Abstract

Understanding the dynamics and implementing successful soil drainage is one of the key components to applying soil physics. Water management is a critical key to success for most commercial outdoor enterprises. This chapter will help explain the science of soil drainage and address some of the myths associated with the science, including the use of nonscientifically-based practices and unproven materials and products. The chapter also covers various drainage methods including surface and subsurface, soil modification to improve drainage, drain line types and use concepts including successful field application of Hooghoudt’s equation. Real world application of drainage concepts and practices are then used in field situations such as golf course greens and fairways plus sports fields including football, soccer and baseball fields. Questions at the end of the chapter are applicable, being from actual field situations. Ample illustrations and photographs help reinforce the written concepts throughout the chapter.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Drainage

- Surface drainage

- Subsurface drainage

- Soil modification

- Volume to volume ratios

- Drain lines

- Hooghoudt’s equation

- Golf greens

- Golf fairways

- Sand capping

- Sports fields

- Native soils

- Modified sports fields

- Football

- Baseball

- Soccer

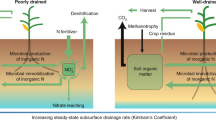

Water management is the primary key to success for most commercial turfgrass facilities. Soil serves as the storehouse for water used for plant growth that must be readily available to satisfy the demand created by transpiration . Being able to apply water when needed (irrigation ) and being able to expediently remove excess water (drainage) ensures good plant growth and prevents prolonged delay in play. Improper or inadequate drainage is the most common agronomic problem cited by golf course superintendents and sports field managers (Fig. 2.1a, b). As with many topics in turfgrass management, drainage is a subject widely misunderstood, full of myths, nonscientifically-based practices, and unproven materials and products.

All too often, the concepts, machines, and technology used to design and construct roads are used to build turf facilities. In most cases this is a serious mistake, as the exacting requirements and internal drainage needs for turf sites are much different and more precise than for roads.

2.1 Drainage Methods

Two primary forms of drainage are utilized in turfgrass facilities—surface and subsurface.

-

1.

In surface drainage , land surfaces are reshaped, sloped , and smoothed as needed to eliminate ponding and to induce gravitational flow overland to an outlet (Fig. 2.2a). Diverting and excluding water from an area often involves diversion ditches, swales, and floodways (Fig. 2.2b).

Fig. 2.2 A combination of surface and subsurface drainage systems are needed for high profile turf venues which must play regardless of weather conditions. Left illustrates a “crowned” sports field with sideline drains which capture surface runoff while right demonstrates surface contouring to redirect excessive surface runoff away from a golf green

-

2.

With subsurface drainage , soils may be modified to induce surface water infiltration and percolation through the rootzone to buried drains that collect and transport excess soil water to an outlet (Fig. 2.3). The drop in pressure (or water potential ) due to outlet discharge induces excess soil water flow into the drains. Subsurface drainage may also involve interceptor drains oriented perpendicular to the direction of groundwater flow.

A combination of surface and subsurface drainage is often required to quickly remove water from the soil surface to minimize delays in play, avoid excessive compaction , and allow maintenance practices to continue (Fig. 2.4).

2.1.1 Surface Drainage

Surface drainage is often a missing component in the design of modern golf courses and sports fields . Traditionally, sports fields were raised (crowned) in the center to encourage surface drainage. More recently, soccer fields , for example, have almost totally gone to “flat” surfaces, as have many football fields . Some of the major problems of poor playability and performance of these facilities are caused by insufficient surface drainage, especially when the rootzone has poor internal drainage properties. Almost all long-term successful turfgrass facilities have adequate surface slope (grade) to remove excess surface water. Surface drainage uses the potential energy existing due to elevation change to provide a hydraulic gradient . The surface drainage system creates a water-free surface by moving surface water to an outlet at a lower elevation. For native soil constructed (or push-up) facilities characterized by low infiltration and poor internal drainage from high silt and clay content of the soil, surface drainage represents the only effective method for removal of excess surface water. Several designs are available to help facilitate surface drainage (Fig. 2.5).

Runoff occurs when the rate of precipitation or irrigation exceeds the soil infiltration rate (the rate water can enter a soil). The infiltration rate is dependent on the permeability of groundcover and on two soil parameters: soil structure and soil texture . Infiltration into heavier textured soils, such as clay , will be slower than infiltration into lighter soils, such as sandy soil. Soils with a low moisture content have higher infiltration rates that continue until the point of saturation is reached, the rate of water entry then begins to slow.

As water enters the soil, pores (large and small) near the soil surface fill first. When pores become full, gravity begins to move water downward. Water on the soil surface will puddle (or pond) if the water application rate exceeds the amount of water gravity can pull further down the profile. Once soil saturation is reached in shallow golf green or sports field profiles, the rate of water entering the soil is dependent on the rate the subsoil can remove it. If water sits or ponds on the surface, the whole topsoil is saturated. This is most common in surface depressions and on flat surfaces. If play commences while soil is saturated, the moisture acts like a lubricant allowing the soil particles to slide closer together, causing compaction . Turf plants and roots are easily damaged when soils are saturated (Fig. 2.6). In addition, saturated soils contain less oxygen, thus encouraging anaerobic conditions that lead to root loss and possible buildup of toxic gases such as carbon dioxide and methane, as well as substances such as iron and aluminum oxides, the chief causes of black layer.

A major advantage of good surface drainage is the capability to remove large volumes of water. This capability is especially important during heavy rainfall events as a 1 in rainfall across 1 ac equals 27,154 gal (25 mm over 0.40 ha equals 102,870 L).

2.1.1.1 Slopes

The slope at which a particular surface should be constructed is determined by several variables. Slopes up to 3 % (1:33) are acceptable for soils with poor infiltration rates (Fig. 2.7). In competitive sports, players and coaches often feel slopes greater than 3 % affect ball roll and play. A minimum of 1 % slope (1:100) is almost always necessary for proper surface drainage, except with extensively modified rootzones and subsurface drainage such as USGA or California-style constructed greens or sports fields . For these modern greens , the surface slope surrounding the cup should typically be no more than 3 % for bermudagrass or ryegrass or no more than 2 % for bentgrass greens to prevent putting speeds from becoming excessive. For most non-modified soils, a 1.5 % (1:66) to 2.5 % (1:40) slope is usually adequate.

The following equation calculates the velocity of water across a bare surface as influenced by the surface slope and depth of ponded water or rainfall:

where:

-

V = Velocity (in s −1)

-

D = water depth (in)

-

S = slope (decimal)

Note: The constant 0.35 includes conversion factors valid only for units shown.

Examples

-

1.

What runoff velocity would a 1 in (25 mm) rainfall onto saturated soil with a 1 % slope yield?

$$ \begin{array}{l}\mathrm{V}=0.35\times {(1)}^{0.67}\times {(0.01)}^{0.5}\hfill \\ {}=0.035\; in\;{s}^{-1}\left(0.09\; cm\;{s}^{-1}\right)\;\mathrm{water}\ \mathrm{movement}\ \mathrm{over}\ \mathrm{a}\ \mathrm{bare}\ \mathrm{surface}\hfill \end{array} $$ -

2.

A similar rainfall on a 2 % slope would yield:

$$ \begin{array}{l}\mathrm{V}=0.35\times {(1)}^{0.67}\times {(0.02)}^{0.5}\hfill \\ {}=0.049\; in\;{s}^{-1}\left(0.12\; cm\;{s}^{-1}\right)\;\mathrm{water}\ \mathrm{movement}\ \mathrm{over}\ \mathrm{a}\ \mathrm{bare}\ \mathrm{surface}\hfill \end{array} $$ -

3.

On a 3 % slope , velocity increases to:

$$ \begin{array}{l}\mathrm{V}=0.35\times {(1)}^{0.67}\times {(0.03)}^{0.5}\hfill \\ {}=0.06\; in\;{s}^{-1}\left(0.15\; cm\;{s}^{-1}\right)\;\mathrm{water}\ \mathrm{movement}\ \mathrm{over}\ \mathrm{a}\ \mathrm{bare}\ \mathrm{surface}\hfill \end{array} $$

These examples demonstrate the large amount of surface water drainage provided by properly designed and constructed slopes. Insufficient slope means water must be drained through soil infiltration , which can be too slow to be efficient.

The length of slope becomes important as areas at the bottoms of long slopes remain wet for longer periods than areas further up the slop e; thus, they become subject to wear and compaction . Such areas are often found at the intersection of surface drainage from the fairway and front of golf greens (Fig. 2.8). This type of damage also often occurs in front of soccer and football goals. Golf course fairways should be designed so surface drainage is toward the outside edges of the fairway, rather than down the slope toward the green (Fig. 2.9). A maximum practical distance for surface drainage is approximately 150 ft (46 m). A minimum slope for adequate grassed surface drainage is 2 to 3 %.

2.1.2 Subsurface Drainage

Subsurface drainage involves water movement through a soil profile and often includes the installation of subsurface drains to remove excess water that can create undesirable (i.e., saturated) growing conditions (Fig. 2.10). Water available to plants is held in soil by capillarity, while excess water flows by gravity into drains. This lowers the groundwater level below the rootzone of plants. The movement of water into drains for turf facilities is influenced primarily by:

-

1.

Soil permeability—this includes soil horizontal and vertical water permeability.

-

2.

Drain spacing—this is often determined using Hooghoudt’s equation .

-

3.

Depth of drain—drain depth and spacing are interrelated. As the depth of the drain increases, generally so does the optimum spacing distance between drain lines .

-

4.

Drain size—more correctly, the ability of the drain to lower the water potential sufficiently to promote water movement to and out of the drain.

2.1.2.1 Soil Modification to Improve Permeability

Soil modification to enhance internal soil moisture percolation is a common practice in the turfgrass industry. However, several misconceptions exist regarding soil modification to improve permeability. One such misconception is manifested in the practice of applying a 2 to 6 in (5 to 15 cm) layer of sand over a native soil with little or no surface slope provided and no subsurface drain lines installed. This is often referred to as the “bathtub” effect where the finer-textured native soil will not adequately drain and the coarse-textured sand holds water like a bathtub (Fig. 2.11). Heavy rainfall then causes saturation of the added sand layer and surface water accumulates, causing poor playing conditions. This is why most heavy use turf areas need 10 to 12 in (25 to 31 cm) of modified topsoil and properly spaced drain lines to lower this excess surface moisture further down in the soil profile (refer to Chap. 3 to determine appropriate sand depths). The drains act similar to a drain in a bathtub, providing a means of water removal.

Another misconception is that an inch (~2.5 cm) or so of a coarse sand, such as a river bottom sand, can be tilled into the top 3 to 6 in (7.6 to 15 cm) of native soil to enhance internal percolation. Unfortunately, this practice is rarely successful. First, a uniform, medium to medium-coarse sand that has consistent particle size should be used. River bottom sand often has a wide range of particle sizes; this variety in particle size allows smaller silt and clay particles to become dispersed among the larger sand particles, effectively reducing the pore space for water to percolate. Similarly, adding sand to native soil, which often has a high degree of silt and/or clay , often “clogs” these larger internal sand pores , again reducing internal percolation. Lastly, trying to uniformly “mix” the surface applied sand with the underlying soil is virtually impossible with a tractor-mounted roto-tiller. These machines will not provide the blended soil mix desired (Fig. 2.12). Proper mixing requires “off-site” machine blending.

Table 2.1 demonstrates the results of blending high-quality (USGA specified) sand into a native Cecil clay soil. The sand:clay blend was performed “off-site” in a laboratory, providing a very uniform distribution of sand and soil in the various ratios. As shown in Table 2.1, adding just 10 % clay soil to this sand reduced its hydraulic conductivity by almost 85 % (from 58 to 9 in h −1, 148 to 23 cm h −1). Conductivity values quickly dropped as the clay soil content increased; for example, with a 50:50 blend, the hydraulic conductivity was less than 0.2 in h −1 (0.5 cm h −1), totally unacceptable by today’s standards. Furthermore, adding 20 % sand to the soil reduced drainage more than 50 % compared to straight (100 %) soil. This again represents small soil particles “clogging” the larger pores between sand particles.

The following equation provides a guideline for using a suitable sand with a soil of known mechanical composition to create a rootzone with the desired drainage rate:

where:

-

A = weight of sand to add to 100 weight units of the original soil. Note: this is an absolute value regardless of their positive or neg ative signs.

-

B = percent of original soil in the desired particle-size range (e.g., 0.125 to 0.5 mm).

-

C = percent of desired particle-size range (e.g., 0.125 to 0.5 mm) in the sand used as an amendment .

-

R = percent of desired particle-size range (e.g., 0.125 to 0.5 mm) sand in the final mix.

Example

Assume the following particle-size distribution (%) and bulk density values are found in the sand and soil sources listed below. Determine volume and weight of sand to be added to the soil to achieve a Ksat value of 9 in h −1 (23 cm h −1) based on values in Tables 2.1 and 2.2.

If a 9 in h −1 (23 cm h −1) percolation rate is desired for this sand :soil rootzone , the R value would be 90 % as determined from Table 2.1 in the desired particle-size range of 0.125 to 0.5 mm. The values of B and C would be determined by adding the known values in the columns for 0.5 to 0.25 mm and 0.25 to 0.125 mm particle size for the soil (B) and sand (C) from Table 2.2.

Therefore, 220 tons of sand per 100 tons of soil would be required to raise the percentage of soil particles between 0.125 and 0.5 mm to 90 % in the final mix.

Note: Values generated are absolute values regardless of their positive or negative signs, as the actual calculation value in the previous example is −220.

If mixed on a volume basis (such as with off-site blending) instead of a weight basis, one must find the volumetric ratio of sand to soil using the equation: volume = mass/density . The bulk density of sand in this example is 1.65 g cm −3 and soil is 1.35 g cm −3, giving:

Therefore, 1.8 unit volumes of this particular sand are needed per one unit volume of this soil to achieve the desired ratio of 220 tons of sand per 100 tons of soil.

2.1.2.2 Calculating Volume to Volume (V/V) Ratios

If one wishes to determine the outcome of mixing sand with topsoil on a volume to volume (v/v) ratio basis, the following calculations can be performed for a sand to soil ratio mix.

Example

Calculate the new percent particle size in the 0.5 to 0.25 mm range from the sand/soil ratio listed in Table 2.2 in a 3:1 ratio.

The following example demonstrates how to determine the new particle-size distribution obtained by tilling a known volume of sand into native soil.

Example

1,500 tons (1,814 metric tons) of sand with a bulk density of 1.65 g cm −3 is tilled into the top 5 in (13 cm) of native soil 1.7 ac (0.7 ha) in area. Calculate the predicted new particle-size distribution percentages and bulk densities .

First, determine the depth of 1,500 tons of sand over the 1.7 ac:

Since 4.7 in (12 cm) of sand in depth is to be tilled into the top 5 in (13 cm) of soil, it is possible to approximate the new particle size distribution percentages and bulk density using a 1:1 ratio as presented in Table 2.2.

Although this equation helps predict projected particle-size distribution and bulk density values of two known sand/soil sources , it cannot be reliably used to predict hydraulic conductivity (or “perc”) rates. For example, with the same sand and soil from the previous example (Table 2.1) in a 1:1 ratio, the following calculations could be performed to attempt to predict a percolation rate for the mix.

However, when actual samples are mixed in a 1:1 ratio, the percolation rate is only 0.15 in h −1 (0.4 cm h −1) (Table 2.1). The small amount of fine-textured clay in the soil mix is sufficient to “clog” the pores in the sand , thus reducing the actual percolation. This demonstrates the importance of actually measuring particle-size distribution, bulk density , and hydraulic conductivity (percolation rate ) of the various soil/sand mix being considered as well as the ratios of each.

Table 2.3 reflects the percent (by volume) change when a known amount of amendment is mixed into a soil. For example, if a contractor places 2 in (5 cm) of an amendment on the existing soil surface and roto-tills this 6 in (15 cm) deep , the theoretical percent volume this added amendment occupies is 25 %.

2.1.3 Lateral Soil Water Movement

Lateral (sideways) water movement in a soil is influenced or restricted by three factors:

-

1.

Depth (hydraulic head) of the saturated free-water zone in the topsoil .

-

2.

Hydraulic conductivity of the rootzone soil.

-

3.

Slope of the subgrade or base.

As a soil absorbs more water into its pores, a saturated zone develops and reaches the subsoil base. Until this saturated zone reaches the subsoil base and a buildup of “free water” occurs atop this much less permeable layer, little water will move laterally (sideways). This saturated zone of free water is the only water moved horizontally by resultant forces due to the vertical force of gravity . The smaller the soil pore space, the slower water will move laterally.

Lateral water movement ceases when the free-water zone is removed. This occurs even if the capillary fringe is still saturated. Hooghoudt’s equation (discussed later) is used to calculate the rate at which the saturated free-water zone of the topsoil will drain at the midpoint between two drains (the slowest draining point).

Lateral water movement in soil is generally limited in distance and time. However, gravity is able to “pull” water down a sloped base (subgrade). The steeper the subgrade slope, the greater the effect of gravity . Generally, water will move laterally (sideways) along the subgrade’s surface in direct proportion to the subgrade’s slope. For example, if the slope is 2 % (1:50), water will move laterally 2 % (or one-fiftieth) as fast as it will move downward. If the rate of downward movement of water in a soil is 15 in h −1 (38.1 cm h −1), the maximum rate at which water would move laterally due to the same head would be 2 % of 15 in h −1 = (0.02 × 15 in h −1) = 0.3 in h −1 (0.76 cm h −1).

In addition, for water to continuously drain (move) down the subgrade, water must be removed from the end or low point of the subgrade with drains or ditches. If this water is not removed, an equilibrium will be reached, often resulting in ponding of water on the surface and excessively wet conditions at the end of a slope or against an impermeable obstruction such as a wall. Such conditions frequently occur when water drains down banks or hills onto a flatter playing surface (Fig. 2.13). In this case, disposal of water from the bottom of the slope can be achieved by: (1) installing a cutoff surface drain at the top of the hill to collect water before it reaches the hill (Fig. 2.14); (2) constructing a terrace to move the water gently across or around the perimeter of the hill; or (3) most commonly, by placing an interceptor drain near the bottom of the hill (discussed earlier).

2.1.4 Drain Lines

Subsurface drain lines are designed to function as open channels, meaning the water flow through the pipe is from the influence of gravity due to the slope or grade of the pipe, not from pressure pushing water through the pipe (Fig. 2.15). If the subsurface drainage pipe tries to convey more water than it was designed for, it will first fill to capacity and then become pressurized along some portion of its length. When perforated pipes become pressurized, water tries to escape through the inlet holes of them. This pressure on the water in the drain line trench can create flow back into the surrounding soil, causing the soil to become saturated. This can cause the saturated soil to begin to act like a fluid and flow, thus making it prone to high levels of erosion. When under extreme pressure, drainage pipes can erode out of the trenches, requiring extensive repair. This is especially true near the outlet of a long run of pipe at a steeper slope. This pipe pressure can also create a floating ‘lens’ of water between the turf and soil. The turf and thatch layer essentially floats off the soil surface, creating play and maintenance problems. The key to avoid this problem is to properly size the drainage pipe, taking into account the expected water flows, so the pipe can function as an open channel.

Two parameters largely determine the rate at which water is removed by a drain; (1) depth and (2) spacing of drain lines. In addition, the slope of drain lines in the trenches also affect drainage capacity. Generally, the deeper the drain lines and closer their spacing, the quicker and more effectively soil moisture is removed. However, water cannot enter a drain any faster than the soil around it can conduct water into it. Optimum depth and spacing are directly related to the permeability of the soil. Since golf greens have a relatively shallow rootzone (~1 ft, 30 cm) of highly permeable soil (sand ), and need to quickly and completely remove surface water so play can resume, their optimum drain spacings are much narrower (closer) than most unmodified soil situations.

As mentioned, the closer drain lines are together, the faster a profile will drain. Also, as the free-water depth in the soil profile decreases, so too does the gravitational gradient. A deeper topsoil has a greater storage space in the profile for the free-water zone. Therefore, in shallower soils, the rate of drainage and soil water storage capacity decrease and drains need to be spaced closer together. Golf green drainage lines should be spaced so water will not have to travel more than 10 ft (3 m) to reach any individual line. If the golf course is situated on an area with a high water table , it may be necessary to place larger drainage lines deeper into the subgrade to lower the water table and handle the increased internal flow of water.

Calculating drainage line spacing can be done with a modification of Hooghoudt’s equation . In Hooghoudt’s equation, the drain discharge is assumed to equal the incoming rainfall or irrigation , and the water table midway between drains is maintained at a steady height above the drain level. Water enters the soil more rapidly nearer to the drains than midway between them. The equation takes into account both horizontal flow and radial flow caused by the convergence of flow lines over the drains (Fig. 2.16). In shallow topsoil , widely spaced drains only remove water from a very small area immediately adjacent to the drains and do not adequately drain the topsoil between them.

Hooghoudt’s equation and components used to determine proper spacing of drainage lines. S is the distance between drain line spacing, v is the amount of rainfall or irrigation applied, and h is the height or depth of the saturated zone with free water, also known as the water table . Hydraulic conductivity of the soil is another variable needed to calculate drain tile spacing. Hooghoudt’s equation calculates drainage at the slowest draining point over the total soil surface in consideration

2.1.4.1 Hooghoudt’s Equation

where:

-

S = Drain line spacing (in); the units used for h must be the same as those used for S.

-

K = K sat = Saturated hydraulic conductivity (in h −1) of the soil.

-

h = Height of the (saturated) free-water zone midway between the two drains (in).

-

v = Drain discharge rate, assumed to equal irrigation or rainfall rate (in h −1).

Normally, the anticipated maximum rainfall or irrigation event rate is used here.

Since S and h are squared in Hooghoudt’s equation , varying them will change the drainage rate by the square of the magnitude of drains distance apart or height, respectively. In other words, if drain spacing (S) is halved, or depth of the saturated zone (h) is doubled , the effective drainage rate of drains increases fourfold. Conversely, shallower topsoil and wider-spaced drains decrease soil water drainage rates exponentially.

Two calculations are suggested. The first involves the assumption of a worst-case scenario where the free-water zone extends to the surface or the total depth of the topsoil resulting in ponding. The other calculation is performed with the free-water zone lowered by 2 or 3 in (5 or 7.6 cm). This gives an indication of how quickly water can be removed from the top of the profile. Often this removal is slow if drains alone are being relied on.

Several points are illustrated by Hooghoudt’s equation:

-

1.

As the allowable free water (water table ) depth (h) decreases (i.e., the shallower the topsoil), the gravitational gradient decreases, resulting in decreased drainage, and the closer drain lines need to be spaced. Conversely, the deeper the topsoil, the greater the storage space in the profile for the free-water zone, and the further apart drain lines may be spaced.

-

2.

The closer the drains, the faster a profile will drain.

Note: Hooghoudt’s equation becomes inaccurate when drain spacing (S) approaches the same value as the height of the saturated free-water zone (h). However, this does not occur often in turfgrass facilities since relatively shallow topsoils are used. Hooghoudt’s equation cannot be used in a two-tier soil profile with a sand rootzone over a gravel bed (USGA specified green). The gravel bed allows rapid vertical rootzone drainage and movement to the drain pipes, and soil water movement is most influenced by the saturated hydraulic conductivity of the rootzone. For Hooghoudt’s equation to be accurate, the soil must be uniform in hydraulic conductivity and must have an impervious layer located below the soil and the drain.

Example

If the hydraulic conductivity of a loam soil is 12 in h −1 (30 cm h −1), the height from the drain line to the soil surface is 18 in (46 cm), and the design rainfall event is 1 in h −1 (2.5 cm h −1), determine the drain line spacing required to prevent ponding.

2.1.4.2 Calculating Necessary Soil Hydraulic Conductivity

Hooghoudt’s equation also can be rearranged to calculate the desired hydraulic conductivity (percolation) for a given drain line spacing:

Example

-

1.

If an area has a proposed drain spacing of 10 ft (120 in or 30 cm) between drain lines , a 10 in (25.4 cm) deep rootzone above the drains, a 1 in h −1 (2.54 cm h −1) anticipated rainfall rate, and the free-water zone extends to the surface, as might occur after prolonged rain, determine the necessary hydraulic conductivity (in h −1) of the soil.

$$ \mathrm{K}=\frac{{\mathrm{S}}^2\mathrm{v}}{4{\mathrm{h}}^2}=\frac{{\left(120\; in\right)}^2\times \left(1\; in\;{h}^{-1}\right)}{4\times {\left(10\; in\right)}^2}=36\; in\;{h}^{-1}\left(91\; cm\;{h}^{-1}\right) $$ -

2.

If the same area had a 12 in (1 ft or 30 cm) deep rootzone instead of 10 in (25 cm), what would be the necessary hydraulic conductivity of the soil?

$$ \mathrm{K}=\frac{{\mathrm{S}}^2\mathrm{v}}{4{\mathrm{h}}^2}=\frac{{\left(120\; in\right)}^2\times \left(1\; in\;{h}^{-1}\right)}{4\times {\left(12\; in\right)}^2}=25\; in\;{h}^{-1}\left(63.5\; cm\;{h}^{-1}\right) $$ -

3.

If the same 10 in (25 cm) rootzone area had an anticipated maximum rainfall of 0.5 in h −1 (1.3 cm) instead of 1 in h −1 (2.5 cm h −1), what would be the necessary hydraulic conductivity of the soil?

$$ \mathrm{K}=\frac{{\mathrm{S}}^2\mathrm{v}}{4{\mathrm{h}}^2}=\frac{{\left(120\; in\right)}^2\times \left(0.5\; in\;{h}^{-1}\right)}{4\times {\left(10\; in\right)}^2}=18\; in\;{h}^{-1}\left(46\; cm\;{h}^{-1}\right) $$

2.1.4.3 Calculating Drainage Rates

Hooghoudt’s equation can also be rearranged to calculate the drainage rate between subsoil drains.

where: v = drainage rate (in h −1) of the saturated free-water zone at the midpoint between drains.

Example

-

1.

A soil has a hydraulic conductivity of 2 in h −1 (5 cm h −1), a saturated depth midway between the drains of 10 in (25 cm), and drains spaced 10 ft (120 in or 3 m) apart. Determine the drainage rate at the midpoint between the drain lines .

$$ \mathrm{v}=\frac{4{\mathrm{Kh}}^2}{{\mathrm{S}}^2}=\frac{4\times \left(2\; in\;{h}^{-1}\right)\times {\left(10\; in\right)}^2}{{\left(120\; in\right)}^2}=0.055\; in\;{h}^{-1}\left(0.14\; cm\;{h}^{-1}\right) $$ -

2.

If the soil’s depth in the above example is increased to 12 in (0.3 m), determine the new drainage rate at the midpoint between the drain tiles.

$$ \mathrm{v}=\frac{4{\mathrm{Kh}}^2}{{\mathrm{S}}^2}=\frac{4\times \left(2\; in\;{h}^{-1}\right)\times {\left(12\; in\right)}^2}{{\left(120\; in\right)}^2}=0.08\; in\;{h}^{-1}\left(0.2\; cm\;{h}^{-1}\right) $$ -

3.

If the same soil in question 2 has drain tile spaced at 15 ft (180 in or 4.5 m) instead of 10 ft (3 m), what will be the resulting drainage rate?

$$ \mathrm{v}=\frac{4{\mathrm{Kh}}^2}{{\mathrm{S}}^2}=\frac{4\times \left(2\; in\;{h}^{-1}\right)\times {\left(12\; in\right)}^2}{{\left(180\; in\right)}^2}=0.036\; in\;{h}^{-1}\left(0.09\; cm\;{h}^{-1}\right) $$Increasing tile spacing from 10 to 15 ft (3–4.5 m) decreases the drainage rate from 0.08 to 0.036 in h −1 (0.2–0.09 cm h −1).

-

4.

Now determine the drainage rate for the above example if tile lines are spaced 5 ft (60 in or 1.5 m) apart.

$$ \mathrm{v}=\frac{4{\mathrm{Kh}}^2}{{\mathrm{S}}^2}=\frac{4\times \left(2\; in\;{h}^{-1}\right)\times {\left(12\; in\right)}^2}{{\left(60\; in\right)}^2}=0.32\; in\;{h}^{-1}\left(0.8\; cm\;{h}^{-1}\right) $$Decreasing tile spacing from 10 to 5 ft (3–1.5 m) increases the drainage rate from 0.08 to 0.32 in h −1 (0.2–0.8 cm h −1).

These examples illustrate that, the closer the drain tiles or deeper the saturated rootzone , the faster a profile will drain. Specifically, if the drain spacings are halved, drainage increases fourfold. Similarly, as soil depth is doubled, drainage increases fourfold.

2.1.4.4 Determining Drain Line Discharge Rates

If the length of the drain line is known (Fig. 2.17), then the total amount of water expected to drain from a particular area following a known amount of rainfall or irrigation can be determined from the following equation, modified from Darcy’s and Hooghoudt’s equations :

Variables used in the modified Hooghoudt’s equation and Darcy’s Law for determining the total volume (area) of a section of drained soil and appropriately sized drain lines . S is the distance between drain lines, v is the amount of rainfall or irrigation applied, and h is the height or depth of the saturated zone of free water, also known as the water table ; w is the width (length) of the drain line

where:

-

Q = discharge rate of water from drain line (in 3 h −1),

-

K = Ksat = saturated hydraulic conductivity (in h −1),

-

h = height of saturated free water zone midway between drains (in),

-

w = length of the drain line (in),

-

S = drain line spacing (in).

Example

Determine the volume of water flowing from an area with a drain spacing of 10 ft (120 in or 3 m), drain lines of 12.5 ft (150 in or 3.8 m) length, and a rootzone hydraulic conductivity of 16 in h −1 (41 cm h −1), with the saturated zone midway between the drain lines at the surface of a 10 in (2 cm) rootzone. (Water has a volume of 0.00434 gal in −3, 1 ml cm −3.)

Therefore, drain lines should be selected that can remove at least 18 gal h −1 (68 L h −1).

Hooghoudt’s equation can be used here to calculate the rainfall or irrigation rate expected to cause the saturated zone to rise to the surface, in this example, the rootzone depth of 10 in (25 cm).

2.1.4.5 Determining Drain Size and Length

Sizing drain pipe for a particular area requires a considerable amount of information, including proposed drain depth, slope, width, length, and spacing; average rainfall event (inflow rates); soil type; area to be drained; and surface slope. First, the amount of water to drain following a rainfall event needs to be determined. Hooghoudt’s equation is only valid for drainage rates (equal to rainfall rates) where the saturated zone does not rise above the rootzone surface . A more conservative design for effective pipe length can be performed by assuming the entire rootzone to be saturated. This results in a drainage system designed to remove water at rates equal to the design rainfall rates, even during flood conditions.

Example

Calculate the effective length of (a) 2 in (5 cm) and (b) 4 in (10 cm) diameter drain pipe with 1 % slope and a drain spacing of 10 ft (3 m), following a design rainfall event of 2 in h −1 (5 cm h −1) [1 ft 3 (0.028 m 3) = 7.5 gal (28 L)].

First, the rate of water every foot (0.3 m) of trench should collect is calculated as:

-

a.

The maximum drainage rate the pipe can handle is 7.9 gal min −1 (30 L min −1) based on the manufacturer’s specification for 2 in (5 cm) pipe with 1 % slope). Therefore, the 2 in (5 cm) pipe’s effective length can be calculated as:

$$ \frac{7.9\; gal}{min}\times \frac{mi{n}^1\;f{t}^1}{0.21\; gal}=38\; ft\;\left(11.4\;m\right) $$A collector (lateral) drain would be needed after a maximum 2 in (5 cm) pipe run of 38 ft (11.4 m).

-

b.

Per the manufacturer’s specifications, the 4 in (10 cm) pipe has a maximum flow rate on a 1 % slope of 0.85 gal s −1 (or 51 gal min −1). Therefore, the 4 in (10 cm) pipe’s effective length can be calculated as:

$$ \frac{51 gal}{min}\times \frac{mi{n}^1f{t}^1}{0.21 gal}=243 ft\kern0.2em (74m) $$A 4 in (10 cm) drain pipe is the current standard for most golf greens. These are more than sufficient to handle most rainfall events. Lateral lines are typically increased to 6 in (15 cm) in diameter to handle the total output of a draining green.

2.1.4.6 Drain Line Types

A wide array of drain line types, sizes, and configurations are available (Fig. 2.18). A common misconception is that all of these products work equally well. Unless the drainage line provides lower water potential than the surrounding soil and the pipe is laid on grade in the bottom of the trench, water will not efficiently enter nor move down it. A suitable outlet is also needed to remove drained water.

2.1.4.6.1 Corrugated Pipe

In the past, drainage lines were built from agricultural clay tile, concrete, or flexible corrugated plastic. Today 4 in (10 cm) diameter corrugated high-density polyethylene (HDPE) pipe with perforations (slits or holes) is the industry standard, due to its ease of installation and relatively low cost (Fig. 2.19a, b). The perforations in HDPE pipe are laid facing downward on a bed of gravel to prevent clogging by downward-migrating soil particles. Drain lines with smooth inner walls provide more efficient water removal than lines with corrugated inner walls.

Water moves down through the medium and stops at the bottom of the trench. As the water level rises in the trench, it moves into the pipe through slits or holes fabricated by the manufacturer (Fig. 2.20) and then moves down the pipe. An alternative to corrugated HDPE pipe is rigid polyvinyl chloride (PVC) pipe with two rows of holes drilled adjacent to each other over the length of the pipe for drainage water to enter. PVC pipe is generally more expensive but is able to withstand heavier traffic pressure than flexible HDPE pipe.

2.1.4.6.2 Strip Drains

Strip drains exist where a narrow (2 to 4 in wide, 5 to 10 cm) trench is dug, a narrow (1 to 2 in wide, 2.5 to 5 cm) perforated drain (or “strip”) sleeve is installed, and trenches are backfilled with sand (Fig. 2.21). The drain types used include cloth-wrapped, waffle- or honeycomb-shaped drain sleeves, vertically stacked small diameter pipes (composite drains), or other similar narrow sleeved material. Drains are placed at the bottom of the trench and extend about halfway to the soil surface. Water will enter the lowest pipe of a composite drain first. Once this pipe is filled, water will enter and flow through the next lowest, and so on. Narrower trenches are used for this stacked pipe, reducing the costs of trenching and fill material. However, the smaller diameter pipe means greater surface area contacting the water; thus, there is more friction loss and lower water-carrying capacity. This makes stacked pipe less efficient for water removal and more prone to clogging than single larger tile lines.

Strip drains allow an increase in water infiltration rates into the soil surface without complete renovation of the native soil profile. However, in many cases the trenches filled with gravel and sand on grade actually work as “dry wells” where they lower the water table , removing surface water. The drain lines are not directly involved in this water removal. Drain lines must be installed deep enough to avoid disruption or displacement by heavy equipment.

2.1.4.6.3 Slit Drains

Slit drains are essentially narrow trenches (slits) dug into a soil and filled with permeable medium to facilitate drainage. A modification of the slit drain is a French drain , which consists of a trench 4 to 8 in (10 to 20 cm) wide dug on a 1 to 3 % slope, with a drainage pipe laid at its bottom and backfilled with sand (Fig. 2.22). This drainage system provides a wider trench than strip drains , which extends its life expectancy and potentially drains a larger area. Additional fill material is necessary for this system and more surface area disruption occurs. However, many facilities readily have access to the trenching equipment and the wider trench is usually easier to work with. In heavy soils, the wider trench filled with sand easily desiccates , shows nutrient deficiencies, and may become more susceptible to low-temperature damage (Fig. 2.23).

The advantages of strip and slit drains include installation with minimal surface disturbance and the need for less labor, as these installations are largely mechanized. They also provide drainage to poorly designed and constructed facilities at an attractive cost compared to complete soil profile renovation (Fig. 2.24). However, due to the complex design of the drains, personnel turnover in management often leads to eventual disturbances of the drain’s integrity as new turfgrass managers are not as aware of the positioning of these drains or their required upkeep. Sufficient surface slopes must be present for lateral water movement to these drains. Gravel and possibly small pipe in the bottom of the slits also are needed to expedite water removal from the site. Traffic from play, soil migration, erosion, and aerification can also cause glazing of silt and/or clay over the sand, reducing water infiltration . Topdressing with finer sand or soil used to fill the trench can also clog pore spaces and disrupt water infiltration. Heavy equipment can crush or disturb the integrity of the drain. The smaller diameter (1 in, 2.5 cm) pipe used in a strip drain is also prone to eventual clogging by downward-migrating soil particles. These drains typically require closer spacings than traditional lateral drains; thus more pipe junctions are needed.

Due to these inherent limitations, strip or slit drains should be viewed as a technique for removing the symptoms of waterlogging rather than as a technique for curing the problem. They also have a finite life span and often are a means of providing a temporary fix that will have to be performed repeatedly to succeed continually. They generally are not viewed as a substitute for sound surface and subsurface drainage planning and installation, which should occur prior to construction.

2.1.4.6.4 Filter Cloth

Nylon-netted filter drainage sleeves are also available, with the filter cloth wrapped around perforated pipe to prevent soil particles from impeding water flow into drainage lines. There is much debate over the probability of these nets/sleeves clogging over time from soil particle movement toward the drain. If excessive (>5 to10 %) silt and clay are present in the topsoil , these drainage sleeves may clog. In this situation, filter cloth should be considered to line the drainage ditch but should not be physically wrapped around the individual drain line s. It is also believed this cloth can become clogged from the bio-products of algae and other organisms that may colonize the perpetually wet cloth.

2.1.4.6.5 Drainage Line Patterns

Typically, a gridiron or herringbone pattern is used for drainage line arrangement (Fig. 2.25). The drainage pattern should be designed so drain lines are placed nearly perpendicular to the slope and rotated downhill as required to drain. However, any pattern is acceptable as long as each line has a continuous downward slope. Water in golf greens should not have to travel more than 10 ft (3 m) to a drainage line. An additional lateral drain line is placed at the furthest downslope location of the green, adjacent to the perimeter of the green. This perimeter drain (referred to as a ‘smile’ drain) helps avoid wet areas where the modified greens sand meets native soil.

2.1.4.6.6 Drainage Line Trenches

Trenches in which golf green drainage lines are to be laid should be cut a minimum of 6 to 8 in (15 to 20 cm) in depth into the subgrade and 5 to 6 in (12.7 to 15 cm) in width (Fig. 2.26). In native soil, 3 to 4 ft (0.9 to 1.2 m) deep drain lines are sufficient. Lines less than 2 ft (0.6 m) deep become subject to damage or disruption by heavy machinery or excessive traffic.

The bottom of the trench should be a minimum of 2 in (5 cm) wider than the outside diameter of the pipe. Trenches up to 12 in (30.5 cm) wide have been utilized. However, more gravel is needed to fill the wider trenches, which increases cost. Normally, a drainage line trench should be no more than twice the width of the drain pipe. A 5 to 6 in (12.7 to 15 cm) wide “U”-shaped trench will allow for a 0.5 to 1 in (12.7 to 25.4 mm) bed of gravel to be placed around (below, above, and on either side of) a 4 in (10 cm) diameter drain line to reduce washing of subgrade soil into the drain line. The soil displaced by digging the trench should be removed or placed between drainage lines to provide a slight slope toward the trench and then compacted .

Prior to digging trenches, the area should be surveyed. Proposed trench lines should be staked and labeled with the desired depth of cut. Drain lines should not be placed any deeper than necessary to obtain the desired slope. Trenches should have a minimum downward slope of 0.5 % (1 ft of drop for every 200 ft, 0.3 m per 60 m) and a maximum slope of 4 % (1 ft of drop for every 25 ft, 0.3 m per 7.5 m). Slopes of 1 to 2 % (1 ft of drop for every 100 ft, 0.3 m per 30 m, to 1 ft of drop for every 50 ft, 0.3 m per 15 m, respectively) are ideal. Drain lines with slopes of less than 0.5 % are difficult to properly grade, install, and maintain due to the slight elevation changes and slow flow rates. Drain lines with slopes greater than 4 % will lose lateral drainage capability. Steeper slopes also require greater elevation changes within the drain line and a lower outlet point.

When establishing the subgrade of a drain system, it is best to start at the outlet and establish the grade of the main collector line. After establishing this main line grade, the grade of each lateral can be determined. Care must be taken to ensure the drainage trench and drain lines always slope downward to avoid any entrapment or collection of water along the drainage lines. If a section of pipe is lower than the section closer to the outlet, water will pond in the lower section. This causes any sediment in the water to settle and collect in the bottom of the pipe, eventually clogging (or slowing) drainage. Grades of all main and lateral drainage lines should be checked with a level prior to backfilling.

2.2 Putting Greens

Putting green rootzones are formulated to drain quickly and allow play to be resumed shortly after heavy rain or irrigation . However, installation of a well-designed drainage system is critical for water removal from the subgrade, especially if the native soil is a clay or has an impermeable layer. Without drainage, the green could remain excessively wet and unplayable for several days after heavy rain.

2.2.1 Subgrade

Final subgrade contours should closely reflect the contours of the surface. Consequently, successful green construction starts with a properly planned and constructed subgrade (Fig. 2.27). Internal drainage follows the contours of the subgrade. Under normal circumstances, subgrade contours should not be sloped exclusively toward the front of the green since this will cause the front edge to be extremely wet. A soggy turf exposed to concentrated foot traffic quickly becomes worn and thin. It is better to have the green’s slopes draining away from high traffic areas and also from any side facing the cart path’s entrance and exit.

Depending on the green design and elevation of the site, the subgrade will be built into the existing grade or cut into the subsoil. If the grade is to be cut into the subsoil, the stripped topsoil may be stockpiled for future construction, such as mounds adjacent to the green, or distributed over the fairway and rough. Usually, greens built into the existing grade are elevated, requiring outside fill material for the subgrade. Heavier soils, such as clay s, are desirable for the subgrade since these are easily compacted to form a firm base that does not readily shift or settle. In either case, the subgrade must be compacted to prevent future settling that might create depressions or pockets of poor drainage or, in the event of a higher grade, droughty areas. This is accomplished with a power-driven vertical compactor (modified jack-hammer), a vibratory plate, or with a water-filled mechanical roller operated in several directions across the subgrade.

The subgrade for a USGA specification green should be constructed 16 in (41 cm) below the planned surface, and should look like the finished green, but at a lower elevation. Contours of the subgrade should match those of the surface to within a tolerance of 1 in (2.5 cm). The gravel layer must conform to the finished surface grade even if the subgrade does not. Initial shaping of subgrade contours involves placement of fixed grade stakes that are referenced to a permanent bench mark. The grading equipment operator then follows these pre-marked stakes to the depths indicated. Once the initial grade is established, it should be re-surveyed and then inspected by the architect to ensure the settled contour elevations match original specifications (Fig. 2.28).

A uniform subgrade, or uniform depth of green, is critical since soil and water physics that dictate the amount of water retained in a soil profile are inversely proportional to its depth. This means the deeper a soil profile, the less water the top surface will hold. Uneven soil profile depths will have areas that remain excessively dry (high spots) while others will remain soggy (low spots). This greatly increases costs later as the superintendent struggles to maintain uniform soil moisture, usually by using extensive hand watering.

The finished subgrade should be smooth, free of any pockets, rocks, or tire tracks, and firm enough to support construction equipment to prevent settling later. Any plants growing in the subgrade should be removed or killed before applying gravel or sand layers.

2.2.2 Gravel Size and Shape

In USGA specification profiles, the height of the perched water table is also determined by the contact area between the gravel and the sand above it. As the gravel size decreases, contact with the sand above increases and a shallow perched water table develops; more water is able to flow downward across these contacts. In addition, if the gravel particle shape becomes flatter and narrower, it is able to pack closer together, lie more horizontally, and thus create a larger surface area in contact with the sand. Gravel more round in shape will have only a small point of contact with the sand and less water will flow downward across these contacts, creating a higher (or deeper) perched water table . The USGA has developed specific guidelines for matching gravel size to rootzone sand mix texture. These guidelines include factors for bridging , permeability and uniformity. Proper gravel sizing is discussed further in Chap. 3.

2.2.3 Drainage Systems

2.2.3.1 Drain Line Outlets

The first task in drainage installation is locating an adequate outlet area for the water. Typically, drain lines are routed into nearby ditches, ponds, retention areas, larger drain lines, existing French drains in the fairways , or nearby out-of-play grass areas. Discharge lines are normally non-perforated pipe and should be laid across, rather than down, a steep slope to reduce the flow rate from the green. In some cases, a suitable discharge area may not be readily available and a sump and pump may be required. The sump may be formed with several concrete rings placed on top of each other and enclosed with a lid. A low-lift pump is installed inside the sump with float-activated switching so the water level may be controlled within specified limits (Fig. 2.29). Once a predetermined level of water is drained into the sump, the water is then pumped up to an appropriate discharge area. Sumps should be located away from the green and in areas receiving little traffic. Avoid directing the main drain line from the green into adjacent sandtraps, as washouts will be common. It is also a good idea to cover the main drain line outlet with a screen to prevent animals from entering the line.

2.2.3.2 Drain Spacing

Drain lines should be spaced 10 to 20 ft (3 to 6 m) apart . If the golf green is in an area with a high water table , it may be necessary to place larger drain lines deeper into the subgrade to lower the water table and handle the increased drainage. Specific drain line spacing can be calculated using Hooghoudt’s equation as discussed earlier in this chapter, based on rainfall intensity, rootzone hydraulic conductivity , and rootzone depth .

2.2.3.3 Drain Layout Design

Typically, drainage lines are installed diagonally to the grade in a gridiron or herringbone pattern (Fig. 2.30). However, any arrangement is acceptable as long as each line has a continuous downward slope and water does not have to travel more than 10 ft (3 m) to a drain line . Greens with slopes greater than 2 % or having surface water run-off from higher surroundings should have an interceptor drain line that rings the perimeter of the green, especially in the front or lowest areas.

Herringbone designs are generally the most popular, and are well-suited for irregularly shaped or relatively large turf areas due to the numerous lateral drain lines. However, herringbone systems are complicated to install and the pipes may be difficult to locate once installed. If slit drainage is needed later, cutting the slits at 90° angles to the lateral lines becomes difficult.

2.2.3.4 Drain Line Types

In the past, drain lines were fashioned of agricultural clay tile or concrete. Today, 2 to 4 in (5 to 10 cm) diameter corrugated, flexible, plastic pipe with slits is widely used because it is easy to install and inexpensive. The slits in the plastic pipe should always be placed face-down on the gravel bed to prevent clogging of drain lines with soil migrating downward from the rootzone . Nylon drain sleeves that wrap around the line are available. However, if silt and clay exist in the rootzone, these may plug the filters and ultimately restrict drainage. Another popular design is to place a fabric along the perimeter of the tile ditch, fill to grade with gravel, and place the edges of the fabric over the drainage ditch. Other pipe or tile designs are also available; however, little research exists on the total benefits of these .

An alternative design involves using flat drainage pipe instead of the traditional round pipe (Fig. 2.31). The flat pipe is laid directly on the subgrade base and is not cut into the subgrade as with round pipe. Pea gravel is then placed around the flat pipe. The flat pipe still must be on a downward grade to facilitate drainage. This technique is cheaper as drainage ditches are not needed and less gravel is required to surround the flat pipe. Limited research suggests this pipe design is beneficial; however, use of this system is a new technique, and this construction design has not been proven for all situations and environmental conditions.

2.2.3.5 Drain Line Installation

Drain lines are laid in trenches dug into the subgrade 6 to 8 in (15 to 20 cm) deep and 6 to 8 in (15 to 20 cm) wide. Wider trenches are sometimes used, but this means more gravel and higher costs are required to fill the trench. Normally, the trench width and depth should be no greater than twice the diameter of the drain line. Soil (or spoil) dug from the trenches should be removed or spread between the drain lines and then compacted to provide a slight crown . A 1 in (2.5 cm) bed of pea gravel should be placed in the bottom of the trenches before the drain line is laid. Once drain tile is installed, the trenches should be filled with gravel . Care should be taken not to contaminate the gravel with surrounding native soil or drainage may be sacrificed.

2.2.3.5.1 Slopes

Before excavation, drainage trenches should be surveyed and staked with the desired depth of cut clearly marked (Fig. 2.32). Drains should be placed only as deep as necessary to obtain the desired slope. Stakes should be marked to give drain lines a minimum downward slope of 0.5 % (or 1 ft 200 ft −1, 0.3 m 60 m −1), an ideal slope of 1 to 2 % (or 1 ft 100 ft −1 to 1 ft 50 ft −1, 0.3 m 30 to 15 m −1), and a maximum slope of 3 to 4 % (or 1 ft 33 ft −1 to 1 ft 25 ft −1, 0.3 m 9.9 to 7.5 m −1). Care must be taken to ensure the trench and drain line always slope downward so pockets of standing water do not develop. These lines should be placed diagonally to the slope of the green and not at right angles. All main and lateral lines should be double-checked with a level prior to backfilling to ensure the grade provides the desired drainage. Joints connecting drain lines should be covered with tape, asphalt paper, fiberglass composition, plastic spacers, or covers to prevent gravel and sand from entering the line.

It is recommended that the main drain line has its upper end extended to the soil surface and capped (Fig. 2.33). If this line becomes clogged with soil in the future, the cap can be removed and the line periodically flushed . This greatly extends the useful life of the drainage system and reduces the need to disturb the playing surface to clean the lines.

2.3 Fairways

2.3.1 Subsurface Drainage Design

Surface drainage , as discussed previously, is the first and quickest means of removing excess surface water. However, in areas that do not surface drain sufficiently, subsurface drainage is often used to lower the water table below the soil surface and avoid waterlogged conditions. Subsurface pipe drain lines can be installed as either singular or composite systems. A singular system consists of an array of individual drain lines, each emptying into an outlet. Composite systems consist of laterals connected to a common main line (Fig. 2.34).

Similar to golf greens, fairway subsurface drainage design can have a variety of patterns such as a gridiron, herringbone, or random. Gridiron and herringbone patterns are used to drain larger areas while random drains are used when small localized areas need drainage while areas in between are satisfactory drained. A gridiron system is often used to drain an area with a uniform slope in one direction while a herringbone system is generally best used to drain an area with a swale near the center.

With each design, the main drainage lines should generally follow natural valleys and be perpendicular to the contours . Lateral drain lines are generally laid across the slope with a gentle downward grade of 0.5 to 2.0 %. These drains intercept subsurface interflow that generally moves perpendicular to the contours. Lateral drains should maintain a sufficient uniform grade while keeping the laterals at a consistent depth from the soil surface. The laterals lines typically are from 2 to 2.5 ft (0.6–0.8 m) deep. Spacing varies from as little as 10 ft (3.3 m) on less permeable soils such as clay s and silt loams to as much as 30 ft (9 m) on highly permeable sandy soils. Hooghoudt’s equation , as discussed earlier in this chapter, can be used to determine the drain tile spacing or hydraulic conductivity needed for a particular drain spacing design. Modifications of Hooghoudt’s equation are available for designing fairway subsurface drainage systems where a drainage coefficient is used to estimate water loss from a soil profile and is then multiplied by the area and converting it to the desired units. This provides the outflow volume of drainage which allows one to then choose the appropriately sized pipe to carry this flow using a drainage pipe capacity chart.

2.3.2 Interceptor Drains

Surface drainage from areas adjacent to golf course fairways, such as parking lots, hills, or adjacent fairways, often becomes problematic (Fig. 2.35). Water that infiltrates into the soil can either continue to move downward to eventually recharge the groundwater or can move laterally through the soil down a hill, this is referred to as interflow. Interflow is the major source of water for stream and pond recharge during periods between rains and slows considerably near the bottom of a hill. Wetter soils near the hillside base often occur and result in a seep . Attempts to drain seeps by installing subsurface drainage typically fail since the source of the seeping water remains unchecked. Usually this water is easily collected by installing surface cutoff (or interceptor) drains to collect the water at the bottom (or “toe”) of slopes, prior to entering the playing surface, or by diversion using surface terraces (or swales) (Fig. 2.36). Interceptor drains consists of a gravel - or coarse sand -filled trench cut along the contour and perpendicular to the overland flow.

Sloping water tables are found in slightly rolling, hilly, or mountainous areas. The free groundwater in these areas will flow in the direction of the slope, usually along an underlying impervious soil layer. Precipitation on the soil surface percolates downward until it encounters this impervious layer and then flows laterally over this layer. The most likely place for a water table (seep) to appear at the soil surface is near the intersection of a steep slope and a flatter slope (Fig. 2.37). This is a common problem on golf courses, such as when the surrounding land area meets an elevat ed green. Wet seep areas are also common on approaches where the fairway slopes downhill toward the green, which is slightly elevated. Here the approach may be wet from irrigation water being retained in the green base material, and a seep may be caused in the same approach area from a surfacing water table on the fairway side. Interceptor drains are placed in these situations where the free groundwater of the hill meets the flat area to intercept the water flowing on the slowly permeable subsoil layer before it appears on the soil surface.

Determining placement of an interceptor drain can best be performed by digging test holes or miniature wells (called piezometers ) when most of the surrounding area is dry enough to use, but the seep area is still wet. Piezometers are small-diameter pipes driven into the subsoil so no leakage occurs around the pipes and water entrance is only from the open bottom. This indicates hydrostatic pressure of groundwater at the specific point in the soil. The piezometers should extend, in a grid pattern, upslope from the seep area to a depth of 2 to 3 ft (0.6 to 0.9 m). By observing the water level in the piezometer holes 24 h after being dug, the depth to the water table or water flowing over the impervious layer in the ground can be determined. Once this occurs, a trench should be dug to approximately 2.5 ft (0.75 m) deep to extend below the water table. To facilitate drainage, the trench should be backfilled to the depth of the water table with gravel . If the water table intersects the soil surface, additional drains may be necessary. If not, additional interceptor drains may be needed further down the slope.

The bottom of drain trenches should be uniform in slope to prevent depressions and should have a minimum slope of 2 % (1:50) if a pipe is not placed at the bottom of the trench. Placement of a pipe in the trench allows grades down to 0.5 % (1:200). This allows quick removal of surface water, and helps prevent ponding, wheel depressions, and trash accumulation . Mowable drains or graded drains are ideal to minimize maintenance requirements and to facilitate play.

2.3.3 Springs

Springs are weak points in the soil strata w here groundwater is under sufficient pressure to allow surfacing of the water. Springs are drained by placing a perforated drain pipe directly in the actual spring head to a depth of about 2.5 ft (0.76 m) and about 5 to 10 ft (1.5 to 3.0 m) beyond it and filling with gravel to facilitate water entry into the drain. In some instances it is possible to collect spring water for irrigation purposes.

2.3.4 Outlets

Water intercepted by surface and subsurface drainage requires a suitable outlet to discharge its flow, typically into channels, streams, or lakes. If the outlet is inadequate, the effectiveness of the entire drainage system can be reduced. Outlets types include the classic outlet or extension of the subsurface drainage pipe to the discharge location, pumped outlets, siphon outlets, dry wells and subsurface reservoirs, and wetlands (Fig. 2.38).

With classic outlets, the location of the drainage pipe outlet must be at the low point of the drainage system. Efficient drainage system design requires identifying the outlet location for an area and then extending the drainage system array upslope from this location. An adequate slope must also occur along the entire run of the system, along with adequate soil cover as a protection from crushing, and excessively deep excavations should be avoided.

The drain outlet often is the weakest portion of a drainage system since it is exposed and subject to damage or clogging. To prevent this, extending the tile or plastic tubing directly to the discharge point should be avoided. A section of non-perforated plastic or metal pipe 10 to 15 ft (3 to 4.5 m) in length is used to carry the water from the point where sufficient soil cover is available to the discharge to avoid crushing that may occur if insufficient cover is present to protect the pipe. A concrete collar is placed at this intersection of pipes to prevent pipe displacement. The outlet pipe should be the same size or larger than the main discharge line at the collar and should discharge at least 1 ft (0.3 m) above the normal water level in the receiving waterway. If flooding periodically occurs, the outlet pipe should be equipped with a flood gate to prevent water backing up into the pipe. The outlet pipe should be covered with a wire mesh to prevent animals from entering it.

Sometimes a pump and siphon outlet is necessary if a gravity outlet is unavailable or the area to be drained is completely contained with a large depressed area. A pumped outlet consists of an automatically controlled pump with float switches set to start and stop levels, placed within a small sump to provide some degree of active water storage. A siphon outlet is when the entire drainage system is located in a depression and a sump contains a non-perforated, 2 in (5 cm) siphon tube leading to a remote discharge location. As long as the entrance and exit of the siphon pipe remains under-water, the tube can convey water across higher elevations than the location of the sump or relief point. These systems work best for relatively flat areas and should be connected to an irrigation line so it can be primed and occasionally flushed.

Dry wells are holes dug into the ground at the end of a drain line that are used to receive normal drainage water from relatively small areas. They are used when discharge locations are too far to trench and pipe. Dry wells are usually buried beneath the soil surface and covered with turf or other material to hide them. Stormwater wetlands are constructed systems designed to mitigate downstream impacts of stormwater quantity and quality by temporarily storing drainage waters in shallow pools and marshes. Drainage design specialists consider these and other options when planning stormwater and normal surface and subsurface drainage systems.

2.3.5 Sand Capping

Sand capping can be the most reasonable means of “drying” a fairway located in perpetually wet (low) area without installing expensive sump and pump systems (Fig. 2.39). However, on most courses, unless sound soil science is applied to the situation, unsatisfactory results may occur.

Sand-capping increases the depth of growing medium, thus increasing the depth from the soil surface to the water table , and reducing surface puddling and wet conditions. These benefits may or may not be realized for several reasons. As the depth of the soil profile increases, the gravitational pull on the water throughout the profile above increases, thereby decreasing the soil water content, and consequently increasing the storage capacity for rain water. However, water flow may be so slow in the original soil below the sand-cap that vertical drainage in the sand-cap zone may also be too slow, especially if the sand-cap is not of sufficient thickness. Refer to Chap. 3 for more information on using soil moisture retention curves to determine sand capping depths for particular soils and situations.

2.4 Sports Fields

Water drains or exits a field in four major ways: (1) evaporation ; (2) surface runoff; (3) internal rootzone drainage ; and eventually, (4) percolation or other movement out of the rootzone profile, preferably, through an underground drainage network. Three types of soil profiles are currently used for sports fields in most areas which include one or more of these drainage means.

2.4.1 Soil Profiles

2.4.1.1 Native Soil Fields

These fields use existing soils and depend primarily on surface drainage to remove excess water. The advantages of native soil fields include: (1) they hold adequate nutrients and have a high water holding capacity , thus, require less fertilizer and water; (2) they provide good stability, shear strength and traction; and, (3) they are less expensive to construct as soil is on-site. Costs depend on how much surface grading is performed and if drain tile is installed (Fig. 2.40).

Disadvantages of native soil fields include: (1) most provide inadequate internal drainage, as these fields depend on a crown for surface drainage, thus, may compact easily; (2) due to the heavy nature of many native soils, internal drainage of the playing area is inefficient during heavy rainfall; (3) perimeter drain lines are needed to move surface run-off; and, (4) they are prone to surface rutting, puddling, and tracking unless aggressive maintenan ce is performed.

2.4.1.2 Modified Soil Fields

These are native soil-based fields modified by topical addition and roto-tilling in of sand . Performance depends on various proportions of sand and soil and the relative particle size distribution of each.

Advantages of modified soil fields include: (1) they are less expensive to build and maintain than sand fields; and, (2) they may have better drainage than native soil fields.

Disadvantages include: (1) their drainage still may be limited, and like native soil fields, they must still depend heavily on surface crowning; (2) they need irrigation and semi-aggressive fertilization; and, (3) their proper construction is difficult to achieve.

Often, with modified soil fields , lower budgeted fields have 1 to 4 in (2.5 to 10 cm) of sand placed on the existing soil surface and then roto-tilled in the top 4 to 6 in (10 to 15 cm). As Fig. 2.41 indicates, this procedure is often more deleterious than beneficial as the small particles of the existing soil will “clog” the pore spaces created by the much larger sand particles. For example, 10 % clay was added to a sand, which reduced its hydraulic conductivity by almost 85 % (from 58 to 9 in h −1, 147 to 23 cm h −1). Conductivity values quickly dropped as the clay soil content increased, for example, with a 50:50 blend, the hydraulic conductivity was less than 0.2 in h −1 (5 mm h −1), unacceptable by today’s standards. Furthermore, adding 20 % sand to soil reduced drainage more than 50 % compared to straight (100 %) soil. Significant increases in drainage and aeration properties are not normally seen until sand volumes are greater than 80 %.

Sand-capped fields are a modified soil construction method where a 3 to 6 in (7.6 to 15 cm) sand layer is “capped” over a native soil and not roto-tilled into the subgrade. The advantages and disadvantages of these fields are similar to where the sand is mixed with the native soil. However, this construction technique can pose problems when subgrade has been compacted and does not allow for drainage. Water will rapidly move through the sand “cap” and not penetrate the compacted subsoil, creating a “bath tub” effect. The field then holds too much water, too close to the playing surface leading to wet conditions and ultimately thin turfgrass . Many of these problems can be minimized b y deep tillage (4 to 8 in, 10 to 20 cm) of the subgrade prior to adding the sand cap , and not re-compacting the tilled area prior to “capping” the surface with sand. The addition of drain tile is still necessary with sand-capped fields for expedient water removal. Refer to Chap. 3 for more information on determining appropriate depths of sand capping for a particular site, soil, and sand source.

2.4.1.3 Sand-Based Fields

These rely on 80 to 100 % sand rootzones plus 0 to 20 % native soil or other amendment (Fig. 2.42). Sand-based fields are essentially flat, not heavily crowned, and have high infiltration rates . Internal drainage needs to be designed to move large amounts of water away quickly. Selecting the proper, uniform sand particle size is the key.

Advantages of sand-based fields include: (1) they provide the best internal drainage of the three designs; (2) minimum crown is needed, since internal drainage is high; and, (3) minimum soil compaction occurs as properly sized sand has a greater resistance to soil compaction compared with silty or clayey soils.

Disadvantages of sand-based fields include: (1) they require increased irrigation and fertility compared to native soils as sand s have less cation exchange and water holding capacities ; (2) they can be subject to layering problems as only a 1/8 in (3.2 mm) thick layer of dissimilar soil can interfere with drainage; (3) they are usually more expensive to build as sand typically has to be trucked in; (4) expert management is needed, due to sand holding nutrients and moisture poorly; (5) increased organic matter buildup due to excessive nitrogen needed to provide satisfactory playing conditions and/or less soil organisms present in inert sand fields which normally decompose organic matter for a food source, and, (6) decreased surface stability often occurs early in the life of the field, typically this is less problematic in the second year. Stabilization products may be incorporated to reduce shearing and tearing and allow for better grass growth, and recuperation, i.e., mats, carpets, fabrics, fragments of interlocking mesh, grids, fibers, and fibers sown into the rootzone .

Within the sand rootzone profile , two main drainage systems are currently used. The most proven is one with a 12 in (30 cm) layer of rootzone mix overlying a 4 in (10 cm) layer of “pea” gravel with 4 in (10 cm) drain tiles embedded in the subsoil (Fig. 2.43). This provides optimum drainage when heavy rain necessitates prompt water removal and allows the “flattest” surface in terms of minimum crown. The gravel layer, however, helps retain enough soil moisture in the rootzone to prevent constantly dry soil often experienced with pure sand rootzones and no gravel layer.

The second popular profile deletes the 4 in (10 cm) gravel layer leaving 12 in (30 cm) of pure sand rootzone along with the embedded drain line s. Pure sand is not as effective at removing soil water as a sand/gravel rootzone, since the moisture has to traverse the soil profile laterally to a drain line before it is removed. Research indicates for sand-based fields to equal the time necessary to drain compared to fields with a 4 in (10 cm) gravel layer, an increase in percolation rate of 20 in h −1 (51 cm h −1) is necessary in the rootzone sand . This is because in a gravel layer field, water is essentially drained vertically when it encounters this layer, typically 12 in (30 cm) deep. However, when the gravel layer is absent , water must move down and across the soil profile and encounter a drain line before it is removed. To overcome the drainage issues in a field without the gravel layer, designs may include a deeper soil profile (i.e., 14 to 16 in deep, 36 to 41 cm) or closer tile spacing (i.e., 10 ft, 3 m). Sand-based fields often stay drier than the first two field types, but require more irrigation and fertilization.

Sports field managers typically have only one opportunity to build or renovate a facility. Careful attention to expected use and quality weighted against maintenance budgets should be considered during this process.

2.4.2 Football Fields

2.4.2.1 Minimum Drainage Requirements

For many high school and local municipal fields, adequate surface contouring is the most effective and economical means of providing surface drainage . If insufficient sloping of the surface occurs, water will stand (puddle), saturating the soil causing compaction and damage by traffic. To provide surface drainage, high school or similar football fields should have a 12 in (30 cm) crown for sandy soils and 18 in (46 cm) for clay soils from center to the sideline, or a 1 to 2 % slope (Fig. 2.44). The slope at the sideline may be reduced, but the area should not be flat. Surface water movement away from the high-traffic sideline areas where players stand is important.

Optimum surface drainage of lower-budgeted sports fields consisting of a 12 to 18 in (30–46 cm) crown with a pair of drainage tile imbedded along the hash marks of football fields and a pair parallel to the sidelines. Surface catch basins or strip drains help remove surface from the playing surface, sidelines, and water draining from spectator stands

A minimum of four drainage lines should be installed, one running parallel to the center crown, typically down each hash mark, and the other set just off the field along each sideline. Drain lines are usually 6 in (15 cm) wide and 12 to 36 in (30 to 91 cm) deep. Two inch (5 cm) of gravel is placed at the bottom of the lines, a 4 in (10 cm) perforated drain pipe laid on top of this gravel layer and “pea” gravel (industry designation ‘789’, ¼ to ½ in, 6.4 to 12.7 mm diameter) or very coarse sand is used to fill the trench to grade. Sometimes the drainage trench is lined with a geotextile fabric to prevent clogging of the drainage system.

The drainage tile should not be laid within 4 in (10 cm) of the surface, to prevent future aerification practices from disrupting the integrity of the drainage system. The pipe should be laid on a continuous ½ to 1 % downward slope (3 to 6 in drop in 50 ft, 7.6 to 15 cm in 15 m) and should be connected at the ends to allow for water to drain away from the field. Surface catch basins or surface strip drains should also be installed between the playing field and both sideline stands (Fig. 2.45a). These intercept surface drainage from the field as well as water draining from the spectator stands. At least 3 (preferably 4 or more) catch basins or strip drains should be considered for each side of the field. For safety purposes, catch basins should be located no closer than 10 ft (preferably 15 ft, 3 to 4.6 m) from the playing surface. Strip surface drains are becoming more popular as a replacement for catch basins (Fig. 2.45). Strips are less noticeable and less likely to cause injury, plus their length offers more intercepting surface area to facilitate drainage.