Abstract

We consider a computer manufacturer who assembles customized final products from various components. Customer orders specify the product configuration, the quantity and a desired delivery date. The online order promising (OP) process must announce a first promised delivery date to the customer. Demand fulfillment in this Assemble-to-Order (ATO) case is still little investigated and differs remarkably from the more popular Make-to-Stock (MTS) case: Bottlenecks are the assembly capacity and the stocks of components, which are available to promise (ATP). An important task of the demand fulfillment, besides OP, is Demand Supply Matching (DSM), i.e. deciding on the assembly date of orders and eventually changing the delivery date of promised orders (repromising). We present a new concept for demand fulfillment in the ATO case which consists of online OP for single orders arriving during the day and DSM once a day, linked in a rolling-horizon scheme. The DSM is based on a mixed integer programming (MIP) model which simultaneously determines assembly and delivery dates for all promised orders. We report on a case study with real data of a computer manufacturer with more than 10,000 orders on hand and 2,000 different components.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Taking care of the fulfillment of customer orders is of great practical importance for most companies, but this task has been neglected in the research on supply chain planning in the past. In the last few years the demand fulfillment gained more attention, probably due to the rise of online retailing and EDI-connection in business-to-business relationships. We consider the case where customer orders arrive during the day and every order has to be confirmed instantly. This task is referred to as online order promising (OP) and leads to a first promised delivery date. Further tasks are necessary to fulfill the order completely, depending on the decoupling point of the underlying production system. In MTS production customer orders are fulfilled from finished goods on stock and planned production, which constitute the quantities available to promise (ATP). However, in ATO production systems, such as computer manufacturing, customer orders initiate the final assembly of (customized) products (e.g. PCs or Servers) from various components (like casing, mainboard, HDD, GPU, RAM, optical drives, etc.). Thus bottlenecks are the assembly capacity and the ATP quantities of components. Typically the components have a n:m-relationship to the orders, i.e. a specific order requires several different components and a specific component can occur in several different orders. The promised delivery dates are simultaneously based on the ATP-quantities of components and on capacity. Due to the assembly step, the order fulfillment time for ATO is longer than for MTS. During this time, after the first OP, unforeseen events like faulty material supply, machine breakdowns or the arrival of urgent new orders can happen As a consequence, it may become impossible to meet all promised delivery dates. Hence a very important task of demand fulfillment in ATO-production is to monitor the promised delivery dates during the order fulfillment time. We refer to this task as short term Demand Supply Matching (DSM). DSM decides on the assembly dates of orders and eventually on repromising, i.e. changing the delivery dates of some promised orders. In the worst case, repromising leads to a cancellation of promised orders.

The next section explains a rolling horizon planning concept for online OP and DSM. Section 3 develops a MIP model for the DSM. Section 4 shows some computational results of the rolling horizon procedure for a real life case study from an international computer manufacturer.

2 Rolling Horizon Planning for Demand Fulfillment

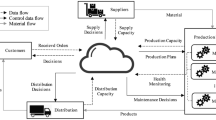

Figure 1 shows the planning scheme for OP and DSM in a rolling horizon. OP takes place for every single order at the arrival and entails an update of the ATP quantities of the concerned components. By contrast, DSM runs once a day, overnight, for the whole set of promised, but yet unfulfilled orders. It respects the interdependency of these orders, which compete for common components and for capacity. Thus, repromising may improve the delivery dates for some important orders at the expense of other orders. The new delivery dates are determined by reserving ATP quantities and capacity for every order on appropriate days of the planning horizon. As a result, the remaining free ATP quantities are a starting point for the OP at the next day. More details about the use of ATP quantities are explained in [1].

3 Mixed-Integer Program for Demand Supply Matching

Table 1 specifies the notation for the DSM model. The main data are, day by day, the assembly capacity and the supply of every component, which consists for day \(1\) of the initial stock and for the days \(t=2, \ldots , T\) of known or planned inflow from suppliers or from production. The main decisions are, for every order, the delivery date, the quantities and days of assembling, and the reservation of supply of the required components. In order to avoid splitting the delivery over several dates which is not allowed, the delivery date is expressed by binary variables \(z_{it}.\) Assembling may be split and must take place on days \(s\) prior to delivery. Every assembly quantity \(y_{is}\) requires sufficient reservations \(x_{ijr}\) of all relevant components \(j\) on previous days \(r.\)

subject to

Part (1) of the objective function corresponds to the minimization of the cost of deviations from the desired delivery dates and the cost for non-fulfillment whereas part (2) minimizes the inventory costs for order specific stock of components and of finished products. Constraints (3) ensure that the reservation of components does not exceed the supply, and (4) is the capacity restriction. Constraints (5) enforce a unique delivery date, which may also be in the dummy period. Constraints (6) and (7) express, for every order, the dependencies between reservations of components, assembly quantities and delivery date, as explained before. The model formulation and the parametrization can only be sketched here, details can be found in [2].

4 Computational Results

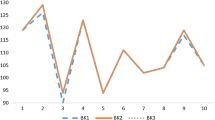

The presented concept has been tested with several real-life data sets, provided by a European computer manufacturer, with more than 10,000 promised orders and 2,000 components. The results can be influenced by determining the penalty cost rates for unpunctual delivery and for non-fulfillment. As an example, Fig. 2 shows a contrary behavior for the two objectives minimal deviation from the desired delivery date and minimal number of non-fulfilled orders. With higher relative costs for a non-fulfillment of orders, not only the proportion of fulfilled orders increases, but also the proportion of on-time delivery decreases. Thus, the trade-off between on-time delivery and fulfillment of orders has to be considered carefully. Stability of the promised delivery dates is a further objective of great practical importance. In the test runs for the rolling-horizon scheme, additional penalty costs were introduced for repromising. We simulated DSM runs on two consecutive days, starting with the determination of the delivery dates for 10,493 orders on day \(t-1.\) The resulting ATP quantities were used for the online OP for 1,203 arriving orders on day \(t.\) According to the DSM planning, 1,710 orders were fulfilled on day \(t.\) Then, a DSM run for day \(t\) was performed. Table 2 shows results for different values of the repromising cost. For penalty costs of 1.28 times the order priority \(r_i,\) deviations of delivery dates, representing a deterioriation of delivery service, can be avoided, while some improvements of delivery dates (mainly of newly arrived orders on day \(t\)) are even possible.

5 Conclusions

The study shows that in the demand fulfillment for ATO production, DSM plays an important role. Combined with the online OP for single orders in a rolling horizon scheme, it generates valid and stable delivery plans. It improves the results of the OP by taking the interdependency of all orders into account. Future research effort is required for developing advanced concepts for order promising in ATO production, in particular the incorporation of customer classes.

References

Fleischmann, B., & Geier, S. (2011). Global available-to-promise (global ATP). In H. Stadtler, et al. (Eds.), Advanced planning in supply chains (pp. 195–215). Heidelberg: Springer.

Geier, S. (2013). Demand fulfillment bei assemble-to-order-Fertigung—Analyse, Optimierung und Anwendung in der Computer-Industrie. Dissertation, Universitaet Augsburg.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this paper

Cite this paper

Geier, S., Fleischmann, B. (2014). Demand Fulfillment in an Assemble-to-Order Production System. In: Huisman, D., Louwerse, I., Wagelmans, A. (eds) Operations Research Proceedings 2013. Operations Research Proceedings. Springer, Cham. https://doi.org/10.1007/978-3-319-07001-8_19

Download citation

DOI: https://doi.org/10.1007/978-3-319-07001-8_19

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-07000-1

Online ISBN: 978-3-319-07001-8

eBook Packages: Business and EconomicsBusiness and Management (R0)