Abstract

This chapter deals with the most important possibilities for improving the overall vehicle performance of electrified vehicles. Thus, it describes the results and the key messages of several IEA-IA-HEV-Task 17 workshops and studies, by focusing on the following topics:

-

E-Motors: This section is focusing on the advantages and disadvantages of Permanent Magnet Motors with rare-earth permanent magnets, representing one of the most common motors being used so far (based on the reporting year 2012). Additionally it focuses on alternatives for permanent magnet motors, which are currently at a few level.

-

Battery Management Systems (BMS): A BMS constantly controls the functionality and charge of the battery cells. Therefore, it is necessary to lengthen battery life. This chapter addresses concerns for current BMS, provides an overview about their basics and highlights the most important BMS-Tasks for High Voltage batteries as well as the demonstration of a Lithium-Ion battery performance and cost model for electrified vehicles.

-

Thermal Management Systems: The optimization of thermal management has become an important business segment, as it is essential for effective operation of electrified vehicles in all climates. The results and outcomes of a study (Argonne National Laboratory) as well as various workshops addressed innovative methods for Thermal Management Systems. The results are described within this chapter and include specific thermal management technologies, explored innovations on components and Phase-Change-Materials.

-

Simulation Tools: For many years now numerical simulation has become an essential tool to engineers in the product development process. Computing methods have been refined to such an extent that today simulations are more and more referred to as a basis for important product decisions. This chapter deals with a few simulation tools in the field of system optimization and vehicle integration, including “Autonomie”, “Cruise” and “Dymola/Modelica”.

-

Functional and Innovative Lightweight Concepts and Materials: In the future, the proportion of high-tensile steels, aluminium and carbon-fibre-reinforced plastics in vehicles is set to increase from 30 % today to up to 70 % in 2030 (McKinsey & Company, Lightweight, heavy impact, 2013). High-tensile steel will remain the most important lightweight material and carbon-fiber-reinforced plastics are expected to experience annual growth of 20 %.

As Lightweight construction of the vehicle body has become a very important field of R&D activities, this chapter focus on the outcomes of a study on the impacts of the vehicle’s mass efficiency and fuel consumption (Argonne National Laboratory) as well as on various methods of light weighting a vehicle, like simulation tools, advanced “smart” materials, bionic concepts and functional integration.

-

Power Electronics and future Drive Train Technologies: Around 40 years ago, the first piece of software was used in a vehicle to control the ignition of the engine. Today, up to 90 % of all innovations in a car are realized with electronics and software, based on the customers demand for new safety and convenience functions—Advanced Driver Assistance Systems—which are the basics for autonomous driving. This chapter points out that modular drivetrain topologies are as much important as the requirement of layered, flexible and scalable architectures. The further improvement of the power control unit as well as the E/E-Architecture will play a key role in the future of electrified vehicles.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 System Optimization and Vehicle Integration

The optimization of vehicle components significantly help to improve the overalls vehicle performance. Especially light weighting the vehicle has a massive impact on the increase of range and on the improvement of energy efficiency.

The use of thermal-, and battery management but also the optimal use of power electronics and electronic and electrical architecture will be one of the key challenges and most important steps of the future.

This chapter describes the most important possibilities for improving the overall vehicle performance. Thus, it describes the outcome and the key messages of several Task 17 workshops, by focusing on:

-

overview of different e-motors and their abilities,

-

management systems like battery management systems as well as

-

thermal management systems,

-

simulation tools,

-

functional and innovative lightweight components and materials and

-

power electronics and drive train technologies for future xEVs

2 Electric Motors

In this section electric motors (e-motors) for use in EV’s are described. The focus is put on alternatives to Permanent Magnet Synchronous Motors (PMSM). Advantages and disadvantages are pointed out.

This section is hosted by Steven Boyd from U.S. DoE (year 2012).

2.1 Introduction

Currently (FY 2013), permanent magnet (PM) motors with rare-earth (RE) permanent magnets are almost universally used for hybrid and EVs because of their superior properties, particularly power density. However, there is now a distinct possibility of limited supply or very high cost of RE PMs that could make these motors unavailable or too expensive. Since the development of e-motors for vehicle applications is of interest, it should be determined which motor options are most promising and what barriers should be addressed. Currently, the focus is limited to induction and switched reluctance (SR) motors, as these types do not contain PMs and are currently used in electric drive vehicles.

In considering alternatives, cost and power density are two important properties of motors for traction drives in EVs, along consideration for efficiency and specific power.

For each technology, the following aspects can be considered:

-

current state-of-the-art performance and cost,

-

recent trends in the technology,

-

inherent characteristics of the motor, including ones that can limit the ability of the technology to meet performance targets,

-

what R&D would be needed to meet the targets,

-

potential for the technology to meet the targets

So far, alternatives are few. First, if high-strength Neodymium-Iron-Boron (NdFeB) RE magnets are not available, the following alternative PMs may be considered for use in PM motor designs: Samarium-Cobalt have similar magnetic properties to NdFeB magnets, have better high-temperature stability, but are very costly; Aluminum-Nickel-Cobalt (AlNiCo) magnets have somewhat lower cost but very low coercivity; iron or ceramic magnets are the least expensive but also are the weakest magnets; or new PM materials could be created or discovered. Next, AC induction motors are seen as a viable alternative despite lower power density compared with IPM motors, and are a mature, robust technology that can be less expensive. Alternatively, SR motors are durable and low cost, and contain no magnets. Their peak efficiency is slightly lower than that of PM motors, but the flatter efficiency profile of SR motors can give higher efficiency over a wider range of operation. Significant concerns about SR motors are torque ripple and acoustic noise. Finally, there are other alternative motor designs that have not been completely researched or characterized at this time, and further insight into these designs and reports from ongoing R&D projects may prove useful.

2.2 PM Motors

A PM motor is a hybrid motor design that uses both reluctance torque and magnetic torque to improve its efficiency and torque. These motors are created by adding a small amount of magnets inside the barriers of a synchronous reluctance motor. They have excellent torque, efficiency, and low torque ripple. They have now become the motor of choice for most EV applications. PM motors have high power density and maintain high efficiency over their entire torque and speed range except in the field-weakening speed range. This translates into a challenge to increase the constant power speed range without a loss of efficiency. Other major issues are failure modes and the relative high cost of the motor due to the cost of the (currently favored) RE PMs and rotor fabrication. Major R&D challenges are to develop bonded magnets with high energy density capable of operating at elevated temperatures and motor designs with increased reluctance torque. These developments may result in reducing the magnet cost. Other challenges include thermal management and the temperature rating of the electrical insulation.

2.3 Induction Motors

The induction motor was invented by Nicola Tesla in 1882 and is the most widely used type of e-motor. Mostly because of its ability to run directly from an alternating current (AC) voltage source without an inverter, it has been widely accepted for constant-speed applications. For vehicle applications, recent developments in low-cost inverters have made variable-speed operation possible for traction drives. Induction motors have the advantages of being the most reliable, possessing low maintenance, high starting torque, and a wide manufacturing base due to high acceptance by industry. These motors offer robust construction, low cost, and excellent peak torque capability. However, their power density is somewhat limited, and increasing speed is one of the few available paths to increase power density. So, many AC traction drives run at high speeds of 12,000–15,000 RPM at maximum vehicle speeds. This use of high motor speeds results in smaller, light-weight traction motors, but it requires a high-ratio gear box that also has associated mass and losses.

There are few recent improvements to the AC motor for vehicle applications. One of these is the use of a copper rotor instead of aluminum. Depending upon the size of the motor, the use of copper can increase the efficiency of an AC induction motor by one to three percentage points. Although this may seem like a small increase, it is significant in reducing the losses generated by the motor, easing thermal management. Depending on the vehicle, this could also add some distance to all-electric driving range as well. Another improvement that has been studied is determining the effect of different pole numbers, and it has been shown in several studies by Allen Bradley, Reliance Electric, General Electric, and Siemens that the optimum pole number for AC induction motors below 1000 NM is four poles. Increasing the pole numbers for smaller motors reduces the power factor, but is the torque density is increased in the same frame size by increasing the number of poles. For ac induction motors driven by inverters, the number of poles should be increased from 4 to 6 for motors above 1000 NM torque.

As an alternative to PM motors, induction motors are not as efficient or power dense. Furthermore, because AC motors are considered a mature technology, the likelihood of achieving the required additional improvements in efficiency, cost, weight, and volume is low. However, if PM motors become infeasible for reasons of cost or availability, induction motors seem to be the consensus next choice, and therefore remain a relevant technology for EVs.

2.4 Switched Reluctance Motors

The SR motor uses a doubly salient structure with toothed poles on the rotor and stator. Each set of coils is energized to attract a rotor pole in sequence so it acts much like a stepper motor. With current technology, SR motors have inherently high torque ripple and the high radial forces generated can create excessive noise levels if not carefully designed. These motors are currently best suited in high-speed applications where torque ripple is not an issue. In comparison with mature motor technologies such as the AC induction motor and the relatively recent brushless PM synchronous motor, the SR motor offers a competitive alternative to its counterparts despite these aforementioned issues. The basic concept of the SR motor has been around for over 100 years, but recent advances in power electronics, digital control, and sensing technologies have opened up the possibilities of the SR motor and provide some novel design opportunities which can be suited for vehicle propulsion.

Unlike most other motor technologies, both the rotor and stator of the SR motor comprise salient teeth such that torque is produced by the tendency of its rotor to move to a position where the inductance of an excited stator winding is maximized and reluctance is minimized. This condition generally occurs when the corresponding stator tooth is fully aligned with a rotor tooth. The non-steady state manner in which torque is produced in the SR motor introduces the requirement of a sophisticated control algorithm which, for optimal operation, requires current and position feedback. In addition to non-steady state operation, the SR motor often operates with the rotor and stator iron in saturation, increasing the difficulty of optimal control and making the motor very difficult to accurately model without the aid of computer processing and modelling techniques. Therefore, since the SR motor is very technologically demanding in terms of design, modelling, and control, the evolution of SR motor technology has been limited until these demands were adequately addressed. Furthermore, the progression of other motor technologies such as the induction motor and PM motor have not been as limited by the state of other technologies. Since the torque of an SR motor is based on reluctance, no excitation is required from within the rotor, making it more simple, mechanically resilient, and cost effective than other motor technologies. The absence of PM material, copper, aluminum or other artefacts in the rotor reduces the requirement of mechanical retention needed to counteract centrifugal and tangential forces. This causes the SR motor to be especially well suited for rugged applications or high-speed applications wherein high power density is desired. As there are no conductors in the rotor, only a low amount of heat is generated therein, and most of the heat is generated in the stator, which eases motor thermal management requirements. In addition to having low material costs, the simplicity of the SR motor facilitates low manufacturing costs as well.

In regards to electric drive vehicles, the primary issues with SR motors are the torque ripple and acoustic noise that is associated with the fundamental manner in which torque is produced. When current is supplied to the coil of a SR motor stator tooth with proper respect to rotor position, torque is created until the nearby rotor tooth is fully aligned with the stator tooth. Thereafter, torque is created in the opposite direction if the rotor continues to rotate and if current is still supplied to the coil. Therefore, it is typically desirable to reduce the current to zero prior to generating an undesirable torque. However, the inductive behavior of the coil and corresponding magnetic path prevent rapid evacuation of current in the coil, and thus a torque transient occurs and provokes the issue of acoustic noise and torque ripple. Perhaps the second most significant problem with the conventional SR motor is that it cannot be driven with a conventional three-phase power inverter. Nonetheless, a unipolar inverter for a three-phase SR motor contains three diodes and three switching elements, as is the case with a conventional three-phase power inverter, so similarities do exist.

Having lower material and manufacturing costs, the SR motor presents a competitive alternative to the PM motor. And while the power density and efficiency of the PM motor may not be surpassed, the SR motor can approach meeting similar metrics. Various comparison studies have shown that the efficiency and power density of the SR motor and AC induction motor with copper rotor bars are roughly equivalent, while the AC induction motor with aluminum rotor bars falls slightly behind these two types of motors.

2.5 Conclusions and Future Work

Due to the importance of electric traction drive motors to the future of EVs, motor R&D will continue to play an important aspect in the development of these vehicles. This is now further emphasized with the recent uncertainty in the future price and supply of RE magnets.

A proposal for alternatives and future work is to concentrate efforts in three distinct areas:

-

continued development of PM motors with RE magnets,

-

develop novel motor designs that use non-RE PMs or no magnets at all,

-

develop novel magnet materials that could be used in PM motor designs.

Continuing the development of PM motors using RE magnets could result in motor designs that use less RE magnet material, and maintains the technology development path with the consideration of possible future material availability through expanded RE supply or increased recycling. Developing other novel motor designs could potentially use other existing PM materials, improve upon existing motor technologies to better rival PM motor performance, or even develop new motor designs entirely. Finally, PM magnet material development could reduce the cost of existing RE PM magnets through reduced processing cost, reduce RE PM cost by reducing heavy RE content, or develop new magnets through the investigation of novel inter-metallic compounds.

3 Battery Management Systems in EVs

In this section the relevance of Battery Management Systems (BMS) (FY 2013) for system performance and costs are evaluated.

This section was partly provided by Mr. Andrea Vezzini and Ms. Irene Kunz from Bern University of Applied Sciences (BFH).

Content of this section:

-

general information and Tasks of BMS,

-

battery requirements for different configurations including: HEV, PHEV, BEV,

-

battery type considered (Li-ion),

-

information from a workshop (technology trends and open points) and information provided by BFH and ANL

In general the main electrical components of EVs can be summarized as:

-

e-motor,

-

e-motor drive (inverter),

-

(Li-ion) battery cells,

-

regenerative brakes,

-

Vehicle Control Unit (VCU) or board computer,

-

access to standard vehicle electronics systems (regular ABS,ESP, etc.) and

-

Battery Management System (BMS)

A detailed look at the components which have been used for one of the first generation BEVs (Ford) is shown in Fig. 1.

Components that will make up a BEV [1]

The VCU is a board program which reads the actual accelerator position and translates it to the actual torque of the motor. This value is sent to the inverter which drives the motor. Further, the VCU is responsible for monitoring the measured values which are relevant for the vehicle user (e.g. speed, battery SoC, etc.).

The VCU generally exchanges information with all the units in the vehicle. This means that the communication takes place with inverters, chargers, DC/DC converters, BMS and monitor devices over a Controller Area Network (CAN) Interface.

Figure 2 shows an overview of the different block modules in an EV. It is obviously, that it is very important that the BMS has access to most of these modules.

Scheme of block modules in an EV [2]

The new market segment of EVs sets off an increasing demand for battery storage systems (see Fig. 3). To guarantee a safe operation of these systems, batteries need to be protected from several malfunctions. This protection is realized with battery management systems.

High voltage battery systems require advanced BMS (image courtesy of Bosch [3])

A battery management system (BMS) is any electronic device that manages a rechargeable battery pack. The BMS is required to ensure that the cells in a battery are operated within their safe and reliable operating range. The BMS monitors voltages and temperatures from the cell stack. From there, the BMS processes the inputs, making logic decisions to control the pack performance, and reporting input status and operating state through communication outputs. Concisely, a BMS turns a collection of “dumb” cells into an intelligent, safe and more efficient battery pack [4].

Definition of the terms “battery”, “module” and “cell”:

A “battery” is the complete assembled pack of singular cells. It may consist of several modules, wired in series. In a module, single cells are connected in series or parallel (Fig. 4).

From powder to system integration (image courtesy of CEA [5])

It is possible to obtain higher currents if the cells or the modules are connected in parallel. A series connection leads to higher voltages. The module controls every cell to guarantee a proper function in the desired operating range by monitoring voltage, current and temperature. The control of these modules and battery packs is realized with a BMS. The process from the material towards the batteries prototype can be seen in Fig. 5.

BMS-Tasks for high voltage batteries [6]

3.1 Description and Tasks of a BMS in an EV Application

An intelligent implementation of a BMS will extend the battery’s lifetime and the driving range of the vehicle. The operation of a BMS in an EV includes normal protection functions like charge control and cell protection against limit-exceedance (voltage, current, temperature). BMS used in EVs have to interact with several on-board systems. Further, there is the requirement to act as a real-time application. This means that the safety-relevant applications are handled as prioritized functions and thus should never be blocked due to other less relevant functions of the electric car (like air-conditioning control).

The main functions of a BMS (for high voltage batteries, focusing on Li-ion batteries) are depicted in Figs. 5 and 6 and can be summarized as follows:

-

battery monitoring: BMS monitors key operational parameters, such as voltages, currents, and temperatures, during charging and discharging of batteries. Based on these values, BMS estimates the state of the battery [e.g. state of charge (SoC) and the state of health (SoH)]. Information which is relevant for the car driver has to be sent over CAN-Interface to the VCU. Here the data will be forwarded to the dashboard where it can be monitored. This information includes the SoC, SoH, error messages and available driving range,

-

energy/power management and prediction: BMS prevents the battery from operating outside its safe operating area such as: over-current, overvoltage, over-temperature and under temperature. The main goal of the energy management is to guarantee a constant supply of energy for the important vehicle functions. The vehicle can fundamentally be in three states: drive, park or charge. For each of these three states the priority of the different functions change:

-

in drive state, all devices which control the vehicle are to be preferentially treated;

-

if the vehicle is parked, the management system enters a sleep mode with the BMS being turned off for a period of several minutes after which, it becomes repowered to control important parameters of the battery for safety reasons;

-

in charge state a system detecting mechanical collisions on each side has to be active. If such a collision takes place, the connection between battery and vehicle will be immediately interrupted,

-

-

battery’s performance optimization: in order to maximize battery capacity, and to prevent localized under-charging or overcharging, the BMS ensures that all cells that compose the battery are kept at the same state of charge, through balancing and

-

communication: BMS communicates the above data to users/external devices. In EVs, the BMS interfaces with other on-board systems such as engine management, climate control, communication and safety systems, responsible for communications with the world outside the battery pack. The BMS transmits the measured and calculated values to the VCU which processes the data and forwards it to the right target component in the car. The SoC of the battery as an example, is forwarded by the VCU to the dashboard monitor.

Scheme of a BMS in an EV application [7]

These tasks are managed by the VCU, which can be seen as the ‘heart’ of the system.

It is important, that the program of the BMS never reaches a deadlock. Therefore the software should be implemented with a real-time operating system (RTOS). Moreover, sensitive tasks like overvoltage protection can be set to high priority in order to be processed first. On the other hand, the BMS involves also less important tasks like sending the actual SoH value to the dashboard monitor. For this task, the priority is set low.

In high power applications, around ten to over one hundred high-capacity elementary cells are series connected to build up the required battery voltage. The overall cell string is usually segmented into modules consisting of 4–14 series connected cells. Thus, the battery can be composed by three layers: namely, the elementary cell, the module and the pack.

Within each module the cells are connected together to complete the electrical path for current flow. Modern BMS systems for EV applications are typically distributed electronic systems. In a standard distributed topology, routing of wires to individual cells is minimized by breaking the BMS functions up into at least 2 categories, pack management unit and module management units (as it can be seen in Fig. 7 ). The monitoring of the temperature and voltage of individual cells is done by a BMS “sub-module” or “slave” circuit board, which is mounted directly on each battery module stack, (in a normal passenger car the number would be 10–15 modules). Higher level functions such as computing state of charge, activating contactors along with aggregating the data from the sub modules and communicating with the engine control unit are done by the BMS ‘master’ or ‘main module’. The sub-modules and main module communicate on an internal data bus such as CAN (controller area network). In an electric vehicle, the pack management unit is linked to the vehicle management system through the external CAN bus. Almost all electronic functions of the EV battery pack are controlled by the BMS, including the battery pack voltage and current monitoring, individual cell voltage measurements, cell balancing routines, state of charge calculations, cell temperature and health monitoring, which ensures overall pack safety and optimal performance, and communication with the vehicle management system [8].

BMS structure scheme [9]

In general the BMS consist of several Module Control Units, which protect the battery cells, and a top level control, which supervises the modules. Generally it includes at least voltage, temperature and current measurements. These values are processed with an Electronic Control Unit (ECU) in order to protect the single cells against malfunctions.

This protection includes the following points:

-

charge control: limitation of the rate at which the electric current is fed into or drawn from each battery cell to hold the battery in the safe operating area. This includes additional protection of the battery cells against overcharge, overvoltage and deep discharging and

-

cell balancing: in a multi-cell battery (serial connection) small differences between the cells appear due to production tolerances or different operating conditions and tend to increase with each charging cycle. Weaker cells become overstressed during charging and this causes them to become even weaker, until they eventually fail. Without cell balancing, the individual cell voltages will drift apart over time. Cell balancing is a way of equalizing the charge of all cells in the chain.

The overall control of the different modules is realized with a Battery Control Unit (BCU). This unit has the following functions:

-

precharge function: this function is needed, when the battery is connected for the first time with a system which has a high capacity (e.g. EV). In this case, a very high inrush current is flowing for a short time. To reduce these current peaks, there are two switches needed in parallel (compare Fig. 8). The switch above includes a resistor, which attenuates the current peak (precharge relay). After a while, the main switch below can be closed to reduce the connection resistance to a minimal value and

-

module protection: in the case of a battery parameter exceeding the allowable range, the unit will open immediately the main switch (compare Fig. 8).

-

SoC determination: the SoC indicates the proportion of the charge currently available in the battery compared to the fully charged battery pack (100 %). This function is comparable with a fuel gauge in a car. Chapter 6.3.2 describes different calculation methods to determine this SoC,

-

SoH determination: the SoH is a relative figure of merit. It provides the actual condition of the battery compared to the completely new battery (100 %) whereas 0 % corresponds to a completely worn out battery pack. The SoH can be determined by the decrease in the capacity of the battery with increasing age. More information on the determination methods for the SoH is provided in Chap. 6.3.3,

-

demand management: this function provides an intelligent energy management system, which stores the energy amount in the battery as long as possible. The energy management system has to be adapted individually to each specific application,

-

communication with host: the BMS transmits data to a host computer or an external device. The data can then be stored or plotted in a Graphical User Interface and

-

history (log book function): monitoring and storing the data over an extended period of time is another possible function of the BMS. Parameters such as number of cycles, maximum or minimum voltage, temperature and maximum charging and discharging current can be tracked.

BMS topology

BMS technology varies in complexity and performance:

-

active regulators intelligently turning on and off a load when appropriate, again to achieve balancing further a complete BMS also reports the state of the battery to a display, and protects the battery,

-

simple passive regulators achieve balancing across batteries or cells by bypassing charging current when the cell’s voltage reaches a certain level. The cell voltage is a poor indicator of the cell’s SOC, thus, making cell voltages equal using passive regulators does not balance SOC, which is the goal of a BMS. Therefore, such devices, while certainly beneficial, have severe limitations in their effectiveness.

BMS topologies fall in 3 categories:

-

centralized: a single controller is connected to the battery cells through a multitude of wires. They are most economical and least expandable,

-

distributed: a BMS board is installed at each cell, with just a single communication cable between the battery and a controller. These are the most expensive, simplest to install, and offer the cleanest assembly,

-

modular: a few controllers, each handing a certain number of cells, with communication between the controllers. Modular BMS offer a compromise of the features and problems of the other two topologies [10].

3.2 SoC Determination Algorithm

At the moment no direct way of measuring the SoC is provided. There are indirect ways of estimating it but each has limitations. This session deals with several indirect determination methods:

-

voltage based SoC estimation,

-

current based SoC estimation,

-

combination of the current and

-

voltage based methods and SoC estimation from internal impedance measurement.

Voltage based SoC estimation

Several cell chemistries show a linear decrease of voltage with decreasing SoC. This characteristic is used to determine the actual SoC. It is possible to estimate the actual SoC by measuring the open circuit voltage of the battery. Figures 9 and 10 show the discharge voltage of two different battery chemistries. The characteristics are dependent on the temperature and the discharge rate.

Open circuit voltage vs. remaining capacity for a lead acid cell [11]

Open circuit voltage versus remaining capacity for a Li-ion cell [12]

In Fig. 9, it can be seen that the voltage in a lead acid battery decreases significantly as it is discharged. By knowing this characteristic the battery voltage can be used to estimate the SoC. A drawback of this method is that the battery voltage is dependent on the temperature and the discharge current. These effects have to be compensated in order to increase the accuracy of the estimation.

In the case of Li-ion batteries in Fig. 10, the voltage changes only slightly. So the estimation of the SoC is nearly impossible. However the voltage of a Li-ion cell changes at both ends of the characteristic abruptly. This effect can be used to detect if the battery cell is fully charged or depleted. But in most systems an earlier alert is required, because a completely discharge of a Li-ion cell will significantly reduce its life span.

Current based SoC estimation (coulomb counting)

With the coulomb counting method the charge which flows in and out of the battery is measured. It is not possible to measure the charge directly. Therefore a measurement of the current is needed, which will be integrated over time.

The start of the measure has to be in a defined initial state, for example if the battery is fully charged. Then the determined charge value is measured relatively to the fully charged battery cell. The drawback of this method is that in case of even a very small current sensor offset, the SoC determined will show a deviation from the real value. Due to the fact that this error is integrated over time it leads to significant estimation errors in longer time periods. This effect is shown in Fig. 11.

Drift of the SoC due to a current sensor offset [13]

Combination of the current and voltage based methods

A calibration of the integrator’s output can be realized if the coulomb counting variant and the voltage based method are combined:

-

the battery current is integrated to get the relative charge in and out of the battery,

-

the battery voltage is monitored to calibrate the SoC when the actual charge approaches either end.

This method is a more accurate and reliable way to estimate the SoC (compare Fig. 12).

Combining current and voltage based SOC-algorithm for higher accuracy [14]

A drawback of this method is that the application in HEVs is not possible. Because the normal SoC range in a HEV is between 20 and 80 %. It never reaches the threshold voltage on either end.

SoC estimation from internal impedance measurement

In a discharging cycle the cell impedance varies with the SoC. Therefore by measuring the internal impedance it is possible to determine the SoC (compare Fig. 13).

Internal resistance of a lead acid battery versus OCV—Open Circuit Voltage [15]

In all battery technologies the internal resistance will increase at the end of a discharging cycle. This effect can be used to determine the actual SoC. This method is rarely used because the battery has to be disconnected from the system to measure the internal resistance. Moreover the results are very temperature sensitive.

If changes of the voltage and current can be measured, then it is possible to calculate a dynamic approximation of the internal resistance with the following formula:

With this variant it is possible to estimate the resistance online, this means without disconnecting the battery.

A further effect, which is observed in Li-ion batteries is that the internal resistance also changes at a SoC of 100 % (bathtub function in Fig. 14). The largest change of the internal impedance occurs in the range of 0 to 30 % and from 80 to 100 % SoC.

Internal resistance of a Li-ion battery versus cell capacity (DoD) [16]

3.3 SoH Determination Algorithm

There are several battery parameters which change significantly with increasing age:

-

increase of the resistance,

-

decrease of capacity.

The SoH can be determined from one of these values. Basically the SoH describes the actual condition of the battery in relation to the new battery pack. But actually every BMS manufacturer defines the SoH differently. For a new battery it is necessary to fully charge and discharge the battery in order to determine the initial capacity. This value has to be permanently stored in the BMS, because this value determines 100 % SoH.

After an arbitrary number of cycles, i.e. 100 cycles a correction of the SoH is required, based on a new reference measurement.

First the battery should be fully discharged and in the next charging cycle the capacity of the battery is determined. By comparing this value with the capacity of the completely new battery it is possible to determine the SoH of the battery.

A plot of the capacity versus the number of cycles is shown in Fig. 15. In this graph the Depth of Discharge (DoD) is 100 % (the battery was fully discharged in each cycle). A decrease of capacity with increasing number of cycles is observed.

Cycle life time of Li-Ion Phosphate cell, 2.3 Ah [17]

3.4 Integration of BMS into the EV—State of the Art

In EVs, the battery system has to be developed as an integral part of the vehicle to avoid malfunctions (see Fig. 16). In the planning phase of the vehicle design, it is important to reserve space for all the battery systems and the BMS. The best solution is to design the system in modular blocks which could then be placed in different locations within the vehicle allowing an optimal use of the available space.

Implementation of BMS [18]

These modular blocks consist of the BMS, charger unit and battery modules. The voltage of the battery pack can be determined from the number of battery modules connected in series.

Two additional points which have to be considered:

-

one critical point is the integration of a thermal management in the vehicle. The battery can be cooled down either by air or water flow. An advantage of the water-cooling version is the higher thermal cooling capacity. Moreover the battery can also be heated through the cooling water if other heat sources are included in the same coolant loop (e.g. e-motor, power electronics). Often liquid cooling uses special heating elements and the water is a good medium to distribute that heat,

-

the second issue is to protect the battery in case of an accident. Attention has to be paid to the fact that the battery is not located in the crash zone, where the battery can get mechanically damaged (Fig. 17).

Fig. 17 Integration of a battery system in an EV [19]

The weight of the whole battery pack should be reduced as much as possible. Figure 18 shows that the Li-ion technology is well applicable in EVs due to its high energy density compared to other cell chemistries. In the current EV models, often a combination of Li-ion batteries and supercaps is used. The supercap can provide high power for short-time periods. This power is used to accelerate the vehicle.

Energy density of different battery chemistries [21]

The lithium content in a high capacity lithium battery is actually quite small (typically less than 3 % by weight) [20]. Lithium batteries used in EVs and HEVs weigh about 7 kg (15.4 lb)/kWh. Thus their lithium content will be about 0.2 kg (0.4 lb)/kWh. Current EV passenger vehicle use batteries with capacities between 30 and 50 kWh (lithium content will be about 6 (13 lb) to 10 kg (22 lb) per EV battery).

The capacity of HEV batteries is typically less than 10 % of the capacity of an EV battery and the weight of Lithium used is correspondingly 10 % less.

Several BMS structures (compare Fig. 19) are currently offered on the market and differ in simplicity and price.

As it can be seen in Fig. 19, the different BMS structures can be divided into:

-

single board: this is the low cost variant, the BMS is assembled on one single printed circuit board (PCB). The battery modules do not require any special electronics beside voltage, current and temperature sensing devices. The BMS board consists of several application specific integrated circuit (ASICs) which controls the battery modules. The top-level control is supervised by the BCU. This unit disconnects the battery from the application as soon as one battery parameter exceeds the predefined range. Advantage: low cost BMS; Disadvantage: each measurement point has to be connected individually to the BMS board,

-

smart modules: in this case, each battery module has its own ASIC, which protects the module directly. The ASIC’s are able to communicate with the battery control unit over a serial peripheral interface (SPI). All connections from the single board structure can be reduced to one SPI bus common for all modules. Advantage: less wire connections than in the single board structure; Disadvantage: the module control unit can only send information if the BCU (Master) is requesting it which could lead to data loss,

-

light intelligent modules: in this case, the communication disadvantage of the smart modules has been resolved. The Module Control Unit (MCU) in this case communicates over a private CAN interface with the BCU; in this way errors can be prevented. To initialize this way of communication on each module is a microcontroller needed. In this configuration, the MCU performs the following tasks: measure and supervise the voltage, measure temperature and balance the cells. The BCU includes the determination of SoC and SoH, the thermal management and the control of the precharge relay. A further task is to connect the BMS with the rest of the vehicle via CAN bus and

-

full intelligent modules: The only difference of this configuration, compared with the light intelligent module, is that some functions of the BCU will be taken over by the MCU. This includes for example determination of SoC and SoH.

3.5 Examples of Integrated BMS in EVs and HEVs

Daimler MILD-HYBRID S400 (Reporting Year 2009)

The S400 BlueHYBRID (see Fig. 20) was the first series-production model to be equipped with a Li-ion battery. Continental and Johnson Controls Saft (JCS) were teaming on the pack, with JCS was providing the cells. The compact hybrid module is a disc-shaped e-motor that also acts as a starter and generator. The hybrid module also has a start/stop function, and supports regenerative braking.

Daimler Mild-S400 BlueHYBRID with Li-ion battery pack [22]

The high torque of the e-motor at low speeds offsets the reduction in low-end torque resulting from applying the Atkinson cycle to the combustion engine.

Moving to a more powerful e-motor increased the weight of the hybrid system and decreased the fuel consumption. Furthermore, at a higher electrical to combustion power ratio, the e-motor operates increasingly in less favorable areas of the performance map as maximum requirements increase. Although relatively low in power, the e-motor delivers rated torque of 160 Nm (118 lb-ft), contributing to a combined system torque of 385 Nm (284 lb-ft).

The power electronics comprise a control unit which acts as the master of the E-drive system and a power unit that converts the direct current generated by the battery. The power electronics can cope with continuous currents of 150 A, and short-term as high as 310 A. Power is supplied to the e-motor by a bus bar.

The power electronics are situated in the engine compartment in the location of the conventional starter motor and are cooled by a separate circuit.

Li-ion battery pack: the compact Li-ion pack (compare Table 1), developed by Continental and JCS Saft, comprises 35 cells and provides 19 kW of power, with a capacity of 6.5 Ah. The battery is connected to the vehicle air conditioning circuit so it can be cooled independent from the engine. Cut-off valves are integrated into the system that allows the customer to switch off the air conditioning without interrupting battery cooling. When the engine is not running, the electric A/C compressor not only provides air conditioning but also guarantees that the battery’s operating temperature limits are not exceeded. Battery pack temperatures do not increased above 50 °C (122 °F) in any operating state to prevent serious damage.

Operating strategy: the operating strategy of the S400 hybrid is based around start/stop, regenerative braking, boost and load point shifting. When providing support for load-point shifting, the operating strategy only allows shallow discharge cycle of the Li-ion battery to maintain the cycle strength. Fuller deployment of the electrical support is only provided based on the driver’s request, as indicated by accelerator pedal position and a large pedal value gradient. The focus of SoC swings is in the range of 5 %. Values of up to 10 % occur less frequently, while SoC cycle of more than 10 % are rarely observed. This contributes to the 10-year expected service life.

GM Chevrolet Volt (2012)

At the heart of the Chevrolet Volt, a sophisticated battery-stack management system ensures the safety and reliability of the multi-cell Li-ion battery stack (see Fig. 21) that delivers power on demand to the Volt drive system. Within the management system, battery-monitoring boards use two key subsystems to reliably monitor cell health and deliver digital results to a host processor that orchestrates system operation. Separating those subsystems, a signal interface ensures isolation between high voltage battery-sensing circuitry and communications devices on the boards.

GM Chevrolet Volt (view of battery) [23]

The Chevy Volt was described as an example of an extremely sophisticated vehicle. Over 100 microprocessors were used among in the various subsystems, to control each system. The majority of these controlling microprocessors were in the battery pack (for the BMS) and the inverter controlling the motor.

The Volt’s BMS (compare Fig. 22) runs more than 500 diagnostics at 10 times per second, allowing it to keep track of the Volt’s battery pack in real-time, 85 % of which ensure the battery pack is operating safely and 15 % monitor battery performance and life.

The Chevy Volt BMS [24]

The battery installed in this vehicle has the following characteristics, as shown in Table 2.

In a PHEV, the battery will be discharged with the full vehicle power over a longer period (e.g. highway driving in pure electric mode). Therefore the battery has therefore to be sized accordingly. In this example of the Chevrolet Volt the pack is arranged in tunnel and under the seat.

Nissan Leaf (2014)

Perhaps the best known and highest selling EV on the market is the Nissan Leaf. The all electric Nissan Leaf was the first affordable, mass produced, lithium battery EV. Key to the Leaf’s success was a battery design that balances safety, performance, cycle life, calendar life, energy density, power density, charge rate, discharge rate, weight, structural integrity, and thermal management.

The Nissan Leaf’s battery is made of 48 modules. Each module is made with 4 large surface area laminate Lithium Manganese/Lithium Nickel batteries. The module battery configuration is 2p 2s, meaning that two of the cells are wired in parallel and then this pair of cells is wired to the other pair in series. The results in a 7.4 V nominal voltage battery module with approximately 33 Ah. The modules are encased in an aluminum enclosure. Together these 48 modules form a string that produces between about 290 V empty and 400 V full. The total energy storage capacity of this battery system is approximately 24 kWh.

Each module is essentially sealed, with no active thermal management system installed in the pack. Here, the thermal management is done via passive means, with the heat of the cells being transferred to the metal enclosure of the modules and then to the external pack enclosure.

The Leaf is using a centralized BMS, with a single control unit and a wiring harness that extends to each module (Fig. 23).

Nissan Leaf BMS [25]

Renault ZOE (2015)

In early 2015, Renault announced that due to an improved BMS, as well as to the motor, Renault is able to increase the ZOEs range. The new “more compact” motor (10 % less volume)—including improved BMS—will reportedly increase the range of the ZOE by around 8 %, roughly 20 km (12.5 mi.) on the generous European testing cycle. It also accelerates quicker but consumes less power than the original motor. The ZOE uses a 22 kWh Li-ion battery (see Fig. 24).

Battery module of Renault ZOE [26]

Renault has been granted 95 patents for its passenger car e-motor. Innovations include replacing the previous liquid cooling with air cooling (the power control unit is still liquid cooled) and reducing the size of the power control unit by 25 %. The ZOE now features a built-in Chameleon charger that can recharge at either 3 kW or 11 kW. The charger is now built into the power control unit and charging times have been reduced.

One aspect of EV that is largely ignored by ordinary drivers is the BMS. Electric car batteries are composed of many individual cells. It is possible for some cells to become fully depleted sooner than others or to be fully recharged sooner. The BMS constantly monitors the SoC of each individual cell to maximize power and to prevent overcharging [27].

The Renault engineers have substantially upgraded the BMS for the ZOE to better manage battery usage. Those changes play a major role in the car’s improved performance and longer range. In essence, the new software uses the stored electrical energy more efficiently.

Especially this example highlights the key role of a BMS.

3.6 Technology Trends of BMS

BMS have a significant potential for improvement regarding the determination of the SoC. As discussed in this chapter, there are several methods available to measure the actual charge, but none of the options are accurate concerning Li-ion batteries.

One of the main problems is that the batteries will exhibit different characteristics depending on their history (temperature, charge/discharge cycles).

The current trend therefore is to implement an observer (Fig. 25), which compares the actual values of the battery with a state space model running in parallel. Using a Kalman Filter Feedback several internal parameters of the battery (SoC, SoH etc.) are tracked and corrected if necessary.

An improvement of the SoC determination is mainly needed in HEVs, because there the battery operates only within a limited SoC range (20–80 %). As discussed above the coulomb counting method is not accurate enough in this SoC range over extended periods of time.

In order to accurately determine the SoC and therefore achieve an optimal performance of the system it is important to obtain an exact characterization of the battery. Therefore a detailed battery model is needed (compare Fig. 26).

Basically, the battery model can be split into two parts:

-

electrical battery model and

-

thermal battery model

With the application of this determination method, the system is suitable for on-line calculation. The disadvantage in this case is the high complexity of the model which has to cover also the complete operating temperature and dynamic range of the battery. The dynamic range takes into consideration different chemical phenomena taking place within the cell over a wide frequency spectrum. The model also should cover pulsating currents (pulses of several seconds) as well as constant currents over minutes. Moreover, the aging of the battery has also to be taken into account within the battery model.

Bosch presented their development scenario and future trends for BMS at a Task 17 workshop (Geneva, 2011). Figure 27 highlights where future BMS will focus on. State of the art BMS are focusing on safety, while next generation BMS will have their focus on optimized generation and further more on extended functionality.

State of the art and development scenario of BMS [28]

3.7 BatPaC: A Li-Ion Battery Performance and Cost Model for Electric-Drive Vehicles

The information for this section have been provided by a revised final report [ 29 ]: “Modeling the Cost and Performance of Lithium-Ion Batteries for Electric-Drive Vehicles” and by the information on a Task 17 workshop in Chicago (2011) on battery performance and cost by Kevin Gallagher from ANL.

The United States Vehicle Technology Office has supported work to develop models that help researchers design and calculate potential costs of batteries. One major model is the bottom-up Battery Performance and Cost Model (BatPaC) at ANL. This model was developed utilizing efficient simulation and design tools for Li-ion batteries to predict: precise overall (and component) mass and dimensions, cost and performance characteristics—understand how performance affects cost—battery pack values from bench-scale results

The recent penetration of Li-ion batteries into the vehicle market has prompted interest in projecting and understanding the costs of this family of chemistries being used to electrify the automotive powertrain. The performance of the materials within the battery directly affects the end energy density and cost of the integrated battery pack. The development of a publically available model that can project bench-scale results to real world battery pack values would be of great use.

This first version of the model, the battery performance and cost (BatPaC) model, represents the only public domain model that captures the interplay between design and cost of Li-ion batteries for transportation applications.

BatPaC has more accurate predictions than previous models and allows vehicle manufacturers to choose the best and smallest battery for the application. Based on expert recommendations of this model, the U.S. EPA used BatPaC to develop its most recent round of fuel economy standards. In addition, work at the National Renewable Energy Laboratory led to a multi-scale multi-dimensional framework for battery design that uses computer-aided engineering tools.

Approach to understanding cost and energy

BatPaC is built on a foundation of work by Paul Nelson at Argonne. It Designs Li-ion battery and required manufacturing facility based on user defined performance specifications for an assumed cell, module, and pack format (power, energy, efficiency, cell chemistry, production volume). Thus, it calculates the price to OEM for the battery pack produced in the year 2020. Therefore, it isn’t modeling the cost of today’s batteries but those produced by successful companies operating in 2020; some advances have been assumed while most processes are similar to well-established high-volume manufacturing practices. BatPaC efficiently completes calculations in fractions of a second [30].

Assumed battery format: cell

Various cell and battery design concepts are under development of battery manufacturers. ANL found out that the exact design of the battery doesn’t have an import effect on the cost for a set cell chemistry; the amounts of electrode materials and the number, capacity and electrode area of the cells are the determining cost factor. The most common cell designs for batteries nearing large scale production are cylindrical wound cells, flat wound cells, and prismatic cells with flat plates.

Some previous efforts were based on flat-wound and cylindrical cells. The assumed format of ANL scientists is most likely not the best design, however those successful in producing batteries in the year 2020 will reach similar energy densities and costs through other means.

To provide a specific design for the calculations, a prismatic cell in a stiff-pouch container was selected (compare Fig. 28).

Prismatic cell in a stiff-pouch container, to enable calculations [31]

Battery Pack Design

The cells are placed on their sides in the module. The model designs the battery pack in sufficient detail to provide a good estimate of the total weight and volume of the pack and the dimensions of the battery jacket so that its cost can be estimated. The modules in a row are interconnected, negative to positive terminals by cooper connectors. The modules (Fig. 29) are supported by a tray that provides space for the heat transfer fluid (ethylene glycol-water solution) to flow against the top and bottom of each module.

Assumed battery format: module and pack [32]

Modeling of battery design and performance

The design portion of the model calculates the physical properties of a battery based on user defined performance requirements and minimal experimental data (compare Fig. 30). The user is asked to enter a number of design parameters such as the battery power, number of cells and modules, etc. In addition, the user must enter one of the following three measures of energy: battery pack energy, cell capacity or vehicle electric range. The model of the battery cost calculations is shown in Fig. 31. This figure shows the baseline Li-ion battery manufacturing plant schematic diagram. This baseline plant is designed to produce 100,000 battery NCA-Gr packs per year. This figure highlights also the adjustment of costs for varying production volumes.

Summary flow of the design model [33]

Battery cost calculations [34]

Illustrated results

For a set battery pack power, the number of cells in the pack has substantial effects on the price of the pack, the pack voltage and the maximum current. These effects are illustrated in Fig. 32 for NMC441-Gr PHEV25 batteries (providing 40 km (25 mi.) electric range) with 60 kW power at a V/U = 0.8. The price of the pack increases by 17 % in changing the number of series-connected cells in the pack from 32 to 96 and the entire pack integrated cost increases by 15.7 %. The integrated cost includes additions to the vehicle air-conditioning system to provide for battery cooling and the BMS with disconnects. The change of the maximum current, resulting from differing pack voltages, would also affect the cost of the motor and the electronic converter and controller, but in the opposite direction.

Optimization of system costs [35]

Thus, BatPac demonstrates how to reduce the cost of today’s batteries by lowering the cell count, moving to large cell formats (from 15 to 45 Ah) and by increasing the maximum achievable electrode thickness. Further, it quantifies the benefits of the future chemistries, as it can be seen in Fig. 33.

Path forward for Lithium battery research [36]

The developed BatPaC model may be used to study the effects of battery parameters on the performance and the manufactured cost of the designed battery packs.

BatPaC can be downloaded by the following link: http://www.cse.anl.gov/batpac/download.php.

3.8 Selection of BMS Suppliers and Manufacturers

As this Task started in 2010, where e-mobility was not so familiar and common as it is today, one of the key activities of this Task was the collection of different suppliers and manufacturers. During the last five years of reporting a lot of business fields have been changed, modified, extended or have been removed. Thus, quiet a lot of suppliers and manufacturers which have been reported from the first Operating Agent in 2011, are not existing anymore, due to financial crises, a wrong business plan or the weak demand for e-mobility.

This section of the report tries to show a selection of common suppliers, in order to enable an overview of different model and concepts.

AVL List GmbH

The Austrian company AVL is the world’s largest independent company for the development of powertrain systems with internal combustion engines as well as instrumentation and test systems.

AVL Software and Functions offers, among others, innovative and automotive-compliant solutions for the following core functions of different battery types: the determination of the loading and health condition (SoC and SoH), the provision of different functions (SoF), active and passive balancing and cell failure detection.

The BCU consists of both, a low voltage and a high voltage part. The low voltage part includes a powerful 32 Bit floating point CPU, and several output drivers to control auxiliary components like HV contactors, water pumps, LV relays, fans or charge sockets. A variety of digital and analog input ports ensure enough flexibility for additional sensors and signals.

The high voltage part of the BCU includes high voltage measurement inputs and an integrated isolation guard, capable of up to 800 V total system voltage.

The vehicle interface is designed to be simple and easily understandable. The battery activation can be done by a discrete wake-up signal or a combination of wake-up signal and a single CAN request. The internal battery control (switching contactors, contactor weld diagnoses, balancing, isolation monitoring, SoC calculation, and much more) is handled by the BCU and does not need external algorithms. The BCU outputs the necessary CAN signals like pack and DC-link voltage, pack current flow (100 Hz), voltage and current limits, temperatures and SoC.

Hardware

The BCU features a 32-bit microcontroller including a wide variety of I/Os to manage and communicate with various sensors and actuators as well as to interface with the module control units. The BCU supports up to 3 CAN networks which are typically used for vehicle communication, internal CAN between BCU and MCUs and optional CAN for such items as instrumentation CAN or service CAN. There is also a redundant digital synchronization and fault circuitry for BCU/MCU network safety monitoring.

The MCU is an 8-bit controller that supports up to 12 cells in series. The MCU senses cell voltage (every cell) and temperature (up to 4 temperatures per module) and reports these values to the BCU. There are different MCU HW design sizes available, from minimal sized MCU (passive balancing, XX communication) to smart-MCUs for 48 V packs incorporating all necessary features for standalone operation.

Software functions

The in-house developed BMS software comprises basic and application layer software. Many functions are model based. Supported functions include: Battery Core Functions, BCU State Control, Contactor Control, Electrical Hazard Protection, Thermal Management, Battery Protection, Module Control, BCU Communication, Charge Control, Diagnostic Event Handling, Diagnostic Event Manager and Balancing Control: Control cell balancing [37] (Fig. 34).

Overview of AVL module system [38]

A123 Systems

A123 Systems, LLC develops and manufactures advanced Nano phosphate lithium iron phosphate batteries and energy storage systems that deliver high power, maximize usable energy, and provide long life, all with excellent safety performance.

A123’s system design takes advantage of the patented Nano phosphate® cell technology which delivers high power, excellent safety, and long life. This high-performance cells are incorporated into battery modules which serve as the building blocks for advanced energy storage systems. All modules and systems are built with high-grade components, battery management systems, and thermal management for long battery life and retained capacity.

A123 has developed and validated an automotive-grade electronics and software set for battery management, designed to ensure the safe and reliable operation of large battery systems. The distributed system consists of a battery control module, current sense module, monitor and balance electronics, and an electrical distribution module. Features of the BMS include industry standard CAN and diagnostic interfaces, SoC and SoH algorithms, charge management, and safety management. The BMS components can be reused use across energy and power systems to enable rapid design and development of a cost effective system.

Figure 35 shows the Nano phosphate® Energy Core Pack (23 kWh) module, which is designed for PHEV and EV applications as ready-to-use sample packs for rapid deployment into powertrains for testing and development purposes. Off-the-shelf energy core packs offer an already finished design to facilitate early vehicle development with less lead time and no engineering charges. Each pack comes equipped with battery management electronics, thermal management, and standard vehicle communication and control interface.

Cell (left), module (middle) and system (right) [39]

AKASOL Engineering

The German company AKASOL, develops and produces innovative Li-ion battery systems for the automobile and commercial vehicle industries, as well as for wind energy, hydropower, and solar industries as well as for the shipbuilding industry. Thus, this company is working on battery systems like AKASYSTEM (previously known as AIBAS), which is one of the world’s most powerful battery solutions for BEVs or (P)HEVs. The system is freely scalable, automotive-certified, standardized, and ready to order and made in Germany. AKASYSTEM operates with passive and active thermos management using liquid cooling. Cell temperatures therefore always remain within the recommended range even under heavy use. This promotes high performance values and prolongs service life.

The basis of the modular scalable Li-ion AKASYSTEM (compare Fig. 36) battery systems is formed by the highly integrated module AKAMODULE (see Fig. 37).

AKASYSTEM is regarded as one of the most powerful battery solutions [40]

Battery system and module by AKASOL [41]

One of the decisive advantages: despite the extremely high functional integration on a modular level, the AKAMODULE achieves energy density of more than 140 Wh/kg. This enables long vehicle range with simultaneously exceptional durability. Every AKAMODULE is cooled with a water-glycol fluid mix and it provides an extremely compact and lightweight solution here with an intelligent combination of housing and cooling structure. The technical data of the battery module is shown in Table 3.

Bosch

Bosch Battery Systems develops, manufactures and markets battery systems for all kind of xEVs (see Fig. 38). As well as providing individual components, Bosch Battery Systems also offers a full range battery system—all from a single source. The areas of operation are including: battery systems for HEVs, PHEVs and BEVs, modules for systems, hardware and software for BMS as well as thermal management systems. Thus, it covers all types of applications including Li-ion battery technology for automotive powertrain applications.

Overview of different battery systems by Bosch [42]

Bosch is working on smart Li-ion BMS and is developing a system that sends data through the cell connectors rather than a dedicated communications network. The system, designed for EVs and PHEVs, should boost performance, safety and battery service life as well as reducing weight in Li-ion packs. Bosch is researching the innovative system, which uses the path travelled by the electricity in the battery to carry data. The data is then sent to a central control unit, eliminating the need for costly data-transmission wiring (see Fig. 39).

Using a battery’s internal wiring to send data [43]

Bosch’s intention is to constantly monitor and to control each battery cell individually. This will allow optimum use of the battery’s energy. If a single cell in the battery is no longer operating efficiently, then only that single cell will have to be replaced, not the whole module. Migrating data transfer to the internal wiring would allow the battery pack’s energy use to be optimized, and would also help to reduce costs.

I+ME ACTIA

I+ME ACTIA performs research of new battery technologies based on Ni- MH and Lithium Polymer (LiPo) batteries. They have also been working on the development of BMS since 1995. The BMS are mainly designed for the implementation of NiMH or Li-Po batteries in mobile applications.

The BMS of I+ME ACTIA consists of one master and up to 20 slaves (compare Fig. 40).

Master (left) and slave (right) unit of Actia [44]

The master function includes the voltage measurement for the whole battery and the communication with the slave modules. The master takes control over the protective relay, if a limit is exceeded. Further, the SoC and SoH were determined and can be sent over a CAN Interface to the vehicle controller. Thus, the master consists of 8 digital inputs with different characteristics, 8 digital outputs for activation of contactors or relays, CAN bus for communication with other control units, an Ethernet interface for representation of system data and status RS232 interface for communication with a PC.

Whereas the slave module is responsible for measuring the cell voltages, it includes also the cell balancing of the battery module. Here we have an accuracy of maximum ±5 mV.

The slave consists of a microprocessor controlled part of the BMS, the measuring and monitoring of 5–10 cells on a Li-ion basis, the measuring of voltage and temperature of cells and control the voltage balancing, 10 differential analogue inputs and 3 analogue inputs for measuring of temperatures.

Moreover the slave measures the temperature and sends all data to the master unit for the top-level control. The limit values of the BMS can be configured by software.

The battery systems of this company are often used in hybrid vehicles, bicycles, forklifts, wheel chairs and robots. The technical details of the Master and Slave unit are online available [45].

Johnson Control

Johnson Control supplies complete battery systems covering activities from design to manufacturing and is the leading independent supplier of hybrid battery systems to make vehicles more energy-efficient (see Fig. 41). It was the first company in the world to produce

Product portfolio of Johnson Control (batteries from left to right: advanced start-stop vehicles; micro HEVs; (P)HEVs and EVs) [46]

Li-ion batteries for mass-production HEV. The BMS from Johnson Control is well suited for applications in the automotive sector. Battery systems using the Johnson Control BMS are able to interact with other automotive systems and adjust their performance to go with the ever-changing conditions. This is realized with the help of microprocessors and hardware adaptations. Further in this BMS a thermal management is included. Thus, Johnson Controls has expertise in designing, developing, and integrating fully integrated air- and liquid-cooled battery thermal management systems.

Electronic Management-Johnson Controls’ system electronics integrate cell balancing for extended driving range and battery life. Diagnostics and voltage monitoring can be run on each individual cell which includes temperature controls. Johnson Controls has the capability to design and produce the cell supervision circuit and balancing electronics in our global Li-Ion battery technology centers and facilities. The technical specifications are listened in Table 4.

The functionality of the Johnson Control Battery management system is shown in Fig. 42. This figure shows that the BMS gains on the one hand information from the power electronics and the motor, while on the other hand the BMS controls the power output stage. Over the battery disconnect unit, the battery can be suspended from the electronic. This is for secure, if a failure occurs. Further the charger gives information of the battery to the BMS, which adapts the characteristics to the actual battery. The thermal management is important, due to the fact that the temperature of a Li-ion battery does not exceed the temperature limitation. Else the life expectancy of the battery will decrease.

BMS functionality of the firm Johnson Control [48]

The BMS (compare Fig. 43) measures the battery voltage and current. With this information the system is able to control the secure of the system. Moreover the cell balancing is supervised and also the temperature.

Schematic of the BMS [49]

4 Thermal Management

During the last years strong attention has been paid to increase the energy density of EVs batteries or to improve the energy consumption of the electric powertrain as well as of the auxiliary components of the vehicle. For BEVs, heating and cooling the cabin is an issue, many people have been working on since years.

Thermal management has a high potential for improving fuel economy and reducing emissions of HEVs and BEVs. Thus, thermal management of batteries is essential for effective operation in all climates. During the last years, the optimization of thermal management of vehicles has become an important business segment [50].

Thermal Management effects (compare Fig. 44):

-

fuel/energy consumption (e.g. friction losses, combustion process, recovery of energy losses, efficiency, etc.),

-

emissions (e.g. cat-light-off, EGR/SCR strategies, etc.),

-

engine performance (e.g. effective cooling, engine efficiency, reduction of friction losses, etc.),

-

comfort and safety (e.g. cabin conditioning, windscreen defrosting, etc.)

Compared to a conventional vehicle in a HEV there are additional heat sources like e-motors, power electronics, batteries, etc. which have to be kept in a certain temperature range to generate high efficiencies and protect components against overheating. Due to the interaction between different subsystems like the combustion engine, e-motor/generator, energy storage and drive train for hybrid systems a comprehensive simulation model is necessary.

Figure 45 gives an overview about different drive train configurations, including the ICE, micro HEV, mild HEV, full HEV and PHEV/BEV and their requirements concerning new vehicle constraints; new thermal needs and new systems and components. This picture demonstrates the need for further thermal management systems.

HEV/EV thermal management activities [51]

During the last years a lot of companies and R&D institutions realized the demand for thermal management solutions. Therefore two Task 17 workshops were held in Chicago (2013) and Vienna (2014), focusing on Thermal Management Systems (TMS) and concepts for HEVs.

Companies and Research Institutes as ANL, Austrian Institute of Technology (AIT), Delphi, Fraunhofer, qpunkt, Valeo presented their results and concepts.

A selection of the most imported ones are mentioned in this section.

Overview of ambient temperature impact and drive pattern on energy consumption for HEVs, PHEV and BEV

The ANL highlighted the ambient temperature impact and drive pattern on energy consumption. Thus, they compared a BEV (Nissan Leaf 2012), HEV (Toyota Prius 2010) and a conventional one (Ford Focus 2012).

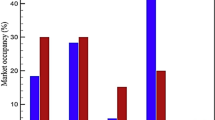

The study included a comprehensive thermal study: 7 vehicles spanning conventional vehicles (CV) (gas and diesel), HEVs (mild to full), a PHEV and a BEV, which have been tested on cold start UDDS, hot start UDDS, HWFET and US06 at ambient temperature of −7 °C (20 °F), 22 °C (72 °F) and 35 °C (95 °F) with 850 W/m2 of sun emulation (compare Fig. 46).

Wide technology spectrum of research vehicles [52]

The output of this study demonstrates the following facts:

-

−7 °C (20 °F) cold start has the largest cold start penalty due to high powertrain losses and frictions. Once a powertrain reached operating temperatures, the energy consumption is close to the 22 °C (72 °F) results again (see Fig. 47),

Fig. 47 UDDS energy consumption for cold and hot start [53]

-

35 °C (95 °F) environment requires a constant A/C compressor load which impacts the energy consumption across all vehicle types on hot and cold starts,

-

worst cases scenarios for the different vehicle types:

-

CV: 35 °C (95 °F) environment due to 4–5 kW of extra air conditioning load,

-

HEV: both −7 °C (20 °F) and 35 °C (95 °F) have a large range of increase due to a change in hybrid operation (fuel and electricity trade off),

-

PHEV: −7 °C (20 °F) where the PHEV uses both the engine and the electric heater to warm up the powertrain and the cabin,

-

BEV: −7 °C (20 °F) due to 4 kW of heater which can double the energy consumption on a UDDS,

-

-

Battery system resistance doubles from 35 °C (95 °F) to −7 °C (20 °F) for all battery chemistries in the study

Looking in more detail into the study, as it can be seen in Fig. 48, using the heater in an electric car may double the energy consumption in city type driving. Figure 49 shows that driving at higher speeds and aggressively will increase the energy consumption in an electric car.

Using the heater in an electric car may double the energy consumption in city type driving [132]

Driving at higher speeds and aggressively will increase the energy consumption in an electric car [54]

By comparing the cold start energy function and the hot start energy consumption it is obviously that the cold start energy consumption is larger than the hot start one (see Fig. 50).

Cold start energy consumption is larger than the hot start energy consumption [55]

Figures 51 and 52 are showing the largest energy consumptions increases for a BEV and for a conventional one. Thus, the largest energy consumption increase for an EV occurs at −7 °C (20 °F) and for a conventional at 35 °C (95 °F), while a conventional vehicle has the largest absolute energy consumption penalty on a cold start.

Largest energy consumption increase for an EV occurs at −7 °C (20 °F) and for a CV at 35 °C (95 °F) [56]

A conventional vehicle has the largest absolute energy consumption penalty on a cold start [57]

Figure 53 shows that generally increased speeds and accelerations translate to higher energy consumption, except for the conventional due to low efficiency in the city.

Generally increased speeds and accelerations translate to higher energy consumption except for the CV due to low efficiency in the city [58]

For more information of this study refer to Journal of Automobile Engineering [59].