Abstract

The thermal decomposition and combustion of binary mixture of octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine (HMX) and ammonium perchlorate (AP) are investigated at various concentrations. Thermal stability was investigated by thermal analysis techniques, i.e., DSC/TGA, combined with FTIR spectrometry, and accelerating rate calorimetry (ARC). Twofold HMX/AP interaction result is observed: ammonium perchlorate as synergistic additive effectively (in 60 °C) reduces the onset decomposition temperature of HMX, whereas gaseous products of the HMX thermolysis, in turn, catalyze the AP decomposition. Burning rate of mechanical mixtures exceeds the HMX level at 4 MPa, when HMX content lies in the range close to above synergistic effect at thermolysis, and AP particle size is fine (10 μm). Addition of large AP particles to HMX does not enhance the burning rate. Comparative analysis of the combustion parameters of the mechanical mixtures and large HMX crystals covered with AP layer revealed that the direct contact between components is not a necessary condition for the HMX/AP interaction for compositions without binder, proving the gas-phase character of this effect. However, for compositions with active binder, the direct contact between components is important. Finally, the synergistic effect changes the decomposition pathway for mixtures with HMX content above 40 % and below 90 % and noticeably increases the burning rate of HMX-based compositions with active binder. Formulations with active binder and coated HMX provide higher burning rate than those ones with mechanical mixtures of HMX with fine AP. It means the possibility to use the considerably less amount of ammonium perchlorate to achieve the same level of the burning rate.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine (HMX) and ammonium perchlorate (AP) are the most used components in modern solid propellants. Both compounds have very different monopropellant flame temperatures, i.e., 3200 K for HMX versus 1400 K for AP, but quite close burning rates (1.1 cm/s and 0.8 cm/s, respectively, at 68 atm) [1]. Addition of AP to HMX formulations is known to increase the burning rate and decrease the pressure exponent and the fume formation. Although the regularities of thermolysis and combustion of these two components are of very high practical importance, the systematic study of interaction between them is still to be done.

It is known that compounds with melting point below the HMX decomposition onset decrease the temperature of HMX thermolysis. Thus, ammonium nitrate addition leads to the exothermic peak temperature decrease down to 247 °С; NH 4 NO 3 melts at 169 °С [2]. The addition of 10 % of LiClO 4 results in the onset temperature reduction to 200 °С, which is caused by the eutectic melt formation. The hydrophilic lithium perchlorate forms under air monohydrate with melting temperature T m = 149 °С and trihydrate with T m = 95.1 °С. Eutectic LiClO 4 ·H 2 O-LiClO 4 melts at 146 °С. Magnesium perchlorate forms three congruently melting hydrates and decreases the HMX onset temperature down to 177 °C. Nitroguanidine melts at 230 °С, which results in onset temperature reduction to 227 °С [3].

The same effect has the addition of the metal salts of propionitrile nitramine, which melt and decompose below 200 °С, thus decreasing the HMX decomposition temperature in 60–70 °С. Authors propose that the reason of this result is formation of the highly reactive anion radicals during the salt decomposition, which in turn interact with the HMX molecule [4].

The addition of HMX to AP-based composite propellants with inert binder resulted in a marked reduction in the ignition times due to the lowering of nitramine’s exothermic reaction onset [5]. Neat HMX decomposes at 280 °С, whereas the heating of HMX particles covered by AP leads to the considerable decomposition temperature decrease down to 200–225 °С with the corresponding burning rate increase [3].

During heating of the formulations active binder/HMX/AP/Al, when the ratio between AP and HMX is equal to 14/86, the DSC curve reveals three exothermic peaks. But with increasing of AP content to 35 %AP/65 %HMX, the DSC signal shows one exo peak only [6]. Thus, the literature data reveal the influence of AP on the thermal stability of HMX-containing compositions with both inert and active binder.

According to thermal analysis data, ammonium perchlorate does not melt and decompose below the phase transition temperature (240 °С); thus the reason of the considerable (up to 60 °С) decrease of the HMX onset thermolysis temperature during heating of the mixture HMX/AP is not clear. The aim of this article is to shed the light on the mechanism of the HMX thermal stability decrease in presence of ammonium perchlorate. We have focused on the systematic investigation of the HMX/AP decomposition and combustion processes by thermal analysis and burning rate measurements in the wide range of AP concentrations. The role of the contact between both components was investigated too by comparative analysis of the HMX crystals covered with AP and HMX/AP mixtures with the same components concentration. Understanding of the HMX/AP interaction is important, in particular, for the HMX-based formulations with active binder, because the search of the HMX combustion modifier, which is compatible with the active binder, is still an open unsolved problem. Understanding of the mechanism of HMX/AP interaction will enable to increase the combustion efficiency of HMX-based formulations.

2 Materials and Methods

2.1 Materials

The feedstock materials used in this work included two HMX powders with the average particle sizes of 50 and 200 μm, as well as three ammonium perchlorate powders with the average particle sizes of 230, 40, and 10 μm. AP powders were dried at 333 K during 6 h in an oven prior to use to eliminate moisture.

For thermal analysis and combustion experiments, two types of binary systems were used. First one was mechanically mixed HMX and AP powders with Turbula® mixer. The second types were HMX crystals coated with AP layer of different thickness, thus having different HMX/AP ratio.

2.2 Microstructure

To study the microstructure of the as-received powders and HMX crystals covered with ammonium perchlorate, scanning electron microscope Versa 3D DualBeam™ instrument (FEI) was used. To evaluate the uniformity and the thickness of the AP layer on the HMX crystals, X-ray 3D-tomograph Xradia VersaXRM-500 (FEI) was applied.

2.3 Thermal Analysis

Simultaneous DSC/TGA thermal analysis was performed with STA 449 F3 thermal analyzer (Netzsch). The sample with mass ≈1 mg was placed in closed alumina pan with a pinhole lid and heated to 500 °C with the heating rate 10 К/min under argon flow (70 ml/min).

Evolved gas products during DSC/TGA analysis were detected online with FTIR spectrometer (Alpha, Bruker) with the resolution of 4 cm−1.

Accelerating rate calorimetry (MMC 274 Nexus, Netzsch) was performed on AP samples ≈ 300 mg in heat-wait-search mode.

2.4 Combustion Experiments

To obtain the burning rate parameters, HMX/AP mixtures or HMX crystals covered with AP were pressed at 350 MPa in 3 min into cylinders with diameter 8 mm and then coated on the lateral surface with epoxy adhesive Poxipol™ to provide the linear propagation of the combustion front. Measurements were performed using a constant pressure bomb (volume 1.5 l) under nitrogen. In addition to the pressure-time recording, high-speed video with 1200 fps (Casio EX-F1) was used to measure the burning rate. The resulting accuracy of the burning rate measurements was ±5 %.

3 Results and Discussion

3.1 Microstructure

Two types of the HMX/AP mixtures were investigated, i.e., the mechanical mixture of the particles, where dHMX = 50 μm and dAP = 40 μm, and HMX crystals (d = 200 μm) covered with AP, which were produced with the ammonium perchlorate content 5–30 mass %, with the corresponding AP layer thickness variation 3–10 μm. Continuous uniform AP layer formation on the HMX crystals was achieved. The local partial absence of the coating on HMX crystal edge allows observation of the microstructure of the coating layer and the estimation of the layer thickness, as presented in Fig. 1. The AP coating consists of one layer of the closely packed grains with the relatively constant thickness. SEM images in Fig. 1 are obtained in the backscattered electron registration regime, thus providing the compositional contrast – AP particles are brighter than HMX. X-ray 3D tomography confirms the estimated layer thickness. The AP content for the particular sample presented in Fig. 1 is 30 mass %, whereas the layer thickness is 10 μm.

3.2 Thermal Analysis

3.2.1 General Remarks

The DSC and TGA curves obtained for neat HMX, AP powders, and HMX/AP mixture (mass ratio of HMX to AP is 1:1) at the heating rate of 10 K/min are shown in Figs. 2 and 3. Obtained dependencies for the HMX particles coated with AP were almost identical to HMX/AP mixtures with equivalent HMX content.

The first endothermic peak at DSC curve for HMX at 180–190 °C corresponds to the phase transition, where the β-polymorph converts into δ-HMX. The small endothermic peak at 280 °C is caused by the HMX melting followed by the subsequent exothermic decomposition.

According to Brill [7], the global decomposition branches for HMX are represented by the following reactions:

N2O and NO2 appear before CH2O and HCN, which are formed from the residue left by elimination of N2O and NO2. This residue is a mixture of products like hydroxymethylformamide and acetamide [8, 9].

The thermal effect of HMX decomposition, as determined by DSC experiments, is equal to 1500 ± 150 J/g (average on three experiments).

Three thermal events are observed at DSC curve for AP: an endothermic peak near 240 °C and two exothermic peaks around 300 and 450 °C. The endothermic peak near 240 °C is attributed to the phase transition of AP from the orthorhombic to cubic form with the density decrease in 9.7 % (from 1950 to 1760 kg/m3 [10]), resulting in micro-cracks formation inside AP crystals [11]. Two exothermic peaks of AP decomposition are assigned to low- and high-temperature decomposition. According to [12], the brutto formula of AP decomposition could be presented as:

where α is the amount of sublimated substance at low-temperature decomposition, which in turn depends on the free volume.

Two main differences appear when HMX/AP (1:1) mixture decomposes: the onset decomposition point is considerably shifted to the lower temperature with the corresponding shift of DSC peak, and decomposition terminates considerably earlier than that for neat AP.

Brill [13] investigated the influence of gaseous environment on HMX decomposition in H2, CO, O2, or NO environments. No changes in the composition of the primary thermolysis products were revealed, but variations in secondary reactions only. In NH3 environment the HMX decomposition starts considerably earlier than that in other investigated gases. Significant changes in the primary decomposition species were observed: the amount of CH2O, HCN, and NO2 quickly drops, whereas N2O one increases probably due to reaction NHx + NOx. Ammonia acts as a hydrogen donor for HMX.

Results presented in Fig. 2 reveal that AP decomposition in the mixture HMX/AP is terminated at 360 °C, which is in ∼90 °C lower than that for the neat AP. This indicates that the thermal decomposition of AP is catalyzed by HMX too. Similar effect of AP decomposition catalysis by RDX was found recently [14].

Thus, twofold HMX/AP interaction result is observed: AP decreases the onset of HMX thermolysis, whereas decomposition of nitramine, in turn, catalyzes the AP degradation.

3.2.2 Two “Scenarios” of HMX/AP Mixture Decomposition

Analysis of thermograms obtained at various component concentrations revealed that, depending on the HMX content in the HMX/AP binary mixture, thermolysis follows to one of two different “scenarios,” i.e., “independent” (several exo peaks) and synergistic (one pronounced exo peak) decomposition of components.

“Independent” regime (Fig. 4) was observed for two ranges of HMX concentration: 0< C HMX <40 % and 90 < C HMX <100 %. Decomposition starts with sharp DSC peak at 220–230 °C. The shape of first exo peak, the amount of heat release, and the mass loss at this stage correspond to the HMX concentration in the mixture, whereas the subsequent DSC peaks and the mass loss are ascribed to ammonium perchlorate decomposition.

“Synergistic” decomposition (Fig. 5) was founded for the HMX concentration lying in the range 40 % ≤C HMX ≤90 %. DSC curve has only one pronounced DSC peak around onset temperature of 225 °C, indicating both component thermolysis at this temperature. The maximum of the heat release rate is achieved at 230 °C, whereas the heat release of 2100 J/g exceeds this value for the neat HMX (1500 J/g at 280 °C) at the same experimental conditions. The catalytic effect of the HMX gaseous products on the AP decomposition is also the most pronounced within indicated HMX concentration range.

Figure 6 presents diagram of DSC signals (in one scale) as a function of HMX concentration in the binary mixture HMX/AP.

The position of the HMX exo peak strongly depends on the HMX/AP ratio. Below 40 % in mixture, nitramine decomposes at ~225 °C with the heat release corresponding to its mass, wherein ammonium perchlorate reacts mostly at temperature slightly below the neat AP, as presented in Fig. 4. Increasing of the HMX content to 40 % ≤ CHMX ≤90 % results in synergistic decomposition of both components starting at temperature 216≤ Т 0 ≤232 °С, where one sharp exo peak with higher heat release is observed. Complete mass loss of the mixture occurs in about 90 °C earlier than that for pure AP. The increase of the HMX content above 90 % leads to splitting of sharp exo peak into several peaks: part of the nitramine decomposes at temperature ~225 °C, whereas the rest of HMX – at its “own” temperature 280 °C.

3.2.3 Onset Decomposition Temperature

Figure 7 represents the T0 dependency on the HMX concentration (CHMX) within the mixture and reveals T0 to be practically independent on CHMX, except 0 and 100 % points. The observed decrease of the onset decomposition temperature and its independency on the component concentration are very probably caused by the phase transition phenomena of HMX and/or AP, occurring in the same range.

3.2.4 HMX Phase Transition

Thermal decomposition process of HMX, AP, and HMX/AP mixture was monitored by in situ FTIR measurements at heating in DSC-TGA thermal analyzer. Resulting IR spectra at temperatures just prior and at the onset point of synergistic decomposition, i.e., 150–230 °C, are presented in Fig. 8. No gas-phase products were observed in this temperature range for ammonium perchlorate, whereas for HMX two volatile decomposition products, i.e., N2O and HCN (not indicated in Fig. 8), were identified, accompanied by the small mass loss of 0.03 % within the temperature range from just phase transition point 187 °C till 230 °C.

It is known that β→δ phase transformation is accompanied by the density decrease from 1900 to 1780 kg/m3 with the correspondent increase of the crystal volume in 7 %, which in turn results in the crystal fracturing [15]. Increase of the chemical reactivity of HMX during or just after its polymorph transformation is initiated by the high mobility of the moving parts of the crystal lattice during its rearrangement, analogous to Hedvall effect – a significant change in the reactivity near the temperature of the phase transition [16]. It is known that the primary decomposition products react with the parent molecule and can therefore increase the sensitivity of the material and catalyze further decomposition. Both thermal decomposition and the phase transition are concerned with disruption of intermolecular forces (since the conformational change associated with β-δ has low activation energy).

Weeks et al. [17] used atomic force microscopy (AFM) to monitor the crystal surface during phase transition. They observed an increase in surface roughness by a factor of four and the opening up of voids.

Our observation of N2O and HCN just after the phase transition is in line with Behrens data [9] on isothermal HMX decomposition at 195 °C. These products were the first ones observed; moreover, the influence of the morphology changes on the decomposition was also noticed.

3.2.5 AP Phase Transition

The phase transition of ammonium perchlorate starts under the crystal surface [18] and proceeds in two steps [10, 18–20]. The orthorhombic to cubic transformation at 240 °C follows to the transition of AP into metastable phase (order-disorder phase transition) at about 200 °C with formation of not-oriented grains of the cubic phase, as it was found experimentally by measuring the ultrasonic velocity within AP crystals [19]. This transformation proceeds without heat effect and can’t be observed on DSC curves. The same phase transitions are known for other ammonium salts [20, 21]. At Т >240 °С the polymorph phase transition goes via formation and abrupt increase of the needle-shaped nucleus, which is the first-order phase transition with the energy cost 11.3 kJ/mol [22]. The mass loss due to low-temperature decomposition starts just after this phase transition.

Destabilization of AP crystal during phase transformation effectively facilitates the partial conversion from the ionic state to neutral NH 3 and HClO 4 molecules, which are the primary products of AP decomposition at 200–250 °С, as a result of proton transfer from \( {\mathrm{NH}}_4^{+} \) to \( {\mathrm{ClO}}_4^{-} \). Ammonia is released into the gas phase, whereas perchloric acid is predominantly accumulated at the crystal surface [11, 18, 23] .

Our FTIR experiments did not show gas-phase decomposition products after the metastable phase formation (200 °C) prior to endothermic phase transformation at 240 °C.

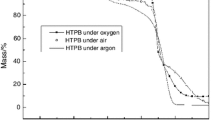

We use accelerating rate calorimetry to study the thermolysis of AP with enhanced sensitivity due to the increased sample mass. Figure 9 shows the self-heating and pressure increase rates as function of temperature in a pseudo-adiabatic environment. Decomposition of AP starts with the strong acceleration at 185 ± 5 °C, below the crystal phase change at 240 °C. The same result has been published by Bohn [24].

3.2.6 Gaseous Products at Maximum Decomposition Rate

The FTIR of gaseous products of AP, HMX, and HMX/AP (1:1) mixtures are presented in Fig. 10 at temperature corresponding to the maximum rate of the heat release (230 °C). Practically no gaseous products of AP at this temperature were detected, excepting CO2, which is most likely originated from background.

N2O and HCN peaks were identified for neat HMX. Addition of AP to HMX in proportion 1:1 results in NO2 peak appearance, indicating the N-N bond homolysis in HMX molecules, thus proving the nitramine decomposition at this temperature.

Some bands in the range of 2778–2896 cm−1 (I, Fig. 10) and 1715–1788 cm−1 (II, Fig. 10) were not identified using the NIST Standard Reference Data [25], although authors [14] contradictorily interpreted these peaks as HCl and CH2O, respectively. Note that these peaks are observed also in HMX spectra at 230 °C, but with much lower intensity.

Thus, before the onset decomposition temperature of HMX/AP (1:1) mixture, both components undergo the phase transition. According to the literature data, AP converts into metastable phase with the crystal structure rearrangement starting from 200 °C with the subsequent gas products release. ARC experiments also prove this statement. Our experiments reveal HMX begins to decompose simultaneously with the phase transition with release of N2O and HCN. Significant change of the reactivity of both components near the phase transition points (Hedvall effect) results in intensive interaction of the decomposition gas products with thus destabilized molecules.

3.3 Combustion Parameters

The burning rate of pressed samples, consisting of the HMX particles (d = 200 μm) coated with different amount of AP, i.e., having a layer of different thickness, was measured under nitrogen pressure 4 MPa. Increasing of the AP content to 30 mass % results in the burning rate growth, as presented in Fig. 11.

Burning rate dependency on the AP content under nitrogen pressure 4 MPa for two types of HMX/AP compositions:

-pressed mixtures of HMX with AP (d = 10 μm), ○-pressed mixtures of HMX with AP (d = 230 μm), and ●-HMX particles covered with AP (layer thickness 10 μm). HMX particle size is equal to 200 μm for these experiments

-pressed mixtures of HMX with AP (d = 10 μm), ○-pressed mixtures of HMX with AP (d = 230 μm), and ●-HMX particles covered with AP (layer thickness 10 μm). HMX particle size is equal to 200 μm for these experiments

To compare obtained U(CHMX) dependency with one for the mechanical mixture of components, identical samples were fabricated with HMX (d = 200 μm) and AP (d = 10 μm) particles. The size of ammonium perchlorate powder was selected to be equivalent to AP layer thickness on coated HMX particles. The evolution of the burning rate of this mixture with CHMX shows that (i) in the range 30< CHMX <93 %, close to the region of the synergistic effect appearance, U values exceed the HMX-monopropellant level at this pressure and (ii) burning rate of HMX crystals coated with AP coincides with this value for the mechanical mixture when AP particle size is close to the layer thickness. Thus, the contact between components is not a necessary condition for the HMX/AP interaction for composition without binder, proving the gas-phase character of this effect.

The use of large AP particles (d = 230 μm) for HMX/AP mixtures leads to the burning rate insensitivity to the AP content, confirming the key role of the AP specific surface for the synergistic effect implementation.

Results of the burning rate dependency on pressure for formulations HMX/AP/active binder revealed that the burning rate of the base composition HMX/active binder is increased with addition of HMX/AP mixtures, identically to U growth for formulations with HMX particles covered by ammonium perchlorate. The most important is that to get the same U(P) dependency for formulations with coated HMX as for compositions with AP and HMX as powdered ingredients, we can use much less amount of AP.

4 Summary

Experimental results on the HMX and AP interaction during constant rate heating and combustion have been presented. Thermal stability study revealed twofold HMX/AP interaction: from the one hand, ammonium perchlorate as synergistic additive effectively (i.e., from 280 to 225 °C) reduces the onset decomposition temperature of HMX; from the other hand, gaseous products of the HMX thermolysis catalyze the AP decomposition.

Depending on the HMX concentration in the HMX/AP binary mixture, thermolysis follows to one of two different “scenarios,” i.e., “independent” (several exo peaks) and synergistic (one pronounced exo peak) decomposition of components for mixtures with HMX content above 40 % and below 90 %.

Onset decomposition point does not depend on the HMX concentration (CHMX) within the HMX/AP mixture, excepting 0 and 100 % points. The observed decrease of the onset decomposition temperature and its independency on the component concentration are very probably caused by the phase transition phenomena of both components.

Our experiments revealed that before the onset decomposition temperature of HMX/AP mixture, both components undergo the phase transition conversion. AP starts to decompose at temperature far below the phase transition point 240 °C, i.e., at 185 °C with the gas products release. HMX begins to decompose simultaneously with the phase transition at 187 °C with the release of N2O and HCN. Significant change of the reactivity of both components near the phase transition points results in intense interaction of destabilized molecules with the decomposition gas products.

To study the role of the contact between components, large HMX crystals were covered with AP layer. HMX content from 70 % to 95 % for thus modified HMX particles was achieved by varying of the AP layer thickness. The burning rate dependency on the HMX content showed that in the HMX concentration range 30< CHMX <93 %, close to the region of the synergistic effect appearance, burning rate of mechanical mixtures exceeds the HMX level at pressure 4 MPa. Specific surface of ammonium perchlorate plays a key role for the synergistic effect manifestation in combustion: addition of large AP particles to HMX does not enhance the burning rate.

Comparative analysis of the combustion parameters of the mechanical mixtures and covered crystals revealed that the direct contact between components is not a necessary condition for the HMX/AP interaction for compositions without binder, proving the gas-phase character of this effect. However, for compositions with active binder, the direct contact between components is important. Thus, formulations with active binder and coated HMX provide higher burning rate than those ones with mechanical mixtures of HMX with fine AP. It means the possibility to use the considerably less amount of ammonium perchlorate to achieve the same level of the burning rate.

Obtained results need further investigations to get deeper insight into the nature of observed synergistic interaction between HMX and ammonium perchlorate.

Abbreviations

- AFM:

-

atomic force microscopy

- AP:

-

ammonium perchlorate

- ARC:

-

accelerating rate calorimetry

- DSC:

-

differential scanning calorimetry

- FTIR:

-

Fourier transform infrared spectrometry

- HMX:

-

octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine

- NIST:

-

National Institute of Standards and Technology

- SEM:

-

scanning electron microscopy

- TGA:

-

thermogravimetric analysis

References

Beckstead MW, Overview of combustion mechanisms and flame structures for advanced solid propellants. In: Yang V, Brill T., Wu-Zhen Ren (ed.) Solid propellant chemistry, combustion, and motor ballistics. Progress in astronautics and aeronautics. Washington, DC, USA. volume 185; AIAA, 2000.

Oxley JC, Smith JL, Wang W (1994) Compatibility of ammonium nitrate with monomolecular explosives. J Phys Chem 98:3893–3900

Fifer RA (1984) Chemistry of nitrate esters and nitramine propellants Fifer R.A. In: Kuo KK, Summerfield M (eds) Fundamentals of solid propellants combustion, vol 90, Progress in astronautics and aeronautics: chemistry of nitrate esters and nitramine propellants. AIAA, New York, pp 177–237, Chap. 4

Sokolov EV, Popenko EM, Sergyenko AV et al (2007) Influence of nitraminopropionitrile and its salts on the HMX thermal decomposition, Polsunovsky Vestnik № 3, pp 130–139, in Russian

Saito T, Shimoda M, Yamaya T et al (1991) Ignition of AP-based composite solid propellants containing nitramines exposed to CO2 laser radiation at subatmospheric pressures. Combust Flame 85:68–76

Fang C, Li S (2002) Synergistic interaction between AP and HMX. J Energetic Mater 20:329–344

Brill TB (1995) Multiphase chemistry consideration at the surface of burning nitramine monopropellants. J Propuls Power 11(4):740–751

Karpowicz RJ, Gelfand LS, Brill TB (1982) Application of solid-phase transition kinetics to the properties of HMX. AIAA J 21(2):310–312

Behrens R (1990) Thermal decomposition of energetic materials: temporal behaviors of the rates of formation of the gaseous pyrolysis products from condensed-phase decomposition of octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine. J Phys Chem 94(17):6706–6718

Keenan AG, Siegmund RF (1969) Thermal decomposition of ammonium perchlorate. Q Rev Chem Soc London 23(3):435–452

Koroban VA et al (1981) Mechanism of the ammonium perchlorate thermal decomposition. In: Manelis GB (ed) Thermal decomposition of ammonium perchlorate. Semenov Institute of Chemical Physics, Chernogolovka, pp 5–29

Guirao C, William FA (1971) A model for ammonium perchlorate deflagration between 20 аnd 100 atmospheres. AIAA J 9:1345–1356

Palopoli SF, Brill TB (1991) Thermal decomposition of energetic materials 52. On the foam zone and surface chemistry of rapidly decomposing HMX. Combust Flame 87:45–60

Qing-Jie Jiao et al (2014) Thermal decomposition of RDX/AP by TG-DSC-MS-FTIR. J Therm Anal Calorim 1(3), Published online. doi:10.1007/s10973-013-3621-2

Henson BF et al (1999) Dynamic measurement of the HMX β-δ phase transition by second harmonic generation. Phys Rev Lett 82(6):1213–1216

Hedvall JA (1966) Solid state chemistry – whenсe, where and whither. Elsevier Publishing Company. Amsterdam/London/New York, p 100

Weeks BL, Ruddle CM, Zaug JM, Cook DJ (2002) Monitoring High-temperature Solid-solid Phase Transitions of HMX with Atomic Force Microscopy. Ultramicroscopy 93:19–23

Boldyrev VV (2006) Thermal decomposition of ammonium perchlorate. Thermochim Acta 443:1–36

Tesleva EP (2006) Investigation of polymorphic transformations of ion-molecular insulator by physical acoustics and thermophysical techniques. Dissertation, Barnaul, in Russian

Slater JC (1939) Introduction to chemical physics. McGraw-Hill Book Co., New York, p 293

Cheselske FJ (1965) Aerojet-general rept. 0372-01F, AD 458854, AF 49(638)–851, 15 March 1965

Evans MW, Beyer RB, McCulley L (1964) Initiation of deflagration waves at surfaces of ammonium perchlorate–copper chromite–carbon pellets. J Chem Phys 40(9):2431–2438

Pellet GL, Cofer WR (1969) Thermal decomposition of ammonium perchlorate by rapid heating, seventh AIAA aerospace science meeting. N Y 20:141

Bohn MA, Pontius H (2012) Thermal behaviour of energetic materials in adiabatic selfheating determined by ARCTM. In: Proceedings of the 43rd international annual conference of ICT, pp 57-1–57-39

NIST Chemistry WebBook, NIST Standard Reference Database Number 69. In: Linstrom PJ, Mallard WG (eds) National Institute of Standards and Technology, Gaithersburg MD, 20899, http://webbook.nist.gov. Retrieved 2 Dec 2014

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Pivkina, A.N. et al. (2017). Synergistic Effect of Ammonium Perchlorate on HMX: From Thermal Analysis to Combustion. In: De Luca, L., Shimada, T., Sinditskii, V., Calabro, M. (eds) Chemical Rocket Propulsion. Springer Aerospace Technology. Springer, Cham. https://doi.org/10.1007/978-3-319-27748-6_15

Download citation

DOI: https://doi.org/10.1007/978-3-319-27748-6_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-27746-2

Online ISBN: 978-3-319-27748-6

eBook Packages: EngineeringEngineering (R0)