Abstract

The use of nanoporous-sensitive covering that has extended surface of interaction is one of the ways to increase the sensitivity of sensors. Рorous anodic alumina (PAA) due to its unique nanoporous structure, physical and chemical properties, and the simplicity of its fabrication is one of the most perspective materials. Good compatibility of PAA formation with modern thin-film technologies allows to use PAA in multilayer covering for optical biosensors. In the present research, we have developed optical metal-clad waveguide (MCWG) sensors with nanoporous PAA covering.

The developed technology includes a magnetron deposition of the adhesive layer of niobium and aluminum films, formation of PAA waveguide layer and semitransparent Al film by anodic oxidation, widening of PAA pores by chemical etching, and coating of PAA by ultrathin gold layer. The in situ control method of the reflective curves of MCWG with nanostructured coatings in the process anodic oxidation and pore widening has been developed. Research on the covering by SEM method and preliminary immunochemical studies on MCWG Al-PAA-Au were carried out. We found that synthesized recombinant analogue of Staphylococcal protein A (SPA) modified by an additional cysteine residue (SPA-Cys) efficiently immobilized on gold surface of nanostructured coating PAA with thin gold layer retaining its ability to bind human IgG. The data, received in the course of the experiments, proved high sensitivity of immunosensors with nanoporous coatings and their potential for further use in biosensorics.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Aluminum film

- Magnetron sputtering

- Anodic oxidation

- Biosensor

- Etching

- Metal-clad waveguide (MCWG)

- Nanoporous

- Pore widening

- Porous anodic alumina (PAA)

- Reflective curve

- SEM images

- Sensor

- Sensor substrate

- Thin-film technology

- Antigen-binding site

- Biosensorics

- C-terminal cysteine residue

- Immobilization

- Immunoglobulin (IgG)

- Immunoreagent

- Immunosensor

- Recombinant analogue of SPA

- Sensogram

- Staphylococcal protein A (SPA)

- Surface plasmon resonance (SPR)

1 Introduction

Over the last few years, the research on nanoporous coatings for sensors intended for medical diagnostics, environmental monitoring, study of biomolecular interactions, etc. has been growing in popularity. A wide range of impedance, capacitive, acoustic, optical, and other sensors and biosensors are being developed. The devices on the surface plasmon resonance (SPR) [1] and waveguide sensors, including sensors on a metal-clad waveguide (MCWG) [2–4], where the remaining unanodized Al (near 15 nm) acted as the metal layer to excite the plasmon for waveguide coupling, are among the most sensitive optical sensors. SPR and MCWG sensors can be implemented by observation of shift of the resonance angle of incidence light or the wavelength. The shift corresponds to the changes in dielectric properties of the layer of molecules near the surface of the sensor (Fig. 29.1).

Coatings for sensors of porous anodic oxides generated by electrochemical oxidation on metal surfaces, such as porous anodic alumina (PAA), are being intensively developed [5, 6]. Highly porous surface provides the larger area of interaction of receptor and analyte and thus enables increase in the sensitivity of sensors. The unique structure of the vertical self-ordering pores and possibility to form into them the nanowires and nanodots can also serve as a basis for the development of new sensors, involving not previously used physical phenomena [7].

An advantage of PAA for practical application is the simplicity and the cheapness of its production, the possibility of forming arrays of homogeneous pore diameters ranging from a few to hundreds of nanometers. Moreover, PAA has a number of chemical, mechanical, electrical, and optical characteristics, including high hardness and thermal and chemical stability that are important for sensor applications. Biocompatibility of PAA is especially important for biosensors. Sensor devices with PAA can be used as chemical sensors and biosensors in a wide range of tests for the presence of gas molecules, organic molecules, biomolecules (DNA or proteins), microorganisms (viruses, bacteria), and cancer cells. These devices can be used in gaseous and aqueous environments [6].

Most of the works оn PAA were conducted at sufficiently thick layers of aluminum (thin plate or foil). Formation of porous anodic oxides on Al films is much less studied, though the thin-film structures with PAA can be efficiently used for coating of biosensor, in particular for SPR sensors and MCWG. It is the thickness and structure of the PAA film that determine the sensitivity of the sensors, as well as the shape of the resonance curve and design features of sensor devices [5, 6]. Special types of sensors and biosensors are developed on the PAA coating with an additional layer of nanoparticles or ultrathin metal film [7, 8]. The use of gold enables implementation of well-developed bioimmobilization techniques for SPR sensors [1] and in the case of MCWG improves the sensitivity of the sensors due to the redistribution of the intensity of the light wave field. Due to relative simplicity, cheapness of production, and good compatibility with modern thin-film technologies, PAA has strong potential for routine use in sensors for environment, food control, and medical diagnostics.

We should remark that while PAA have the potential for numerous applications in sensor technology, it can also be used in other fields such as separation of molecules, catalysis, photonics, tissue engineering, controlled drug delivery, etc. [9].

The ultimate aim of our current studies is to develop nanoporous coating on PAA for optical waveguide sensors on a metal-clad waveguide (MCWG).

2 Development of the Technology of Nanostructured PAA as a Part of MCWG Sensors

We developed the technology of MCWG sensors with nanostructured PAA coating that includes the following steps (Fig. 29.2):

-

1.

Magnetron deposition of aluminum films on optical glass plates

-

2.

One-step anodic oxidation to form PAA and a semitransparent aluminum film with in situ control of the optical parameters of nanostructured coatings

-

3.

Chemical etching for widening of pores with in situ control of the optical parameters of nanostructured coatings

-

4.

Thermal deposition of nanometer-thick gold for the formation of covering with metal nanoparticles or nanofilms

Formation of aluminum films was carried out by magnetron sputtering at constant current. We used the round-shape magnetron with Al (purity 99.99) target of a diameter 140 mm. As an adhesive layer, we used thin (1–2 nm) layer of niobium. Thickness of deposited aluminum was preliminary calculated so that thickness of anodic oxide for the first waveguide mode has been formed and the aluminum layer 15 nm thick remains on glass.

The study of anodic oxidation of Al films was carried out on a specially designed computer-controlled stand, providing various regimes of forming and continuous time control of electrical parameters of the process of anodic oxidation and temperature stabilization [8]. Anodization was carried out in an aqueous solution of H2C2O4 0.3 M as electrolyte. The test areas were limited by photoresist mask. For potentiostatic oxidation, we used two-electrode cell with a flow of electrolyte and thermal stabilization. The oxidation was carried out at the temperature of 10 °C. In the galvanostatic mode, we used a capillary cell without any temperature control. Kinetic curves of the anodization of aluminum films of 250 nm thickness on glass are shown in Fig. 29.3.

3 Formation of Nanostructured MCWG Sensor with Monitoring of Reflective Curves In Situ

In order to control the optical characteristics of MCWG sensors, we developed an original technique of PAA formation with simultaneous monitoring of the reflection curves. A specially designed clamping cell for anodic oxidation and etching was put on the sample and placed on the prism of the Plasmontest device [4]. Optical setup of the device corresponds to Fig. 29.1a. Refractive index of prism and sensor plate is 1.61. As the light source, the Hamamatsu LED L7868 with wavelength 670 nm is used. The Plasmontest device provided monitoring of reflective curves for the waveguide mode after reaching the front of the oxidation the thickness of aluminum that provides for the penetration of light into the waveguide layer. Sensogram (change of the angle of the reflection curve minimum) was recorded simultaneously with the above process.

Glass plates with initial thickness of deposited Al films in the range of 270–400 nm were used. The thickness of final Al films was 15–25 nm, the thickness of PAA was 300–450 nm, and the porosity of PAA constituted 0.1–0.5 depending on the regimes of oxidation and etching.

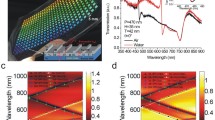

Reflective curves received under oxidation at a constant voltage 40 V are shown in Fig. 29.4a. The waveguide minimum on the reflective curve appeared when aluminum layer was thinning down to about 45 nm. In the processes of porous layer growth and Al layer thinning, the minimum on the reflective curves becomes deeper and the angle of the minimum increases. After formation of PAA by anodic oxidation, the etching was carried out in a 5 % aqueous solution of H3PO4 at room temperature. Sequence of the reflective curves reveals decreasing of the angle of the minimum in the process of pore widening by etching (see Fig. 29.4b). The sensogram of the process of MCWG formation is shown in Fig. 29.4c. Anodizing and etching were stopped once the reflective curve achieved the desired shape.

Monitoring of formation of sensor structures Al/porous Al2O3 by the Plasmontest device. (a) Change in the shape of the reflection curve in the process of anodic oxidation of aluminum film on glass for MCWG Al/porous Al2O3 fabrication: 1, appearance of waveguide mode; 2, final of anodic oxidation. (b) Change in the shape of the reflection curve in the etching process: 1, beginning of the etching; 3, final structure. (c) Sensogram received during the process of formation of MCWG structure Al/porous Al2O3

4 Study of Coatings by SEM

Samples of PAA on glass and Si produced by anodizing and etching as it was described above have been investigated by SEM. Studies have shown that traces of the polishing on glass substrates make the surface of aluminum film wavy. It leads to disordering of pore position in PAA film (Fig. 29.5a). Two-step anodization resulted in significantly smaller pore size distribution; however we have not received the self-ordering in the structure of PAA on glass.

SEM images of the samples PAA/Au on Si formed by anodic oxidation of aluminum film in 3 % oxalic acid at 30 V and then etched during 30 min at room temperature in 5 % phosphoric acid solution with subsequent thermal deposition of 12 nm thick gold film are shown in Fig. 29.5b, c. The cross-sectional SEM image shows vertically aligned pore structures of PAA. Figure 29.5c shows that the film of gold that was exfoliated from the PAA surface at cracking of sample is perforated at places of pore location.

5 Biosensory Experiments

We conducted preliminary experiments on the MCWG sensor substrates Al/porous Al2O3/Au employing a couple of immunoreagents—Staphylococcal protein A (SPA) and immunoglobulins (IgG). SPA can bind immunoglobulins mostly for their Fc fragments exposing their antigen-binding sites into solution. Preparation of recombinant analogue of PA modified by an additional cysteine residue (SPA-Cys), which due to the exposed SH-group strongly interacts with the gold sensor surface, can increase the reliability of its immobilization. Genetically engineered protein SPA-Cys contains five immunoglobulin-binding domains—His-tag for chromatographic purification and C-terminal cysteine residue. SPA-Cys was received in a soluble form at its expression in Escherichia coli. The immunoreagents were dissolved in phosphate buffer (PBS, pH 7.4); the same buffer was used for washing. The sensogram of test immunochemical experiments of SPA-Cys-IgG on MCWG with nanostructured coating Al/PAA/Au is shown in Fig. 29.6.

The experiment showed that SPA-Cys efficiently immobilized on gold surface of SPR sensors and nanostructured coating PAA with thin gold layer retaining its ability to bind human IgG. The data proved high sensitivity of immunosensors with nanoporous coatings and their potential for further use in biosensorics. To increase the sensitivity of biosensors with nanoporous coatings, it is necessary to develop the procedures of surface modification and structural engineering of PAA.

6 Conclusion

As the result of the research, the technology of optical metal-clad waveguide sensors with nanoporous anodic alumina covering was developed. It includes processes of magnetron deposition of Al films on optical glass plates, anodic oxidation, and chemical etching. Original technique of PAA formation with simultaneous monitoring of the reflection curves gives the opportunity of timely stop of the anodization and etching for fabrication of sensor substrates with optimal characteristics. Samples of PAA and PAA/Au have been tested by SEM. Preliminary investigations on the MCWG Al/porous Al2O3 and Al/porous Al2O3/Au biosensors were successfully carried out. We came to the opinion that with the aim to increase the sensitivity of biosensors based on PAA, it is necessary to thoroughly develop surface modification methods and testing of modes of sensory analysis.

References

Voitovich I, Korsunsky V (2011) Sensory na osnove plazmonnogo rezonansa: printsipy, tekhnologii, primeneniya. (Сенсоры на основе плазмонного резонанса: принципы, технологии, применения. SPR sensors: principles, technologies, applications). Stal’, Kiev

Skivesen N, Horvath R (2005) Optimization of metal-clad waveguide sensors. Sens Actuators B 106:668–676

Hotta K, Yamaguchi A, Teramae N (2010) Properties of a metal clad waveguide sensor based on a nanoporous-metal-oxide/metal multilayer film. Anal Chem 82(14):6066–6073

Budnyk M, Lebyedyeva T, Kurlov S, Minov Y, Sutkoviy P, Frolov Y, Shpylovyy P (2011) Modeling and data processing for thin-film optical sensors. In: Proceedings of sixth IEEE international conference on intelligent data acquisition and advance computing system: technology and application, Prague, 15–17 Sept, vol 1, pp 119–124

Hotta K, Yamaguchi A, Teramae N (2012) Nanoporous waveguide sensor with optimized nanoarchitectures for highly sensitive label-free biosensing. ACS Nano 6(2):1541–1547

Santos A, Kumeria T, Losic D (2013) Nanoporous anodic aluminum oxide for chemical sensing and biosensors. Trends Anal Chem 44:25–38

Hernández-Eguía L, Ferré-Borrull J, Macias G, Pallarès J, Marsal LF (2014) Engineering optical properties of gold-coated nanoporous anodic alumina for biosensing. Nanoscale Res Lett 9:414

Sulka GD (2008) Highly ordered anodic porous alumina formation by self-organized anodizing. In: Nanostructured materials in electrochemistry. Wiley, Weinheim

Ingham CJ, ter Maat J, de Vos WM (2012) Where bio meets nano: the many uses for nanoporous aluminum oxide in biotechnology. Biotechnol Adv 30:1089–1099

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Voitovich, I., Lebyedyeva, T., Rachkov, A., Gorbatiuk, O., Shpylovyy, P. (2015). Anodic Alumina-Based Nanoporous Coatings for Sensory Applications. In: Fesenko, O., Yatsenko, L. (eds) Nanoplasmonics, Nano-Optics, Nanocomposites, and Surface Studies. Springer Proceedings in Physics, vol 167. Springer, Cham. https://doi.org/10.1007/978-3-319-18543-9_29

Download citation

DOI: https://doi.org/10.1007/978-3-319-18543-9_29

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-18542-2

Online ISBN: 978-3-319-18543-9

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)