Abstract

Construction Microbial Biotechnology is a new area of science and engineering that includes microbially-mediated construction processes and microbial production of construction materials. Low cost, sustainable, and environmentally-friendly microbial cements, grouts, polysaccharides, and bioplastics are useful in construction and geotechnical engineering. Construction-related biotechnologies are based on activity of different microorganisms: urease-producing, acidogenic, halophilic, alkaliphilic, denitrifying, iron- and sulfate-reducing bacteria, cyanobacteria, algae, microscopic fungi. The bio-related materials and processes can be used for the bioaggregation, soil biogrouting and bioclogging, biocementation, biodesaturation of water-satured soil, bioencapsulation of soft clay, biocoating, and biorepair of the concrete surface. Construction Microbial Biotechnology is progressing toward commercial products and large-scale applications. The biotechnologically produced materials and construction-related microbial biotechnologies have a lot of advantages over conventional construction materials and processes.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Sewage Sludge

- Municipal Solid Waste

- Biogas Production

- Municipal Wastewater Treatment Plant

- Biogeochemical Reaction

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

2.1 Introduction

The discipline of Microbial Biotechnology includes a scientific and practical knowledge of using microorganisms and their products. We differentiate by the area of biotechnological applications such subdisciplines as Medical, Pharmaceutical, Industrial, Agricultural, and Environmental Biotechnology. Currently, a new subdiscipline of Microbial Biotechnology, Construction Microbial Biotechnology, can be differentiated. There are two major directions in Construction Microbial Biotechnology: (1) the microbial production of construction materials and (2) the applications of microorganisms in construction process. Many different biotechnological products and biotechnologies for civil engineering are developing within these directions (Fig. 2.1).

Production of cement, which is a major construction material, is energy-consuming and environmentally-unfriendly. Energy represents 20–40 % of the total cost of cement production because temperature above 950 °C is needed for transformation of limestone to cement clinker. New construction materials, microbial biocements, can be produced from limestone, dolomite, or iron ore at temperature 20–60 °C with less than 10 % of energy used for the manufacturing of conventional cement. Therefore, cost of biocements can be lower than that of conventional cement. There are also a lot of other advantages of microbially-based biocementing or bioclogging materials over conventional cements and grouts, for example sustainability due to production from organic matter, low viscosity, and low risk of negative environmental consequences. It is important that biocement can be produced from the same raw materials that are using for cement production.

Another type of biomaterials, which are used in construction industry are industrially produced or in situ synthesized microbial polysaccharides. Such industrially produced polysaccharides as xanthan, welan, succinoglucan, curdlan, chitosan are used in dry-mix mortars, wall plasters, self-leveling underlayers, injection grouts to improve viscosity, water retention, set retarding, flowability (Plank 2004). Other biopolymers for example, proteins or their hydrolysates as biosurfactant, can also be used for if the cost is acceptable. Sewage sludge of municipal wastewater treatment plants, which is a waste microbial biomass producing in quantities of several million tons a year, could be used also as a source of cheap microbial polymers.

Production of bacterial polysaccharides in soil after addition of bacterial cells and necessary nutrients in situ is used to modify soil properties. This approach could be used for such geotechnical applications as dam control, wind soil erosion control, earthquake liquefaction mitigation, construction of reactive barrier, and long-term stabilization of contaminated soils. Different kinds of organic wastes can be used as a source of organic matter for polysaccharide-producing microorganisms in large-scale geotechnical applications to diminish the cost of soil clogging. Initiated growth of exopolysaccharide-producing photosynthetic bacteria or algae on the surface of sand can be used for the wind erosion control. Surface growth of microbial photosynthetics in irrigation channel or aquaculture pond is an effective way for the seepage control.

The biotechnological production of construction biomaterials is sustainable process because renewable agricultural and biotechnological biomass residues are used as organic raw materials and as the components of composite biocement. One potentially important construction material, microbial bioplastic, can be produced from agricultural residuals and organic fraction of municipal solid wastes.

In some geotechnical processes, microorganisms themselves are performing useful function. There are at least eight types of construction-related biotechnological processes classified by the results of the microbial treatment:

-

bioaggregation of soil or particles is a process to increase size of the fine particles so that water and wind soil erosions, sand movement, as well as dust emission will be reduced (Bang et al. 2011; Stabnikov et al. 2013a);

-

biocrusting of soil surface is a process to form mineral or organic crust onto soil surface so that that erosion, dust emission, and water infiltration will be reduced (Stabnikov et al. 2011; Chu et al. 2012a);

-

biocoating of solid surface is a process to form a layer on solid surface so that aesthetics or colonization of surface will be enhanced;

-

bioclogging of soil or porous matrix is a process to fill in the pores and channels in soil/matrix so that hydraulic conductivity of soil or porous matrix will be significantly reduced (Ivanov et al. 2012);

-

biocementation of soil or particles is a process to increase significantly strength of soil or particles (Ghosh et al. 2005; Mitchell and Santamarina 2005; Whiffin et al. 2007; Ivanov and Chu 2008; De Muynck et al. 2008a, b, 2010, 2012; Sarda et al. 2009; van der Ruyt and van der Zon 2009; Achal et al. 2010; Ivanov 2010; Van Tittelboom et al. 2010; Dosier 2013; Chu et al. 2012a; 2014;DeJong et al. 2010, 2013; van Paassen et al. 2010; Harkes et al. 2010; Dhami et al. 2012; Li and Qu 2012; Raut et al. 2014);

-

biodesaturation of soil is a process to decrease saturation and liquefaction potential of soil through biogas production in situ (Chu et al. 2009a, 2013b; He et al. 2013; Rebata-Landa and Santamarina 2012);

-

bioencapsulation of clay/soil/particles is a process to increase strength of soft clayey soil through the formation of strong shell around a piece of soft material (Ivanov et al. 2014);

-

bioremediation of soil is a process to remove pollutants from soil or immobilize pollutant in soil before construction (Warren et al. 2001; Fujita et al. 2004; Mitchell and Ferris 2005).

Classification of construction biotechnologies by the results of their applications is illustrated in Fig. 2.2.

Any biotechnology for the production of construction materials includes three major stages:

-

(1)

upstream processes such as preparation of medium, equipment, and microbial inoculum (seeds);

-

(2)

core process such as cultivation of microorganisms;

-

(3)

downstream processes such as concentration of biomass or microbial product, its drying, packing, washing of the equipment, treatment or disposal of wastes.

The example can be the biotechnology for the production of calcium- and urea-based biocement (Figs. 2.3, 2.4).

All these processes should be monitored and controlled to ensure efficiency of the processes.

Any biotechnological application of microorganisms in construction process also includes three major stages:

-

(1)

upstream processes such as preparation of soil or construction material for the treatment, preparation of the reagents, equipment and microbial inoculum for the treatment;

-

(2)

core process such as biotreatment of soil, construction material, or the construction objects;

-

(3)

downstream processes such as disinfection (if needed) and solid, liquid, or gaseous wastes treatment or disposal.

All these processes should be monitored and controlled to ensure efficiency of the processes. The example can be the biotechnology for mitigation of saturated sand liquefaction using denitrifying and biosealing bacteria (Fig. 2.5).

Application of microorganisms for ground improvement can be performed by indigenous microorganisms of soil, without preparation and supply of the microbial inoculum, and without downstream processes. However, there could be such downstream step as detoxication of polluted air and water after biocementation.

The medium for microbial cultivation and the treatment medium for soil/particles can be mixed together or used separately in the form of solution, suspension, or slurry by the mixing of chemical reagents and agricultural fertilizers. Different kind of wastes or residuals such as mining and agricultural residuals, organic fraction of municipal solid wastes, sewage sludge, and reject water of municipal wastewater treatment plants can be used as a medium to reduce the cost of large-scale biogeotechnical work.

2.2 Microorganisms in Construction Microbial Biotechnology

Most applicable microorganisms for Construction Microbial Biotechnology among kingdoms of Archaea, Bacteria, Fungi, Plants, and Animals are representatives of Bacteria because of their small cell size (0.5–10 µm), big physiological diversity (pH 2–10; temperature from −10 to +110 °C), big spectrum of biogeochemical reactions (oxidation-reduction of organics, oxygen, nitrate, ferric, sulfate), highest growth and metabolic rates. There are three evolutionary lines of chemotrophic (feeding by energy of chemical compounds) Gram-positive Bacteria (prokaryotes of terrestrial evolutionary origin with thick and rigid cell wall), Gram-negative Bacteria (prokaryotes of aquatic evolutionary origin with thin and elastic cell wall) and Archaea (prokaryotes of environments with extreme temperature, pH, or strong anaerobic conditions). These three evolutionary lines contain four parallel physiological groups differentiated by the type of energy-yielding oxidation-reduction reactions: (1) fermenting, (2) anoxic respiring, (3) microaerophilic and facultative anaerobic, and (4) aerobic respiring prokaryotes. In total, there are 12 groups of chemotrophic prokaryotes differentiated by the type of energy-yielding oxidation-reduction reactions (Table 2.1).

Depending on the real conditions and requirements of the construction process, all these physiological groups can be involved in biotechnologies of construction materials or construction process biotechnologies. However, in majority cases anaerobic, anoxic, facultative anaerobic, and aerobic Gram-positive bacteria are most suitable for applications related to the soil improvement because of osmotic tolerance of these bacteria. Facultative anaerobic or aerobic Gram-negative bacteria are most suitable for biosynthesis of construction biomaterials. Applications of phototrophic (utilizing light energy) prokaryotes in civil engineering are rare. For example, Gram-negative phototrophic Bacteria, cyanobacteria can be used for the formation of soil crust to diminish water and wind erosion of soil.

The microorganisms that are used to start up the bioprocess are called inoculum by microbiologists or “seeds” by civil and environmental engineers. The inoculum could be a suspended, frozen, dried, or cooled microbial biomass. Cultivation after inoculation is performed in batch or continuous mode. Inoculum for construction materials production or biotreatment of soil/particles is selected using the following microbiological and molecular-biological methods:

-

(1)

Obtaining and testing of the microbial strains from national collections of microorganisms, for example American Type Culture Collection (ATCC, USA) or German Collection of Microorganisms and Cell Cultures (DSMZ, Germany).

-

(2)

Isolation, identification, and testing of wild strains from natural sites with environmental conditions close to the conditions that are needed for the biotreatment, for example, with high salinity, high or low temperature, aerobic or anaerobic conditions, alkaline, or acid pH. However, many bacteria are pathogenic (causing diseases) for human, animal, and plants. Therefore, biosafety of biotechnological process is always an important issue and only nonpathogenic isolated strains of bacteria can be used for civil engineering applications.

-

(3)

Autoselection in continuous culture (Cheng and Cord-Ruwisch 2013), screening of the mutants (Li et al. 2011), and construction of the recombinant microbial strains from wild strains for the biotreatment. However, there are many restrictions on the applications of recombinant microbial strains so they can be used mainly for industrial production of such construction materials as polysaccharides or bioplastic.

-

(4)

Selection and testing of suspended enrichment cultures using such selective conditions (selection pressure) as source of energy, carbon, nitrogen and phosphorus, temperature, pH, salinity (osmotic pressure), concentration of heavy metals, concentration of dissolved oxygen, spectrum and intensity of light (for photosynthetic microorganisms). Some autoselected features of the enrichment culture can be genetically unstable and could disappear after several generations when the selection pressure will be absent (Ivanov et al. 2012b).

-

(5)

Selection and testing of aggregated enrichment cultures, such as flocs, biofilms, granules using such selective pressure as settling rate of microbial aggregates and adhesion of cells to solid surface. An example is formation of bacterial cells aggregates that cannot penetrate inside sand, settled onto the surface of sand and formed calcite crust (Stabnikov et al. 2011; Chu et al. 2012b).

In some cases, when soil is rich with indigenous microorganisms able to perform needed biogeochemical reaction, for example urease activity, soil biotreatment can be performed by indigenous microorganisms, without preparation and supply of microbial inoculum (Burbank et al. 2011, 2012a, b). To enhance the needed biogeochemical function of indigenous microorganisms, soil can be amended with the related reagent. For example, to enhance urease activity of indigenous microorganisms before the biotreatment, urea can be added to soil (Burbank et al. 2011). However, if microorganisms used in geotechnical bioprocess are indigenous it does not mean that they are safe for human, animals, and plants because nonselective conditions of the soil bioprocess, especially application of nutrients-rich medium, can enhance the proliferation of pathogens or opportunistic pathogens in soil.

Core process in the production of construction material, i.e., cultivation of microorganisms is performed in batch, semi-continuous (sequencing batch), complete mixing continuous, or plug-flow continuous mode in the bioreactor, where the components are mixing using stirring, upflow of liquid or gas through the reactor, or horizontal rotation of the bioreactor.

2.3 Application of Microbial Biopolymers in Construction Industry and Geotechnical Engineering

Animal biomaterials such as blood, urine, eggs, milk, lard, and plant biopolymers such as wood, straw, bark, cactus juice, flour have been used as admixtures from ancient times to improve properties of mortars and plasters. Straw and cattle dung were used and are used even at the present time in rural construction as the composite biomaterials to improve construction properties of clay. Probably, the Aztecs used fermented juice of nopal cactus (Opuntia ficus indica) to improve plasticity and water absorption capacity of lime mortar and earthen plasters due to the presence of cellulose fibers, gel polysaccharides, and fermentation products. Extracts of this nopal cactus and water hyacinth are proposed in our days to enhance viscosity of cement-based materials (León-Martínez et al. 2014; Sathya et al. 2013). The chemical derivates of plant biopolymers, for example carboxymethylcellulose, carboxymethylcellulose sulfate or such industrial waste as lignosulfonates are often used as cement and mortar admixtures for set retarding and increase of plasticity of self-consolidated concrete (Plank 2004; Yuan et al. 2013).

Chemical and biological admixtures in cement- and gypsum-based materials are using for dispersing/thikening effects, viscosity enhancement, water retention, set acceleration and retardation, air-entrainment, defoaming, hydrophobization, adhesion and film forming (Plank 2003) to improve such properties of the material as plasticity, water retention, adhesion, shrinkage reduction, flow ability, and stability. The global market of admixtures is estimated at the level of US$15 billions with the share of more than 500 different biological and biodegradable admixtures about 13 % (Plank 2004).

The advantage of microbial admixtures is that the biosynthesis rate of the microbial biopolymers is significantly higher, by 2–4 orders of magnitude than that of the plants and these substances can be produced in industrial scale on biotechnological factories. The major application of microbial biopolymers in construction industry is addition to concrete and dry-mix mortars. The examples of microbial admixtures that are used in concrete are protein hydrolysates and welan gum; and in case of dry-mix mortar these admixtures are succinoglycan and xanthan gum. The market share of microbial biopolymers is expected to increase because of technological advances and the growing trend to use naturally based or biodegradable products in building materials (Plank 2004; Ramesh et al. 2010). These microbial products of biotechnological industry are mainly viscosity-enhancing admixtures used to achieve high resistance to segregation of concrete. Major biotechnological admixtures are shown in Table 2.2.

Sewage sludge or dewatered dry sewage sludge of municipal wastewater treatment plants, are used in the cement and concrete industry (Mun 2007; Fytili and Zabaniotou 2008). It is mainly biomass of anaerobic Bacteria and Archaea performing acidogenic and methanogenic fermentations. This material contains various biopolymers, such as linear and branched polysaccharides, globular proteins and rRNA, and linear chains of DNA and mRNA. Our experiments with addition of pure linear (xanthan, DNA), branched (amylopectin) or globular (albumin) biopolymers to Portland cement showed that even addition of 0.1 % of these hydrophilic biopolymers changed strength of concrete. It was higher with addition of biopolymers than in control after 3 days but was lower than in control after 7 days, probably because a thin layer of the hydrophilic biopolymer on the cement grain hindered its hydration (Wang et al. 2013, not published data).

Another important application of microbial biopolymers is production of bacterial polysacchartides in soil to modify its geotechnical properties (Stewart and Fogler 2001). The most suitable groups of microorganisms that produce insoluble extracellular polysaccharides to bind the soil particles and fill in the soil pores are as follows:

-

oligotrophic bacteria from genus Caulobacter (Tsang et al. 2006);

-

aerobic Gram-negative bacteria from genera Acinetobacter, Agrobacterium, Alcaligenes, Arcobacter, Cytophaga, Flavobacterium, Pseudomonas, and Rhizobium (Portilho et al. 2006; Ross et al. 2001);

-

species of Gram-positive facultative anaerobic and aerobic bacteria, such as Leuconostoc mesenteroides producing water-insoluble exopolymer dextran (Stewart and Fogler 2001) and Cellulomonas flavigena producing a curdlan-type (beta-1,3-glucan) exopolysaccharide from cellulose (Kenyon et al. 2005).

It is well known that almost all bacteria produce exopolysaccharides under excess of carbohydrates or other water soluble sources of carbon over source of nitrogen. Therefore, such food-processing wastes or sub-products as corn glucose syrup, cassava glucose syrup and molasses with C: N ratio > 20 are used for industrial production of bacterial water-insoluble polysaccharides (Portilho et al. 2006). After growth of exopolysaccharide-producing bacteria in soil, its permeability for water is greatly reduced. Growth of exopolysaccharide-producing bacteria in soil can be used for different geotechnical applications such as selective zonal bioremediation, harbor and dam control, erosion potential minimization, earthquake liquefaction mitigation, construction of reactive barrier, and long-term stabilization of contaminated soils (Yang et al. 1993). Organic wastes such as organic fraction of municipal solid wastes, sewage sludge, composted poultry manure can be used as a source of organic matter for exopolysaccharide-producing microorganisms in large-scale applications to diminish the cost of soil clogging.

2.4 Construction Bioplastics

There is clear trend in construction industry for using of biodegradable materials and biopolymers (Plank 2004; Ramesh et al. 2010). There is considerable interest in the development of biodegradable bioplastics for construction industry. Its advantages are that use of this bioplastic will reduce the land for disposal of construction wastes and it is producing from renewable sources so their production will increase environmental and economic sustainability of construction industry.

However, the cost of bioplastics produced aseptically in fermenters is usually several times higher than the cost of petrochemical-based plastics, so the reduction of the bioplastic production costs using cheap raw materials and technological innovations is still essential for the bioplastic industry and applications. Most available types of bioplastics for construction industry are polyhydroxyalkanoates (PHAs), which are polyesters accumulated up to 80 % of dry bacterial biomass as a storage compound. Most important PHAs are poly-3-hydroxybutyrate (PHB) with monomer formula (-OCH(CH3)-CH2-C(O)-) and polyhydroxyvalerate (PHV) with monomer formula (-OCH(CH2CH3)-CH2-C(O)-). Accumulated PHAs can be extracted from bacterial biomass and used in practice as bioplastic with melting temperature 160–180 °C, tensile strength 24–40 MPa, and elongation at break 3–142 %. Chemical and physical properties of PHAs can be found in numerous reviews (Lowell and Rohwedder 1974; Braunegg et al. 1998; Castilho et al. 2009; Sudesh et al. 2000; Sudesh and Abe 2010; Volova 2004; DeMarco 2005; Khanna and Srivastava 2005; Lenz and Marchessault 2005).

The following options for raw materials, biotechnology of production, and applications of bioplastic can help to diminish the cost of the bioplastic PHAs:

-

1.

Use of cheap raw materials (Serafim et al. 2008): organic fraction of municipal solid wastes, liquid wastes of municipal wastewater treatment plants, food-processing waste, or agricultural wastes such as unbaled straw; corn cobs, stalks, and leaves (corn stover); silage effluent; horticulture residuals; farm yard manure; coconut fronds, husks, and shells; coffee hulls and husks; cotton (stalks), nut shells; rice hull, husk, straw, and stalks, sugarcane bagasse. Globally, 140 billion metric tons of biomass is generated every year from agriculture, which is equivalent to approximately 50 billion tons of oil. So, biomass wastes have attractive potentials for large-scale industries and community-level enterprises (UNEP 2009).

-

2.

Batch or continuous nonaseptic cultivation for biosynthesis of bioplastic by mixed bacterial culture (Yu et al. 1999; Lu 2007);

-

3.

Production of crude bioplastic for construction industry and agriculture avoiding its concentration and extraction of bioplastic using chemical treatment, filtration, centrifugation, or flotation.

For the biosynthesis of PHAs under nonaseptic conditions, organic wastes can be converted to organic acids through acidogenic fermentation of organics, then organic acids can be converted to PHAs (Yu 2006). Most typical material balance of acidogenic fermentation is as follows (Madigan et al. 2012):

where C6H12O6 is a monomer of cellulose, CH3COOH, C2H5COOH, C3H7COOH are acetic, propionic and butyric acids, respectively. The pH of organic fraction of municipal waste can be dropped below 5.5 during acidogenic fermentation (Barlaz et al. 2010), meanwhile optimal pH for acidogens is above 6.0 (Moosbrugger et al. 1993). To maintain optimal pH during acidogenic fermentation of organic wastes the fine powder of limestone (CaCO3) or dolomite (CaMgCO3) can be added. There will be two fractions at the end of the process: dissolved acetate salts of Ca and Mg that could be used for biosynthesis of bioplastic, and semi-solid residuals that can be used for biocementation (Ivanov and Chu 2008; Ivanov 2010) of sand and gravel in road, pond, or channel construction or for soil erosion control. Using this semi-solid residual all solid wastes from bioplastic production can be used as the components of biocement (see below).

Batch biosynthesis of bioplastic is simpler but less productive than continuous process, which productivity can be about 1 kg of PHAs/day/m3 of bioreactor (Ben Rebah et al. 2009). Production of PHAs can be done as semi-continuous cultivation of a mixed culture using a feast-famine cycle comprising a feast phase and a famine phase in one bioreactor. This cycling process promotes not only accumulation of PHAs in biomass but also selection of PHAs-producing microorganisms (Beun et al. 2006; van Loosdrecht et al. 1997, 2008).

All known methods of PHAs extraction suffer from a high cost or environmental pollution and are difficult to be industrialized. Therefore, crude bioplastic, without extraction of PHAs, could be used for construction applications. Major advantage of PHAs for construction applications is biodegradability of bioplastic to carbon dioxide and water for about 1.5 months in anaerobic sewage, 1.5 years in soil, and 6.5 years in seawater (Mergaert et al. 1992; Reddy et al. 2003; Castilhio et al. 2009). Dead bacterial biomass with PHAs contains also polysaccharides of cell wall, proteins, polynucleotides, and phospholipids, which content is about 15, 50, 25, and 10 % of dry biomass without PHAs, respectively, and biodegradation rate is higher than that of PHAs. Therefore, from the point of view of biodegradability of bioplastic construction wastes there is no need to extract PHAs from biomass but to use dry biomass with PHAs as a crude nanocomposite material. Such nanocomposites should be more flexible and better biodegradable than extracted PHAs. Sustainability of this biodegradable construction materials is due to: (1) production of bioplastic from renewable sources or even from organic wastes; (2) fast biodegradability of this material under the conditions of landfill or composting so negative effect of construction waste on environment will be minimized.

One area of applications of nanocomposite bioplastic from bacterial biomass containing PHAs is the production and use of biodegradable construction materials, which do not require removal and incineration after temporary application. Biodegradable bioplastic foam can be used for insulation walls and partitions, construction of nonstructural (internal) elements such as separating walls and partitions, and for the temporarily constructions that can be landfilled for fast degradation. Other examples of potential application of crude nanocomposite from bacterial biomass and PHAs are construction silts and dust fences that can be landfilled for fast biodegradation or composted as biomass. Biodegradable plastics could be also useful for vertical drains, geotextile, geomembranes, soil stabilization mats. These materials are used temporarily for soft soil stabilization, filtration and drainage (Park et al. 2010; Ogbobe et al. 1998; Arunaye and Mwasha 2011; Chu et al. 2009b), so biodegradability of the material can eliminate the cost of extraction and disposal of the temporal objects. There could be a big market for biodegradable bioplastic construction material, which does not require removal and incineration after use.

2.5 Biocements and Biogrouts

There are possible and used different types of biocementation based on diverse biogeochemical reactions performed by microorganisms (Ivanov and Chu 2008; Ivanov 2010).

2.5.1 Calcium- and Urea-Dependent Biocementation

Most popular type of biocementation is based on so-called microbially-induced calcium carbonate precipitation (MICCP), which is formation of calcium carbonate minerals such as calcite, vaterite, or aragonite on the surface of soil particles due to: (1) adhesion of cells of urease-producing bacteria (UPB) on the surface of particle; (2) creating a microgradient of concentration of carbonate and pH in the site of cell attachment due to hydrolysis of urea by urease of UPB. The biogeochemical reactions of this biocementation process are as follows:

Total

Enzyme urease (EC 3.5.1.5) is produced by a wide range of microorganisms because urea is a final product of nitrogen metabolism of human and animals and plays a role of nitrogen source for many microorganisms in nature. Another enzyme with important role in MICP is carbonic anhydrase (EC4. 2.1.1) catalyzing the reversible hydration of CO2 (Dhami et al. 2014).

MICP is developing and testing in the field mainly for numerous geotechnical applications (Seagren and Aydilek 2010; DeJong et al. 2010, 2013; Sarayu et al. 2014): to enhance stability of the slopes and dams (van Paassen et al. 2010; Harkes et al. 2010); for road construction and prevention of soil erosion (Mitchell and Santamarina 2005; Whiffin et al. 2007; Ivanov and Chu 2008; Ivanov 2010); for the construction of the channels, aquaculture ponds, or reservoirs in sandy soil (Chu et al. 2013a, b; Stabnikov et al. 2011); for sand immobilization and suppression of dust (Bang et al. 2011; Stabnikov et al. 2013a); to reinforce sand in near-shore areas (van der Ruyt and van der Zon 2009).

The applications of MICP in civil engineering can be as follows: the production of bricks (Sarda et al. 2009; Dhami et al. 2012; Raut et al. 2014); the remediation of cracks in concrete and rocks and increase of durability of concrete structures (De Muynck et al. 2008a, b, 2010, 2012; Achal et al. 2010; van Tittelboom et al. 2010; Ghosh et al. 2005; Li and Qu 2012); the concrete improvement (Pacheco-Torgal and Labrincha 2013a; Pacheco-Torgal and Jalali, 2014); the self-remediation of concrete (Jonkers 2007; Jonkers et al. 2010; De Muynck et al. 2008a, b; Wiktor and Jonkers 2011; Ghosh et al. 2006; Siddique and Chahal 2011; Wang et al. 2012); the modification of mortar (Ghosh et al. 2009; Vempada et al. 2011); consolidation of porous stone (Jimenez-Lopez et al. 2008); the bioremediation of weathered-building stone surfaces (Fernandes 2006; Webster and May 2006; Achal et al. 2011); the fractured rock permeability reduction (Cuthbert et al. 2013); dust suppression (Bang et al. 2011; Stabnikov et al. 2013a); the construction of ponds and channels (Chu et al. 2012b, 2013a; Stabnikov et al. 2011); the mitigation of earth quake-caused soil liquefaction (DeJong et al. 2006, 2013; Chu et al. 2009a; Weil et al. 2012; Montoya et al. 2012); the encapsulation of soft clay (Ivanov et al. 2014); the coating of surfaces with calcite for enhanced marine epibiota colonization (Ivanov et al. not published data).

In majority of the biocementation research, the Gram-positive bacterial species Sporosarcina pasteurii (former Bacillus pasteurii), especially the strain S. pasteurii ATCC 11859 (DSM 33), is used because of its high urease activity and ability to grow at pH above 8.5 and at high concentration of calcium, at least at 0.75 M Ca2+. Last property is especially important for MICP. Other physiologically similar species using for biocementation are the representatives of the genus Bacillus: B. cereus (Castanier et al. 2000); B. megaterium (Bang et al. 2001; Dhami et al. 2014), B. sphaericus (Hammes et al. 2003; De Muynck et al. 2008a, b; Wang et al. 2012), B. pseudofirmus (Jonkers et al. 2010), B. subtilis (Reddy et al. 2010), B. alkalinitrilicus (Wiktor and Jonkers 2011), B. licheniformis (Vahabi et al. 2014), B. lentus (Sarda et al. 2009) and not identified species (Stabnikov et al. 2011, 2013b; Hammes et al. 2003; Lisdiyanti et al. 2011). It is well known that some halotolerant species of genus Staphylococcus exhibited high urease activity (Jin et al. 2004; Christians et al. 1991). Halotolerant urease-producing strain of Gram-positive bacteria of Staphylococcus succinus was isolated from water of the Dead Sea with salinity 34 % (Stabnikov et al. 2013b). However, the strains of S. succinis are often hemolytic and toxigenic ones (Zell et al. 2008) and were associated with some infectious diseases (Novakova et al. 2006; Taponen et al. 2008). Therefore, the isolated strain was not used for biocementation studies and applications.

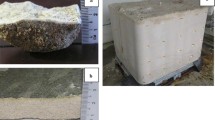

Biocementation can be performed as bulk biocementation through the supply of bacterial suspension altogether or separately with solutions of calcium and urea by injection, and using surface percolation (Cheng and Cord-Ruwisch 2012; Stabnikov et al. 2011) or surface spraying (Stabnikov et al. 2011, 2013a; Chu et al. 2012a). Modifying types of the treatment it is possible to form the crust on surface of soil (Fig. 2.6a), biocemented layer of defined thickness (Fig. 2.6b) or biocemented monolith (Fig. 2.6c).

There are several drawbacks in the conventional MICP process: (1) by-product of urea hydrolysis is ammonium and ammonia that are toxic substances for workers, harmful for aquatic environment and atmosphere, and increases the risk corrosion because of high pH (Pacheco-Torgal and Labrincha 2013a); (2) the brittleness of calcite crystals bonding the soil particles; and (3) the cost of calcium reagent and urea are higher than the cost of conventional cement. Therefore, the improvements of MICP as well as new types of biocementation have to be developed to overcome these disadvantages of conventional MICP.

2.5.2 Biocementation Based on Production of Carbonates by Heterotrophic Bacteria During Aerobic or Anoxic Oxidation of Organics

Precipitation of calcium carbonate can be due to increase pH and production of carbonate by heterotrophic bacteria during aerobic oxidation of organics (Ehrlich 1999; Wright and Oren 2005), for example, in such biogeochemical reactions as

Calcium carbonate precipitation due to oxidation of organics was used for biocementation of the porous stones (Rodriguez-Navarro et al. 2003; Jimenez-Lopez et al. 2008).

Dissolved salts or chelates of Fe(II) produced by iron-reducing bacteria under strong anaerobic conditions can be also transformed to ferrous carbonate by anaerobic heterotrophic bacteria:

Precipitation of calcium carbonate due to increase pH and production of carbonate by heterotrophic bacteria during anoxic oxidation of organics, for example due to bioreduction of nitrate:

Calcium carbonate precipitation due to nitrate bioreduction of organics is useful for the combination of biocementation with nitrogen gas production in situ during partial desaturation of sandy soil, which is an effective method for the mitigation of earthquake-caused soil liquefaction (Chu et al. 2009a; Rebata-Landa and Santamarina 2012; He et al. 2013). Bioreduction of nitrate (bacterial denitrification process) can also increase pH and initiate precipitation of CaCO3 without pH buffering (Hamdan et al. 2011). For example, precipitation of CaCO3 can be performed using bioreduction of calcium nitrate by ethanol:

The biogeochemical reactions in case of denitrification and iron-based bioclogging are similar:

2.5.3 Biogas Production in Situ for Mitigation of Soil Liquefaction

Earthquake is one of the most devastating types of geohazards on Earth causing great economic losses including damages to infrastructures and properties. Many of the damages were related to soil liquefaction—a phenomenon whereby soil substantially loses strength and stiffness. Conventional ground improvement for mitigating liquefaction-induced geotechnical hazards are vibroreplacement, compaction grouting, and deep dynamic compaction methods. However, these methods are energy-consuming and expensive. Furthermore, dynamic compaction cannot be used for retrofitting or in the city or built-up areas. Recent fundamental studies in soil mechanics showed that inclusion of gas bubbles in saturated sand can reduce its susceptibility for liquefaction substantially (Xia and Hu 1991; Yang et al. 2004; Yegian et al. 2007; Eseller-Bayat et al. 2012). This finding has paved the way for the development of one of the best solutions to the mitigation of liquefaction disasters. It has been demonstrated that the liquefaction resistance of saturated sand can be significantly increased when the sand is slightly de-saturated with some voids displaced by nitrogen gas produced by denitrifying bacteria (Chu et al. 2009a, ; Rebata-Landa and Santamarina 2012; He et al. 2013). The biogas production in situ (Eqs. 2.15–2.20) has three major advantages over the other methods: (1) the distribution of gas is uniform because bacteria and reagents are in the liquid form and can be distributed evenly in sand; (2) the gas bubbles generated by bacteria are tiny and thus the gas bubbles are relatively stable; and (3) nitrogen gas is inert and has low solubility.

Different organic and inorganic substances can be biooxidized by nitrate but ethanol (C2H5OH), acetic acid (CH3COOH), or glucose (C6H12O6) that can be as used as 75 % (w/v) syrup from corn, are most suitable electron donors because of their low cost, availability, and high solubility in water. Their biooxidation by nitrate (denitrification), is shown below:

These electron donors are very similar from stoichiometrical and economical points of view (Table 2.3).

The stoichiometrical parameters of these reactions are almost same: consumption of electron donor is 3.4 kg/m3 of N2 and consumption of electron acceptor (sodium nitrate) is 7.6 kg/m3 of N2. The consumption of electron donor and acceptor for 10 % (volume of gas/volume of water) desaturation of soil with porosity 50 % is 0.55 kg/m3 of saturated soil. Production of carbon dioxide in reactions 2.1–2.3, which is from 120 to 159 g/m3 of N2 or from 12 to 16 g/m3 of water in saturated soil with 50 % porosity, is not accounted for desaturation of soil because solubility of CO2 in water at 10 °C is 2500 g/m3.

There is almost no cost difference between these electron donors: the cost of electron donor is from $0.5 to $0.7/kg, the cost of electron acceptor (sodium nitrate) is from $0.4 to $0.5/kg, so the estimated cost of electron donor and acceptor for partial desaturation is from $5.1 to $6.2/m3 of N2. The estimated cost of electron donor and acceptor for 10 % (volume of gas/volume of water) desaturation of soil with porosity 50 % is from $0.25 to $0.31/m3 of saturated soil. However, even stoichiometrical and economic parameters of the electron donors are similar, ethanol could be more preferable electron donor then acetic acid or glucose sirup for geotechnical applications because it is liquid with neutral pH and not corrosive substance with low viscosity.

Biocementation of loose sand using a MICP process to increase the liquefaction resistance of sand has also been reported by DeJong et al. (2006), Montoya et al. (2012). It was shown (Montoya et al. 2012) that the resistance of sand to liquefaction, as measured by a decrease in the excess pore water pressure ratio, was significantly increased after MICP. However, sufficiently strong biocementation of saturated sand, at the level of unconfined compressive strength 250–500 kPa, could be at the content of precipitated calcium carbonate of 75–100 g/kg of sand (Ivanov et al. 2012a; Cheng et al. 2013). Therefore, it could be material-consuming process requiring about 88 kg CaCl2 and 96 kg of urea per 1 m3 of sand, which will cost at least $41/m3 of saturated soil. This value is about 140 times higher than 10 % desaturation of soil using biogas production in situ. So, biocementation of soil to mitigate liquefaction could be too expensive to be applicable for large-scale geotechnical practice.

2.5.4 Calcium- and Magnesium-Based Biocementation

The biocement for this biocementation can be produced through dissolution of dolomite, which is a common raw material for the production of cement, in hydrochloric acid:

Our experiments showed that this biocementation produced the unconfined compressive strength of the biocemented sand column 12.4 MPa at the content of precipitated Ca and Mg 6 % (w/w). However, the hydraulic permeability of the biocemented sand was high, 7 × 10−4 ms−1. For calcium-and urea based biocementation the hydraulic conductivity and strength are correlated and high strength is accompanied with low hydraulic conductivity of the biocemented sand. Probably, high strength but at the same time high permeability of sand after magnesium-based biocementation is due to coating of whole surface of sand grains with crystals, while calcium- and urea-based biocementation produced crystal mainly in the contact areas of the sand grains (Fig. 2.7).

Combined calcite and struvite (NH4MgPO4) precipitation using triple superphosphate and magnesium salt to avoid formation of soluble ammonia and release of ammonia to atmosphere during biocementation:

2.5.5 Calcium-Phosphate Biocementation

Calcium phosphate precipitation from calcium phytate (myo-inositol hexakisphosphate, calcium salt) solution, (the main storage form of phosphorus in the plant seeds) using phytase activity of microorganisms (Roeselers and van Loosdrecht 2010) producing a mixture of the crystal forms such as monetite (CaHPO4), whitlockite [Ca9(Mg,Fe2+)(PO4)6HPO4], and hydroxyapatite [Ca5(PO4)3OH] with the Ca-to-P molar ratio 1.55. The problem of this type of biocementation is a low solubility of calcium phytate (in the described study the concentration was 5.6 mM), so big volumes of solution must be pumped through soil.

Triple superphosphate, which is a relatively cheap commodity, has also low solubility about 0.08 M, and can be used for calcium phosphate precipitation using acidotolerant urease-producing microorganisms as shown below.

Monetatite precipitation:

Hydroxyapatatite precipitation:

2.5.6 Calcium Bicarbonate Biocementation

Important biocementation technology could be precipitation of calcite using removal of CO2 from solution of calcium bicarbonate (Ehrlich 1999) because it releases low quantity of ammonia and can be performed without increase of pH to 8.5–9.0 as conventional MICP:

Solubility of calcium bicarbonate is relatively high, about 1 M, to perform practically feasible biocementation. This method is a model of the naturally occuring dissolution-precipitation of calcium carbonate

The difference is that biocementation has to be performed at high concentration of calcium bicarbonate and with significantly higher rate than in nature. The rate of precipitation of calcium carbonate from calcium bicarbonate in nature is determined by the removal rate of CO2 from the reaction. The rate of biocementation can be accelerated due to increase of pH during hydrolysis of urea by enzyme urease. The problem of bicarbonate biocement is its instability, so the solution must be produced and stored at elevated partial pressure of CO2.

2.5.7 Iron-Based Bioclogging and Biocementation

Iron-based biocementation could be suitable for geotechnical applications if to combine three bioprocesses shown below.

-

Acidogenic fermentation of cellulose-containing agricultural or food-processing residuals producing mainly acetic acid (see Eq. 2.1);

-

bioreduction of cheap commodity, iron ore, using products of acidogenic fermentation or many organic electron donors (Ivanov et al. 2009; Guo et al. 2010), see equation for the reduction of ferric ions by iron-reducing bacteria using acetate:

$$4\;{\text{Fe}}_{ 2} {\text{O}}_{ 3} + \;{\text{CH}}_{ 3} {\text{COOH}}\; + \; 1 6\;{\text{H}}^{ + } \to 8 {\text{Fe}}^{ 2+ } \; + \; 2\;{\text{CO}}_{ 2} + \; 10\;{\text{H}}_{ 2} {\text{O,}}$$(2.24)$$8\;{\text{Fe}}^{ 2+ } + \; 1 6\;{\text{CH}}_{ 3} {\text{COOH}} \to 8\;{\text{Fe}}\left( {{\text{CH}}_{ 3} {\text{COOH}}} \right)_{ 2} + \; 1 6\;{\text{H}}^{ + } ,$$(2.25)$$4\;{\text{Fe}}_{ 2} {\text{O}}_{ 3} + \; 1 7\;{\text{CH}}_{ 3} {\text{COOH}} \to 8\;{\text{Fe}}\left( {{\text{CH}}_{ 3} {\text{COOH}}} \right)_{ 2} \; + \; 2\;{\text{CO}}_{ 2} + \; 10\;{\text{H}}_{ 2} {\text{O}} .$$(2.26) -

oxidation and bioprecipitation of ferrous chelates (Stabnikov and Ivanov 2006; Ivanov et al. 2012a):

$$\begin{aligned}{\text{Fe}}^{ 2+ } + \; 1. 5\left( {{\text{NH}}_{ 2} } \right)_{ 2} {\text{CO}} + \;0. 2 5\;{\text{O}}_{ 2} + \; 5. 5\;{\text{H}}_{ 2} {\text{O}}\; + {\text{UPB}}& \to {\text{Fe}}\left( {\text{OH}} \right)_{ 3} \downarrow \\&\quad+ 1. 5\;({\text{NH}}_{ 4} )_{ 2} {\text{CO}}_{ 3} + 2 {\text{H}}^{ + } . \end{aligned}$$(2.27)

Urease-producing bacteria and urea are used to maintain the pH to be above the neutral value because oxidation of ferrous ions and hydrolysis of ferric ions is accompanied with acidification of solution. The advantages of using iron hydroxide as the clogging compound are that the soil treated by iron minerals is more ductile and able to resist low pH conditions. The soil treated using iron based biocement is not as strong as that treated using calcium based biocement (Ivanov et al. 2012a) but the clogging effect of precipitated iron hydroxide is higher than that of calcium carbonate (Fig. 2.8).

Precipitation of ferric and manganese hydroxide from chelates of Fe2+ and Mn2+ for soil bioclogging can be done using neutrophilic iron-oxidizing bacteria. For example, precipitation of iron/manganese minerals by iron-oxidizing bacteria Leptothrix discophora is a promising technology for modifying engineering soil properties and mitigating geologic hazards (Weaver et al. 2011).

2.5.8 Eco-Efficient Biocement

By the analogy with eco-efficient concrete (Pacheco-Torgal and Jalali 2011; Pacheco-Torgal et al. 2012; Pacheco-Torgal and Jalali, 2013), eco-efficient biocement can be produced using mining tails/residuals of limestone, dolomite, iron ore and organic agricultural, food-processing, or municipal wastes using acidogenic fermentation and bioreduction of iron with production of dissolved salts of calcium, magnesium, and iron.

The problem with the brittleness of biocementation could be solved using biomimetic approach (Sarikaya 1994; Mayer and Sarikaya 2002) using composite strengthening through combination of mineral and organic nano- and micro-particles. By the analogy with nanomaterials in cement (Pacheco-Torgal and Jalali 2011), applications of composite micro- and nano-materials can also be useful to increase strength and ductility of biocement. Theoretically, ductile biocement could be made as a bioinspired material (Pacheco-Torgal and Labrincha 2013b), with the 3D-composite structure of hierarchically arranged nano- and micrometric units (Imai and Oaki 2010), or just simply with the layers or inclusions, where inorganic crystals of calcium carbonate (calcite, aragonite, vaterate), calcium phosphate (hydroxyapatite), oxides of Si and Fe and others create the hardness and the organic components such as proteins and polysaccharides ensure flexibility of the biocemented structure. This property is well known from the structure of the natural biominerals such as bones, shells, and corals as well as artificial engineering composite materials (Yao et al. 2011; Mayer and Sarikaya 2002). However, the cost of micro- and nano-composites could be too high to be suitable for construction practice.

One prospective application of biocementation is repair of the cracks in concrete and self-healing concrete. The repair of the cracks in the surface layer of concrete is a major portion of multi-billion maintenance and repair cost of the concrete structures (Neville 1996; FHWA 2001). Self-healing concrete is based on the embedding into concrete the glass or plastic capsules with material, which could be released after simultaneous cracking of concrete and capsules. One type of material for self-repair of the concrete proposed to be based on MICP (Ramachandran et al. 2001; Jonkers 2007; Jonkers et al. 2010). However, volume of produced CaCO3 will be always significantly smaller of the volume of capsule and the crack to be filled.

2.6 Bioremediation and Biodecontamination of Construction Site Through Biocementation

When site can be used for construction but is polluted with chemical substances above permitted levels, microbial remediation of this site could be the cheapest option in comparison with mechanical or chemical cleaning of the construction site. Bioremediation can be done using such biogeochemical reactions as oxidation, reduction, and transformation of pollutants to nontoxic or not dissolved substances. Bioremediation of polluted sites is now well developed area with hundreds of published research papers, reviews and books as well as a lot of commercially available biotechnologies and equipment.

Meanwhile, bioremediation of construction sites through biocementation is a relatively new area. Usually, the aim of these methods of construction biotechnology is to prevent the dispersion of hazardous substances from the accidentally polluted site to environment. It is performed through either biocementation of soil or formation of biogeochemical barrier. For example, MICP has the ability to co-precipitate toxic radionuclides 90Sr, 60Co and metal contaminants such as Cd and this can be used to prevent their dispersion in environment (Warren et al. 2001; Fujita et al. 2004; Mitchell and Ferris 2005). After MICP treatment of sand surface with the quantity just 15.6 g Ca/m2 the release of the sand dust and its artificial pollutants to atmosphere decreased in comparison with control by 99.8 % for dust, 92.7 % for phenantherene, 94.4 % for led nitrate, and 99.8 % for bacterial cells of Bacillus megaterium due to bioaggregation of the fine sand particles. Bioaggregation treatment of the soil surface could be useful method to prevent the dispersion of dust and the dust-associated chemical and bacteriological pollutants in water, air and soil (Stabnikov et al. 2013a), so it could be useful in construction and probably to protect atmosphere in fixation response to a radiation dispersal devise attack (Cordesman 2002; Parra et al. 2009).

Another way of environmental protection from the polluted sites can be construction of permeable, reactive, biogeochemical barriers, which will precipitate heavy metals and degrade toxic chemicals due to microbial activity inside the barrier (Kavamura and Esposito 2010; Gibert et al. 2013).

2.7 Conclusions

Construction biotechnology includes microbial production of construction materials and microbially-mediated construction processes. Microbial cements, polysaccharides, and construction bioplastics can be made using biotechnologies. Microbial cement could be produced with lower cost than conventional cement. Biodegradability of the bioplastic constructions after their demolishing reduces the cost of construction wastes disposal. Microbial polysaccharides are used to modify the cement properties and soil bioclogging. Construction biotechnologies are based on the activity of urease-producing, acidogenic, halophilic, alkaliphilic, denitrifying, iron- and sulfate-reducing bacteria, cyanobacteria, algae, and microscopic fungi. The bio-related materials and processes can be used for the particles aggregation, soil grouting and clogging, cementation of the particles, desaturation of soil, encapsulation of soft clay, and coating of the solid surfaces. The biotechnologically produced materials and construction biotechnologies have a lot of advantages in comparison with the conventional construction materials and processes so the practical implementations of the construction biotechnologies could give significant economic and environmental benefits.

References

Achal V, Mukherjee A, Reddy MS (2010) Microbial concrete: way to enhance the durability of building structures. J Mater Civil Eng 23:730–734. doi:10.1061/(ASCE)MT.1943-5533.0000159

Achal V, Mukherjee A, Reddy MS (2011) Effect of calcifying bacteria on permeation properties of concrete structures. J Ind Microbiol Biotechnol 38:1229–1234. doi:10.1007/s10295-010-0901-8

Arunaye FI, Mwasha A (2011) On behavior of limited life geotextile materials for reinforcing embankment on soft ground. World J Eng 8:195–199. doi:10.1260/1708-5284.8.2.195

Bang SS, Galinat JK, Ramakrishnan V (2001) Calcite precipitation induced by polyurethane-immobilized Bacillus pasteurii. Enzyme Microb Technol 28:404–409

Bang S, Min SH, Bang SS (2011) Application of microbiologically induced soil stabilization technique for dust suppression. Int J Geo-Eng 3:27–37

Barlaz MA, Staley BF, De Los Reyes III FL (2010) Anaerobic biodegradation of solid waste. In: Mitchell R, Gu JD (eds) Environmental microbiology, 2nd edn. Wiley, Hoboken, NJ, USA, pp 281–299

Ben Rebah F, Prevost D, Tyagi RD, Belbahri L (2009) Poly-beta-hydroxybutyrate production by fast-growing rhizobia cultivated in sludge and in industrial wastewater. Appl Biochem Biotechnol 158:155–163

Beun JJ, Dircks K, van Loosdrecht MCM et al (2006) Poly-β-hydroxybutyrate metabolism in dynamically fed mixed microbial cultures. Water Res 36:1167–1180

Braunegg G, Lefebvre G, Genser KF (1998) Polyhydroxyalkanoates, biopolyesters from renewable resources: Physiological and engineering aspects. J Biotechnol 65:127–161

Burbank MB, Weaver TJ, Green TL, Williams BC, Crawford RL (2011) Precipitation of calcite by indigenous microorganisms to strengthen liquefiable soils. Geomicrobiol J 28:301–312. doi:10.1080/01490451.2010.499929

Burbank MB, Weaver TJ, Williams BC, Crawford RL (2012a) Urease activity of ureolytic bacteria isolated from six soils in which calcite was precipitated by indigenous bacteria. Geomicrobiol J 29:389–395. doi:10.1080/01490451.2011.575913

Burbank M, Weaver T, Lewis R, Williams T, Williams B, Crawford W (2012b) Geotechnical tests of sands following bioinduced calcite precipitation catalyzed by indigenous bacteria. J Geotech Geoenviron Eng 139:928–936. doi:10.1061/(ASCE)GT.1943-5606.0000781

Castanier S, Le Métayer-Levrel G, Orial G., Loubière JF, Perthuisot JP (2000) Bacterial carbonatogenesis and applications to preservation and restoration of historic property. In: Ciferri O, Tiano P, Mastromei G (eds) Of microbes and art. the role of microbial communities in the degradation and protection of cultural heritage. Kluwer Academic/Plenum Publisher, New York, pp 203–218

Castilho LR, Mitchell DA, Freire DMG (2009) Production of polyhydroxyalkanoates (PHAs) from waste materials and by-products by submerged and solid-state fermentation. Bioresour Technol 100:5996–6009

Cheng L, Cord-Ruwisch R (2012) In situ soil cementation with ureolytic bacteria by surface percolation. Ecol Eng 42:64–72. doi:10.1016/j.ecoleng.2012.01.013

Cheng L, Cord-Ruwisch R (2013) Selective enrichment and production of highly urease active bacteria by non-sterile (open) chemostat culture. J Ind Microbiol Biotechnol 40:1095–1104. doi:10.1007/s10295-013-1310-6

Cheng L, Cord-Ruwisch R, Shahin MA (2013) Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can Geotech J 50:1–10

Christians S, Jose J, Schäfer U, Kaltwasser H (1991) Purification and subunit determination of the nickel-dependent Staphylococcus xylosus urease. FEMS Microbiol Lett 80:271–275

Chu J, Ivanov V, Jia H, Chenghong G, Naeimi M, Tkalich P (2009a) Microbial geotechnical engineering for disaster mitigation and coastal management. In: Proceedings of WCCE-ECCE-TCCE joint conference: earthquake & tsunami, Istanbul, Turkey

Chu J, Varaksin S, Klotz U, Mengé P (2009b) Construction processes. state-of-the-art-report. In: Proceedings of the 17th international conference on soil mechanics and geotechnical engineering, Alexandria, Egypt, 5–9 Oct 2009 vol 4, pp 3006–3135

Chu J, Stabnikov V, Ivanov V (2012a) Microbially induced calcium carbonate precipitation on surface or in the bulk of soil. Geomicrobiol J 29:1–6

Chu J, Indraratna B, Shuwang Yan S, Rujikiatkamjorn C (2012b) Soft soil improvement through consolidation: an overview. In: Proceedings of the international conference on ground improvement and ground control, pp. 251–280. doi:10.3850/978-981-07-3559-3103-0007

Chu J, Ivanov V, Stabnikov V (2013a) Microbial method for construction of aquaculture pond in sand. Géotechnique 63:871–875. doi:10.1680/geot.SIP13.P.007

Chu J, He J, Ivanov V (2013b) Mitigation of liquefaction of saturated sand using biogas. Geotechnique 63:267–275. doi:10.1680/geot.SIP13.P.004

Chu J, Ivanov V, Naeimi M, Stabnikov V, Liu HL (2014) Optimization of calcium-based bioclogging and biocementation of sand. Acta Geotech 9:277–285. doi:10.1007/s11440-013-0278-8

Cordesman AH (2002) Terrorism, asymmetric warfare, and weapons of mass destruction: defending the U.S. homeland. Praeger Publishers, Westport

Cuthbert MO, McMillan LA, Handley-Sidhu S, Riley MS, Tobler DJ, Phoenix VR (2013) A field and modeling study of fractured rock permeability reduction using microbially induced calcite precipitation. Env Sci Technol 47:13637–13643. doi:10.1021/es402601g

DeJong J, Fritzges M, Nusstein K (2006) Microbially induced cementation to control sand response to undrained shear. J Geotech Geoenv Eng 32:1381–1392

DeJong JT, Mortensen BM, Martinez BC, Nelson DC (2010) Bio-mediated soil improvement. Ecol Eng 36:197–210

DeJong JT, Soga K, Kavazanjian E et al (2013) Biogeochemical processes and geotechnical applications: progress, opportunities and challenges. Geotechnique 63:287–301

DeMarco S (2005) Advances in polyhydroxyalkanoate production in bacteria for biodegradable plastics. Basic Biotechnol eJ 1:1–4

De Muynck W, Cox K, Verstraete W, De Belie N (2008a) Bacterial carbonate precipitation as an alternative surface treatment for concrete. Constr Build Mater 22:875–885

De Muynck WD, Debrouwer D, De Belie ND, Verstraete W (2008b) Bacterial carbonate precipitation improves the durability of cementitious materials. Cem Concr Res 38:1005–1014

De Muynck W, De Belie N, Verstraete W (2010) Microbial carbonate precipitation in construction materials: a review. Ecol Eng 36:118–136

De Muynck W, Verbeken K, De Belie N, Verstraete W (2012) Influence of temperature on the effectiveness of a biogenic carbonate surface treatment for limestone conservation. Appl Microbiol Biotechnol 97(3):1335–1347 doi:10.1007/s00253-012-3997-0

Dhami NK, Reddy MS, Mukherjee A (2012) Improvement in strength properties of ash bricks by bacterial calcite. Ecol Eng 39:31–35. doi:10.1016/j.ecoleng.2011.11.011

Dhami NK, Reddy MS, Mukherjee A (2014) Synergistic role of bacterial urease and carbonic anhydrase in carbonate mineralization. Appl Biochem Biotechnol 172:2552–2561 doi:10.1007/s12010-013-0694-0

Dosier GK (2013) Methods for making construction material using enzyme producing bacteria. US Patent App. 13/093,335, 2011

Ehrlich HL (1999) Microbes as geologic agents: their role in mineral formation. Geomicrobiol J 16:135–153

Eseller-Bayat E, Yegian MK, Alshawabkeh A, Gokyer S (2012) Prevention of liquefaction during earthquakes through induced partial saturation in sands. Geotechnical engineering: new horizons. IOS Press, Amsterdam, pp 188–194

Fernandes P (2006) Applied microbiology and biotechnology in the conservation of stone culture heritage materials. Appl Microbiol Biotechnol 73:291–296

FHWA-RD-01-156 (2001) Corrosion cost and preventive strategies in the United States, Report by CC Technologies Laboratories, Inc. to Federal Highway Administration. (FHWA), Office of Infrastructure Research and Development

Fujita F, Redden GD, Ingram JC, Cortez MM, Ferris FG, Smith RW (2004) Strontium incorporation into calcite generated by bacterial ureolysis. Geochim Cosmochim Acta 68:3261–3270. doi:10.1016/j.gca.2003.12.018

Fytili D, Zabaniotou A (2008) Utilization of sewage sludge in EU application of old and new methods—a review. Renew Sustain Energy Rev 12:116–140. doi:10.1016/j.rser.2006.05.014

Ghosh P, Mandal S, Chattopadhyay BD, Pal S (2005) Use of microorganism to improve the strength of cement mortar. Cem Concr Res 35:1980–1983. doi:10.1016/j.cemconres.2005.03.005

Ghosh P, Mandal S, Pal S, Bandyopadhyaya G, Chattopadhyay BD (2006) Development of bioconcrete material using an enrichment culture of novel thermophilic anaerobic bacteria. Indian J Exp Biol 44:336–339

Ghosh S, Biswas M, Chattopadhyay BD, Mandal S (2009) Microbial activity on the microstructure of bacteria modified mortar. Cem Concr Compos 31:93–98

Gibert O, Cortina JL, de Pablo J, Ayora C (2013) Performance of a field-scale permeable reactive barrier based on organic substrate and zero-valent iron for in situ remediation of acid mine drainage. Env Sci Pollut Res 20:7854–7862. doi:10.1007/s11356-013-1507-2

Guo CH, Stabnikov V, Ivanov V (2010) The removal of nitrogen and phosphorus from reject water of municipal wastewater treatment plant using ferric and nitrate bioreductions. Bioresour Technol 101:3992–3999

Hamdan N, Kavazanjian E, Rittman BE, Karatas I (2011) Carbonate mineral precipitation for soil improvement through microbial denitrification. In: Han J, Alzamora DA (eds) Geo-frontiers 2011: advances in geotechnical engineering. American Society of Civil Engineers, Dallas

Hammes F, Boon N, de Villiers J, Verstraete W, Siciliano SD (2003) Strain-specific ureolytic microbial calcium carbonate precipitation. Appl Env Microbiol 69:4901–4909

Harkes MP, van Paassen LA, Booster JL, Whiffin VS, van Loosdrecht MCM (2010) Fixation and distribution of bacterial activity in sand to induce carbonate precipitation for ground reinforcement. Ecol Eng 36:112–117

He J, Chu J, Ivanov V (2013) Mitigation of liquefaction of saturated sand using biogas. Geotechnique 63:267–275

Imai H, Oaki Y (2010) Bioinspired hierarchical crystals. MRS Bull 35(2):138–144. doi:10.1557/mrs2010.634

Ivanov V, Chu J (2008) Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev Env Sci Biotechnol 7:139–153

Ivanov V, Kuang SL, Guo CH, Stabnikov V (2009) The removal of phosphorus from reject water in a municipal wastewater treatment plant using iron ore. J Chem Technol Biotechnol 84:78–82

Ivanov V (2010) Environmental microbiology for engineers. CRC Press, Taylor & Francis Group, Boca Raton, p 402

Ivanov V, Stabnikov V, Hung YT (2012) Screening and selection of microorganisms for the environmental biotechnology process. In: Yung-Tse H, Lawrence KW, Nazih KS (eds) Handbook of environment and waste management: air and water pollution control. World Scientific Publishing Co., Inc., Singapore, pp 1137–1149

Ivanov V, Chu J, Stabnikov V, Li B (2014) Strengthening of soft marine clay using biocementation. Marine Georesour Geotechnol. doi:10.1080/1064119X.2013.877107

Jimenez-Lopez C, Jroundi F, Pascolini C, Rodriguez-Navarro C, Piñar-Larrubia G, Rodriguez-Gallego M, González-Muñoz MT (2008) Consolidation of quarry calcarenite by calcium carbonate precipitation induced by bacteria activated among the microbiota inhabiting the stone. Int Biodeterior Biodegrad 62:352–363

Jin M, Rosario W, Walter E, Calhoun DH (2004) Development of a large-scale HPLC-based purification for the urease from Staphylococcus leei and determination of subunit structure. Protein Expr Purif 34:111–117

Jonkers HM (2007) Self healing concrete: a biological approach. In: van der Zwaag S (ed) Self healing materials: an alternative approach to 20 centuries of materials science. Springer, Berlin, pp. 195–204

Jonkers HM, Thijssen A, Muyzer G, Copuroglu O, Schlangen E (2010) Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol Eng 36:230–235

Kavamura VN, Esposito E (2010) Biotechnological strategies applied to the decontamination of soils polluted with heavy metals. Biotechnol Adv 28:61–69. doi:10.1016/j.biotechadv.2009.09.002

Kenyon WJ, Esch SW, Buller CS (2005) The curdlan-type exopolysaccharide produced by Cellulomonas flavigena KU forms part of an extracellular glycocalyx involved in cellulose degradation. Antonie Van Leeuwenhoek 87:143–148

Khanna S, Srivastava AK (2005) Recent advances in microbial polyhydroxyalkanoates. Proc Biochem 40:607–619

León-Martínez FM, de Cano-Barrita PFJ, Lagunez-Rivera L, Medina-Torres L (2014) Study of nopal mucilage and marine brown algae extract as viscosity-enhancing admixtures for cement based materials. Constr Build Mater 53:190–202. doi:10.1016/j.conbuildmat.2013.11.068

Lenz RW, Marchessault RH (2005) Bacterial polyesters: biosynthesis, biodegradable plastics and biotechnology. Biomacromolecules 6:1–8

Li M, Guo H, Cheng X (2011) Application of response surface methodology for carbonate precipitation production induced by a mutant strain of Sporosarcina pasteurii. In: Geo-Frontiers, ASCE, pp 4079–4088

Li P, Qu W (2012) Microbial carbonate mineralization as an improvement method for durability of concrete structures. Adv Mater Res 365:280–286

Lisdiyanti P, Suyanto E, Ratnakomala S, Fahrurrozi, Sari MN, Gusmawati NF (2011) Bacterial carbonate precipitation for biogrouting. In: Proceedings of the national symposium on ecohydrology, Jakarta, pp 204–211

Lowell WL, Rohwedder WK (1974) Poly-beta-hydroxyalkanoate from activated sludge. Env Sci Technol 8:576–579

Lu Y (2007) Advance on the production of polyhydroxyalkanoates by mixed cultures. Front Biol China 2:1673–3509

Madigan MT, Martinko JM, Stahl D, Clark DP (2012) Brock biology of microorganisms (13th Edn). Pearson, San Francisco

Mayer G, Sarikaya M (2002) Rigid biological composite materials: structural examples for biomimetic design. Exp Mech 42:395–403

Mergaert J, Anderson C, Wouters A, Swings J, Kerster K (1992) Biodegradation of polyhydroxyalkanoates. FEMS Microbiol Rev 103:317–322

Mitchell AC, Ferris FG (2005) The coprecipitation of Sr into calcite precipitates induced by bacterial ureolysis in artificial groundwater: temperature and kinetic dependence. Geochim Cosmochim Acta 69:4199–4210

Mitchell JK, Santamarina JC (2005) Biological considerations in geotechnical engineering. J Geotech Geoenv Eng ASCE 131:1222–1233

Montoya BM, DeJong JT, Boulanger RW, Wilson D W, Gerhard R, Ganchenko A, Chou JC (2012) Liquefaction mitigation using microbial induced calcite precipitation. In: GeoCongress, pp 1918–1927

Moosbrugger RE, Wentezel MC, Ekama GA, Marais GV (1993) Weak acid/bases and pH control in anaerobic systems: a review. Water South Africa 19:1–10

Mun KJ (2007) Development and tests of lightweight aggregate using sewage sludge for nonstructural concrete. Constr Build Mater 21:1583–1588. doi:10.1016/j.conbuildmat.2005.09.009

Neville AM (1996) Properties of concrete, 4th edn. Pearson Higher Education, Prentice Hall, New Jersey

Novakova D, Sedlacek I, Pantucek R, Stetina V, Svec P, Petras P (2006) Staphylococcus equorum and Staphylococcus succinus isolated from human clinical specimens. J Med Microbiol 55:523–528

Ogbobe O, Essien KS, Adebayo A (1998) A study of biodegradable geotextiles used for erosion control. Geosynth Int 5:545–553

van der Ruyt M, van der Zon W (2009) Biological in situ reinforcement of sand in near-shore areas. Geotech Eng 162:81–83

van Loosdrecht MCM, Pot MA, Heijnen JJ (1997) Importance of bacterial storage polymers in bioprocesses. Water Sci Technol 33:41–47

van Loosdrecht MCM, Kleerebezem R, Muyzer G, Jian Y, Johnson K (2008) Process for selecting polyhydroxyalkanoate (PHA) producing micro-organisms. WO/2009/153303. International application No.: PCT/EP2009/057571, 18 June 2008

van Paassen L, Ghose R, van der Linden T, van der Star W, van Loosdrecht M (2010) Quantifying biomediated ground improvement by ureolysis: large-scale biogrout experiment. J Geotech Geoenv Eng 136:1721–1728

van Tittelboom K, De Belie N, De Muynck W, Verstraete W (2010) Use of bacteria to repair cracks in concrete. Cem Concr Res 40:157–166. doi:10.1016/j.cemconres.2009.08.025

Pacheco-Torgal F, Jalali S (2011) Nanotechnology: advantages and drawbacks in the field of construction and building materials. Constr Build Mater 25:582–590. doi:10.1016/j.conbuildmat.2010.07.009

Pacheco-Torgal F, Jalali S, Labrincha J, John VM (2012) Eco-efficient concrete using industrial wastes: a review. Mater Sci Forum 730–732, 581–586. doi:58110.4028/www.scientific.net/MSF.730-732.581

Pacheco-Torgal F, Labrincha JA (2013a) Biotech cementitious materials: Some aspects of an innovative approach for concrete with enhanced durability. Constr Build Mater 40:1136–1141. doi:10.1016/j.conbuildmat.2012.09.080

Pacheco-Torgal F, Labrincha JA (2013b) Biotechnologies and bioinspired materials for the construction industry: an overview. Int J Sustain Eng. doi:10.1080/19397038.2013.844741

Pacheco-Torgal F, Jalali S (2013) Eco-efficient construction and building materials. Springer, London, p 247 doi:10.1007/978-0-85729-892-8

Park JH, Yuu J, Jeon HY (2010) Green geosynthetics applications to sustainable environmental fields from the viewpoint of degradability. In: Proceedings of the international symposium and exhibition on geotechnical and geosynthetics engineering: challenges and opportunities on climate change, Bangkok, pp. 43–50, 7–8 Dec (2010)

Parra RR, Medina VF, Conca JL (2009) The use of fixatives for response to a radiation dispersal devise attack – a review of the current (2009) state-of-the-art. J Env Radioact 100:923–934

Pei R, Liu J, Wang S, Yang M (2013) Use of bacterial cell walls to improve the mechanical performance of concrete. Cem Concr Compos 39:122–130. doi:10.1016/j.cemconcomp.2013.03.024

Plank J (2003) Applications of biopolymers in construction engineering. In: Steinbüchel A (ed) Biopolymers, V.10. General aspects and special applications. Wiley, Weinheim

Plank J (2004) Application of biopolymers and other biotechnological products in building material. Appl Microbiol Biotechnol 66:1–9

Portilho M, Matioli G, Zanin GM, de Moraes FF, Scamparini AR (2006) Production of insoluble exopolysaccharide Agrobacterium sp. (ATCC 31749 and IFO 13140). Appl Biochem Biotechnol 129–132:864–869

Ramachandran SK, Ramakrishnan V, Bang SS (2001) Remediation of concrete using microorganisms. ACI Mater J 98:3–9

Ramesh BNG, Anitha N, Rani HKR (2010) Recent trends in biodegradable products from biopolymers. Adv Biotechnol 9:30–34

Raut SH, Sarode DD, Lele SS (2014) Biocalcification using B. pasteurii for strengthening brick masonry civil engineering structures. World J Microbiol Biotechnol 30:191–200. doi:10.1007/s11274-013-1439-5

Rebata-Landa V, Santamarina JC (2012) Mechanical effects of biogenic nitrogen gas bubbles in soils. J Geotech Geoenv Eng 138:128–137

Reddy CS, Ghai R, Rashmi C, Kalia VC (2003) Polyhydroxyalkanoates: an overview. Bioresour Technol 87:137–146

Reddy S, Rao M, Aparna P, Sasikala C (2010) Performance of standard grade bacterial (Bacillus subtilis) concrete. Asian J Civ Eng (Build Hous) 11:43–55

Rodriguez-Navarro C, Rodriguez-Gallego M, Ben Chekroun K, Gonzalez-Muñoz MT (2003) Conservation of ornamental stone by Myxococcus xanthus-induced carbonate biomineralization. Appl Env Microbiol 69:2182–2193. doi:10.1128/AEM.69.4.2182-2193.2003

Roeselers G, van Loosdrecht MCM (2010) Microbial phytase-induced calcium-phosphate precipitation– a potential soil stabilization method. Folia Microbiol 55:621–624

Ross N, Villemur R, Deschenes L, Samson R (2001) Clogging of limestone fracture by stimulating groundwater microbes. Water Res 35:2029–2037

Sarda D, Choonia HS, Sarode DD, Lele SS (2009) Biocalcification by Bacillus pasteurii urease: a novel application. J Ind Microbiol Biotechnol 36:1111–1115

Sarayu K, Iyer NR, Murthy AR (2014) Exploration on the biotechnological aspect of the ureolytic bacteria for the production of the cementitious materials—a review. Appl Biochem Biotechnol. doi:10.1007/s12010-013-0686-0

Sarikaya M (1994) An introduction to biomimetics: a structural viewpoint. Microsc Res Tech 37:360–375

Sathya A, Bhuvaneshwari P, Niranjan G, Vishveswaran M (2013) Influence of bio admixture on mechanical properties of cement and concrete. Asian J Appl Sci. doi:10.3923/ajaps.2013

Seagren EA, Aydilek AH (2010) Bioremediated geomechanical processes. In: Mitchell R, Gu J-D (eds) Environmental Microbiology, 2nd edn. Wiley, Hoboken, pp 319–348

Serafim LS, Lemos PC, Albuquerque MGE, Reis MAM (2008) Strategies for PHA production by mixed cultures and renewable waste materials. Appl Microbiol Biotechnol 81:615–628

Siddique R, Chahal NK (2011) Effect of ureolytic bacteria on concrete properties. Constr Build Mater 25:3791–3801. doi:10.1016/j.conbuildmat.2011.04.010

Stabnikov VP, Ivanov VN (2006) The effect of various iron hydroxide concentrations on the anaerobic fermentation of sulfate-containing model wastewater. Appl Biochem Microbiol 42:284–288

Stabnikov V, Chu J, Naeimi M, Ivanov V (2011) Formation of water-impermeable crust on sand surface using biocement. Cem Concr Res 41:1143–1149

Stabnikov V, Chu J, Myo AN, Ivanov V (2013a) Immobilization of sand dust and associated pollutants using bioaggregation. Water Air Soil Pollut 224:1631. doi:10.1007/s11270-013-1631-0

Stabnikov V, Chu J, Ivanov V, Li Y (2013b) Halotolerant, alkaliphilic urease-producing bacteria from different climate zones and their application for biocementation of sand. World J Microbiol Biotechnol 29:1453–1460. doi:10.1007/s11274-013-1309-1

Stewart TL, Fogler HS (2001) Biomass plug development and propagation in porous media. Biotechnol Bioeng 72:353–363

Sudesh K, Abe H, Doi Y (2000) Synthesis, structure and properties of polyhydroxyalkanoates: biological polyesters. Prog Polym Sci 25:1503–1555

Sudesh K, Abe H (2010) Practical guide to microbial polyhydroxyalkanoates. Smithers Rapra Technology, UK, p 160

Taponen S, Björkroth J, Pyörälä S (2008) Coagulase-negative staphylococci isolated from bovine extramammary sites and intramammary infections in a single dairy herd. J Dairy Res 75:422–429

Tsang PH, Li G, Brun YV, Freund LB, Tang JX (2006) Adhesion of single bacterial cells in the micronewton range. Proc Natl Acad Sci USA 103:11435–11436

UNEP (2009) Converting waste agricultural biomass into a resource. Compendium of technologies, United Nations Environment Programme, p 441

Vahabi A, Ramezanianpour AA, Sharafi H, Shahbani HZ, Vali H, Noghabil KA (2014) Calcium carbonate precipitation by strain Bacillus licheniformis AK01, newly isolated from loamy soil: a promising alternative for sealing cement-based materials. J Basic Microbiol 53:1–7. doi:10.1002/jobm.201300560

Vempada SR, Reddy SSP, Rao MVS, Sasikala C (2011) Strength enhancement of cement mortar using microorganisms-an experimental study. Int J Earth Sci Eng 4:933–936

Volova TG (2004) Polyhydroxyalkanoates - plastic materials of the 21st Century. Nova Publishers, Hauppauge, p 282

Warren LA, Maurice PA, Parmar N, Ferris FG (2001) Microbially mediated calcium carbonate precipitation: implications for interpreting calcite precipitation and for solid-phase capture of inorganic contaminants. Geomicrobiol J 18:93–115. doi:10.1080/01490450151079833

Wang JY, De Belie N, Verstraete W (2012) Diatomaceous earth as a protective vehicle for bacteria applied for self-healing concrete. J Ind Microbiol Biotechnol 39:567–577. doi:10.1007/s10295-011-1037-1

Webster A, May E (2006) Bioremediation of weathered-building stone surfaces. Trends Biotechnol 24:255–260. doi:10.1016/j.tibtech.2006.04.005

Weil MH, DeJong JT, Martinez BC, Mortensen BM, Waller JT (2012) Seismic and resistivity measurements for real-time monitoring of microbially induced calcite precipitation in sand. ASTM Geotech Test J 35:330–341

Whiffin VS, van Paassen LA, Harkes MP (2007) Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol J 24:417–423

Weaver TJ, Burbank M, Lewis A, Lewis R, Williams B (2011) Bio-induced calcite, iron, and manganese precipitation for geotechnical engineering applications. In: Geo-Frontiers: Adv Geotech Eng ASCE, 211:3975–3983. doi:10.1061/41165(397)406)

Wiktor V, Jonkers H (2011) Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem Concr Compos 33:763–770

Wright DT, Oren A (2005) Nonphotosynthetic bacteria and the formation of carbonates and evaporites through time. Geomicrobiol J 22:27–53

Xia H, Hu T (1991) Effects of saturation and back pressure on sand liquefaction. J Geotech Eng 117:1347–1362

Yang IC, Li Y, Park JK, Yen TF (1993) Subsurface application of slime - forming bacteria in soil matrices. In: Proceedings of the 2nd international symposium in situ and on site bioreclamation, April 1993, San Diego, CA. Lewis Publishers, Boca Raton

Yang J, Savidis S, Roemer M (2004) Evaluating liquefaction strength of partially saturated sand. J Geotech Geoenv Eng 130:975–979

Yao L, Yang J, Sun J, Cai L, He L, Huang H, Song R, Hao Y (2011) Hard and transparent hybrid polyurethane coatings using in situ incorporation of calcium carbonate nanoparticles. Mater Chem Phys 129:523–528

Yegian M, Eseller-Bayat E, Alshawabkeh A, Ali S (2007) Induced-partial saturation for liquefaction mitigation: experimental investigation. J Geotech Geoenv Eng 133:372–380

Yuan F, Xiao H, Wu J, Ying WF, Yu YP, Chi HX (2013) Effect of carboxylmethyl cellulose sulfate (CMC-S) on the hydration process of cement paste. Adv Mater Res 838–841:123–126

Yu PH, Chua H, Huang A, Ho KP (1999) Conversion of food industrial wastes into bioplastics with municipal activated sludge. Macromol Symp 148:415–424