the thermal efficiency and performance characteristics of a flat plate solar collector using SiO2/ethylene glycol (EG)–water nanofluids. Volume fractions up to 1 % and mass flow rate between 0.0018 and 0.0045 kg/s were considered for the study. They reported that when there is an increase in nanofluid concentration from 0 to 1 %, then it results in an efficiency enhancement approximately between 4 and 8 %. It was observed that the thermal efficiencies associated with concentrations of 0.75 and 1 % were very close. The experimental data demonstrated that energy parameter decreases with an increase in the mass flow rate of nanofluid. Said et al. (2015) executed the energy and exergy efficiency analysis of a flat plate solar collector using controlled pH for Al2O3–H2O nanofluid both theoretically and experimentally. The effect of mass flow rate, nanoparticle volume fraction, and the effect pH on the exergy and energy efficiency of the collector were examined. Stability of nanofluid was obtained by controlling the pH of the solution over a period of 30 days. It shows that in contrast with water as the working medium, nanofluid efficiency was enhanced up to 83.5 % for the first law for 0.3 % v/v and 1.5 kg/min. The second-law efficiency had enhanced up to 20.3 % for 0.1 % v/v and 1 kg/min. They noted that the increased volume flow rate can strengthen the effectiveness of the system, but the exergy efficiency decreases. The thermal efficiency of the system was found to be more than 50 % compared to the existing system. Eshan et al. (2015) experimentally and numerically investigated the optimization of exergy efficiency of a nanofluid-based solar collector using Al2O3 nanoparticles in water as a base fluid. Collector area and tilt angle are assumed to be constant. The effect of different parameters such as mass flow rate of liquid, collector inlet fluid temperature, solar radiation, ambient temperature, and nanoparticle volume concentration on the collector exergy was investigated. The procedure to determine the optimum value of nanoparticle volume concentration, mass flow rate of fluid, and collector inlet fluid temperature for maximum exergy delivery had been developed by applying the interior-point method for constrained optimization under a given condition. It shows that each of the parameters can differently affect the collector exergy. Optimization result indicates that under actual constraints, in both pure water and nanofluid cases of working fluids on solar collector, efficiency had increased about 0.72 %. The corresponding optimized values of mass flow rate and collector inlet fluid temperature are decreased about 67.8 and 1.9 %, respectively. Said et al. (2015) analyzed numerically and experimentally the use of TiO2–water nanofluid as a working fluid for enhancing the performance of flat plate solar collector. The volume fraction of nanoparticles of 0.3 and 0.1 % and mass flow rate of nanofluid varied from 0.5 to 1.5 kg/min were studied. They found that thermal conductivity is enhanced up to 6 % with 0.3 vol% of TiO2. They reported that the viscosity increases with particle loading and reduces with rising temperature. Energy efficiency and exergy efficiency were observed to be 76.6 and 16.9 % for 0.1 vol and 0.5 kg/min, respectively, with respect to water. Using TiO2 nanofluid in the solar collector, it was found to have higher energy and exergy efficiencies than water.

2.2 Direct Absorption Solar Collector

Otanicar and Golden (2009) determined the environmental and economic effects of using nanofluids to enhance solar collector efficiency as compared with conventional solar collectors for domestic hot water systems. For the current cost of nanoparticles, the nanofluid-based solar collector was found out to have slightly higher payback period but has the same economic savings as compared to the conventional solar collector. A nanofluid-based collector has a lower embodied energy 9 % and approximately 3 % higher levels of pollution offsets than a typical collector. The solar-weighted absorption coefficient for fluid’s baseline capacity for absorbing solar energy had investigated. Results showed that water is the best absorber among the four tested liquids, namely water, EG, propylene glycol, and therminol VP-1. Tyagi et al. (2009) theoretically studied the capability of using a non-concentrating direct absorption solar collector (DASC) and investigated its performance with that of a conventional flat plate collector. In this research, a nanofluid mixture of water and aluminum nanoparticles was used as the absorbing medium. According to the results, the efficiency of a DASC using nanofluids as the working fluid is up to 10 % higher than that of pure water in a flat plate collector. Otanicar et al. (2010) investigated the use of nanofluid-based in direct absorption solar collectors. They found that mixing nanoparticles in a liquid dramatically affects the liquid thermophysical properties, such as thermal conductivity. Nanoparticles can improve the radiative properties of fluids and increase the efficiency of DASC. The experimental results were obtained from solar collectors based on the nanofluids from various nanoparticles such as carbon nanotubes, graphite, and silver. They demonstrate efficiency improvements of up to 5 % in solar thermal collectors by utilizing nanofluids as the absorption mechanism. The experimental and numerical evaluation shows that the efficiency increases rapidly initially with volume fraction and then gets stabilized as the volume fraction continues to grow. The addition of small amounts of nanoparticles results in a rapid enhancement in the efficiency from the pure fluid case until a volume fraction of approximately 0.5 %. With 20-nm silver particles, an efficiency improvement of 5 % can be achieved as shown in Fig. 4. As shown in figure, reducing the particle size further leads to an even greater enhancement in efficiency through the dependence of the optical properties on particle size.

Collector efficiency as a function of silver nanoparticle diameter—squares bulk properties; circles size-dependent properties—and volume fraction (Otanicar et al. 2010)

Taylor et al. (2011) theoretically and experimentally investigated the optical property characterization of different nanoparticles such as silver, copper, graphite, aluminum, and gold suspended in water and therminol VP-1 as the base fluids in DASC. To determine the optical property of nanofluids, modeling and measurement techniques was used. For different concentrations of aqueous graphite nanofluids, extinction coefficients were studied by using experimental and modeling methods. They obtained a nanofluid that could absorb approximately 95 % sunlight with very low nanoparticle volume fractions of 10 ppm. So nanofluid could be used to absorb sunlight with a small amount of viscosity and density. They concluded that energy absorption for nanoparticles was at shorter wavelengths and for the base fluids at longer wavelengths. Taylor et al. (2011) reported that power tower solar collectors could benefit from the potential efficiency improvements that arise from using a nanofluid as a working fluid. A notional design of this type of nanofluids receiver was presented. Using their design model, they had shown a 10 % increase in theoretical nanofluid efficiency compared to that of surface-based collectors when solar concentration ratios range from 100 to 1000. Experiments on laboratory-scale nanofluid dish receiver suggest that up to 10 % increase in efficiency is possible under optimal operating conditions. Khullar and Tyagi (2012) examined the potential of the nanofluid-based concentrating solar water heating system to the existing systems based on fossil fuels. The paper presented a quantitative assessment to assess the potential environmental benefits that could be obtained from the nanofluid-based concentrating solar water heating system to that obtained using fossil fuels. Their analysis revealed that considerable emission reductions by approximately 2.2103 kg of CO2/household/year and fuel savings can be obtained by using nanofluid-based concentrating solar water heating system. Saidur et al. (2012) analyzed the effect of using nanofluids as working fluid on the DASC. The extinction coefficients of water-based aluminum nanofluids were evaluated under different nanoparticle sizes and volume fractions. Aluminum nanoparticles showed the highest extinction coefficient at a short wavelength and a peak of 0.3 mm, and at the visible and shorter wavelength region, these nanoparticles can be used to increase the light absorption ability of water. Particle size shows minimal influence on the optical properties of nanofluids, whereas extinction coefficient is linearly proportionate to volume fraction. Although the extinction coefficient of nanofluids was independent of the nanoparticle size, they should be controlled to below 20 nm. The transmissivity of light is valued between nanofluids and pure water-based fluid. The improvement was promising only with 1.0 % volume fraction; the nanofluids were almost opaque to a light wave to the rest of volume fraction. A volume fraction of 1.0 % shows satisfactory improvement to solar absorption; therefore, they concluded that the aluminum nanofluids were meant to be a real solution for direct solar collector compared with the others.

Kundan and Sharma (2013) performed experimental work on performance evaluation of a DASC using CuO–H2O nanofluid. They found that by using CuO nanofluids in DASC efficiency enhancement was of the order of 4–6 %. With 0.005 % volume fraction possess 2–2.5 % of efficiency improvement than 0.05 % volume fraction, when compared to water. Enhancement of effectiveness is due to a subtle particle size that enhances the absorption capacity of nanofluids. He et al. (2013) prepared Cu–H2O nanofluids through a two-step method. The transmittance of nanofluids is over the solar spectrum (250–2500 nm). Factors—such as particle size, mass fraction, and optical path—influencing transmittance of nanofluids were investigated. The extinction coefficients were measured experimentally compared with that of theoretically calculated value. The photothermal properties of nanofluids were studied. The transmittance of Cu–H2O nanofluids is considerably less than that of deionized water. Also, it decreases with increasing nanoparticle size, mass fraction, and optical depth. The highest temperature of Cu–H2O nanofluids (0.1 wt%) can be up to 25.3 % compared with deionized water. The good absorption ability of Cu–H2O nanofluids for solar energy indicates that it is suitable for direct absorption solar thermal energy systems. Ladjevardi et al. (2013) experimentally and numerically studied the performance of DASC by using different diameter and volume fraction of graphite nanoparticles. Here for every case, the efficiency of solar receivers in the absorption of solar energy, irradiation spectrum distribution, impacts on the harvested solar energy, and irradiation energy level versus the depth of flow have been studied and compared. They used numerical code to solve radiative transfer equation along with momentum, and mass and energy equations are solved together for simulating the operating characteristics of direct absorption solar collector. It is seen that increase in graphite nanoparticle diameters from 50 to 300 nm enhances the extinction coefficient from around 0.4–10 in UV and visible ranges. It states that increase in nanoparticle concentrations increases collector output temperature and volume fraction around 0.00025 %. The rises in the outlet temperature from 0.27 to 0.915 was compared to pure water that lead to an increase in cost around 0.045$/L. Verma and Kundan (2013) investigated the effect of Al2O3–H2O-based nanofluids experimentally as an absorbing medium in DASC as shown in Fig. 5. The volume fractions of Al2O3 nanoparticles used were 0.005 and 0.05 %, respectively. They calculated the efficiency of the collector for different mass flow rates (60, 80, and 100 ml/h) of the nanofluid. They found that the collector efficiency increased by 3–5 % when the nanofluid used was compared to mere water. They also concluded that the collector efficiency depended on the size, shape, and the volume fraction of nanoparticles.

Direct absorption solar collector (Verma and Kundan (2013)

Parvin et al. (2013) numerically investigated the heat transfer performance and entropy generation of forced convection through a DASC using Cu–water nanofluid as working fluid. Various Reynolds number (Re) and solid volume fraction (Ø) was considered for the temperature and heat flux fields as well as heat transfer rate. The percentage of collector efficiency, mean entropy generation, and Bejan number of the fluids through the collector was analyzed. It had found that the structure of isotherms and heatlines through the solar collector depends upon Re and Ø. The Cu nanoparticle with highest Re and Ø = 3 % is established to be most effective in enhancing the performance of heat transfer rate, and it enhances with a variation of Re and Ø. Collector efficiency increases more than two times with two times for increasing Reynolds number and volume fraction. Bejan number approaches to 1 for Reynolds number variation. Hordy et al. (2014) quantitatively examined both the long-term and high-temperature stability of plasma-functionalized MWCNT nanofluids for wide concentration dispersed in water, ethylene glycol, propylene glycol, and therminol VP-1 for use in direct solar absorption. They reported long-term room temperature stability currently tested up to 8 months had been demonstrated for glycol-based nanofluids, while gradual MWCNT agglomeration had observed with water-based nanofluid because of polar nature of oxygen functionalities. It was reported from the high-temperature test that no agglomeration was found to occur at a temperature range from 85 to 170 °C for both the nanofluids. MWCNTs show 100 % solar energy absorption even at low concentrations and small collection volume for various optical characterization of nanofluid.

Bandarra Filho et al. (2014) experimentally investigated the potential of silver nanoparticles as direct sunlight absorbers for solar thermal applications under direct sunlight without focusing, for 10 h. The result showed that thermal energy is increased by 52, 93, and 144 % for silver particle concentrations of 1.62, 3.25, and 6.5 ppm, respectively, at peak temperature. They reported that nearly constant specific absorption rate (SAR) ~0.6 KW/g was obtained for the initial heating period for nanofluid up to 6.5 ppm, but significantly decreases at higher concentrations. Luo et al. (2014) numerically investigated the performance improvement of a DASC with nanofluids. A simulation model was designed by combining the radiative heat transfer in particulate media with conduction and convection heat transfer in the DASC collector to predict the photothermal efficiency. TiO2, AL2O3, Ag, Cu, SiO2, graphite nanoparticles, and carbon nanotubes were dispersed into base medium and used as nanofluids. It shows that nanofluid improved outlet temperature and effectiveness by 30–100 K and by 2–25 % than the base fluid. The photothermal efficiency of nanofluid with 0.01 % graphite and 0.5 % Al2O3 is found to be 122.7 and 117.5 % to that of the coating absorbing collector. The low loading can efficiently enhance the absorption of radiation from 200 to 2000 nm. Zhang et al. (2014) studied the radiation properties of nanofluids systematically for the first time by experimental and theoretical methods by varying particle material, volume fraction, and optical path length. The extinction coefficients of the nanofluids have been obtained based on theoretical predictions and experimental investigations. They found that at the volume fraction of 10 ppm, the extinction coefficient of the nanofluid containing the Ni nanoparticles with an average size of 40 nm is higher than that containing the Cu nanoparticles. Nanofluid containing the carbon-coated Ni (Ni/C) nanoparticles exhibits lower transmittance and higher extinction coefficient, compared with the one containing the Ni nanoparticles with the similar average size. The radiative properties of this Ni/C nanofluids increase with the volume fraction of the nanoparticles. As the volume fraction rises to 40 ppm, the absorbed energy fraction by the Ni/C nanofluid reaches up to almost 100 % after that incident light only penetrates 1 cm.

Sadique and Verma (2014) performed an experimental study on the effect of the nanofluid on the performance of a direct solar thermal collector. Three different groups of nanofluids with water were considered—graphite sphere of 30 nm diameter, carbon nanotube of 6–20 nm diameter, and silver sphere of 20 and 40 nm diameters. They concluded that nanofluids could be used to absorb sunlight with a negligible amount of viscosity and density increase. Liu et al. (2015) experimentally and numerically studied high-temperature direct solar thermal collector using graphene/ionic liquid, i.e., 1-hexyl-3-methylimidazolium tetrafluoroborate ([HMIM]BF4) nanofluids as the absorbers. A model was used to predict the temperature of graphene/ionic liquid with various geometrical parameters and operating conditions such as graphene concentration, heat transfer fluid (HTF) height, and solar concentration. Based on the model, it was shown that the receiver efficiency increases with receiver height and solar concentration but decreases with the graphene concentration. An experimental setup was used to measure temperature profiles of 0.0005 and 0.001 wt% of graphene in 1-hexyl-3-methylimidazolium tetrafluoroborate ([HMIM]BF4). For corresponding fluid height 7.5 cm and 3.8 cm, the experimental results show good agreement with the numerical results. Gupta et al. (2015) experimentally studied the effect of Al2O3–H2O nanofluid on the efficiency of a DASC flowing as a thin film over the glass absorber plate as a direct absorbing medium under outdoor condition. Three different nanofluid flow rates, i.e., 1.5, 2, and 2.5 L/min at a volume fraction of 0.005 %, were considered. The DASC efficiency and performance were compared with base fluid distilled water. They found that collector efficiency enhancement of 8.1 and 4.2 % increased with nanofluid at a mass flow rate of 1.5 and 2 L/min. In this study, optimum mass flow rate of 2.5 L/min for water and 2 L/min for nanofluid leads to maximum collector efficiency. Chen et al. (2015) performed experimental simulation of photothermal conversion efficiency and specific absorption rate using ZnO, TiO2, and Ag nanofluid at different concentrations. Under simulated sunlight, the efficiency of silver nanofluid is 84.61 % after 5-min irradiation with a mass level of 80.94 ppm that was twice than water and much higher than the rest of nanofluid. They found that after 5 min of irradiance time, both temperature and specific absorption rate (SAR) decreased which show the effect of nanofluid as working fluid was excellent from the start. The highest value of SAR reached is 827 W/g at 20.24 ppm of concentration during increasing period of irradiance time. Moradi et al. (2015) investigated the utilization of carbon nanohorn-based nanofluids for a DASC used in the civil applications numerically. In their work, a three-dimensional model of the absorption phenomena in nanofluids within a cylindrical tube was coupled with a CFD analysis of the flow and temperature fields were studied. They also computed the heat losses due to the conduction, convection, and radiation at the boundaries.

Cregan and Myers (2015) presented an approximate analytical solution to the steady-state two-dimensional model for the efficiency of an inclined nanofluid-based DASC. The model consists of a system of two differential equations. A radiative transport equation is describing the propagation of solar radiation through the nanofluid and an energy equation for analytical progress. They introduced an approximate power law function for the radiative flux. By using the method of separation of variables, the resulting solution is used to investigate the efficiency of the collector subject to variation in model parameters. In their study, they included the wavelength-dependent absorption parameter and scattering due to both the base fluid and nanoparticles. An approximation for reflectance and absorptance due to the collector and its associated surfaces are computed. Gorji et al. (2015) characterized optical properties of chemically functionalized SWCNT aqueous suspensions in the application of DASC. Dispersion of functionalized CNT nanofluids in deionized water was prepared by two methods, by treating it with nitric and hydrochloric acid in the first method and nitric and sulfuric acid in the second method. Their optical properties at room and elevated temperature were measured and compared with the pristine carbon nanotube. Due to their increased polarity, carboxyl-functionalized SWCNTs show better solubility than pristine SWCNTs in water. They can bind hydrogen bonding with a polar solvent, and this effect is more evident in the second method compared to the first method of treated SWCNTs. Optical characterization shows that functionalized carbon nanotube nanofluids show remarkable stability for being left at room temperature for three months and after undergoing thermal cycling. They concluded that compared with pristine SWCNT nanofluids, functionalized SWCNT aqueous suspensions can remarkably enhance radiation absorption of the spectrum without causing significant agglomeration and particle settling.

2.3 Evacuated Tube Solar Collector

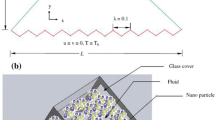

Lu et al. (2011) designed a unique open thermosyphon device utilized in high-temperature evacuated tubular solar collectors. They investigated the thermal performance of the open thermosyphon using water-based CuO nanofluids and deionized water as working liquid using an indoor experimental setup. The effects of base fluid type, mass flow rate, nanoparticle concentration, and temperature on the effect of evaporating heat transfer characteristics in the open thermosyphon are investigated and discussed. Substituting water-based CuO nanofluids for water as the working fluid can significantly increase the thermal performance of the evaporator. Approximately 30 % increase in the evaporating heat transfer coefficients compared with those of deionized water was observed. The mass concentration of CuO nanoparticles has made a remarkable influence on the heat transfer coefficient in the evaporation section. Also, the mass concentration of 1.2 % corresponds to the optimal heat transfer enhancement shown in Fig. 6.

Effect of filling ratio on evaporating high-temperature collector (Lu et al. 2011)

Liu et al. (2013) designed a novel evacuated tubular solar air collector integrated with a simplified compound parabolic concentrator (CPC) and special open thermosyphon using water-based CuO nanofluid as working fluid to provide air at different temperature range. The maximum value and the mean value of the collector efficiency with open thermosyphon by adopting nanofluids can increase by 6.6 and 12.4 %, respectively, as shown in Fig. 7. The maximum temperature of air at outlet is about 170 °C for a volume flow rate of 7.6 m3/h in winter as shown in Fig. 8. They concluded that solar collector integrated with open thermosyphon had greater collecting performance than that incorporated with the conventional concentric tube.

Solar collecting efficiency under different operating temperatures (Liu et al. 2013)

Evaporating HTC of water in thermosyphon under different operating temperatures (Liu et al. 2013)

Tong et al. (2015) analytically and experimentally evaluated the thermal performance of the enclosed-type evacuated U-tube solar collector (EEUSC) with a broad range of operating conditions. A MWCNT nanofluid was used as a working fluid to increase the heat transfer efficiency in U-tube over the thermal resistance offered by the air gap. The influence of the thickness of the air gap between the copper fin and the absorber filled with filling liquid on the heat transfer efficiency was also evaluated. They reported a 4 % increase in the ability of the EEUSC with the use of the MWCNT nanofluid with 0.24 vol% concentration. Heat transfer coefficient was about 8 % higher than that of water, mainly influenced by the air gap. The conductance of filing material was found to be larger than 0.17 W/(m K). They neither corrode the copper tube nor increase the cost. From the environmental and economic point of concern, they concluded that the performance of collector can significantly contribute to the mitigation of greenhouse effects. Thus, enabling significant cost saving of 615 kg of coal yearly contributes to 1600 kg of CO2 and 5.3 kg of SO2, i.e., equivalent to the use of 50 solar collectors.

2.4 Parabolic Trough Collector

Risi et al. (2013) mathematically optimized and modeled the transparent parabolic trough collector (TPTC) based on gas-phase nanofluids. A new method of solar transparent parabolic trough collector (TPTC) which directly absorbs solar energy using gas-based nanofluid as heat transfer medium was suggested and examined. Also, a current composition of CuO and Ni (0.25 % CuO and 0.05 % Ni) nanoparticles has been designed for complete absorption of the solar energy within the receiver tube. Figure 9 shows the solar-to-thermal efficiency as a function of nanofluid mass flow rate. Result shows that the maximum solar-to-thermal efficiency increases up to a maximum value (62.5 %) with the rise in mass flow rate and gradually decreases up to a value of 2.5 kg/s. Simulation showed that TPTC solar-to-thermal efficiency is 62.5 % at 650 °C outlet temperature and 0.3 % nanoparticle volume concentration.

Solar-to-thermal efficiency as a function of nanofluid mass flow rate (Risi et al. 2013)

Sokhansefat et al. (2014) investigated the effect of Al2O3 nanoparticle concentration in the synthetic oil on the rate of heat transfer from the absorber tube in parabolic trough collector (PTC) under turbulent-mixed convection flow. Here, numerical study is validated with standard experimental cases. Studies were performed to determine the heat transfer coefficient for various nanoparticle concentrations (<5 % in volume) at the operational temperatures of 300 and 400 K presented along axial and circumferential directions. They found out that the presence of nanoparticle enhanced their heat transfer coefficient, and it increases with increases in the concentration of nanoparticles in base fluid. For a given Reynolds number, heat transfer coefficient decreased as the operational temperature of the absorber tube is increased. The maximum heat transfer coefficients obtained at the left and right sides of the tube, i.e., θ = 310 and 210. They concluded that the use of a nanofluid in PTC could minimize the environment impact and improve heat transfer, which directly reduces the need for the heat exchanger and heat transfer area of tubes.

Kasaeian et al. (2014) experimentally designed and manufactured solar trough collector for global collector efficiency, using multi-walled carbon nanotube oil-based nanofluid as a working medium. Here, the time constant and optical and thermal efficiency of four different kinds of receiver tubes with different coating are used. They are black painted vacuumed steel tube, copper tube with black chrome coating, a vacuumed copper tube with black chrome coating, and a glass encircled non-evacuated copper tube with black chrome coating has been analysed and compared. All the operating conditions were tested according to ASHRAE standard. Results showed that the copper absorber tube coated with black chrome has the highest absorptivity 0.98 and thermal conductivity, and their global efficiency is 11 % greater than standard absorber tube. Their optical and thermal efficiencies are 0.61 and 0.68, respectively, for vacuumed copper absorber tube. With 0.2 and 0.3 %, MWCNT/mineral oil nanofluid efficiency was enhanced by 4–5 and 5–7 %. They concluded that using MWCNT/mineral oil nanofluid effectively increased the performance of high flux solar collector.

Sunil et al. (2014) experimentally studied the performance of a parabolic solar collector using SiO2–H2O-based nanofluid. Experiments were conducted for nanofluid concentration of 0.01 and 0.05 %, and at different volume flow rates of 20, 40, and 60 L/h. Here, the surfactants are not used; here, they use an ultrabath sonicator to enhance the stability and dispersion of nanoparticles in water. They found at a particular volume concentration of 0.05 % and volume flow rate of 20, 40, and 60 L/h the performance was high. The maximum temperature rises, and maximum overall thermal efficiency is found to be 63.9, 63.2, and 65.4 °C and 7.4, 7.73, and 7.83 %, respectively at volume concentration of 0.05 %.

Jafar and Sivaraman (2014) experimentally studied the heat transfer, friction factor, and pressure drop characteristics of Al2O3/water nanofluids. Nanofluid passed through the receiver with nail twisted tape of two different twist ratios of y = 2.0 and 3.0, at a particle volume concentration of 0.1 and 0.3 % under laminar flow condition. The use of nanofluid enhances the heat transfer coefficient with no significant pressure drop compared to water. Twisted tape inserts result in pressure drop due to the increase of the disturbance in the laminar layer of the boundary layer. They found that the maximum Nusselt number was observed to be around 16 % when nanofluid is 0.3 % of volume concentration in a plain tube. The highest enhancement in Nusselt number is about 20 % when nanofluid with 0.3 % volume concentration is used with nail twisted tape tube.

Mwesigye et al. (2015) numerically investigated the thermal and thermodynamic performance of a parabolic trough receiver with a rim angle of 80° and concentration ratio of 86 using synthetic oil–Al2O3 nanofluid with the entropy generation minimization method. Here, nanoparticle volume fractions vary from 0 to 8 %, and Reynolds number varies from 3,560 to 1,151,000. They reported that using nanofluid improves the thermal efficiency of the receiver by up to 7.6 % at lowest temperature and flow rate considered. Use of nanofluid enhanced the heat transfer by up to 76, 54, and 35 % as volume fraction increases from 0 to 8 %, 0 to 6 %, and 0 to 4 %, respectively. From the analysis, it is concluded that optimal Reynolds number was obtained for which entropy generation at receiver is minimum, and it decreases as volume fraction increases. From observations, there is Reynolds number beyond which the use of nanofluids makes no thermodynamic sense.

2.5 Concentrated–Parabolic Solar Collector

Khullar et al. (2010) performed theoretical and numerical investigation on the application of nanofluids as the working fluid in concentrating parabolic solar collectors using Al–water-based nanofluid as the working medium. The study was conducted to solve the equations numerically using finite difference method technique. To achieve the desired output temperature, the effect of various operating criteria such as receiver length, fluid velocity, concentration ratio, and the volume fraction of nanoparticles is taken into consideration. It showed that in terms of higher outlet temperatures, optical and thermal efficiency under similar working conditions, using nanofluid as a working fluid, showed better performance as compared to the conventional collector. They concluded that the inclusion of aluminum nanoparticles into the base fluid (water) significantly improves its absorption characteristics.

Vishwakarma et al. (2012) modeled the novel vapor absorption air-conditioning system (VACS). They studied the concept of nanofluid-based DASC for space cooling application for approximately 100 tons of refrigeration for both hourly variation in sunlight and seasonal changes for temperate climate conditions. Five types of nanoparticle volume fractions were used, i.e., 0.04, 0.03, 0.01, 0.005, and 0.001 %, respectively, and three nanoparticle sizes are 5, 15, and 40 nm. They found that nanofluids-based concentrated parabolic solar collector (NCPSC) was having higher efficiency compared to conventional parabolic trough solar collector. They concluded that the COP of the VACS kept on increasing with increase in collector outlet temperature as shown in Fig. 10. The NCPSC had the potential to offer high temperature, while maintaining greater efficiency, and hence, potentially can provide a sustainable and alternative way of providing air-conditioning.

Graph between COP and collector outlet temperature (Vishwakarma et al. 2012)

Lenert et al. (2012) integrated a model and experimentally studied to optimize the efficiency of liquid-based solar receivers seeded with carbon-coated absorbing nanoparticles. They experimentally investigated a cylindrical nanofluid volumetric receiver. The efficiency was observed to be increasing with increase in solar concentration and nanofluid height and was a good agreement with varying optical thickness of the nanofluids with the model. Receiver-side efficiencies were predicted to exceed 35 % when nanofluid volumetric receivers are attached to their power cycle. These side efficiencies were optimized with respect to their solar exposure time and optical thickness. Their study provides an important aspect of using nanofluids as volumetric receivers in concentrated solar applications.

Khullar et al. (2013) examined the nanofluid-based concentrating parabolic solar collector (NSPSC). The results of the model obtained were compared to that of experimental results of conventional parabolic solar collectors operating under same operating conditions. Aluminum nanoparticle with 0.05 volume fraction suspended in therminol VP-1 as a base fluid was used for analysis. While maintaining same external conditions, the thermal efficiency of NCPSC compared to a conventional collector is about 5–10 % higher under the same weather conditions. It indicated that the nanofluid-based concentrating parabolic solar collector has the potential to utilize solar radiant energy in a more efficient manner to that of the conventional parabolic trough. They observed that for getting the desired output in terms of thermal efficiency and maximum outlet fluid temperatures, shape, size, and material need to be optimized. They concluded that harvesting solar radiant energy into a commercial reality mathematical analysis needs to be validated by experimentation.

2.6 PV/T Collectors

Kabeel and Said (2013) modeled an integrated system using flashing desalination technique coupled with nanofluid-based collector as a heat source to investigate the effect of different operating modes. They also studied the variation of functioning parameter and weather condition on freshwater production. Thermal properties of the collector are improved by using different concentrated nanoparticles, and economic analysis is also conducted to determine the final cost of water production. Schematic setup of the commercial multi-stage flashing (MSF) shown in Fig. 11 can be applicable for daily freshwater productivity up to 7.7 L/m2/day. They analyzed the cost of potable water to be about 11.68US $/m3. Freshwater production cost decreases with increase in solar collecting area and optimum solar water heater collecting area that gives higher productivity and low cost equal about 3.54 m2. They concluded that increase in collecting the area of solar water heater could reduce the water production cost by 63.3 % with an increase in the fixed capital cost of 87 %.

Schematic diagram of small-scale single-stage flash (SSF) system (Kabeel and Said 2013)

Michael and Iniyan (2015) experimentally studied the performance of novel photovoltaic–thermal (PV\T) collector, constructed by laminating copper sheet directly to silicon cell. By this process, they reduce the heat resistance and its performance was further improved by using copper oxide–water nanofluid. Various characterizations were performed using CuO/water nanofluid at a small concentration of 0.05 % compared to that of water at a fixed mass flow rate of 0.01 kg/s. The analysis shows the effect of higher thermal conductivity of nanofluid on the electrical performance and thermal performance of the PV/T collector. The lower electrical performance was observed in the PV/T collector using nanofluid when compared to water due to higher temperature of the PV/T collector as shown in Figs. 12 and 13. They attributed the reason as higher thermal conductivity of nanofluid and higher outlet temperature of CuO/water nanofluid are partly attributable to the slightly lower Reynolds number and higher viscosity compared to water. They found that nanofluid had enhanced the thermal efficiency up to 45.76 % to that of pure water. They concluded that PV/T collector can improve if the heat exchanger is redesigned for the new nanofluid.

Electrical power output of the PV/T collector (Michael and Iniyan 2015)

Top glass layer temperature of the PV/T collector (Michael and Iniyan 2015)

3 Challenges of Utilizing Nanofluids

There are many challenges that engineers and researchers currently encounter in terms of increasing overall performance of systems including sustainable increase in efficiency, reliability, durability, safety for different operating parameters, and decrease in the overall costs, size, and weight. From the hypothetical perspective, using nanofluid is definitely beneficial with respect to improvement in rate of heat transfer of the system. However, on the contrary, it has some disadvantages when compared to base fluid as reported in the literature on nanofluids. The problems include increased pressure drop and pumping power due to viscosity factor, lower specific heat (Said et al. 2015), and decreased stability of nanoparticles suspension with time (Saidur et al. 2011). Also, the method and cost involved in the preparation of nanofluids is an area of concern where advanced and sophisticated equipment is required for characterization.

4 Future Directions

To account for the use of nanotechnology to overcome future energy challenges, there are several practical issues that need to be solved such as particle migration, Brownian motion of particle, varied thermophysical properties with temperature, particle agglomeration, and change of nanofluid properties with the addition of surfactants (Saidur et al. 2011). Studies on the physical and chemical surface interactions between the nanoparticles and base fluid molecules to understand the mechanisms of enhanced flow and thermal behavior of nanofluids are incomplete. Development of new experimental methods for characterizing and understanding nanofluid behavior in the laboratory scale is scarce. Development of collector with different fluid flow geometries utilizing nanofluid as a working fluid was not yet reported. Lack of studies on optical properties of nanofluid in the solar collector to use a direct absorber and other features needs attention expect that much information is available only on the determination of thermal conductivity. Improving the theoretical understanding of the behavior of complex nanofluids has even broader impact in this field of research.

5 Conclusions

Application of nanotechnology has a high potential for solar energy conversion and highly suitable for domestic hot water and process heating systems. Because properties of nanofluids are unique, due to a smaller size and larger surface area, they make a massive evolution in different thermochemical and photocatalytic applications. Therefore, nanotechnology shows higher potential for engineering applications related to heat transfer by increasing the energy performance and decreasing energy losses. In specific to solar thermal conversion devices, nanotechnology can be used in coatings, fluid dispersions, and storage media. They provide alternative ways for engineers to develop highly efficient green devices. Despite the fact that optical properties of nanofluid change with an increase in concentration, these fluids had a considerable impact on the performance of non-direct collector. Indirect absorber solar collector due to change in optical properties of base fluid such as transmittance and extinction coefficient leads to a significant improvement in the energy collection per unit area. The critical challenges for the use of nanofluids in solar systems comprise high cost of production, agglomeration problems, instability, increased pumping power, and erosion that had reported in the literature. Such type of issues would eventually be overcome shortly with the development of nanotechnology. Optimization and modeling of nanotechnology-based thermochemical and photocatalytic applications with different materials are still scared.

References

Amirhossein, Z., Mansoor, K. R., Maryam, K. N., & Milad, T. J.-A. (2014). An experimental study on the effect of Cu-synthesized/EG nanofluid on the efficiency of flat-plate solar collectors. Renew Energy, 71, 658–664.

Arun, K. T., Vikas, K., & Subrata, K. G. (2015). Implementation of nanofluids in plate heat exchanger. International Journal of Advanced Research in Science, Engineering and Technology, 4, 2319–8354.

Bandarra Filho, E. P., Hernandez Mendoza, O. S., Lins Beicker, C. L., Menezes, A., & Wen, D. (2014). Experimental investigation of a silver nanoparticle-based direct absorption solar thermal system. Energy Conversion and Management, 84, 261–267.

Chaji, H., Ajabshirchi, Y., Esmaeilzadeh, E., Heris Saeid, Z., Hedayatizadeh, M., & Kahani, M. (2013). Experimental study on the thermal efficiency of flat plate solar collector using TiO2/water nanofluid. Modern Applied Science, 7, 60–69.

Chen, M., He, Y., Zhu, J., Shuai, Y., Jiang, B., & Huang, Y. (2015). An experimental investigation on sunlight absorption characteristics of silver nanofluids. Solar Energy, 115, 85–94.

Choi, S. (1995). Enhancing thermal conductivity of fluids with nanoparticles. In D. A. Siginer & H. P. Wang (Eds.), Development and applications of non-newtonian flows (Vol. 66, pp. 99–105). New York: ASME.

Chougule, S. S., Pise, A. T., & Madane, P. A. (2012). Performance of nanofluid-charged solar water heater by the solar tracking system. In Proceedings of IEEE International Conference on Advances in Engineering, Science and Management. EGS Pillay Engineering College Nagapattinam, Tamil Nadu, India, March 30–31, 2012.

Cregan, V., & Myers, T. G. (2015). Modelling the efficiency of a nanofluid direct absorption solar collector. International Journal of Heat and Mass Transfer, 90, 505–514.

Das, S. K., Putra, N., & Roetzel, W. (2003). Pool boiling characteristics of nano–fluids. International Journal of Heat and Mass Transfer, 46, 851–862.

De Risi, A., Milanese, M., & Laforgia, D. (2013). Modelling and optimization of transparent parabolic trough collector based on gas-phase nanofluids. Renew Energy, 58, 134–139.

Dharmalingama, R., Sivagnanaprabhub, K. K., Senthil Kumar, B., & Thirumalaid, R. (2014). Nanomaterials and nanofluids: An innovative technology study for new paradigms for technology enhancement. Procedia Engineering, 97, 1434–1441.

Eastman, J. A., Phillpot, S., Choi, S., & Keblinski, K. (2004). Thermal transport in nanofluids. Annual Review of Materials Research, 34, 219–246.

Eshan, S., Farzad, V., & Ahmad, K. (2015). Exergy efficiency investigation and optimization of an Al2O3-water nanofluid based flat-plate solar collector.

Faizal, M., Saidur, R., Mekhilef, S., & Alim, M. A. (2013). Energy, economic and environmental analysis of metal oxides nanofluid for the flat-plate solar collector. Energy Conversion and Management, 76, 162–168.

Gorji, T. B., Ranjbar, A. A., & Mirzababaei, S. N. (2015). Optical properties of carboxyl functionalized carbon nanotube aqueous nanofluids as direct solar thermal energy absorbers. Solar Energy, 119, 332–342.

Goudarzi, K., Nejati, F., Shojaeizadeh, E., & Asadi, Y.-A. (2014). Experimental study on the effect of pH variation of nanofluids on the thermal efficiency of a solar collector with the helical tube. Experimental Thermal Fluid Science, 60, 20–27.

Gupta, H. K., Agrawal, G. D., & Mathur, J. (2015). Investigations of the effect of Al2O3–H2O nanofluid flow rate on the efficiency of direct absorption solar collector. Case Studies in Thermal Engineering, 5, 70–78.

He, Q., Wang, S., Zeng, S., & Zheng, Z. (2013). Experimental investigation on photothermal properties of nanofluids for direct absorption solar thermal energy systems. Energy Conversion and Management, 73, 150–157.

Hordy, N., Rabilloud, D., Meunier, J.-L., & Coulombe, S. (2014). High temperature and long-term stability of carbon nanotube nanofluids for direct absorption solar thermal collectors. Solar Energy, 105, 82–90.

Jafar, K. S., & Sivaraman, B. (2014). Thermal performance of solar parabolic trough collector using nanofluids and the absorber with nail twisted tapes inserts. International Energy Journal, 14, 189–198.

Jang, S. P., & Choi, S. (2006). Cooling performance of a microchannel heat sink with nanofluids. Applied Thermal Engineering, 26, 2457–2463.

Kabeel, A. E., & El-Said, E. M. S. (2013). Applicability of flashing desalination technique for small-scale needs using a novel integrated system coupled with the nanofluid-based solar collector. Desalination, 333, 10–22.

Kalogirou, S. A. (2004). Solar thermal collectors and applications. Progress in Energy and Combustion Science, 30, 231–295.

Kasaeian, A., Daviran, S., Azarian, R. D., & Rashidi, A. (2014). Performance evaluation and nanofluid using capability study of a solar parabolic trough collector. Energy Conversion and Management, 89, 368–375.

Keblinski, P., Phillpot, S., Choi, S., & Eastman, J. (2002). Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids). International Journal of Heat and Mass Transfer, 9, 855–863. doi:10.1016/S0017-9310(01)00175-2

Khullar, V., & Tyagi, H. (2010). Application of nanofluids as the working fluid in concentrating parabolic solar collectors. Paper presented at the 37th National & 4th International Conference on Fluid Mechanics & Fluid Power, IIT Madras, Chennai, India, December 16–18, 2010.

Khullar, V., Tyagi, H., Phelan, P. E., Otanicar, T. P., Singh, H., & Taylor, R. A. (2013). Solar energy harvesting using nanofluids-based concentrating solar collector. Journal of Nanotechnology in Engineering and Medicine, 3, 1003–1012.

Khullara, V., & Tyagia, H. (2012). A study on environmental impact of nanofluid-based concentrating solar water heating system. International Journal of Environmental Studies, 69, 220–232.

Kulkarni, D. P., Namburu, P. K., Bargar, H. E., & Das, D. K. (2008). Convective heat transfer and fluid dynamic characteristics of SiO2-ethylene glycol/water nanofluid. Heat Transfer Engineering, 29, 1027–1035.

Kundan, L., & Sharma, P. (2013). Performance evaluation of a nanofluid (CuO–H2O) based low flux solar collector. International Journal of Engineering Research, 2, 108–112.

Ladejevardi, S. M., Asnaghi, A., Izadkhast, P. S., & Kashano, A. H. (2013). Applicability of graphic nanofluids in direct solar energy absorption. Solar Energy, 94, 327–334.

Lee, S., Choi, S., & Li, Eastman J. A. (1999). Measuring thermal conductivity of fluids containing oxide nanoparticles. ASME Journal of Heat Transfer, 121, 280–289.

Lenert, A., & Wang, E. N. (2012). Optimization of nanofluid volumetric receivers for solar thermal energy conversion. Solar Energy, 86, 253–265.

Li, Y., Zhou, J., Tung, S., Schneider, E., & Xi, S. (2009). A review on development of nanofluid preparation and characterization. Powder Technology, 196, 89–101.

Liu, Z.-H., Hu, R.-L., Lu, L., Zhao, F., & Xiao, H.-S. (2013). Thermal performance of an open thermosyphon using nanofluid for evacuated tubular high-temperature air solar collector. Energy Conversion and Management, 73, 135–143.

Liu, J., Ye, Z., Zhang, L., Fang, X., & Zhang, Z. (2015). A combined numerical and experimental study on graphene/ionic liquid nanofluid-based direct absorption, solar collector. Solar Energy Materials and Solar Cells, 136, 177–186.

Lu, L., Liu, Z.-H., & Xiao, H.-S. (2011). Thermal performance of an open thermosyphon using nanofluids for high-temperature evacuated tubular solar collectors. Solar Energy, 85, 379–387.

Luo, Z., Wang, C., Wei, W., Xiao, G., & Ni, M. (2014). Performance improvement of a nanofluid solar collector based on direct absorption collection (DAC) concepts. International Journal of Heat and Mass Transfer, 75, 262–271.

Mahian, O., kianifar, A., Kalogirou, S. A., Pop, I., & Wongwises, S. (2013). A review of the applications of nanofluids in solar energy. International Journal of Heat and Mass Transfer, 57, 582–594.

Michael, J. J., & Iniyan, S. (2015). Performance analysis of a copper sheet laminated photovoltaic-thermal collector using copper oxide—water nanofluid. Solar Energy, 119, 439–451.

Moghadam, A. J., Mahmood, F.-G., Sajadi, M., & Monireh, H.-Z. (2014). Effects of CuO/water nanofluid on the efficiency of a flat-plate solar collector. Experimental Thermal and Fluid Science, 58, 9–14.

Moradi, A., Sani, E., Simonetti, M., Francini, F., Chiavazzo, E., & Asinari, P. (2015). Carbon–nano horn based nanofluids for a direct absorption solar collector for the civil application. Journal of Nanoscience and Nanotechnology, 15, 3488–3495.

Mwesigye, A., Huan, Z., & Meyer, J. P. (2015). Thermodynamic optimisation of the performance of a parabolic trough receiver using synthetic oil–Al2O3 nanofluid. Applied Energy, 156, 398–412.

Nasrin, R., Parvin, S., & Alim, M. A. (2013). Effect of Prandtl number on free convection in a solar collector filled with nanofluid. Procedia Engineering, 56, 54–62.

Norton, B. (2013). Harnessing solar heat. Northern Ireland.

Omid, M., Ali, K., Ahmet, Z. S., & Somchai, W. (2014a). Entropy generation during Al2O3/water nanofluid flow in a solar collector: Effect of tube roughness, nanoparticle size, and different thermophysical model. International Journal of Heat and Mass Transfer, 78, 64–75.