Abstract

Cholinesterase biosensors based on various transducers and enzyme carriers have been considered in terms of inhibitor determination. The mechanism of inhibition and influence of immobilization on biosensor performance are briefly considered. The assembly of biosensors for inhibitor detection and measurement conditions are summarized for the period from 2011 to 2015 with particular emphasis to the influence of the sample matrix and immobilization protocol on the sensitivity of inhibitors detection. Finally, the prospects of cholinesterase biosensors are considered, especially those related to miniaturization and operation in extreme environment.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Enzyme sensor

- Biosensor

- Inhibitor detection

- Anticholinesterase agent

- Pesticide determination

- Aflatoxin B1 determination

1 Introduction

There is an urgent need in the development of fast and reliable sensors for the detection of most toxic compounds that are formed in natural and industrial processes and can cause severe consequences for human health. Among many other species, inhibitors of acetylcholinesterase are in the focus of many investigations due to variety of chemical structures and large scale of industrial production. Some anticholinesterase agents, e.g., sarin, soman and VX gas, were specially developed as chemical warfare with extremely low toxic exposures and lethal consequences for the soldiers and civil population. Although the accumulated stockpiles of chemical weapons are mostly destructed following the Chemical Weapons Convention, some incidents related to the use of anticholinesterase agent shave been reported during the civil wars in Iraq and Syria. The use of home-made sarin in Tokyo subway by Aum Shinrikyo in 1995 is most known incident related to nerve gases after the Second World War. Meanwhile the threats related to the production and application of anticholinesterase agents by terrorists exists up to present days. In addition to chemical warfare, organophosphorus and carbamate pesticides irreversibly inhibit cholinesterase activity and can cause poisoning of agriculture workers and contamination of some foodstuffs. These hazards call for the further efforts in the development of appropriate biosensors devoted to detection of anticholinesterase agents in the levels allowing the use of personal protection equipment and hence decrease in the number of potential victims. In this review, the progress in the detection of anticholinesterase species based on biosensing technologies is considered with particular emphasis to the results obtained within last 10 years.

2 Cholinesterase Inhibition

Cholinesterases belong to the class of hydrolases and catalyze the reaction of hydrolysis of a natural neurotransmitter, acetylcholine (Scheme 1).

They are widely present in various biological species, mainly vertebrates, with insignificant variations of the amino acid residues responsible for the substrate binding. In accordance to the relative rate of the hydrolysis of different choline esters, cholinesterases are subdivided into several groups, from which acetylcholinesterase (AChE, EC 3.1.1.7) and butyrylcholinesterase (BChE, EC 3.1.1.8) are preferably used in the enzymatic assay of inhibitors [1].

AChE is mainly bonded to the cellular membranes of excitable tissues and erythrocytes. It hydrolyzes the acetylcholine to terminate the transmission of the neural impulse in presynaptic cell to somatic neuromuscular junction. In case of the AChE inhibition, accumulation of acetylcholine overstimulates autonomic nervous system. The poisoning symptoms include vomiting, abdominal cramps, nausea, salivation, and sweating. Also, the excitation of somatic nervous system results in involuntary muscle twitching, convulsions, respiratory failure and coma.

BChE, serum cholinesterase, was found in plasma, liver and muscle tissues. The biochemical function of BChE is yet not clear but probably is related to scavenging of organophosphate and carbamate inhibitors before they reach AChE. BChE is also involved in regulation of cholinergic transmission in the absence of AChE. Both enzymes participate in biochemical conversion of some drugs, e.g., aspirin, amitriptyline and bambuterol and in metabolic transformation of cocaine and heroin [2].

The AChE active site involves so-called anionic and esteratic centers different in their affinity toward the substrate and choline. The distance between the above centers is not changed in the enzyme acylation. Rather small conformational changes of the enzyme globule corresponded to the substrate binding result in high efficiency of the substrate conversion: the AChE molecule catalyzes breakdown of about 10000 acetylcholine molecules per second. The decoding of the first AChE structure showed that the active site is placed at the bottom of a 20Å deep gorge lined with tryptophan residues. Actually, no anionic sites are involved in acetylcholine binding. The peripheral “anionic site” responsible for acetylcholine sequester lies at the entrance to the gorge and interacts with a substrate by π-cation interactions with the tryptophan residues whereas the carbonyl of the acetyl group forms weak hydrogen bond to tyrosine residue placed further down the gorge. Three amino acid residues, namely, glutamate, histidine and serine, also known as a catalytic triad, are involved in the formation of covalent bond between serine hydroxyl and >C=O double bond of acetyl group of the substrate. This “oxyanion” is stabilized by release of choline leaving acetylserine (acetylated AChE). The serine—acetate bond is then hydrolyzed to the acetate and initial enzyme ready to the further substrate conversion [3].

First cholinesterase based devices have been developed for early detection of chemical warfare and utilized BChE from horse and human serum which showed high sensitivity toward warfare agents and rather high stability of preparations available at that moment [1]. Later on, AChE from electric eel became dominating due to higher specific activity and ability to detect a broader range of organophosphate and carbamate pesticides [4]. Nowadays, most cholinesterases commercially available are produced by genetically modified microorganisms, e.g., Escherichia coli. Modification of enzyme active site makes some difference in the sensitivity of the activity toward various groups of inhibitors. This can be used for differentiation of the response of appropriate biosensors especially in inhibitor mixtures [5, 6].

Most of the analytes determined with cholinesterase biosensors exert irreversible inhibition of immobilized enzyme. Such compounds mimic the structure of the enzyme active site and substitute acetylcholine on the first stage of the formation of serine ester. However, the product of esterification, e.g., phosphorylated cholinesterase in case of organophosphate pesticides and nerve gases, is quite stable toward hydrolysis and stops the following regeneration of the enzyme active site (Scheme 2).

The appropriate stage called as spontaneous regeneration requires the time sufficiently longer than that monitored with biosensor so that it does not affect the decay in the enzyme activity applied for the analyte determination. Similar reaction of carbamylated cholinesterase formed in the presence of carbamate pesticide is much faster so that maximal decay of enzyme activity observed in the determination of carbamates can be below 100 %. For this reason, the influence of carbamates on cholinesterases is named in some sources as reversible inhibition. This seems incorrect because the product of reactivation of carbamylated cholinesterase does not react with free enzyme and has the structure different from initial carbamate. From the point of view of physical chemistry, such interactions are considered as irreversible.

Apart spontaneous reactivation, the regeneration of initial enzyme activity is accelerated by some reagents added to the sample after inhibition. Such reagents, e.g., aldoxime derivatives, are also used as antidotes in case of poisoning with anticholinesterases. 2-PAM and TMB-4 are mostly mentioned in the operation of cholinesterase biosensors [7, 8]. It should be mentioned that such reactivators exert their own weak reversible inhibition on cholinesterases. For this reason, they should be carefully washed out from the immobilized enzyme preparation prior to measurement of residual enzyme activity. Besides, regenerated enzyme shows the sensitivity toward inhibitors different from that of enzyme prior to first contact with the sample tested. This is mainly attributed to different accessibility of enzymes immobilized in inert matrix on the transducer. As a result, a reactivator reacts first with the inhibited enzyme molecules that are positioned near the solution and to a less extent with those placed deeply inside the biolayer. Additional washing steps and protective effect of excessive reactivator quantities (see below) also complicate repeated use of biosensor for multiple inhibitor detection.

Heavy metals, quaternary ammonia compounds and biogenic amines exert reversible inhibition on cholinesterases [9–12]. In this case, the enzyme-inhibitor complex can dissociate to initial enzyme and inhibitor molecule/ion so that the detection of inhibition can be performed only in the presence of an inhibitor. Maximal decay of enzyme activity is sufficiently lower than 100 % and washing the biosensor with buffer solution can restore the signal recorded prior to the contact of the enzyme with an inhibitor. Most of the reversible inhibitors mimic positively charged ammonia group of acetylcholine. The concentrations detected are significantly higher than those of irreversible inhibitors. For this reason, the cholinesterase biosensors cannot be used for direct detection of reversible inhibitors on their permissible levels. The determination of some pharmaceuticals applied as myorelaxants or drugs against Alzheimer’s disease [12] is an exception.

Some reversible inhibitors like mercury (II) ions form rather stable enzyme-inhibitor complexes which reactivation requires special agents like dithiotreithol and EDTA instead of washing. Nevertheless, they belong to reversible inhibitors because the dissociation of enzyme-inhibitor complex produces initial metal ion able to interaction with an enzyme active site. The choice of appropriate reactivator and monitoring of reactivation efficiency provides information which might be useful for preliminary identification of an inhibitor nature especially for complex samples including potential hazards of different nature.

Chemicals exerting denaturation effect and disturbing the protein steric structure also alter the activity of cholinesterases. Urea, surfactants and polar organic solvents suppress the activity of free enzyme to an extent depending on their nature, concentration and contact time [13]. It was shown that the influence of polar solvents is additive to that of dissolved irreversible inhibitor if the total inhibition remains rather low (about 20–50 %) [14]. However, the possible interference of the solvents on the detection of extracted pesticides and other anticholinesterases needs further investigation. Acetonitrile exert activating effect on immobilized cholinesterase and increases the sensitivity of pesticide detection [15]. Immobilization of cholinesterases decreases the influence of denaturation agents due to stabilizing effect of the matrix. This allows adapting the sample treatment schemes developed for HPLC and applying direct detection of an inhibitor in diluted extract with no evaporation of organic solvent.

2.1 Irreversible Inhibition

Irreversible inhibition is measured by consecutive incubation of the enzyme, either free or in the assembly of biosensor, in the inhibitor solution followed by the addition of the substrate which stops interaction of the enzyme with inhibitor. After that, the rate of enzymatic reaction is measured. For immobilized enzyme, additional washing is often used to remove the access of an inhibitor. This makes it possible to vary the conditions of incubation and signal detection, which are not always the same especially in pH region and electrolyte content. Both AChE and BChE are irreversibly inhibited by organophosphates and carbamates that form esteric bonds with serine -OH group in enzyme active site. Chemical structures of common inhibitors applied as pesticides are presented in Fig. 1.

Relative decay of the rate of enzymatic reaction caused by irreversible inhibition depends on the incubation period and the inhibitor concentration in accordance with the Ellman’ Eq. (3) [16].

Here, v0 and vt are the reaction rates prior to and after the contact of the enzyme with an inhibitor, CI is the inhibitor concentration and τ the incubation period. The bimolecular inhibition constant k II depends on the nature of an inhibitor, the enzyme source and incubation conditions but not on the inhibitor concentration. It is used for comparison of the cholinesterases from various sources or in various measurement conditions against the same inhibitor. The Ellman equation assumes the inhibitor concentration to be sufficiently higher than that of an enzyme active site. In the opposite case, the decay of the reaction rate linearly depends on the inhibitor concentration. The use of Eq. (3) gives estimate of the limit of detection (LOD) for irreversible inhibitor. For 15 % inhibition often considered as minimal level reliably detected, the LOD is equal to 0.13/(k II·τ). The k II values vary from n × (106÷108) M−1 s−1 for chemical warfare to n × (103÷105) M−1s−1 for organophosphate pesticides [17, 18].

The following criteria of irreversible inhibition are mostly used: (1) the proportional increase of the inhibition with incubation period; (2) full inhibition of an enzyme with increased inhibitor concentration or incubation period; (3) no recovery of enzyme activity after addition of increasing substrate concentration after inhibition step. The reactivation with oximes is also a sign of irreversible inhibition caused by organophosphates and carbamates because reversible inhibition does not assume the formation of esteric bonds in the active site. It should be mentioned that about all of these criteria are not absolute. Slow establishment of equilibrium in the reaction media and fast spontaneous reactivation can mask irreversible character of enzyme—inhibitor interaction.

The biosensor format of the inhibition measurement with immobilized cholinesterase changes the quantitative relations from those corresponded to Ellman’ equation. Commonly, the sensitivity of inhibitor determination obtained with a biosensor is lower than that of free cholinesterase. Meanwhile, some examples reported recently demonstrate significant decrease of the limits of detection (LODs) against homogeneous reaction conditions. The reasons of such a behavior of cholinesterase biosensors can be summarize as follows [19]:

-

Immobilization matrix effect. The charge and buffering properties of the immobilization matrix affect the transfer of cationic acetylcholine in the surface layer and hence shift the signal of a biosensor. To some extent, the permeability of the surface layer for inhibitor molecules can be also taken into account.

-

Kinetic limitations. Decrease in the rate of the substrate transfer into the surface layer can prevent saturation of the enzyme active site with substrate. As a result, inhibition is partially compensated for by involvement of free active sites in the substrate hydrolysis [20].

-

pH shift. Both AChE and BChE exert maximal activity in weakly basic media. Any reactions resulted in release of hydrogen ions or their neutralization will shift the local pH in the surface layer and hence the parameters of both substrate hydrolysis and enzyme inhibition. Slow transfer of H+ ions from the bulk solution aggravates the situation. This is especially important for potentiometric biosensors based on pH measurement [21].

-

Unspecific transfer of reactants in the surface layer. Adsorption or aggregation of a substrate/inhibitor in the surface layer or on the transducer surface change their distribution in the reaction layer and hence affect experimental values of inhibition.

-

Side reactions of reactants. Non-enzymatic hydrolysis of acetylcholine can be accelerated by matrix material. The same can happen with inhibitors able to hydrolyze (organophosphates and carbamates) or aggregate in inactive complexes (heavy metal ions).

As could be seen, most of these factors decrease inhibitory effect of irreversible inhibitors. However, sorptional accumulation of an inhibitor and changes in the substrate transfer can improve the performance of cholinesterase biosensors with no respect of biochemical backgrounds of inhibition quantification.

2.2 Reversible Inhibition

Reversible inhibitors exert a variety of mechanisms referred to the true equilibria of the stages with the enzyme participation [22]. Most of the reaction schemes assume Michaelis-Menten kinetics and possibility to form triple enzyme—inhibitor—substrate complexes. Contrary to irreversible inhibitors, the binding of reversible inhibitor allows producing the final product of the substrate conversion. The reversible inhibitors of cholinesterases can mimic cationic part of a natural substrate, acetylcholine, nut they cannot form covalent bond with the amino acid residues of the active site. Even involved in the reaction, they do not fully suppress the access of the substrate. For AChE, reversible inhibitors can attack allosteric center of regulation of enzyme activity so that the enzyme-inhibitor complex formed retains the possibility to interact with the substrate. From the point of view of detection of chemical hazards, the determination of reversible inhibitors is not very interesting because the appropriate analytes are sufficiently less dangerous than irreversible inhibitors presented above or their detectable concentrations are much higher than limited threshold values. Nevertheless, the investigation of reversible inhibition is important if the cholinesterase biosensors are intended for the assessment of total contamination of environmental subjects. Besides, reversible inhibitors decrease the influence of irreversible inhibitors due to so called protecting effect. The reversible enzyme–inhibitor complex cannot react with irreversible inhibitor but after incubation of the biosensor it can be destroyed by addition of a substrate followed by restoration of the enzyme activity. Protecting effect is widely used for antidote therapy and prevention of acute poisoning with anticholinesterase species. Some of the organic reversible inhibitors studied with cholinesterase biosensors are presented in Fig. 2.

They include some drugs applied as myorelaxants and for Alzheimer disease treatment and toxins produced by potato (saponine) and molds (aflatoxin B1). The latter one is of special interest because of carcinogenicity of the pollutant and low residual concentrations allowed in foodstuffs. The use of AChE is an alternative of immuno- and aptasensors that show comparable sensitivity but higher specificity of the response. On the other hand, the use of immobilized enzyme makes possible multi-use of the biosensor and decreased measurement time.

Kinetic consideration of reversible inhibition is mainly based on some simplifications found more convenient for application.

In competitive inhibition (Scheme 4), the inhibitor and substrate both compete for the same active site of an enzyme and the enzyme-inhibitor complex cannot catalyze the substrate conversion.

Irreversible inhibition of cholinesterase performed in the presence of the substrate corresponds to this type of inhibition. For such a reaction, the maximal rate of the reaction does not depend on the concentration of the competitive inhibitor whereas Michaelis constant increases with inhibitor content.

Non-competitive inhibition corresponds to the case when the substrate and inhibitor do not interfere with each other in enzyme binding. The interaction with an inhibitor affects the affinity of an enzyme towards a substrate but not the reactivity of the enzyme-substrate complex (Scheme 5).

Non-competitive inhibition can be observed for heavy metal ions which either bind allosteric center of AChE cholinesterase or affect the protein conformation due to participation in the charge distribution and pH shifts within the protein globule.

Uncompetitive inhibition assumes the interaction of an inhibitor only with the enzyme-substrate complex. It is rarely observed for cholinesterases. The same can be said about mixed inhibition, but both types of inhibition can be indicated by the formal kinetics analysis for immobilized enzyme with complicated reactant transfer stages.

In all the mechanisms of reversible inhibition, the equilibrium of enzyme–inhibitor interaction is quantified with equilibrium constant called as inhibition constant (Ki). The increase in the inhibition constant decreases the sensitivity of an enzyme towards an inhibitor. The value of inhibition constant corresponds to the inhibitor concentration resulting in a 50 % decrease of the rate of the enzymatic reaction, or a biosensor signal. However, the Ki values can be compared only for inhibitors interacting with cholinesterase in the same way.

For kinetically ‘pure’ reversible inhibition, the conclusion on the mechanism of enzyme–inhibitor interaction is made from the experiments with varied concentrations of the substrate/inhibitor. The shape of the kinetic curves and their relative position against each other provide the criteria of particular inhibition mechanism described above. Besides, changes in the Michaelis constant and maximal reaction rate can be calculated in a common manner for different content of an inhibitor in the reaction media (see kinetic analysis in more detail in [19]).

The knowledge on mechanism of reversible inhibition makes it possible to optimize the reaction conditions. Thus, for reversible inhibitors, the substrate concentration is of critical importance for the sensitivity of the assay. The lower is the substrate concentration the higher is the slope of calibration curve. Contrary to that, non-competitive inhibition is insensitive to the substrate concentration chosen. Uncompetitive inhibition depends on the substrate concentration only if that is below the Michaelis constant. At upper substrate content, the inhibition does not change with variations of this parameter [14, 19].

As in the case of irreversible inhibitors, immobilization of the enzyme affects the changes in the biosensor response. The sensitivity of inhibitor detection becomes lower due to additional electrostatic interaction and steric limitations of an inhibitor transfer to the enzyme active site. Besides, the use of appropriate substrate concentrations far from optimal values is dictated by the accuracy reasons and properties of appropriate transducer. The reversible character if inhibition can be established from the following experimental evidences:

-

The maximal inhibition of the biosensor signal is significantly below 100 %;

-

The addition of the substrate to the reaction media containing an inhibitor partially restores the signal value observed in the absence of an inhibitor;

-

There is no effect of the increased incubation period on the inhibition;

-

The inhibited biosensor restores its signal after washing in the substrate solution.

A short overview of the inhibition mechanisms and their use for interpretation of a biosensor response shows a variety of the properties that complicate the comparison of various inhibitors in accordance of their ability to suppress the inhibition activity. The calculation of inhibition kinetics requires data on the mechanism and stoichiometry of enzyme–inhibitor interaction. To simplify such comparison, empirical parameters are mostly used for characterization of a biosensor performance. Thus, relative decay of biosensor response (inhibition degree) against that measured prior to the contact with the sample is frequently applied for calibration graphs. The I50, an inhibitor concentration corresponded to 50 % inhibition of the signal, characterizes the sensitivity of the response similarly to k II of irreversible inhibitor and Ki of reversible inhibition.

3 Cholinesterase Biosensor Assembling

The development of cholinesterase biosensor is based on the development of two protocols, i.e. (i) that of the enzyme immobilization, and (ii) measurement of the signal related to the cholinesterase activity. Although both problems mentioned are interconnected, some universal solutions exist. Below, the approaches to the development of cholinesterase biosensors are briefly considered with particular emphasis on the specificity of inhibition measurement.

3.1 Cholinesterase Immobilization

The immobilization assume the procedure that fixes the enzyme on appropriate carrier or directly to the transducer surface. First, the immobilization was directed to the multiple use of a biosensor to decrease the cost of expensive enzyme preparations. However, inhibition decreases the signal and the following application of biosensor once contacted with an inhibitor is often not possible. For this reason, the immobilization of cholinesterase solves other problems like ease operation of biosensor and stability of the signal. To some extent, the requirements to immobilization of cholinesterase are contradictory. The protocol chosen should provide long operation of biosensor and meanwhile high its sensitivity toward an inhibitor. It assumes accessibility of the active site and rather low changes in the flexibility of protein globule and conditions of enzyme–inhibitor interactions in comparison with native enzyme. The following methods for AChE/BChE immobilization were described:

-

Physical adsorption on solid support. From very beginning, BChE preparations were stabilized in starch for batch and flow detection of anticholinesterase agents [23]. The stability of the enzyme was increased by application of polyurethane foam as mechanical carrier and glycerin as plasticizer. The use of screen-printed carbon electrode [24] and especially carbonaceous nanomaterials like carbon black or carbon nanotubes (CNTs) [25–27] significantly improved the performance of biosensors. The electrostatic self-assembling can be additionally stimulated by layering positively charge polyelectrolytes like poly(diallyldimethylammo-nium chloride) [26].

-

Entrapment of in polymer gels. This immobilization protocol is similar to that of physical adsorption and assumes weak non-covalent interactions together with mechanical limitation of enzyme leaching from the polymeric net. Siloxane matrices obtained by sol-gel technology and included other auxiliary agents like mediators provide several months of the storage period due to favorable hydrophilic microenvironment of the enzyme active site [28–30]. Protecting role of chitosan on AChE functioning in methanol solution was also mentioned [31].

-

Cross-linking with glutaraldehyde is used to increase the stability of the enzymes immobilized in polymeric matrices like chitosan [31], bovine serum albumin (BSA) [32], nafion [15, 33, 34] and some polymers obtained by electropolymerization [35–37]. This reagent forms imide bonds with amino groups of proteins and increases average molar mass of the product together with decrease of its solubility in water. The treatment with glutaraldehyde can hence additionally stabilize enzyme entrapped in different matrices or adsorbed on sold supports. The reaction is complicated by partial oligomerization of glutyaraldehyde during the storage and by reversibility of the binding. The latter one can be avoided by chemical reduction of >C=N- bonds with NaBH4.

-

Covalent carbodiimide binding with carboxylated carriers [37–39]. The use of carbodiimides, specifically, N-(3-dimethylaminopropyl)-N′-ethyl-carbo-diimide chloride (EDC), results in formation of amide bonds with aminated molecules including proteins. Contrary to glutaraldehyde binding, the use of carbodiimide provides site specific point attachment of the enzyme globule and is mostly applied for carbonaceous materials, e.g., CNTs or carbon black that have free carboxylic groups on the surface. The reaction is performed at room temperature in the presence of N-hydroxysuccinimide (NHS) to prevent the hydrolysis of unstable intermediate. Carbodiimide binding can be also combined with formation of self-assembled monolayers of thiolated carbon acids on Au electrodes [40].

-

Affine immobilization with concanavalin A binding [41, 42] or application of the nitrilotriacetic complexes able to bind histidine residues [43]. The use of biochemical receptors offers mild and oriented inmmobilization with high residual enzyme activity and sensitivity toward inhibitors.

It should be mentioned that most of the modern immobilization protocols include implementation of auxiliary reagents together with AChE or BChE that electrically wire enzymes (CNTs, metal nanoparticles) or stabilize their structure (dextran, chitosan). The variation of pH and reactant quantities makes it possible to alter the specific enzyme activity and to some extent the sensitivity of an inhibitor detection. In many articles, the optimization of immobilization procedure is directed by the achievement of a maximal signal toward the substrate. On the one hand, this makes it possible to reach more accurate measurement of the inhibition and hence decrease the LOD value. However, increased specific activity of the enzyme decreases inhibition degree. From this consideration, the amount of enzyme to be immobilized is a compromise between the requirements of the measurement accuracy and sensitivity of the response toward an inhibitor. The use of hydrophilic matrices with ionized or polar groups is favorable for enzyme stabilization but can prevent the access of acetylcholine to the enzyme active site. On the other hand, some carriers, e.g. porous graphite or CNTs, accumulate the organic anticholinesterase species and hence increase the sensitivity of biosensor over the values expected from inhibition kinetics studied with free enzyme preparations.

Besides inhibition degree measured against a constant concentration of an inhibitor, the experimental values of Michaelis constant (K m) are often determined as a measure of possible influence of immobilization matrix on the enzyme—substrate interaction. For inert matrices, the experimental K m values are commonly higher than that of free enzyme indicating the limitations in the substrate transfer at the enzyme neighborhood. The opposite effect of immobilization can be found if the matrix exerts accumulating effect on the substrate concentration, e.g., with negatively charged CNTs [38].

3.2 Biosensor Signal Measurement

As could be seen from reaction (1), the enzymatic reaction of acetylcholine results in release of acetic acid which is fully dissociated in the pH region corresponding to maximal enzyme activity (pH 8–10), i.e., is a strong acid able to shift pH of the reaction media. Indeed, first analytical devices with cholinesterases employed pH changes as a measure of enzyme activity. For this purpose, pH indicators like bromothymol blue or neutral red are added to the solution or placed together with the enzyme on solid support and the time required for color change is recorded. However, this way has some serious limitations related to the pH sensitivity of enzyme activity and interfering influence of the sample buffer capacity and of the non-enzymatic hydrolysis of acetylcholine. For this reason, the progress in the development of cholinesterase biosensors demanded new signal measurement protocols. Nowadays, signal measurement of cholinesterase biosensors is mainly based on two approaches, i.e., detection of the second product, choline, by its involvement in the enzymatic oxidation, and the use of synthetic substrates. In the latter case, the products of cholinesterase reactions are measured by more sensitive and selective than colorimetric techniques based mostly on optical and electrochemical transducers.

3.2.1 Optical Systems

Two synthetic substrates, i.e. indoxylacetate [44–46] and indophenylacetate [47, 48], are hydrolyzed with formation of colored products (Scheme 6).

The reaction of indoxylacetate results in formation of an intermediate, leuco-indigo which is irreversible oxidized to deep blue colored indigo. Indophenylacetate reacts in one step to form blue-purple color instable in basic media due to following oxidation. Both substrates can be used with electrochemical transducers recording amperometric oxidation of leuco-indigo or potentiometric monitoring of indophenol conversion. The potential of reaction can be altered by introduction of substituents in phenolic ring of the molecule. Although such colorimetric detection system have been proposed about 50 years ago, they have recently received a new impulse for development related to the use of smartphones and paper based flow lateral systems for signal quantification.

Spectrophotometic determination of cholinesterase activity based on the use of thiocholine ester and 5,5′-dithiobis-(2-nitrobenzoic acid) is a standard method for cholinesterase activity determination first suggested by Ellman [49]. The thiocholine formed in the presence of enzyme reacts with disulfide to form yellow product monitored at 405 nm (7).

The modification of Ellman’ method was proposed for chemiluminescent determination of enzyme activity based on dioxetane derivative of the Ellman’ reagent able to excitation in the presence of thiocholine (8) [50].

Surface plasmon resonance (SPR) technique was utilized for monitoring of AChE activity based on alteration of conditions of light refraction with optical fiber coated with silver [51]. Surface enhanced Raman scattering (SERS) on colloidal silver nanoparticles has been applied for detection of thiocholine giving specific SERS spectrum in interaction with silver [52]. The method was proposed for detection of both enzyme activity and inhibitors present in sample.

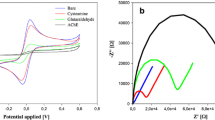

3.2.2 Electrochemical Detection Systems

Although optical systems have been developed from very beginning of cholinesterase assay, electrochemical transducers received privilege due to advantages they possess, i.e., fast and intuitively understandable response, high sensitivity and accuracy of measurement, compatibility with conventional analytical devices including portable measurement tools, low price and prospects of automation and miniaturization. The first attempts to the electrochemical detection of the cholinesterase activity were based on the use of the thiocholine esters that gave the product, thiocholine which could be oxidized on the solid electrodes to appropriate disulfide (9).

First, the reaction was monitored in galvanostatic regime with Pt net electrodes by appropriate shifts of the potential related to two processes, i.e. thiocholine oxidation and iodide oxidation [23]. The latter one was used as a counter ion of thiocholine ester due to much lower hygroscopicity against appropriate chloride and bromide. The formation of mixed potential increased the sensitivity of the response referred to the mediation function of I2/I− pair [53]. Later on, voltammetric and amperometric transducers have been introduced for the same reaction detection. However, in these works, chloride counter ion was used to avoid complication of parallel oxidation of thiocholine and iodide. As was shown on bare metal and carbon electrodes, thiocholine is oxidized with rather high overvoltage at about 0.6–0.8 V. The reaction can result in partial passivation of metal electrodes due to formation of insoluble sulfides. For this purpose, now the reaction is performed in the presence of mediators decreasing working potential of appropriate biosensor to 0.15–0.40 V. Prussian blue [54–56], Co phtalocyanine [57] 7,7,8,8-tetracyanoquinodimethane (TCNQ) [58, 59], silver nanoparticles [38, 60–63] can be used for amplification of the signal related to thiocholine oxidation. In many cases, the mediators are assembled on CNTs or carbon black that exert their own catalytic activity. The application of mediators excludes chemisorption of oxidation products and simplifies recovery of the biosensor after signal measurement. Interpretation of the results obtained with thiocholine esters should take into account that the rate of its enzymatic hydrolysis is lower than that of acetylcholine by 1.5–1.8 times. In addition, thiocholine can release H+ ions with the dissociation constant comparable with that of acetic acid. This increases the pH shift during the reaction run.

Potentiometric biosensors utilize pH-metric glass electrodes [63] or polyaniline layers which potential is pH dependent [64, 65]. Few publications are devoted to the application of membrane ion-selective electrodes sensitive to choline or acetylcholine [66–68]. More recently, pH sensitive field-effect transistors (ISFETs) [69, 70] and conductometric devices [71, 72] have been described as transducers for the detection of cholinesterase inhibitors. Although it could be stated that potentiometric biosensors are less sensitive in inhibitor detection than voltammetric sensors, in comparable conditions and with similar enzymatic membranes the performance of such biosensors is comparable [19].

Second approach to the measurement of AChE/BChE biosensor signal uses enzymatic conversion of choline resulted in formation of betaine and hydrogen peroxide (10). The rate of the second step is estimated by the concentration of hydrogen peroxide which is either oxidized or reduced on the electrode.

The oxidation of the hydrogen peroxide is promoted by mediators of electron transfer, e.g., Pt nanoparticles [73], MnO2 [74] and phtalocyanine complex [75]. Horseradish peroxidase (HRP) [76, 77], Prussian blue [78] and CdTe quantum dots [79] catalyze reduction of hydrogen peroxide.

Choline oxidase differs from cholinesterase by specific activity and pH maximum of activity. This complicates their co-immobilization on the same support. To overcome the difficulties, AChE is used in soluble form whereas the residual activity after inhibitor addition is measured with choline oxidase biosensor.

3.3 Analytical Characteristics of Inhibitor Determination

Performance of cholinesterase biosensors developed for inhibitor determination is summarized in Table 1 for the period from 2011 to 2015. Previous publications as well as alternative approaches to toxicant detection were reviewed elsewhere [4, 14, 80]. Main attention is paid to the signal transduction and sensitivity of inhibitor determination.

As could be seen, many of the biosensors developed were tested on standard inhibitors, i.e., paraoxon as a model of organophosphates and carbaryl as a representative of carbamate pesticides. Relative sensitivity of response toward other inhibitors commonly coincides with the values of appropriate k II values determined for free enzyme. This rule does not work if inhibitors are accumulated on the carbonaceous supports, e.g., CNTs or carbon black. Thus, relative sensitivity of malaoxon and paraoxon determination with appropriate biosensors is opposite to that expected from inhibition kinetics [38, 62]. The same reason explains significant decrease in the detection limits of irreversible inhibitors observed in recent publications in this area.

AChE from E. eel is mainly applied for inhibitor detection due to its high specific activity and broad selectivity toward various substrates. The application of BChE from horse serum increases relative response toward organophosphates against that of carbamates. For this reason, this enzyme source has some advantages in detection of nerve gases or in attempts to increase the selectivity of the response in the mixtures of irreversible inhibitions.

As was mentioned before, all the commercial enzymes are produced by genetically modified microorganisms so that their prize tends to decrease. For the same reason, the aspects of enzyme purity and special purification are not considered in appropriate publication devoted to biosensor design.

The variety of inhibitors detected does not fully correspond to the capabilities of appropriate biosensors. Thus, the use of cholinesterases from various sources for heavy metal detection was rather popular in the past decades due to attempts to create the systems for the total assessment of the sample toxicity [119–122]. Among others, Hg(II), As (III, V), Ag(I), Cu(II), Ni(II) are mainly mentioned as cholinesterase inhibitors [123]. Although the above mentioned metals exert inhibitory effect on cholinesterase on ppm-ppb level, their influence is non-selective and the detectable concentrations are higher than their limited threshold values and characteristics achieved by atomic spectroscopy. Nevertheless, the interest exists in the part related to improvement of biosensor based detection of more dangerous contaminants. Metal ions as reversible inhibitors are able to partially suppress irreversible inhibition and hence to underestimate toxic species content. In multisensory systems, the inhibition of cholinesterases can be compared with that of urease, the enzyme more sensitive toward metals and less sensitive than cholinesterases toward organophosphates [122, 124]. Alternative approach assumes the use of cholinesterase from several sources and chemometric treatment of the results [125, 126].

In addition to heavy metals, some other non-specific inhibitors have been determined with cholinesterase biosensors. Thus, surfactants affect the enzyme activity measured by conductometric sensor [122, 127] or potentiometrically [128]. Hypochlorite ions irreversibly damage AChE globule estimated by the potentiometric biosensor response [129].

The detection systems described during the past 5 years utilize the well-known principles proposed earlier. Most of the articles describe amperometric transducers with mediated thiocholine oxidation monitored either continuously or in batch regime. High reliability of the detection system as well as suppression of interfering chemisorption of the products on the electrode made it possible to develop microfluidic systems and lab-on-chip devices with electrochemical [85, 130, 131] and fluorescent [132] detection of the signal. Although the enzyme activity was found to be stable in the flow-through conditions, the sensitivity of inhibitor detection was sufficiently lower than that in batch conditions. Thus, the LOD of 420 nM of malathion [131] and 10 nM of carbaryl [132] were achieved in flow regime. This is significantly higher than the characteristics of conventional devices (see the results presented in Table 1 for comparison).

Although most cholinesterase biosensors utilize common transducers, a number of new approaches can be mentioned. Thus, the phenomenon of biometallization was proposed to amplify the AChE signal toward the substrate and inhibitors [133]. In this optical biosensor, liquid crystals of AChE are used. The thiocholine released from the substrate hydrolysis reacts with the AuCl4 − ion to form Au nanoparticles that disrupt the orientational arrangement of liquid crystals and hence changes the optical properties of the surface layer. The biosensor was tested on sub-nanomolar concentrations of organophosphate inhibitor.

In the second approach, the association and dissociation of polyelectrolyte complex between polycarboxylated polythiophene and myristoylcholine was recorded by absorbance spectroscopy in the presence of AChE [134]. The addition of myristoylcholine in the system resulted in disaggregation of the thiophene derivative whereas the hydrolysis of the additive in the presence of the enzyme returned the reaction to aggregation. The detection system allows visual detection of very small AChE activity and can be potentially applied for enzyme inhibition quantification.

The sensitivity of thiophosphate detection significantly depends on the sample pre-treatment. Thiophosphorus pesticides, e.g., malathion, parathion, etc., exert only weak reversible effect on human AChE. In the insects, such compounds are metabolically converted in highly toxic oxon derivatives which are real anticholinesterase agents. The application of thiophosphates referred to the second generation of insecticides is explained by lower acute toxicity of such chemicals against first generation pesticides (paraoxon, malaoxon, etc.) for warm-blooded organisms. For this reason, the appropriate pesticides should be first oxidized prior to their contact with the cholinesterase biosensor. This can be made by mixing the standard solution or extract with bromine [38, 62, 74] or bromosuccinimide [135]. The oxidant can be generated by electrolysis of bromides or chlorides performed in the same working cell as the inhibition of a biosensor [136]. The excess of the reagent can be easily removed by addition of formic acid or thiosulfate. In some publication devoted to cholinesterase biosensors such a stage of a pesticide ‘activation’ is assumed but not described in detail. This might be a reason of difference in the sensitivity of the biosensors utilizing the same enzyme and inhibitor. The electrolysis with soluble Al anode was also suggested for removal of phenolic compounds precipitated in the salt forms. This precipitation decreased their interference with cholinesterase detection of organophosphates residuals in grape must and wine [137].

As was mentioned in Sect. 2, inhibition degree is mostly used for the inhibition quantification and inhibitor determination. In semi-logarithmic plots, the appropriate graph is linear within 2–3 orders of magnitude. In many cases, the whole curve is approximated by two linear pieces which dramatically differ in their slope. The idea to increase the range of concentration determined by such mathematical treatment requires consideration in each particular case. An original approach to data processing is suggested in [138] where quantification of inhibitory effect of captan, a new fungicide, is described. The results obtained are processed using principal component analysis followed by establishment of non-linear regression models. The results show rather high accuracy of the prediction of inhibitor concentration for fully non-linear calibration plots.

Low selectivity of irreversible inhibition of cholinesterases remains a main weak point of appropriate biosensors in the detection of potential hazards. Regarding chemical warfare, extremely high toxicity of nerve gases makes it possible to avoid possible influence of other anticholinesterases by sample dilution. As to insecticides, the assessment of their mixtures is limited by some reasons related both to the measurement protocol and inhibition mechanism. Ellman’ Eq. (3) shows non-linear contribution of individual inhibitors in resulting decay of enzymatic reaction rate. The difference in k II values of inhibitors does not allow quantifying their content by a single biosensor. To some extent, distinguishing the signal can be reached by multi-parameter assay. For this purpose, several biosensors different in enzyme source are applied with the following chemometric treatment of their responses [126, 139–143]. In addition, the results of cholinesterase reactivation can be taken into account. It should be mentioned that the reliability of such calculations assumes the fulfilment of strict requirements to the measurement conditions. The use of organic solvents and solid supports for enzyme immobilization can alter the inhibition measurement and disturb the calculation results. The number of such multivariate estimations of inhibitor concentrations based on biosensor technologies grows but their application for real samples seems to be rather far in the future.

4 Conclusion

The risk associated with anticholinesterase species, i.e. pesticide residues, mycotoxins or chemical warfare, is a great challenge in food industry, agriculture and environmental monitoring. Besides some industrial contaminants, e.g. polychlorinated polyaromatics, polyfluorinated compounds and endocrine disruptors, they are of great concern due to large application scale and sever consequences of poisoning. This calls for the development of portable analytical devices for their fast and reliable detection on the level of limited threshold values. The biosensing principles offer such opportunities based on the biorecognition principles as an alternative to conventional instrumentation mostly used in well-equipped laboratories.

The biosensors based on immobilized cholinesterases can serve as early warning devices for preliminary testing of food and agriculture samples (soil, ground water, fertilizers, household equipment).

Three directions of the further progress of the cholinesterase biosensors in the specified area can be named.

-

Significant improvement of the stability of immobilized enzymes and decreased drift of the biosensor performance during the storage. Most of the cholinesterase biosensors described show the lifetime of several months. Moreover, the sensitivity of the signal toward inhibitors is checked in rare cases. More frequently, the substrate signal is recorded as a measure of residual enzyme activity. The application of biosensors needs the prolongation of the storage period for at least one year.

-

Selectivity improvement. Most of the measurements performed in the multi-analyte mixtures represent an estimated of their total inhibitory activity with no selection of the signal into individual contributions of the analytes. The use of genetically modified proteins tested 15-20 years ago did not show significant progress except selected inhibitors like paraoxon. Group specificity of the response is achieved by simultaneous consideration of inhibition and reactivation of the biosensors. Besides, chemometric approaches are demanded for the processing of multisensory systems utilizing several enzymes or transduction principles.

-

Expanding area of biosensor application. Most of cholinesterase based biosensors are intended to use in aqueous solutions though most of the anticholinesterase species are hydrophobic. The use of diluted solutions with a portion of polar organic solvents does not alter the biosensor performance but significantly decreases the biosensor lifetime. Among extract testing, organic solvents are used in the industrial production of new chemicals which should be tested for biological activity to avoid the distribution of potentially highly toxic chemicals in the environment. The enzyme stabilizers as well as further efforts in the immobilization techniques can improve the situation with biosensor operation in extreme media.

The automation and miniaturization of the biosensors is another challenge for cholinesterase biosensors. The irreversible inhibition assumes at least three stages of the measurement, i.e. initial signal measurement, incubation performed in the absence of the substrate and second signal measurement followed by the calculation of relative degree in the enzyme activity. The attempts to perform the measurement in a way adopted from reversible inhibition, i.e., with simultaneous addition of the substrate and inhibitor, showed remarkable increase of the concentrations detected. This is not very important for nerve gases but critical for pesticide detection. Then, the inhibition assumes the replacement of the enzyme after its contact with the sample tested, i.e. the introduction of replaceable elements (membranes, columns, or cartridges) questionable in flow regime. The recovery of cholinesterase activity worsens the repeatability of the signal and increases the chance for a wrong response. For this reason, microfluidics operating with microliters of free enzyme can receive privilege. The application of magnetic nanoparticles for replacement of immobilized enzymes might be an elegant solution compatible with flow-through format.

The validation of enzyme inhibition data is a methodological problem actively discussed. The impact of pesticide residues in common situations is still far from those assessed as harmful. Their detection requires reliable quantification of the signal on the level of several percentages of inhibition. And vice versa, the assessment of the risks related to industrial accidents and terrorist attacks demands fast identification of the toxic species with no respect of their actual concentrations. In both cases, high accuracy of the measurement of extreme inhibition degrees is required. Enzymatic sensors cannot give a reliable response with identification of a toxicant except very rare cases. The anticholinesterase pesticides are detected in total with rather limited information about the source. Nevertheless, the early diagnostics of anticholinesterase species leaves promises to safe life and health of poisoned people especially those with acute toxic effect far from the hospital.

References

Miao Y, He N, Zhu J-J (2010) History and new developments of assays for cholinesterase activity and inhibition. Chem Rev 110:5216–5234

Çokuğraş AN (2003) Butyrylcholinesterase: structure and physiological importance. Turk J Biochem 28:54–61

Taylor JL, Mayer RT, Himel CM (1994) Conformers of acetylcholinesterase: a mechanism of allosteric control. Mol Pharmacol 45:74–83

Arduini F, Amine A, Moscone D, Palleschi G (2010) Biosensors based on cholinesterase inhibition for insecticides, nerve agents and aflatoxin B1 detection (review). Microchim Acta 170:193–214

O’Marques PDB, Nunes GS, dos Santos TCR, Andreescu S, Marty JL (2004) Comparative investigation between acetylcholinesterase obtained from commercial sources and genetically modified Drosophila melanogaster: application in amperometric biosensors for methamidophos pesticide detection. Biosens Bioelectron 20:825–832

Villatte F, Marcel V, Estrada-Mondaca S, Fournier D (1998) Engineering sensitive acetyl-cholinesterase for detection of organophosphate and carbamate insecticides. Biosens Bioelectron 13:157–164

Gabrovska K, Marinov I, Godjevargova T, Portaccio M, Lepore M, Grano V, Diano N, Mita DG (2008) The influence of the support nature on the kinetics parameters, inhibition constants and reactivation of immobilized acetylcholinesterase. Int J Biol Macromol 43:339–345

Gulla KC, Gouda MD, Thakur MS, Karanth NG (2002) Reactivation of immobilized acetyl cholinesterase in an amperometric biosensor for organophosphorus pesticide. Biochim Biophys Acta 1597:133–139

Frasco MF, Colletier J-P, Weik M, Carvalho F, Guilhermino L, Stojan J, Fournier D (2007) Mechanisms of cholinesterase inhibition by inorganic mercury. FEBS J 274:1849–1861

Tsai H-C, Doong R (2005) Simultaneous determination of pH, urea, acetylcholine and heavy metals using array-based enzymatic optical biosensor. Biosens Bioelectron 20:1796–1804

Du D, Chen S, Cai J, Song D (2007) Comparison of drug sensitivity using acetylcholinesterase biosensor based on nanoparticles–chitosan sol-gel composite. J Electroanal Chem 611:60–66

Vandeput M, Parsajoo C, Vanheuverzwijn J, Patris S, Yardim Y, le Jeune A, Sarakbi A, Mertens D, Kauffmann J-M (2015) Flow-through enzyme immobilized amperometric detector for the rapid screening of acetylcholinesterase inhibitors by flow injection analysis. J Pharm Biomed Anal 102:267–275

Andreescu S, Noguer T, Magearu V, Marty J-L (2002) Screen-printed electrode based on ache for the detection of pesticides in presence of organic solvents. Talanta 57:169–176

Evtugyn GA, Budnikov HC, Nikolskaya EB (1999) Biosensors for the determination of environmental inhibitors of enzymes. Russ Chem Rev 68:1041–1064

Gogol EV, Evtugyn GA, Marty J-L, Budnikov HC, Winter VG (2000) Amperometric biosensors based on nafion coated screen-printed electrodes for the determination of cholinesterase inhibitors. Talanta 53:379–389

Ellman GL, Courtney KD, Andres V, Featherstone RM (1961) A new and rapid colorimetric determination of acetylcholinesterase activity. Biochem Pharmacol 7:88–95

Alfthan K, Kenttämaa H, Zukale T (1989) Characterization and semiquantitative estimation of organophosphorus compounds based on inhibition of cholinesterases. Anal Chim Acta 217:43–51

Herzsprung P, Weil L, Niessner R (1992) Measurement of bimolecular rate constants ki of the cholinesterase inactivation reaction by 55 insecticides and of the influence of various pyridiniumoximes on ki. Int J Environ Anal Chem 47:181–200

Evtugyn G (2014) Biosensors: Essentials (Lectures Notes in Analytical Chemistry). Springer Verlag, 274 pp

Thomas D, Bourdillon C, Broun G, Kernevez JP (1974) Kinetic behavior of enzymes in artificial membranes. Inhibition and reversibility effects. Biochemistry 13:2995–3000

Ramachandran KB, Rathore AS, Gupta SK (1995) Modelling the effects of electrostatic interaction with reaction-generated pH change on the kinetics of immobilized enzymes. Chem Eng J Biochem Eng J 57:B15–B21

Leskovac V (2004) Comprehensive enzyme kinetics. Kluwer Academic Publishers, Berlin 438 p

Baumann EK, Goodson LH, Guilbault GG, Kramer DN (1965) Preparation of immobilized cholinesterase fur use in analytical chemistry. Anal Chem 37:1378–1381

Bonnet C, Andreescu S, Marty JL (2003) Adsorption: and easy and efficient immobilisation of acetylcholinesterase on screen-printed electrodes. Anal Chim Acta 481:209–211

Sotiropoulou S, Chaniotakis NA (2005) Lowering the detection limit of the acethylcholinesterase biosensor using a nanoporous carbon matrix. Anal Chim Acta 530:199–204

Liu G, Lin Y (2006) Biosensor based on self-assembling acetylcholinesterase on carbon nanotubes for flow injection/ amperometric detection of organophosphate pesticides and nerve agents. Anal Chem 78:835–843

Joshi KA, Tang J, Haddon R, Wang J, Chen W, Mulchandani A (2005) A disposable biosensor for organophosphorus nerve agents based on carbon nanotubes modified thick film strip electrode. Electroanalysis 17:54–58

Anitha K, Venkata Mohan S, Jayarama Reddy S (2004) Development of acetylcholinesterase silica sol-gel immobilized biosensor-an application towards oxydemeton methyl detection. Biosens Bioelectron 20:848–856

Du D, Chen S, Cai J, Zhang A (2008) Electrochemical pesticide sensitivity test using acetylcholinesterase biosensor on colloidal gold nanoparticles modified sol-gel interface. Talanta 74:766–772

Du D, Huang X, Cai J, Zhang A, Ding J, Chen S (2007) An amperometric acetylthiocholine sensor based on immobilization of acetylcholinesterase on a multiwall carbon nanotube-cross-linked chitosan composite. Anal Bioanal Chem 387:1059–1065

Warner J, Andreescu S (2016) An acetylcholinesterase (AChE) biosensor with enhanced solvent resistance based on chitosan for the detection of pesticides. Talanta 146:279–284

Suprun E, Evtugyn G, Budnikov H, Ricci F, Moscone D, Palleschi G (2005) Acetylcholinesterase sensor based on screen-printed carbon electrode modified with prussian blue. Anal Bioanal Chem 383:597–604

Sharma SP, Tomar LNS, Acharya J, Chaturvedi A, Suryanarayan MVS, Jain R (2012) Acetylcholinesterase inhibition-based biosensor for amperometric detection of Sarin using single-walled carbon nanotube-modified ferrule graphite electrode. Sens Actuators B 166–167:616–623

Arduini F, Palleschi G (2012) Disposable electrochemical biosensor based on cholinesterase inhibition with improved shelf-life and working stability for nerve agent detection. In: Portable chemical sensors (NATO series for peace and security series A: chemistry and biology, Nikolelis D (ed)) Springer, pp 261–278

Curulli A, Dragulescu S, Cremisini C, Palleschi G (2001) Bienzyme amperometric probes for choline and choline esters assembled with nonconducting electrosynthesized polymers. Electroanalysis 13:236–242

Dutta RR, Puzari P (2014) Amperometric biosensing of organophosphate and organocarbamate pesticides utilizing polypyrrole entrapped acetylcholinesterase electrode. Biosens Bioelectron 52:166–172

Turan J, Kesik M, Soylemez S, Goker S, Kolb M, Bahadir M, Toppar L (2014) Development of an amperometric biosensor based on a novel conducting copolymer for detection of anti-dementia drugs. J Electroanal Chem 735:43–50

Evtugyn GA, Shamagsumova RV, Padnya PL, Stoikov II, Antipin IS (2014) Cholinesterase sensor based on glassy carbon electrode modified with Ag nanoparticles decorated with macrocyclic ligands. Talanta 127:9–17

Marinov I, Gabrovska K, Velichkova J, Godjevargova T (2009) Immobilization of acetylcholinesterase on nanostructure polyacrylonitrile membranes. Int J Biol Macromol 44:338–345

Pedrosa VA, Caetano J, Machado SAS, Freire RS, Bertotti M (2007) Acetylcholinesterase immobilization on 3-mercaptopropionic acid self assembled monolayer for determination of pesticides. Electroanalysis 19:1415–1419

Ivanov Y, Marinov I, Gabrovska K, Dimcheva N, Godjevargova T (2010) Amperometric biosensor based on a site-specific immobilization of acetylcholinesterase via affinity bonds on a nanostructured polymer membrane with integrated multiwall carbon nanotubes. J Mol Catal B 63:141–148

Bucur B, Danet AF, Marty J-L (2005) Cholinesterase immobilisation on the surface of screen-printed electrodes based on concanavalin a affinity. Anal Chim Acta 530:1–6

Istamboulie G, Andreescu S, Marty J-L, Noguer T (2007) Highly sensitive detection of organophosphorus insecticides using magnetic microbeads and genetically engineered acetylcholinesterase. Biosens Bioelectron 23:506–512

Pohanka M (2015) Determination of acetylcholinesterase and butyrylcholinesterase activity without dilution of biological samples. Chem Pap 69:1044–1049

Pohanka M (2015) Photography by cameras integrated in smartphones as a tool for analytical chemistry represented by an butyrylcholinesterase activity assay. Sensors 15:13752–13762

Pohanka M (2012) Acetylcholinesterase based dipsticks with indoxylacetate as a substrate for assay of organophosphates and carbamates. Anal Lett 45:367–374

Pohanka M, Drtinova L (2013) Spectrophotometric methods based on 2,6-dichloro-indophenol acetate and indoxylacetate for butyrylcholinesterase activity assay in plasma. Talanta 106:281–285

Hossain SMZ, Luckham RE, McFadden MJ, Brennan JD (2009) Reagentless bidirectional lateral flow bioactive paper sensors for detection of pesticides in beverage and food samples. Anal Chem 81:9055–9064

Ellman GL, Courtney KD, Andres V, Featherstone RM (1961) A new and rapid colorimetric determination of acetylcholinesterase activity. Biochem Pharmac 7:88–95

Sabelle S, Renard P-Y, Pecorella K, de Suzzoni-Dézard S, Créminon C, Grassi J, Mioskowski C (2002) Design and synthesis of chemiluminescent probes for the detection of cholinesterase activity. J Am Chem Soc 124:4874–4880

Rajan CS, Gupta BD (2007) Surface plasmon resonance based fiber-optic sensor for the detection of pesticide. Sens Actuators B 123:661–666

Liron Z, Zifman A, Heleg-Shabtai V (2011) Surface-enhanced Raman scattering detection of cholinesterase inhibitors. Anal Chim Acta 703:234–238

Guilbault GG, Kramer DN, Goldberg P (1963) The application of modified Nernstian equations to the electrochemical determination of enzyme kinetics. J Phys Chem 67:1747–1749

Zhao H, Ji X, Wang B, Wang N, Li X, Ni R, Ren J (2015) An ultra-sensitive acetylcholinesterase biosensor based on reduced graphene oxide-Au nanoparticles-β-cyclodextrin/Prussian blue-chitosan nanocomposites for organophosphorus pesticides detection. Biosens Bioelectron 65:23–30

Wu S, Lan X, Zhao W, Li Y, Zhang L, Wang H, Han M, Tao S (2011) Controlled immobilization of acetylcholinesterase on improved hydrophobic gold nanoparticle/Prussian blue modified surface for ultra-trace organophosphate pesticide detection. Biosens Bioelectron 27:82–87

Song Y, Zhang M, Wang L, Wan L, Xiao X, Ye S, Wang J (2011) A novel biosensor based on acetylecholinesterase/prussian blue–chitosan modified electrode for detection of carbaryl pesticides. Electrochim Acta 56:7267–7271

Ivanov AN, Younusov RR, Evtugyn GA, Arduini F, Moscone D, Palleschi G (2011) Acetylcholinesterase biosensor based on single-walled carbon nanotubes—Co phtalocyanine for organophosphorus pesticides detection. Talanta 85:216–221

Zamfir L-G, Rotariu L, Bala C (2013) Acetylcholinesterase biosensor for carbamate drugs based on tetrathiafulvalene–tetracyanoquinodimethane/ionic liquid conductive gels. Biosens Bioelectrons 46:61–67

Rotariu R, Zamfir L-G, Bala C (2012) A rational design of the multiwalled carbon nanotube–7,7,8,8-tetracyanoquinodimethan sensor for sensitive detection of acetylcholinesterase inhibitors. Anal Chim Acta 748:81–88

Zhang Y, Liu H, Yang Z, Ji S, Wang J, Pang P, Feng L, Wang H, Wu Z, Yang W (2015) An acetylcholinesterase inhibition biosensor based on a reduced graphene oxide/silver nanocluster/chitosan nanocomposite for detection of organophosphorus pesticides. Anal Methods 7:6213–6219

Huang X, Du D, Gong X, Cai J, Tu H, Xu X, Zhang A (2008) Composite assembly of silver nanoparticles with avidin and biotinylated AChE on gold for the pesticidal electrochemical sensing. Electroanalysis 20:402–409

Shamagsumova RV, Shurpik DN, Padnya PL, Stoikov II, Evtugyn GA (2015) Acetylcholinesterase biosensor for inhibitor measurements based on glassy carbon electrode modified with carbon black and pillar[5]arene. Talanta 144:559–568

Crochet KL, Montalvo JG (1973) Enzyme electrode system for assay of serum cholinesterase. Anal Chim Acta 66:259–269

Ivanov AN, Evtugyn GA, Lukachova LV, Karyakina EE, Budnikov HC, Kiseleva SG, Orlov AV, Karpacheva GP, Karyakin AA (2003) New polyaniline-based potentiometric biosensor for pesticides detection. IEEE J 3:333–340

Snejdarkova M, Svobodova L, Evtugyn G, Budnikov H, Karyakin A, Nikolelis DP, Hianik T (2004) Acetylcholinesterase sensors based on gold electrodes modified with dendrimer and polyaniline: a comparative research. Anal Chim Acta 514:79–88

Cuartero M, Ortuño JÁ, García MS, García-Cánovas F (2012) Assay of acetylcholinesterase activity by potentiometric monitoring of acetylcholine. Anal Biochem 421:208–212

Cuartero M, García MS, García-Cánovas F, Ortuño JÁ (2012) New approach for the potentiometric-enzymatic assay of reversible-competitive enzyme inhibitors. Application to acetylcholinesterase inhibitor galantamine and its determination in pharmaceuticals and human urine. Talanta 110:8–14

Khaled E, Hassan HNA, Mohamed GG, Ragab FA, Seleim AEA (2010) Disposable potentiometric sensors for monitoring cholinesterase activity. Talanta 83:357–363

Hai A, Ben-Haim D, Korbakov N, Cohen A, Shappir J, Oren R, Spira ME, Yitzchaik S (2006) Acetylcholinesterase–ISFET based system for the detection of acetylcholine and acetylcholinesterase inhibitors. Biosens Bioelectron 22:605–612

Soldatkin AP, Arkhypova VN, Dzyadevych SV, El’skaya AV, Gravoueille J-M, Jaffrezic-Renault N, Martelet C (2005) Analysis of the potato glycoalkaloids by using of enzyme biosensor based on pH-ISFETs. Talanta 65:28–33

Tekaya N, Saiapina O, Ouada HB, Lagarde F, Ouada HB, Jaffrezic-Renault N (2013) Ultra-sensitive conductometric detection of pesticides based on inhibition of esterase activity in Arthrospira platensis. Environ Pollut 178:182–188

Dzyadevych SV, Soldatkin AP, Arkhypova VN, El’skaya AV, Chovelon J-M, Georgiou CA, Martelet C, Jaffrezic-Renault N (2005) Early-warning electrochemical biosensor system for environmental monitoring based on enzyme inhibition. Sens Actuators B 105:81–87

Upadhyay S, Rao GR, Sharma MK, Bhattacharya BK, Rao VK, Vijayaraghavan R (2009) Immobilization of acetylcholinesterase-choline oxidase on a gold-platinum bimetallic nanoparticles modified glassy carbon electrode for the sensitive detection of organophosphate pesticides, carbamates and nerve agents. Biosens Bioelectron 25:832–838

Dontsova EA, Zeifman YS, Budashov IA, Eremenko AV, Kalnov SV, Kurochkin IN (2011) Screen-printed carbon electrode for choline based on MnO2 nanoparticles and choline oxidase/polyelectrolyte layers. Sens Actuators B 159:261–270

Ciucu AA, Negulescu C, Baldwin RP (2003) Detection of pesticides using an amperometric biosensor based on ferophthalocyanine chemically modified carbon paste electrode and immobilized bienzymatic system. Biosens Bioelectron 18:303–310

Espinosa M, Atanasov P, Wilkins E (1999) Development of a disposable organophosphate biosensor. Electroanalysis 11:1055–1062

Ghindilis AL, Morzunova TG, Barmin AV, Kurochkin IN (1996) Potentiometric biosensors for cholinesterase inhibitor analysis based on mediatorless bioelectrocatalysis. Biosens Bioelectron 11:873–880

Ricci F, Amine A, Palleschi G, Moscone D (2003) Prussian Blue based screen printed biosensors with improved characteristics of long-term lifetime and pH stability. Biosens Bioelectron 18:165–174

Zheng Z, Li X, Dai Z, Liu S, Tang Z (2011) Detection of mixed organophosphorus pesticides in real samples using quantum dots/bi-enzyme assembly multilayers. J Mater Chem 21:16955–16962

Kumar P, Kim K-H, Deep A (2015) Recent advancements in sensing techniques based on functional materials for organophosphate pesticides. Biosens Bioelectron 70:469–481

Pohanka M, Adam V, Kizek R (2013) An acetylcholinesterase-based chronoamperometric biosensor for fast and reliable assay of nerve agents. Sensors 13:11498–11506

Arduini F, Neagu D, Dall’Oglio S, Moscone D, Palleschi G (2011) Towards a portable prototype based on electrochemical cholinesterase biosensor to be assembled to soldier overall for nerve agent detection. Electroanalysis 24:581–590

Hoskovcová M, Dubina P, Halámek E, Kobliha Z (2011) Identification of pairs of organophosphorus warfare agents through cholinesterase reaction. Anal Lett 44:2521–2529

Pohanka M, Vlcek V (2014) Preparation and performance of a colorimetric biosensor using acetylcholinesterase and indoxylacetate for assay of nerve agents and drugs. Interdisc Toxicol 7:215–218

Tan HY, Loke WK, Nguyen N-T, Tan SN, Tay NB, Wang W, Ng SH (2014) Lab-on-a-chip for rapid electrochemical detection of nerve agent Sarin. Biomed Microdevices 16:269–275

Arduini F, Guidone S, Amine A, Palleschi G, Moscone D (2013) Acetylcholinesterase biosensor based on self-assembled monolayer-modified gold-screen printed electrodes for organophosphorus insecticide detection. Sens Actuators B 179:201–208

Ganesana M, Istarnboulie G, Marty J-L, Noguer T, Andreescu S (2011) Site-specific immobilization of a (His) 6 -tagged acetylcholinesterase on nickel nanoparticles for highly sensitive toxicity biosensors. Biosens Bioelectron 30:43–48

Chen D, Wang J, Xu Y, Zhang L (2012) A thin film electro-acoustic enzyme biosensor allowing the detection of trace organophosphorus pesticides. Anal Biochem 429:42–44

Yu G, Wu W, Zhao Q, WeiX L (2015) Efficient immobilization of acetylcholinesterase onto aminofunctionalized carbon nanotubes for the fabrication of high sensitive organophosphorus pesticides biosensors. Biosens Bioelectron 68:288–294

Arduini F, Forchielli M, Amine A, Neagu D, Cacciotti I, Nanni F, Moscone D, Palleschi G (2015) Screen-printed biosensor modified with carbon black nanoparticles for the determination of paraoxon based on the inhibition of butyrylcholinesterase. Microchim Acta 182:643–651

Chen D, Wang J, Xu Y, Li D, Zhang L, Li Z (2013) Highly sensitive detection of organophosphorus pesticides by acetylcholinesterase-coated thin film bulk acoustic resonator mass-loading sensor. Biosens Bioelectron 41:163–167

Nayak P, Anbarasan B, Ramaprabhu S (2013) Fabrication of organophosphorus biosensor using ZnO nanoparticle-decorated carbon nanotube-graphene hybrid composite prepared by a novel green technique. J Phys Chem C 117:13202–13209

Ebrahimi B, Shojaosadati SA, Daneshgar P, Norouzi P, Mousavi SM (2011) Performance evaluation of fast Fourier-transform continuous cyclic-voltammetry pesticide biosensor. Anal Chim Acta 687:168–176

Raghu P, Reddy TM, Swamy BEK, Chandrashekar BN, Reddaiah K, Sreedhar M (2012) Development of AChE biosensor for the determination of methyl parathion and monocrotophos in water and fruit samples: A cyclic voltammetric study. J Electroanal Chem 665:76–82

Marinov I, Ivanov Y, Vassileva N, Godjevargova T (2011) Amperometric inhibition-based detection of organophosphorus pesticides in unary and binary mixtures employing flow-injection analysis. Sens Actuators B 160:1098–1105

Li X, Zheng Z, Liu X, Zhao S, Liu S (2015) Nanostructured photoelectrochemical biosensor for highly sensitive detection of organophosphorous pesticides. Biosens Bioelectron 64:1–5

Kesik M, Kanik FE, Turan J, Kolb M, Timur S, Bahadir M, Toppare L (2014) An acetylcholinesterase biosensor based on a conducting polymer using multiwalled carbon nanotubes for amperometric detection of organophosphorous pesticides. Sens Actuators B 205:39–49

Mishra RK, Dominguez RB, Bhand S, Muñoz R, Marty J-L (2012) A novel automated flow-based biosensor for the determination of organophosphate pesticides in milk. Biosens Bioelectron 32:56–61

Crew A, Lonsdale D, Byrd N, Pittson R, Hart JP (2011) A screen-printed, amperometric biosensor array incorporated into a novel automated system for the simultaneous determination of organophosphate pesticides. Biosens Bioelectron 26:2847–2851

Chauhan N, Pundir CS (2011) An amperometric biosensor based on acetylcholinesterase immobilized onto iron oxide nanoparticles/multi-walled carbon nanotubes modified gold electrode for measurement of organophosphorus insecticides. Anal Chim Acta 701:66–74

Ion I, Ion AC (2012) Determination of chlorpyriphos in broccoli using a voltammetric acetylcholinesterase sensor based on carbon nanostructure-chitosan composite material. Mater Sci Eng C 32:1001–1004

Zhou Q, Yang L, Wang G, Yang Y (2013) Acetylcholinesterase biosensor based on SnO2 nanoparticles-carboxylic graphene-nafion modified electrode for detection of pesticides. Biosens Bioelectron 49:25–31

Santos CS, Mossanha R, Pessôa SA (2015) Biosensor for carbaryl based on gold modified with PAMAM-G4 dendrimer. J Appl Electrochem 45:325–334

Hatefi-Mehrjardi A (2013) Bienzyme self-assembled monolayer on gold electrode: an amperometric biosensor for carbaryl determination. Electrochim Acta 114:394–402

Song Y, Zhang M, Wang L, Wan L, Xiao X, Ye S, Wang J (2011) A novel biosensor based on acetylecholinesterase/prussian blue-chitosan modified electrode for detection of carbaryl pesticides. Electrochim Acta 56:7267–7271

Liu Q, Fei A, Huan J, Mao H, Wang K (2015) Effective amperometric biosensor for carbaryl detection based on covalent immobilization acetylcholinesterase on multiwall carbon nanotubes/graphene oxide nanoribbons nanostructure. J Electroanal Chem 740:8–13

Gong Z, Guo Y, Sun X, Cao Y, Wang X (2014) Acetylcholinesterase biosensor for carbaryl detection based on interdigitated array microelectrodes. Bioprocess Biosyst Eng 37:1929–1934

Cesarino I, Moraes FC, Lanza MRV, Machado SAS (2012) Electrochemical detection of carbamate pesticides in fruit and vegetables with a biosensor based on acetylcholinesterase immobilised on a composite of polyaniline-carbon nanotubes. Food Chem 135:873–879

Caetano J, Dragunski DC, Pedrosa VA, Machado SAS (2013) Quantification of methomyl levels in vabbage, tomato, and soya milk using a renewable amperometric biosensor. Int J Electrochem Sci 8:7795–7805

Kestwal RM, Bagal-Kestwal D, Chiang B-H (2015) Fenugreek hydrogeleagarose composite entrapped gold nanoparticles for acetylcholinesterase based biosensor for carbamates detection. Anal Chim Acta 886:143–150

Pohanka M (2013) Spectrophotomeric assay of aflatoxin B1 using acetylcholinesterase immobilized on standard microplates. Anal Lett 46:1306–1315

Puiu M, Istrate O, Rotariu L, Bala C (2012) Kinetic approach of aflatoxin B1-acetylcholinesterase interaction: A tool for developing surface plasmon resonance biosensors. Anal Biochem 421:587–594

Soldatkin O, Burdak OS, Sergeyeva TA, Arkhypova VM, Dzyadevych SV, Soldatkin AP (2013) Acetylcholinesterase-based conductometric biosensor for determination of aflatoxin B1. Sens Actuators B 188:999–1003

Stepurska KV, Soldatkin OO, Arkhypova VM, Soldatkin AP, Lagarde F, Jaffrezic-Renault N, Dzyadevych SV (2015) Development of novel enzyme potentiometric biosensor based on pH-sensitive field-effect transistors for aflatoxin B1 analysis in real samples. Talanta 144:1079–1084

Espinoza MA, Istamboulie G, Chira A, Noguer T, Stoytcheva M, Marty J-L (2014) Detection of glycoalkaloids using disposable biosensors based on genetically modified enzymes. Anal Biochem 457:85–90

Cuartero M, García MS, García-Cánovas F, Ortuño JÁ (2013) New approach for the potentiometric-enzymatic assay of reversible-competitive enzyme inhibitors. Application to acetylcholinesterase inhibitor galantamine and itsd etermination in pharmaceuticals and human urine. Talanta 110:8–14

Turan J, Kesik M, Soylemez S, Goker S, Kolb M, Bahadir M, Toppare L (2014) Development of an amperometric biosensor based on a novel conducting copolymer for detection of anti-dementia drugs. J Electroanal Chem 735:43–50

Asturias-Arribas L, Alonso-Lomillo MA, Domínguez-Renedo O, Arcos-Martínez MJ (2013) Screen-printed biosensor based on the inhibition of the acetylcholinesterase activity for the determination of codeine. Talanta 111:8–12

Soldatkin OO, Pavluchenko OS, Kukla OL, Kucherenko IS, Peshkova VM, Arkhypova VM, Dzyadevych SV, Soldatkin AP, El’skaya AV (2009) Application of enzyme multibiosensor for toxicity analysis of real water samples of different origin. Biopolym Cell 25:204–209

Evtugyn GA, Rizaeva EP, Stoikova EE, Latipova VZ, Budnikov HC (1997) The application of cholinesterase potentiometric biosensor for preliminary screening of the toxicity of waste waters. Electroanalysis 9:1124–1128

Czolkos I, Dock E, Tønning E, Christensen J, Winther-Nielsen M, Carlsson C, Mojzíková R, Skládal P, Wollenberger U, Nørgaard L, Ruzgas T, Emnéus J (2016) Prediction of wastewater quality using amperometric bioelectronic tongues. Biosens Bioelectron 75:375–382

Stepurska KV, Soldatkin OO, Kucherenko IS, Arkhypova VM, Dzyadevych SV, Soldatkin AP (2015) Feasibility of application of conductometric biosensor based on acetylcholinesterase for the inhibitory analysis of toxic compounds of different nature. Anal Chim Acta 854:161–168

Domínguez-Renedo O, Alonso-Lomillo MA, Arcos-Martínez MJ (2013) Determination of metals based on electrochemical biosensors. Crit Rev Environ Sci Technol 43:1042–1073