Abstract

The effort of material scientists in the discovery, understanding, and development of Li-ion batteries largely depends on the techniques available to observe the relevant processes on the appropriate time and length scales. This chapter aims at demonstrating the role and use of different neutron-scattering techniques in the progress of Li-ion battery electrode and electrolyte properties and function. The large range in time and length scales offered by neutron-scattering techniques is highlighted. This illustrates the type of information that can be obtained, including key parameters such as crystal structure, Li-ion positions, impact of nano-particle size and defects, ionic mobility, as well as the Li-ion distribution in electrodes and at electrode-electrolyte interfaces. Special attention is directed to the development of in situ neutron-scattering techniques providing insight on the function of battery materials under realistic conditions, a promising direction for future battery research.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Neutron Diffraction

- Lower Unoccupied Molecular Orbital

- Solid Electrolyte Interface

- Inelastic Neutron Scatter

- Neutron Powder Diffraction

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Li-Ion Batteries for Energy Storage

Electrochemical energy storage is attractive, having very high storage efficiencies typically exceeding 90 %, as well as relatively-high energy densities. Li-ion battery technology provides the highest energy densities of commercialized battery-technologies and has found widespread use in portable electronic applications. Application of Li-ion batteries in electrical vehicles and as static storage media is emerging, however, improved performance and reduced cost, combined with safety enhancements, are required. This has initiated a worldwide research effort for Li-ion electrode and electrolyte materials that combine desirable properties such as high energy and power density, low cost, high abundance of component elements, and electrochemical stability [1–4]. In the current generation of Li-ion batteries, insertion materials that reversibly host Li in the crystal structure form the most important class of electrodes. Although the future of Li-ion batteries looks bright, it should be noted that the availability of a number of relevant transition metals and possibly Li itself is a topic of interest [2].

In a Li-ion battery two insertion-capable electrodesFootnote 1 with a difference in Li chemical potential (change in free energy upon Li addition) are in contact through an electrolyte (an ionic conductor and electronic insulator) and a separating membrane, see Fig. 7.1. The Li will flow from the insertion material in which Li has a high chemical-potential towards the electrode in which Li has a low chemical-potential. Only Li-ions can flow through the electrolyte and the charge compensation requires electrons to follow via the external circuit which can be used to power an application. By applying a higher electrical potential than the spontaneous equilibrium open circuit polarization the process can be reversed. High energy-density requires a large specific-capacity of ions in both electrodes and a large difference in chemical potential. High power (and fast insertion/extraction) requires both electrons and Li-ions to be highly mobile throughout the electrode materials and electrolyte.

Schematic illustration of the operating principle of a Li-ion battery. Reprinted with permission from (M. Wagemaker, F.M. Mulder, Acc. Chem. Res. 46, 1206 (2013)) [37]. Copyright (2013) American Chemical Society

1.1 Demands and Challenges

The success of Li-ion batteries is based on their high volumetric and gravimetric energy-density available for storage. This has enabled the realization of small portable devices like mobile telephones and laptops. However, important demands also include material and production costs, safety, cycle life (number of charge/discharge cycles), and high (dis)charge rates. Addressing all these demands makes it very challenging to find better electrode and electrolyte materials to improve Li-ion batteries [2, 4]. To gain more insight into the challenges in battery research it is useful to express the performance-related demands in more specific material properties of the electrodes and electrolytes. With respect to the general demands of cost and safety we merely state that batteries require abundant and cheap materials that are intrinsically stable during battery operation. For more extensive literature we refer the reader to some excellent reviews [2, 4–6].

The gravimetric and volumetric energy density of a battery is CV OCP , where C is the specific or volumetric capacity (mAhg−1 or mAgcm−3), respectively, and V OCP is the open circuit, or equilibrium potential of the battery. Large gravimetric energy-density is required for automotive applications, and large volumetric energy densities are essential in mobile electronic equipment. It is important to realize that the specific Li capacity of the electrode materials is not necessarily the only decisive factor, and that the actual capacity of an electrode also depends significantly on the electrode morphology [7–9]. Large gravimetric energy-density requires dense electrodes and hence low porosities. In this context nano-sizing of electrode materials, aimed at higher storage capacities and higher rates, typically carries the disadvantage of low tap densities (powder packing) leading to less dense electrodes and compromising both volumetric and gravimetric energy-density.

The power density is the product of the specific current and the voltage that the battery can deliver. The battery voltage is defined by the difference in potential between the electrodes and the current via the internal resistance of the battery. High power densities, allowing for fast (dis)charge, require low internal resistance of the battery. The various charge-transport phenomena inside a battery contribute to this internal resistance, including the electronic conductivity through the electrodes, the ionic conductivity through the electrode and electrolyte, and finally the charge transfer through the interface between the electrode and electrolyte. Generally, the Li ion and electronic conductivity through the electrodes are assumed to be rate limiting in Li-ion batteries. Note that because the electrode is porous the ionic conductivity of the electrodes includes both the transport of ions through the solid-state electrode as well as through the electrolyte dispersed in the electrode pores. The solid-state transport of ions through electrodes depends on the specific electrode host material and is typically orders of magnitude slower than in liquid electrolytes. The overall Li-ion conductivity within the electrodes also depends strongly on the electrode morphology, such as characterized by the porosity [10] and the interconnectivity of the pores [11, 12].

High energy and power density are conflicting demands, as evidenced by the impact of electrode morphology and electrode thickness on these. High porosities, such as in nanostructured electrodes, generally lead to fast ionic transport throughout the electrodes responsible for high (dis)charge rates, and hence high power densities. However, the downside of large porosities is the larger volume required to store the same amount of energy, resulting in smaller volumetric energy-density. Because in most cases either electronic or ionic conductivity through the electrodes is rate limiting [7–9], thin electrodes can be charged faster than thick electrodes. Hence, the power density of a battery can be improved by the use of thinner electrodes. However, building a battery from thin electrodes leads to a smaller amount of active electrode material per gram of battery because of the relatively larger amount of current collector, electrolyte, and packing materials.

The cycle life of batteries is determined by a combination of the chemical and physical processes that occur during (dis)charging in the electrolyte and electrodes of a battery. Generally, electrodes undergo structural changes upon Li insertion and extraction. Large volumetric changes upon Li insertion and extraction lead to mechanical failure of the electrode. The result is generally that part of the active material is electronically disconnected from the electrode and therefore inactive. Consequently, small structural changes, such as occurring in Li4Ti5O12 spinel (where the change in the unit-cell volume, ΔV unit-cell , ≈ 0.1 %) [13], and moderate structural changes, such as occurring in LiFePO4 (ΔV unit-cell ≈ 6.5 %) [14], contribute to batteries with long cycle-life. The other extreme is the alloying reaction of Li with silicon up to the Li4.4Si composition resulting in a volume expansion >300 %, which leads to mechanical failure of the electrodes containing relatively large silicon particles within only a few charge/discharge cycles [15]. Nevertheless, the very high capacity associated with this type of alloying reaction has motivated chemists and material scientists to develop smart strategies to maintain the mechanical coherence of these electrodes [15–17].

The second factor that is important for the cycle life, and also to safety, is the thermodynamic stability of the electrolyte with respect to the positive and the negative electrodes (Fig. 7.2). The electrodes have electrochemical potentials μ A (anode) and μ C (cathode) equal to their Fermi energies ε F . If μ A is above the lowest unoccupied molecular orbital (LUMO) of the electrolyte, the anode will reduce the electrolyte. This reduction decomposes the electrolyte unless a passivating layer, generally referred to as the solid electrolyte interface (SEI) layer, is formed. The SEI layer often forms in the first few cycles and can act to electronically insulate the anode from the electrolyte, preventing further reduction. The SEI growth tends to stop after a few cycles, resulting in stable battery performance. Similarly, if μ C is below the highest occupied molecular orbital (HOMO) of the electrolyte, the cathode will oxidize the electrolyte unless a passivating SEI layer is formed, electronically insulating and preventing further oxidation. Therefore, not only should the electrolyte provide a wide stability window in terms of voltage, but the gap between its LUMO and HOMO must be larger than the difference between the chemical potentials of the electrodes. That is, the electrolyte voltage window should be positioned such that LUMO > μ A and HOMO < μ C . The large open-cell voltage (V Cell ) of Li-ion batteries (e.g. 3.6 V) that is responsible for their high energy and power densities requires electrolyte stabilities that exceed that of water (ELUMO−EHOMO ≈ 1.3 V) or water-containing electrolytes, leading to the application of non-aqueous electrolytes. Such stability demands do not apply if an electronically-insulating layer is formed upon electrolyte reduction or oxidation which can passivate further reactions. An example of passivation of SEI layers is the graphite or carbon-based anodes that work at about 0.5 V below the stability of typical carbonate electrolyte solutions, and hence 0.5 V above the LUMO of the electrolyte. The first few cycles with these anodes and carbonate-based electrolyte solutions results in the reduction of the electrolyte which leads to the formation of a stable SEI layer that prevents further reduction of the electrolyte. Importantly, the SEI layer does not grow significantly in subsequent cycles. Therefore, strategic combinations of electrodes, electrolytes, and SEI layers can result in better-performing batteries.

Schematic energy diagram of an electrolyte as well as the cathode and anode work functions, ΦC and ΦA, respectively (equal to the electrode electrochemical potentials, the difference of which is the open-cell voltage of the battery, V Cell ). The difference between the LUMO and the HOMO is the stability window of the electrolyte. If the electrode electrochemical potentials fall outside this stability window the electrolyte will decompose, which SEI layer formation can passivate, leading to the kinetic stability of the electrolyte and making the light areas (lower left and upper right) accessible

Improving Li-ion batteries with respect to energy and power density, manufacturing costs, safety, and cycle life is clearly a formidable challenge. A common starting point is to lower costs and use environmentally-benign materials for both the electrodes and the electrolyte, noting that the cathode can account for as much as 40 % of the cost of the battery. The electrolyte should have high Li-ion conductivity over a practical ambient-temperature range and a large stability (potential) window allowing use of large differences in electrode potentials. The electrodes should work within the stability window of the electrolyte and allow fast (dis)charge of a large reversible capacity. This not only depends on the electrode material and composition but also on the electronic and ionic ‘wiring’ of the electrodes determined by the electrode morphology. The development of new electrode and electrolyte materials and the improvement of existing materials requires a fundamental understanding of the Li insertion and transport mechanisms that involve both structural and kinetic phenomena. Probing these is a tremendous challenge given the complexity of the system and the difficulty of probing a light element such as Li, particularly under in situ conditions.

1.2 Development Using Neutron Scattering

The work of material scientists in the discovery, understanding, and development of Li-ion batteries largely depends on the techniques available to observe the relevant processes on the appropriate time and length scales. This chapter aims at demonstrating the role and use of different neutron-scattering techniques in gaining insight into Li-ion battery electrode and electrolyte function. This is not an exhaustive review of the neutron-scattering work on Li-ion battery materials or on the materials themselves, but an attempt to demonstrate the range of possibilities of neutron scattering in Li-ion battery materials research.

The role of neutron scattering in battery research is mainly based on the sensitivity of neutrons to Li compared to X-rays and electrons. The coherent neutron-scattering cross section of Li often allows the determination of the Li positions, atomic displacement parameters (ADPs), and occupancies using diffraction where X-rays do not, making it possible to elucidate Li-ion insertion/extraction mechanisms. The relatively-large coherent neutron-scattering cross section of Li provides sufficient contrast that Li distributions can be studied using imaging and, in thin-films, reflectometry. The incoherent neutron-scattering cross section of Li allows examination of Li mobility. Measuring Li diffusion directly is difficult as Li has only a moderate incoherent neutron-scattering cross section, so each material has to be considered individually to determine if the neutron-scattering signal originates from Li. Often measuring host material dynamics, e.g. anion and hydrogen group dynamics or lattice vibrations using quasi-elastic neutron scattering (QENS) and inelastic neutron scattering (INS), can provide information on Li dynamics. The diffusion pathway can be additionally corroborated or even independently obtained using the abovementioned large coherent cross-section of Li by considering the anisotropic contribution in the displacement parameter because of the deviation from harmonicity due to thermal motion at elevated temperatures. The relatively large neutron absorption cross-section of Li enables neutron depth profiling to determine Li distributions in materials. In these neutron-based techniques used to study Li-ion battery materials, the effective cross-sections of samples under study can be tuned through the isotopic composition. Naturally occurring Li is composed of 7.5 % 6Li and 92.5 % 7Li. The larger coherent neutron-scattering cross section and lower incoherent neutron-scattering and absorption cross-section of 7Li make it possible to improve data quality by tuning compositionally (isotopically) samples according to the neutron investigation technique being used.

2 Electrodes

Since the commercialization of the Li-ion battery by SONY Corporation in 1991, research has focused on identifying better electrode and electrolyte materials. SONY combined LiCoO2 as a positive electrode material with a carbonaceous material as a negative electrode, and LiPF6 in a carbonate solution as the electrolyte. Initially, research focused on replacing the relatively expensive LiCoO2 with other transition-metal oxides where the most important structural groups include spinel and layered transition-metal oxides. Layered Li transition-metal oxides, LiMO2 with M = Mn, Co, and Ni, represent one of the most successful classes of positive-electrode materials. The layered topology offers easily-accessible two-dimensional ion diffusion pathways. In particular, the LiCo1/3Ni1/3Mn1/3O2 composition [18] results in high capacity, safety, and lower material costs than LiCoO2.

An important alternative to LiCoO2 is the spinel LiMn2O4 with the inexpensive and environmentally-benign Mn, which functions with the Mn3+/4+ redox couple. LiMn2O4 operates at 4.1 V versus Li/Li+ offering excellent safety and high power due to its three-dimensional lattice, in principle allowing three-dimensional Li-ion diffusion. Substitution of Mn by M = Co, Cr, Cu, Fe, and Ni, has led to the discovery of the high-voltage spinels LiM 0.5Mn1.5O4 and LiMMnO4 with potentials between 4.5 and 5 V versus Li/Li+ [19], exemplified by spinel LiNi0.5Mn1.5O4 operating at 4.7 V versus Li/Li+ [20, 21]. However, Mn-based spinels have been plagued by capacity fade, generally considered to be the result of Mn dissolution into the electrolyte and Jahn-Teller distortion of Mn3+. Mn dissolution has been largely inhibited by substitution of dopants in the spinel structure [22].

The introduction of LiFePO4 [14] has initiated research on polyanion-based positive electrodes with the structural formula LiM(XO)4 (M = Fe, Mn, Co, and X = S, P, Si). The strong covalent X-O bonds result in the large polarization of oxygen ions towards the X cation, leading to larger potentials compared to oxides. Phosphates, in particular LiFePO4, have been extensively explored because of their favourable electrode properties, reasonably high potential and capacity, stability against overcharge or discharge, and their composition of abundant, cheap, and non-toxic elements. To date, almost a thousand papers have been devoted to the understanding and improvement of conductivity in the semiconductor LiFePO4. These have encompassed studies of surface-conductive phases [23, 24], modification of crystallite size [25], and elegant fundamental mechanistic and modelling studies [26–28]. Compared to the phosphates, the silicates (LiMSiO4) exhibit lower electrode-potentials and electronic conductivity [29]. Other promising groups of positive-electrode materials include fluorophosphates with the A 2 MPO4F (A = Alkali metal) stoichiometry [29].

For many years graphite has been the main negative-electrode material allowing Li-ion intercalation between graphene sheets at ~0.3 V versus Li/Li+. The low potential results in a high battery-voltage, partly responsible for the high energy and power density of Li-ion batteries. The main disadvantage of the low voltage of a negative electrode is the restricted stability of the commercial carbonate-based electrolyte solutions at low potentials versus Li/Li+. Depending on the electrolyte-electrode combination a kinetically stable SEI layer can be formed. For graphite this was achieved by the addition of ethylene carbonate [30] which lead to the success of the LiCoO2–C battery. Efforts to develop low-voltage negative electrodes with capacities that exceed that of C have concentrated on reaction types other than insertion reactions. Metals such as Si and Sn form alloys with Li in so-called conversion (or alloying) reactions [31–34]. Although the (gravimetric) capacities of these reactions can reach almost 10 times that of graphite, the volumetric energy-density is not significantly improved. Moreover, the large volume changes inherently related to this type of reaction make it a challenge to reach good cycleability. The oxide insertion hosts offer much better stability, highlighted by the Li4Ti5O12 spinel [35] that has almost no volume change upon Li insertion. Other titanium oxides that attract considerable attention as negative electrodes are anatase, brookite, and rutile TiO2, particularly in the nanostructured form [36, 37] and in combination with carbonaceous materials providing good with electronic-conductivity [16, 36]. The disadvantage of titanium oxides is their relatively high negative-electrode potentials, reducing the overall working voltage of the battery and thereby reducing both energy and power density. For example, titanium oxides operate at ~1.6 V versus Li/Li+, over four times higher in voltage than graphite. In this context, an interesting oxide exceeding the graphite capacity at similarly low potentials is the layered transition-metal oxide Li1+xV1−xO2 [38].

One of the key strategies that improved electrode performance in general is the nano-sizing of the electrode crystal particles. The nano-sized electrode particles reduce both solid state (Li-ion) diffusion and electron conduction. The latter is achieved by mixing and coating with conducting phases (i.e. with carbonaceous materials). However, numerous recent observations indicate that nano-sizing electrode particles also has a large impact on electrode materials properties [39, 40] creating both opportunities and challenges for enhanced Li-ion storage. Changes in properties that are observed upon nano-sizing include smearing of the voltage profile [41–43], changing solubility limits and phase behaviour [41, 44–46], unexpected kinetics [47], and larger capacities [45, 48–51]. The downside of the large surface-area of nanostructured materials is the relative instability of nano-materials, which can promote electrode dissolution and the increased reactivity towards electrolytes at commonly used voltages, e.g. below 1 V versus Li/Li+, which may adversely affect performance. Another potential disadvantage is the lower packing density of electrodes, leading to lower volumetric energy-densities. Among the materials that benefit from the possibilities of nano-sizing are the relatively stable transition-metal oxides and phosphates operating well within the stability window of the electrolyte.

2.1 Crystal Structure

In Li-ion battery electrode research, neutron powder diffraction (NPD) is one of the first techniques used for structural characterization of synthesized materials, often in combination with X-ray diffraction. NPD also plays an essential role in understanding the insertion mechanisms that may induce phase transitions and/or solid-solution behaviour, both of which may depend strongly on temperature, particle size, doping, and the chemical or electrochemical conditions.

The coherent neutron-scattering cross-sections of Li is relatively greater than that obtained for many transition-elements and greater than the analogous coherent scattering cross-sections of Li for X-ray or electron scattering, making it possible to determine Li-ion positions and occupancies. Thanks to these and other advantages of NPD, the technique has played a key role in the development of the large diversity of Li-ion battery electrode materials that exist to date.

Knowledge of the Li-induced phase transitions in C is primarily based on X-ray diffraction [52]. Although the crystal stages I and II in C are proven, long standing debate exists concerning LiC18 and no evidence of the higher-order lithiated stages exists based on X-ray diffraction studies. Neutron diffraction proved the existence of the LiC18 stage [53] and showed deviations from the common structural picture of lithiated C, including a charge-discharge dependent structural evolution and the appearance of higher-ordered stages [54].

Neutron diffraction has been used to determine the lithiated structures of titanium oxides including LixTiO2 anatase [55–57], rutile [58], brookite [59], and Li1+xTi2O4 and Li4+xTi5O12 spinel [55]. Li4Ti5O12 spinel is a state-of-the-art Li-ion battery electrode material [35, 60–63] operating at 1.56 V versus Li and is suitable as an anode using high-voltage cathode materials. Li4Ti5O12 can be lithiated up to the composition Li7Ti5O12 and possibly higher, with end members having a spinel structure adopting the cubic space group Fd-3m. This material is attractive as a Li-ion insertion electrode because the ‘zero strain’ property results in excellent cycle life: upon lithiation from the initial Li4Ti5O12 to the ‘fully-lithiated’ Li7Ti5O12 there is almost no change in lattice parameters (0.2 %) [35, 60–65]. In the defect spinel Li4Ti5O12 all the energetically-favourable tetrahedral 8a sites are occupied by Li. Additionally, 1/6 of the 16d sites are also randomly occupied by Li while the remaining 5/6 of the 16d sites are occupied by Ti atoms, and this can be represented as [Li3]8a[Li1Ti5]16d[O12]32e. Lithiation leads to occupation of all the octahedral 16c sites and emptying of the tetrahedral 8a sites to reach the lithiated Li7Ti5O12 composition, which can be represented as [Li6]16c[Li1Ti5]16d[O12]32e.

In lithiated anatase, neutron diffraction data obtained to relatively high momentum transfers were used to resolve the split Li-ion positions within the material’s distorted oxygen octahedra [56]. In composite anatase TiO2/Li4Ti5O12, neutron diffraction showed that the TiO2 phase was lithiated before Li4Ti5O12, as expected from the lower potential of Li4Ti5O12 versus Li/Li+, enabling tuned Li insertion/extraction based on the choice of voltage range [66]. The increase in curvature of the voltage profile and larger capacities for nano-sized materials appears to be a general observation for the various TiO2 polymorphs such as the tetragonal anatase [42, 45, 48, 58, 67] and rutile [48], orthorhombic brookite [68] and monoclinic TiO2(B) [50, 69]. The sensitivity of neutron diffraction for Li-ions has been decisive in revealing the altered thermodynamics of nano-sized titanium oxides. In anatase the Li solubility increases systematically when particle sizes are reduced leading to a phase-size diagram [45]. In addition, a second phase transition from the known Li-titanate phase towards tetragonal LiTiO2 was discovered, which was later confirmed by neutron diffraction in anatase nano-tubes [70]. Higher Li-ion solubility was also observed in nanostructured rutile using neutron diffraction [71], suggesting similar size effects. A remarkable finding in spinel nano-sized Li4Ti5O12 is that of increased capacity with decreasing particle size, exceeding the maximum composition observed for the micron-sized Li7Ti5O12. Neutron diffraction proved the increase in capacity to be due to simultaneous Li occupation of both 8a and 16c sites, providing an atomic-scale explanation for the larger capacity of the nano-sized materials [43].

A very interesting negative electrode, exceeding the graphitic anode capacity, at similarly low potentials, is the layered transition-metal oxide Li1+xV1−xO2 [72]. Interestingly, LiVO2 does not allow Li insertion whereas Li1+xV1−xO2 with x > 0 leads to a very low intercalation voltage close to 0.1 V with a capacity almost twice that of graphite. Neutron diffraction has shown that in Li1.07V0.93O2 part of the octahedral V is replaced by Li, which allows additional Li-ions, responsible for the large capacity, to occupy the neighbouring tetrahedral sites that are energetically unfavourable in LiVO2, and is supported by modelling studies [38].

Gummow et al. used neutron diffraction to show that the structure of the low-temperature cubic phase of LiCoO2 is not ideally layered, and that 6 % of the Co reside in the octahedral (8a) sites of the Li layers [73, 74]. The hexagonal structure of the high-temperature phase of LiCoO2 was also determined from neutron diffraction, illustrating that Co and Li planes alternate in the ABCABC oxygen stacking. Aiming at higher capacity cathodes, Li1+xCoO2 has been prepared raising the question of where the additional Li resides [75]. Combined Rietveld refinement using both X-ray and neutron diffraction data excluded both Co in the Li site and the presence of tetrahedral Li and Co [76]. Based on this, it was deduced that excess Li replaces some Co and that the charge is compensated for by O vacancies [77]. In mixed-cation layered transition-metal oxides, such as the so called ‘high capacity’ LiMn1/3Co1/3Ni1/3O2, neutron diffraction continues to be an indispensable tool for determining the cation distributions which have been shown to depend on the synthesis conditions [78–80].

Neutron diffraction has played a pivotal role in understanding the complex insertion and phase transitions in spinel transition-metal oxides. Using NPD, Fong et al. [81] described the crystal structure of Li x Mn2O4 for x = 1 and 0.2 and Wills et al. [82] determined the crystal structure of LiMn2O4 at low temperatures as well as its magnetic properties. Neutron diffraction revealed the partial charge-ordering in spinel LiMn2O4 at 290 K that further hinders its use as a positive-electrode material in Li-ion batteries [83]. From neutron diffraction data, superstructure reflections were found (related to charge-ordering phenomena) at 230 K which in combination with electron diffraction patterns revealed a 3a × 3a × a super cell of the cubic room-temperature spinel representing the columnar ordering of electrons and holes [83]. Two of the five Mn sites correspond to well-defined Mn4+ and the other three sites are close to Mn3+ as derived from Mn–O bond length analysis. This charge ordering is accompanied by simultaneous orbital ordering due to the Jahn-Teller effect in the Mn3+ ions. Li-excess compounds Li1+xMn2−xO4 were found to provide better cycling performance than the stoichiometric LiMn2O4 as they minimize the extent of the Jahn-Teller distortion during cycling (i.e. increase the overall oxidation state of Mn during cycling). In addition, Li doping at octahedral 16c sites reduces the exothermicity of the Li insertion/extraction reactions by an amount similar to that associated with the dilution of the Mn3+ ion [84]. Neutron diffraction by Berg et al. [85] showed that Li occupies 16c sites in Li1.14Mn1.86O4 which is also accompanied by charge-compensating vacancies at Mn 16d sites. Calculations also showed that the 16d sites should be favourable for Li at low Li contents while at higher contents, the 16c and mixed 16c and 16d site occupation is likely [86]. However, a recent study by Reddy et al. [87, 88] shows that at lower Li doping regimes, x = 0.03 and 0.06, the structural model containing Li at 16c sites still results in a better fit to the neutron diffraction data than models with 16d site Li occupation. In the work by Yonemura et al. [89] samples were synthesized in controlled atmospheres which led to the realization and quantification of O-deficient LiMn2O4 and Li-excess (O-deficient) Li1+x Mn2−x O4−y spinels. Using neutron diffraction data they determined the quantity of O, mixing of Li and Mn at the 8a and 16c sites, the interatomic bond distances, and the relationship between these crystallographic parameters.

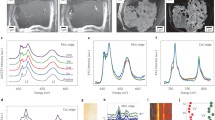

In the high-voltage spinels, neutron diffraction enabled the transition-metal ordering in LiNi0.5Mn1.5O4 that breaks the cubic Fd-3m to cubic P4332 symmetry to be determined and this was found to be dependent on the cooling rates used in the synthesis [90]. In X-ray diffraction data the small difference in atomic number between Mn and Ni makes it hard to quantify this ordering, whereas it is easily modelled using neutron diffraction [91, 92]. In the low-voltage plateau, using the large difference in the coherent neutron-scattering cross section of Mn and Ni, researchers determined that extensive migration of Ni and Mn was occurring in the spinel structure due to the loss of long range Ni-Mn ordering [92].

In the polyanion-based positive-electrode materials, neutron diffraction data contributes significantly in the characterization and understanding of the electrode properties. The higher potential of the Mn3+/Mn2+ redox couple has initiated the synthesis of LiMnPO4 and LiMnyFe1-yPO4 materials. Neutron diffraction data helped reveal that the reduced activity of the Mn3+/Mn2+ couple is related to the distortion of the MO6 octahedra with M = Mn3+, and this distortion was found to be much larger than the change in the unit cell [93], effectively prohibiting the Mn3+ to Mn2+ transition. Neutron diffraction was also used to characterize the cation distribution in related olivine structures with other transition metals and transition-metal mixtures such as LiCoyFe1−yPO4 [94], LixCoPO4 [95], and V-substituted LiFePO4 [96, 97].

For tavorite, LiFePO4(OH), neutron diffraction showed both the Li and H to be located in two different tunnels running along the a and c-axes, the tunnels being formed by the framework of interconnected PO4 tetrahedra [98]. Another promising class of tavorite-structured cathode materials are the fluorophosphates which exhibit good storage capacity and electrochemical and thermal stability. LiFePO4F exhibits a complex single-phase regime followed by a two-phase plateau at 2.75 V. Neutron diffraction in combination with X-ray diffraction was used to resolve the single phase end-member Li2FePO4F structure showing that Li-ions occupy multiple sites in the tavorite lattice [99]. Additionally, in the pyrophosphate-based positive electrode Li2−x MP2O7 (M = Fe, Co), multiple Li sites were identified using neutron diffraction [100].

In general, the combination of X-ray and neutron diffraction has become the established approach to characterizing electrode materials in great detail. The following example concerning the extensively-studied olivine LiFePO4 demonstrates the value of neutron diffraction in revealing the impact of dopants, defects, and particle size on LiFePO4 structure and performance, thereby providing crucial understanding for the design of future electrode materials.

In the last decade LiFePO4 has emerged as one of the most important positive electrodes for high-power applications owing to its non-toxicity and outstanding thermal and electrochemical stability [14]. The first-order phase transition, preserving its orthorhombic Pnma symmetry, results in highly-reversible cycling at the 3.4–3.5 V versus Li/Li+ voltage plateau with a theoretical capacity of 170 mAhg−1. The olivine structure is built of [PO4]3− tetrahedra with the divalent M ions occupying corner-shared octahedral ‘‘M2’’ sites, and the Li occupying the ‘‘M1’’ sites to form chains of edge-sharing octahedra. The magnetic structure of LiFePO4 has been solved using neutron diffraction, with the appearance of extra reflections below the Néel temperature indicating antiferromagnetic behaviour at low temperatures for both end-members FePO4 (Fe3+) and LiFePO4 (Fe2+) [101].

In contrast to the well-documented two-phase nature of this system at room temperature, Delacourt et al. [102, 103] gave the first experimental evidence of a solid solution Li x FePO4 (0 ≤ x ≤ 1) at 450 °C, and in addition, the existence of two new metastable phases with compositions Li0.75FePO4 and Li0.5FePO4. These metastable phases pass through another metastable phase on cooling to room temperature where approximately 2 out of 3 Li-positions are occupied, again determined using neutron diffraction to be Li~0.67FePO4 [103]. In Li~0.67FePO4, the average Li–O bonds are longer than in LiFePO4 due to the shortening of Fe–O bond lengths as shown in Fig. 7.3. It was suggested that this bond-length variation is the origin of the metastability of the intermediate phase, and thus of the two-phase mechanism between LiFePO4 and FePO4. Interestingly, this metastable phase appears to play a vital role in the high charge/discharge rate of the olivine material [104].

View of the FeO6 and LiO6 octahedra for a LiFePO4, b Li~0.67FePO4, and c FePO4, displaying the contraction of average Fe–O bond lengths from LiFePO4 to FePO4, together with the slight expansion of the M1 size (related to the average Li–O bond lengths in Li-containing phases). The models are based on combined structural refinements using neutron and X-ray diffraction data. Reprinted with permission from (C. Delacourt, J. Rodriguez-Carvajal, B. Schmitt, J.M. Tarascon, C. Masquelier, Solid State Sci. 7, 1506 (2005)) [103]. Copyright (2005) Elsevier

The room-temperature miscibility gap in LixFePO4 was determined by Yamada et al. [105] using NPD. These researchers found intermediate Li-poor Liα=0.05FePO4 and Li-rich Li1−β=0.89 phases, as shown in Fig. 7.4. This explains the compositional range over which the voltage is constant (plateau) and proves the presence of mixed-valence states of iron (Fe2+/Fe3+). These mixed-valence states provide ionic and electronic conductivity, an essential ingredient for the material’s application as a Li-ion battery electrode.

Left Refinement using neutron diffraction data of Li0.5FePO4 resulting in solubility limits α = 0.05 and 1−β = 0.89 in the Li-poor triphylite and Li-rich heterosite phases, respectively. Right Open circuit voltage versus composition, where the vertical lines indicate the monophase/biphase boundary as determined from the Li site occupancies resulting from Rietveld refinement using neutron diffraction data. Reprinted by permission from Macmillan Publishers Ltd: (A. Yamada, H. Koizumi, S.I. Nishimura, N. Sonoyama, R. Kanno, M. Yonemura, T. Nakamura, Y. Kobayashi, Nat. Mater. 5, 357 (2006)) [105]. Copyright (2006)

An early report that led to intensive discussions suggested that the poor electronic conductivity of LiFePO4 could be raised by 8 orders of magnitude by supervalent-cation doping, which was proposed to stabilize the minority Fe3+ hole carriers in the lattice [106]. It was only after detailed refinement of models against combined neutron and X-ray diffraction data that researchers were able to determine the positions and role of the dopants. In this case NPD provides contrast between Li and the dopants at the Li site (M1), and X-ray powder diffraction provides contrast between the Fe and many of the dopants at the Fe site (M2). Moreover, to determine three species (Li or Fe, dopants and vacancies) on crystallographic sites (M1 or M2) requires more than X-ray or neutron diffraction alone. The neutron diffraction pattern for one of the doped materials is shown in Fig. 7.5. Although the changes in the diffraction pattern upon doping are extremely small, the accuracy afforded by the data make it possible to conclusively locate the supervalent-cation dopants in LiFePO4. Figure 7.6 shows that supervalent-cation doping of up to ~3 % atomic substitution can be achieved in the LiFePO4 lattice in bulk materials prepared by a solid-state route at 600 °C. The results show that the dopant resides primarily on the M1 (Li) site and that aliovalent-dopant charge is balanced by Li vacancies, with the total charge on the Fe site being +2.000 (± 0.006), within the limit of experimental error [107]. It is thus expected that dopants may have little influence on the electronic conductivity of the material, which is confirmed by calculations [108]. Furthermore, the location of the immobile high-valent dopant within the Li channels is expected to hinder Li-ion diffusion assuming one-dimensional diffusion.

a LiFePO4 adopting Pnma symmetry with the split Li-ion (medium grey) position in the centre. b NPD data for LiFePO4 and Li0.96Zr0.04FePO4 (target composition) including the difference between the fits and data. The fit residuals are wR p = 1.7 % and R p = 1.9 %, as well as wR p = 1.7 % and R p = 1.8 %, respectively. c The same data as in (b) shown for a limited d-spacing range. Reprinted with permission from (M. Wagemaker, B.L. Ellis, D. Luetzenkirchen-Hecht, F.M. Mulder, L.F. Nazar, Chem. Mater. 20, 6313 (2008)) [107]. Copyright (2008) American Chemical Society

Supervalent doping occupancies from refinements using combined X-ray and neutron diffraction data plotted versus the targeted dopant concentration. Reprinted with permission from (M. Wagemaker, B.L. Ellis, D. Luetzenkirchen-Hecht, F.M. Mulder, L.F. Nazar, Chem. Mater. 20, 6313 (2008)) [107], Copyright (2008) American Chemical Society

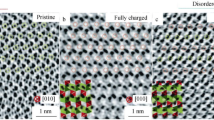

The one-dimensional migration channels through the LiFePO4 olivine structure means that the electrode performance can be severely influenced by defects. In the olivine structure the most favourable defect is predicted to be the Li–Fe anti-site pair, in which a Li-ion (at the M1 site) and a Fe ion (at the M2 site) are interchanged. These defects, with concentrations up to 8 %, were first observed in LiFePO4 synthesized at low temperatures, leading to non-thermodynamically favoured materials [109]. Small concentrations of anti-site defects, as high as 1 %, were suggested to remain even up to solid-state synthesis temperatures as high as 600 °C [110]. In addition, combined neutron and X-ray diffraction has indicated that after fast hydrothermal synthesis crystalline-defective LixFeyPO4 coexists with amorphous Li/Fe-PO4 structures. These techniques also showed that the Fe is included in the structure more rapidly from the amorphous precursor than Li, causing defects in the structure [111]. Anti-site defects are expected to play a decisive role in the Li-ion conductivity and Gibot et al. [112], using combined neutron and X-ray diffraction data, demonstrated that large concentrations (up to 20 %) of these anti-site defects in nanoparticles suppress the first-order phase transition normally observed in LiFePO4 leading to a single-phase room temperature reaction upon (de)lithiation. More detailed insight into the correlation between particle size and Li-ion substoichiometry was obtained by the direct synthesis of substoichiometric Li1−yFePO4 nano-particles [113]. Combined neutron and X-ray diffraction data of partially-delithiated substoichiometric olivines revealed segregated defect-free (where Li is extracted) and defect-ridden (where Li remains) regions, as shown in Fig. 7.7. This proved that both the anti-site defects obstruct Li+ diffusion, explaining the detrimental electrochemistry and that the anti-site defects form clusters.

Interpretation of the combined neutron and X-ray diffraction results for delithiation of Li0.90FePO4: Composition dependence and site disorder. a Evolution of the site-defect concentration in the Li-rich and Li-poor phases as a function of delithiation. b Overall schematic illustration of the phase segregation of the Li-rich and Li-poor regions of the crystallites with regions free of Fe anti-site defects delithiating before regions containing M1 site defects. Reproduced from (S.-P. Badi, M. Wagemaker, B.L. Ellis, D.P. Singh, W.J.H. Borghols, W.H. Kan, D.H. Ryan, F.M. Mulder, L.F. Nazar, J. Mater. Chem. 21, 10085 (2011)) [113] with permission from The Royal Society of Chemistry

Further details of the anti-site clustering in LiFePO4 were obtained using a combination of neutron diffraction with high-angle annular dark-field scanning transmission electron microscopy and ab initio calculations, indicating that they form zig-zag type clusters, completely different from the structurally equivalent LiMnPO4 where the anti-site defects appear to be randomly distributed [114].

Another topic that has been of great interest is the impact of the particle size on the intercalation properties. When insertion electrode materials are downsized to nanometer dimensions, voltage profiles change considerably reflecting a change in thermodynamics [37, 39]. First direct evidence of modified electrochemical-structural behaviour in nano-sized insertion electrodes was provided by neutron diffraction on TiO2 anatase, which showed large changes in Li solubility in phases and a strongly-altered phase composition and morphology [45]. Also, the solubility limits during the insertion reaction in LiFePO4 have been under active research, mainly using neutron diffraction as a direct probe [41, 44, 102, 115–120]. This research shows narrow solid-solution domains in micron size particles at room temperature [117] and a solid solution over the entire compositional range above 520 K [102, 121]. Yamada et al. [117] suggested that the extended solid-solution composition-ranges in small particles and a systematic decrease of the miscibility gap was due to strain based on Vegard’s law [41]. Kobayashi et al. [44] isolated solid-solution phases, also supporting a size-dependent miscibility gap. Direct evidence of enhanced solubility in the end phases with decreasing primary crystallite-size was provided by a systematic neutron diffraction study of particle sizes between 22 and 130 nm [46]. The Fourier-density difference maps in Fig. 7.8 illustrate that the Li densities in the Li-poor and Li-rich phases increase and decrease respectively, with decreasing particle size. These observations could be reproduced by calculations based on a diffuse interface model [46, 122]. The diffuse interface introduces an energy penalty for a Li concentration-gradient creating a smoothly-varying Li concentration over an interface region with a width of ~10 nm, as shown in Fig. 7.9. The confinement of this interface layer in nano-sized particles moves the observed solubility away from the bulk values. Interestingly, neutron diffraction also proved that the solubility in both phases (LiFePO4 and FePO4) depends on the overall composition, especially in crystallites smaller than 35 nm. Furthermore, this observation could be explained quantitatively by the diffuse-interface model. By varying the overall composition the domain sizes of the coexisting phases change, in this case leading to confinement effects in the minority phase.

The structural impact of nano-sizing illustrated by Fourier-density difference maps obtained from neutron diffraction. The maps are shown for both the Li-poor α-phase and the Li-rich β-phase in Li0.5FePO4 for the three different particle sizes indicated. The maps were obtained by the Fourier transform of the difference between the neutron diffraction data and the calculated diffraction pattern based on the structure with no Li present. Therefore, these density maps should show Li density. As expected for large particles, large Li density is observed in the Li-rich heterosite β-phase, and no density is observed in the Li-poor triphylite α-phase. Progressive particle-size reduction decreases observed Li density in the heterosite β and more evidently Li density increases in the triphylite α phase, indicating a reduction of the miscibility gap with decreasing particle size. Reprinted from (M. Wagemaker, D.P. Singh, W.J.H. Borghols, U. Lafont, L. Haverkate, V.K. Peterson, F.M. Mulder, J. Am. Chem. Soc. 133, 10222 (2011)) [46]

Measured and calculated solubility limits as a function of particle size and overall composition. Left a Symbols Li occupancy for both the Li-poor triphylite α-phase LixαFePO4 and the Li-rich heterosite β-phase LixβFePO4 where xα and xβ represent the average solubility limits as a function of particle size, having an overall composition Li0.5FePO4. Vα and Vβ represent the corresponding unit-cell volumes. The size of the symbols is approximately the size of the error. Lines Calculated average compositions based on the diffuse interface model. b Calculated concentration profiles based on the diffuse interface model in the a-lattice direction for three different particle sizes at the overall composition Li0.5FePO4. Right Measured and calculated solubility limits as a function of overall composition. a Symbols Li occupancy derived from neutron diffraction data for both the Li-poor triphylite α-phase and the Li-rich heterosite β-phase representing the average solubility limits as a function of overall composition for different particle sizes. Lines Calculated average compositions based on the diffuse interface model. The size of the symbols is approximately the size of the error. b Calculated concentration profiles based on the diffuse interface model in the a-lattice direction for three different overall compositions all having the particle size 35 nm. Reprinted from (M. Wagemaker, D.P. Singh, W.J.H. Borghols, U. Lafont, L. Haverkate, V.K. Peterson, F.M. Mulder, J. Am. Chem. Soc. 133, 10222 (2011)) [46]

The ex situ neutron diffraction studies discussed above have contributed to our current state of understanding of electrode materials. This is in particular based on the sensitivity of neutrons for Li, the charge-carrying element in Li-ion battery electrodes. This is vital knowledge not only for the synthesis of new materials, but also for mechanistic understanding of the impact of supervalent doping, defects, composition, and particle size on the intercalation process as illustrated for olivine LiFePO4.

2.2 Local Structure

To obtain the local structure in glassy, nano, disordered and amorphous materials, having unresolved, weak or broad signals, neutron total scattering, or/and inelastic neutron scattering (INS) or quasielastic neutron scattering (QENS) can be powerful tools. Total scattering allows extraction of the local structure in terms of interatomic distances, bond angles and coordination numbers. In this case scattering is detected over a wider Q-range and short-range interactions of a sample are probed and modelled. In addition, rotations and vibrations picked up by INS and QENS are very sensitive to local distortions and allow otherwise difficult to detect relevant species such as protons, OH, water and in rare cases Li to be studied.

The negative-anode carbon is a good example of where neutron total scattering, in conjunction with other neutron-based methods, has been able to quantify important, previously ill-defined, aspects of the material’s function [20, 123, 124], as demonstrated with a range of low-crystallinity C negative electrodes. Additionally, C-based anodes can be analysed in the lithiated and delithiated states and over the course of phase transitions. Typical neutron total-scattering data for graphite is presented as a radial distribution function (or pair distribution function) as illustrated in Fig. 7.10, and peak positions are indicative of interatomic distances. Often, neutron total scattering is combined with INS data to provide supporting information concerning the short-range order in C. For further information on total scattering the reader is directed to a review on the structure and dynamics of ionic liquids [125], and total scattering is likely to become increasingly used as the range of nano-sized active electrode materials increase.

Radial distribution functions (RDFs) of graphite and the in-plane honeycomb structure inset. Each concentric circle in the honeycomb structure produces a peak in the RDF. Reprinted with permission from (P. Zhou, P. Papanek, R. Lee, J.E. Fischer, W.A. Kamitakahara, J. Electrochem. Soc. 144, 1744 (1997)) [124]. Copyright (1997), The Electrochemical Society

Total scattering and INS are particularly attractive for disordered C where conventional diffraction provides limited information and more generally for Li arrangements in C. Disordered C where a large amount of H is present can exhibit significant Li capacity (one ‘excess’ Li per H) and studies have investigated how Li is taken into these materials [123, 124, 126]. Studies have shown that these materials exhibit randomly-arranged graphene fragments of different sizes with edges terminated by a single H, similar to Si with H at the surface. The spectra also contain a boson peak, an indicator of disorder, and distinct similarities to polycyclic aromatic hydrocarbon (PAH) spectra exist, some of which feature two or three edge-terminating H. Additionally, comparison with PAH spectra allowed the determination of methyl groupings when higher H concentrations are used. The boson peak is at the same position in samples with different concentrations of H and changes in position and intensity with Li insertion. This shows that the Li interacts with the C environment, contrary to the idea of Li accumulation in voids. These findings agree with two models of Li insertion: One where Li resides on both sides of the graphene layers (the so-called ‘house-of-cards’ model) and the other where Li is bonded to the H-terminated C at the edge of the graphene layers (and reside in interstitial sites). INS data also illustrate that the Li–Li interlayer and intralayer interactions are comparable in strength. Computer modelling showed that there is insignificant energy difference between interstitial Li and those that are bonded to the terminal H. Other models include the formation of covalent Li2 molecules, but no evidence was found in support of these. The key aspect in these studies is that all models satisfy the observed capacity of LiC6. Finally, QENS [124] was used to show that Li jumps between nearest or second-nearest neighbour interstitial sites.

Related work investigated the entropy of intercalation into C [127]. This study shows how the sign of entropy changes from low Li concentrations on initial charge (x < 0.2 in Li x C6) to higher concentrations (x > 0.2) indicating that multiple processes are occurring and that one of these is vibrational in origin. In graphite the entropy remains negative, but reduces in magnitude as lithiation progresses. Similar entropy information from INS data during lithiation of LiCoO2 cathodes has also been reported [128].

Cathode materials pertinent to Li-ion batteries based on olivine LiMPO4 have also been probed with INS, but for magnetic properties (low temperature) rather than Li-ion diffusion or lattice dynamic studies. Studies of LiFePO4 [129], LiNi1−x–FexPO4 [130], and LiMnPO4 [131], show spin-wave dispersions and allow characterisation of magnetic-exchange interactions. Further INS work was motivated by the need to understand the electronic conductivity in LiFePO4 and probed the thermodynamics and vibrational entropy of the phase transition in Li0.6FePO4 [121]. The oxidation state of Fe influences its neighbouring O atoms and the polyhedral distortions can characterize the motion of carrier hopping between Fe sites, which results in relaxations or displacements that can in turn be considered as the sum of longitudinal phonons. Similarly, occupation or vacancy of Li can result in distortions of atom positions and are expected to alter the frequency of phonons, in particular longitudinal optical phonons.

The phase evolution of Li0.6FePO4 as a function of temperature, via a two-phase transition to a disordered solid-solution transition at 200 °C [121], can shed light on the reaction mechanism during charge/discharge of this cathode. This is particularly pertinent as the two-phase or solid-solution mechanism of LiFePO4 is a topical issue as discussed above. The difference in two-phase and solid-solution LiFePO4 optical modes above 100 meV (higher energies) was found, with broadening evident for the solid-solution sample. The low-energy region features mostly acoustic lattice modes, translations and librations of PO4 and translations of Fe. By comparison with infrared (IR) and Raman data, it was found that the PO4 stretching vibrations are damped in the solid-solution sample. The difference in INS data of solid-solution and two-phase samples at higher energy mostly involve optical modes that can arise from motion of Li-ions, charge hopping between Fe-ions, and heterogeneities. The entropy was found to be larger in the solid-solution phase in conjunction with the subtle differences in the dynamics due to different optical modes. The similarity in two-phase and solid-solution phonon density of states (Fig. 7.11) agrees with the ease with which LiFePO4 seems to undergo either transition, and the difficulty in pinning down the experimental evidence related to the reaction-mechanism evolution.

The phonon density-of-states of Li0.6FePO4 at 180 °C (solid) and 200 °C (dashed). Reprinted with permission from (R. Stevens, J.L. Dodd, M.G. Kresch, R. Yazami, B. Fultz, B. Ellis, L.F. Nazar, J. Phys. Chem. B 110, 22732 (2006)) [121]. Copyright (2006), American Chemical Society

Arguably the most studied materials using INS are manganese oxides and lithiated manganese oxides, predominantly due to the ease of using H as a probe for Li. These compounds are used for both primary and Li-ion batteries and ion-exchange methods have been used to show where Li may reside in these compounds. Although indirect, this information can provide further answers to some of the problems in this field of research. Attempts are also being made to use INS to provide comparisons between H and Li where H is used as a calibrated probe for Li [132].

One approach is to replace structural or surface water present on manganese oxides with protons, which can in turn be exchanged for Li to see how Li might displace water in these compounds. This was undertaken for spinel Li1.33−x/3Co x Mn1.67−2x/3O4 [133] which shows, as is the case in many compounds of this family, that protons are inserted as hydroxyl groups giving a strong incoherent INS signal. The hydroxyl groups are located on the O atoms neighbouring the vacant 16d sites and aligned with the 8a sites in the spinel structure. Conversely, studies on undoped spinels have shown that the Li extraction from the 16d sites allows the insertion of protons. The main features of the INS spectra are strong γ(OH) modes, a highly ordered proton site, a shoulder and smaller features between 300–700 cm−1 showing riding of protons on the oxide lattice and some librational water modes. The hydroxyl groups have characteristic signals around 908 cm−1 and their orientations are also determined using INS [134–137] of spinel-derivative compounds. Interestingly, IR data shows features between 950 and 1300 cm−1 which were considered to arise from protons, but the absence of these features at corresponding frequencies in the INS data indicate a manganese oxide lattice origin. Notable discoveries of this and related studies include the finding that in undoped spinels 40 % of protons cannot be exchanged and form disordered water, the chemical re-insertion of Li in Li-rich spinel Li1.6Mn1.6O4 removes most of the hydroxyl groups [137], that generally the reversible Li amount is 50 % in both undoped and doped spinels, and that fewer protons are re-exchanged as the Co concentration increases. The latter is an interesting way to tune the Li-proton exchange capacity of these materials.

Figure 7.12 shows the INS data from a series of Li-rich Li1.6Mn1.6O4 spinels formed through various methods. The pure sample (bottom of Fig. 7.12) shows some evidence of protons, OH and water, whilst the acid-treated version, where acid results in H–Li exchange, shows strong characteristic peaks for protons and γ(OH) groups. Finally, the acid-treated sample undergoes a chemical Li re-insertion step and results in the loss of the proton and OH signatures. However, the re-inserted material does not replicate the pure sample suggesting some protons remain as structural water and hydroxyl groups [137]. Relative comparisons of the INS intensity can be made between the acid-treated and re-inserted samples, with the 909 cm−1 peak showing a larger drop in intensity compared to the 1,087 cm−1 peak, which is attributed to an H site being easier to depopulate. A comparison of INS data for two Li-rich variants, Li1.33Mn1.67O4 and Li1.6Mn1.6O4, shows that the proton stability is higher in Li1.6Mn1.6O4 than in Li1.33Mn1.67O4. This suggests the reason that Li1.6Mn1.6O4 has a larger Li-ion exchange capacity than Li1.33Mn1.67O4 concerns the stability of the inserted species (or more specifically the stabilized proton sites).

INS spectra of as-synthesized Li1.6Mn1.6O4 (p), acid-washed (d), and Li chemically re-inserted (r) samples. Reprinted with permission from (M.J. Ariza, D.J. Jones, J. Roziere, R. Chitrakar, K. Ooi, Chem. Mater. 18, 1885 (2006)) [137]. Copyright (2006) American Chemical Society

Studies of λ-MnO2 [135] illustrate subtle differences in INS spectra depending on synthesis precursors, noting that precursors and conditions are both important. This work again highlights the need to focus on the protons (often disordered). A related study investigated proton-exchanged spinels that form λ-MnO2 showing that the proton diffusion was dependent on octahedral Mn vacancies [136]. In this study, certain features in the INS spectrum were found to disappear in the highly crystalline sample, suggesting that motion can be perturbed with crystallinity. Researchers have also looked at the proton and water environments in bare and lithiated MnO2 [132] to demonstrate how lithiation influences the proton and water motions, which can then be used to extract information on lithiation processes. Using neutron total scattering from oxidized and lithiated versions of λ-MnO2 researchers derived models for oxidation and lithiation [138].

Further work on the spinel LiMn2O4 system investigated the cubic to orthorhombic phase transition near room temperature, which is associated with Mn3+/Mn4+ charge ordering [139]. Excess Li was introduced at the 16c site to study why the phase transition is suppressed in this situation. QENS was used here, where data were found to be dominated by magnetic contributions rather than that from Li hopping, with the slight narrowing of the elastic line near room temperature leading to the preliminary conclusion that electrons are localized on the Mn. A dynamic transition in Li-rich compounds seems to coincide with the structural transition in the parent. The magnetic properties of Li0.96Mn2O4 were explored in a related INS study [140] showing that two short-range magnetic transitions are present and related to spin ordering of Mn3+ and Mn4+.

3 Lithium Diffusion

A critical property of electrode materials is the ability to conduct Li through the host lattice. Li-ion mobility can be directly probed with INS and QENS, however only a few neutron studies report the direct measurement of Li dynamics mostly due to its moderate incoherent neutron-scattering cross section. Typically, each material has to be considered in order to determine whether the signal originates from Li, magnetism or other atoms. Usually, the hopping diffusion in Li-ion insertion electrodes is relatively slow compared to the timescale of INS and QENS in which case the local mobility is observed. As a consequence few studies exist that probe the Li motion directly. A different approach is to probe the Li diffusion in electrode materials with diffraction. Both the anisotropic contribution in the Debye-Waller factor and the deviation from harmonicity due to thermal motions at elevated temperatures can indicate the directionality of Li motion, which in turn may allow the identification of diffusion pathways. Both are illustrated here: anisotropy in the ADPs in combination with a maximum-entropy method (MEM) was used to identify the Li-ion trajectory in the positive-electrode material LiFePO4, and anharmonicity of the ADPs revealed the Li-ion trajectory in the negative electrode material Li4Ti5O12.

Li12C60 fulleride is a good example where Li diffusion was studied using QENS and INS, quantifying the diffusional motion of Li-ions across a phase transition proposing a localized jump-diffusion model in the octahedral voids of the Li12C60 structure. This accounts for the changes in the vibrational density of states near the phase transition and results in a model of the dynamical behaviour [141]. Another QENS study revealed the diffusion coefficient of Li in a highly-oriented pyrolytic graphite electrode at high temperatures, deriving an activation energy of 0.35 eV [142]. Interestingly, the diffusion coefficient obtained is similar to that obtained using electrochemical methods despite the diffusion lengths measured by the two techniques differing by a factor of 15,000. Li diffusion is more frequently determined indirectly using neutrons, and an example of this is the studies of anion dynamics to shed light on Li diffusion. Li-containing metal hydride systems have been investigated, such as in LiBH4 and LiAlH4, where translational modes of Li are linked with BH4 in the high-temperature form of LiBH4 [143]. Additionally, the disappearance of Li-containing lattice vibrations near phase transitions in these compounds is thought to be associated with the delocalisation of Li that enhances diffusivity. In this way, hydrogen-containing group dynamics can provide information on Li dynamics.

One QENS study describes alkali-ion diffusion (including for Li) in alkali-containing silicate melts [144], of interest for cathode materials based on silicates. This study used the decoupling of the incoherent (below 60 ps) and coherent neutron-scattering as a signature for Li-ion diffusion along channels in the immobile Si–O network. The relaxation times for Li were a factor of two smaller than for Na, indicating that Li-ion diffusivity is a factor of two larger, in agreement with conductivity data. QENS experiments have also been performed on single crystals of 7Li2MnCl4 (an inverse spinel-type structure), revealing a lack of anisotropy in the local Li motion [145]. Li-ions at 8a tetrahedral sites were shown to visit neighbouring 16c interstitial sites and jump back, but longer-range translational motion was outside the timescale used for the measurement.

Significant insight into Li diffusion can be gained from diffraction. Diffusion pathways can be identified by the anisotropy in ADPs in combination with MEMs. The exceptionally high discharge rate [47] observed in LiFePO4 indicates that ionic mobility in the LiFePO4 matrix is unusually fast. This has raised the question of how this is possible by the small polarons that are strongly localized at Fe sites in phase-separated LiFePO4 and FePO4 [146]. Morgan et al. [27] used the nudged elastic band method in calculations that show high Li ion mobility occurs in tunnels along the [010] direction, but reveal that hopping between tunnels is unlikely, confirmed by calculations of Islam et al. [108]. Fast one-dimensional conduction along the b-axis in the LiFePO4 Pnma structure was predicted by atomistic modelling [27, 108] and the first experimental proof of the diffusion trajectory came from Nishimura et al. [147] using NPD in combination with the MEM. To enhance the sensitivity towards Li 7LiFePO4 was prepared using 7Li-enriched Li2CO3 as the raw material. In this study the ADPs readily show the direction of the Li-trajectory towards adjacent Li-sites, with green ellipsoids in Fig. 7.13 representing the refined Li vibration (displacement parameters) and indicating preferred diffusion towards the face-shared vacant tetrahedra. This suggests a curved trajectory in the [010] direction, consistent with atomic modelling [27, 39].

Left Neutron diffraction patterns and Rietveld refinement profile of a room temperature and b 620 K Li0.6FePO4. The specific points of measured composition and temperature are given in the inset phase diagram reported by Delacourt et al. [102] and Dodd et al. [120] Right Anisotropic harmonic Li vibration in LiFePO4 shown as green ADPs and the expected diffusion path indicated by the dashed lines. The ellipsoids were refined by Rietveld/MEM analysis of room-temperature NPD data. Reprinted by permission from (S. Nishimura, G. Kobayashi, K. Ohoyama, R. Kanno, M. Yashima, A. Yamada, Nat. Mater. 7, 707 (2008)) [147]. Copyright (2008)

To relate further the vibrational motions with diffusion, the material with the overall composition Li0.6FePO4 was heated to approximately 620 K. In this composition Li0.6FePO4 forms a solid solution at a relatively low temperature, ~500 K, due to the unusual eutectoid as shown in the phase diagram in Fig. 7.13. This is confirmed as single phase by neutron diffraction. Thereby a large number of Li defects are introduced, that in combination with the higher thermal energy, enhances Li motion. Note that the Li trajectory in the solid solution should represent both end members because the crystal symmetry does not change upon heating and Li insertion. In the refinement of the Li0.6FePO4 structure no reliable solution using harmonically-vibrating Li could be found. To evaluate the dynamic disorder of the Li the MEM was used to estimate the nuclear-density distribution from neutron diffraction. By considering the entropy the most probable distributions of nuclear species can be evaluated, making it possible to evaluate not only the missing and overlapping reflections, but also the more complicated nuclear densities. This approach applied to neutron diffraction data of Li0.6FePO4 at 620 K leads to the three-dimensional nuclear distribution of Li (Fig. 7.13). The observed diffusion along the [010] direction is consistent with the shape of the anisotropic thermal motions shown in Fig. 7.13 and atomistic modelling [27, 39]. Note that the Fe, P, and O atoms remain at their normal positions. The data show that the Li-ions move from one octahedral 4a site to the next via the intermediate tetrahedral vacant site. Along this trajectory the sites do not face-share with other occupied polyhedra. This is in contrast to, for instance, diffusion along the [001] direction where the intermediate octahedral position shares two faces with PO4 tetrahedra which will lead to higher activation energies.

Laumann et al. [148] investigated Li migration in commercial spinel Li4Ti5O12 using variable-temperature neutron diffraction. At 900 °C a marked deviation is observed in the linear dependence of the cell volume, O position, and anisotropic displacement parameters. Refinement of the Li occupancies resulted in almost complete 8a site occupation below 900 °C. However, at 900 °C a Li deficiency of approximately 14 % was observed, which was interpreted as the result of anharmonic motions and migration of the Li-ions. Therefore, in the fitting procedure one isotropic anharmonic ADP was refined. Examination of the nuclear density revealed negative scattering-length density peaks next to the 16c site. In this way Li-ion occupancy at the 32e site was discovered and subsequent refinement of Li at the 32e sites results in the probability density shown in Fig. 7.14. This makes it possible to formulate the diffusion pathway. Rather than occupying the 16c as an intermediate site between two 8a sites, which introduces an unacceptably long Li–O bond, Li passes from the 8a site through the face of the surrounding O tetrahedron to the nearby 32e site. This is followed by switching to the adjacent 32e site where it is bonded to another O atom, and from where it can hop to the next tetrahedral 8a position. Effectively, this mechanism results in a number of short jumps along the [111] direction between adjacent 8a sites. The energy barriers can be approximated by assuming Boltzmann statistics for single-particle motion resulting in the one-particle potential shown in Fig. 7.14. These findings are consistent with nuclear magnetic resonance measurements indicating that the 16c site forms the saddle point of the barrier between two 8a sites [149]. In this way NPD is able to reveal the details of the three-dimensional long-range diffusion pathway in spinel Li4Ti5O12.

Left: Probability density function derived from the anharmonic ADPs at 900 °C in the (xxz) plane through 8a and 16c sites. The shortest bond distances between Li (white at 8a and grey at 32e) and O (black at 32e) are indicated. Long dashed lines indicate zero densities and short dashed lines negative densities. Right: One-particle potential of Li at 900 °C in the (xxz) plane through 8a, 32e, and 16c sites (the same section as that in the left figure). Contour lines are in steps of 100 meV. The dotted line shows the linear section along the [111] direction. Reprinted with permission from (A. Laumann, H. Boysen, M. Bremholm, K.T. Fehr, M. Hoelzel, M. Holzapfel, Chem. Mater. 23, 2753 (2011)) [148]. Copyright (2011) American Chemical Society

4 Electrolytes

Commercial electrolytes typically contain a Li salt dissolved in an organic solvent and are often composed of two components: one for the dissolution of the salt and another that assists in the formation of a protective layer on the anode to prevent continuous electrolyte-reduction and self-discharge, e.g. ethylene carbonate. These electrolyte systems, being non-aqueous and highly air-sensitive, tend to be flammable and can turn from liquid to gas at elevated temperatures (Fig. 7.15). The electrolyte also determines the cathode and anode materials that can be used by limiting the applicable voltage range which is associated with the HOMO of the cathode and LUMO of the anode [4]. The key factors that determine a good electrolyte are ionic conductivity, flammability and chemical stability, and applicable voltage windows.

To overcome the safety and long-term reliability issues of using organic electrolytes, research has been directed to aqueous electrolyte systems with Li salts. Unfortunately, voltage limitations have hampered significant development of aqueous electrolytes, but these safe electrolyte-systems have found niche use in medical applications. In addition to aqueous electrolytes, liquid electrolytes based on ionic liquids have attracted significant attention.

Apart from electrolytes in the liquid state, semi-solid or solid-state electrolytes such as gel and solid polymer electrolytes continue to be a preferred option in overcoming safety and leakage issues. Neutron scattering work has been undertaken on ceramic and glass-ceramic solid state Li-ion conducting electrolytes. Some of these electrolytes feature Li-ion conductivities that can be as good as commercial organic electrolytes as elegantly demonstrated for Li10GeP2S12 [150]. This is the first solid-state electrolyte that shows conductivity that matches that of commercially-available liquid electrolytes (Fig. 7.16).

A collection of conductivity data of pertinent electrolytes used for commercial and research-scale Li-ion batteries. Reprinted with permission from (N. Kamaya, K. Homma, Y. Yamakawa, M. Hirayama, R. Kanno, M. Yonemura, T. Kamiyama, Y. Kato, S. Hama, K. Kawamoto, A. Mitsui, Nat. Mater. 10, 682 (2011)) [150]. Nature Publishing Group

4.1 Structure

Detailed structural analysis has been undertaken with the use of neutron diffraction on a variety of Li ionic conductors as demonstrated by studies of Li argyrodites. Using a combination of simulations and structural refinements against X-ray and NPD data, the structure of the Li-ion conducting argyrodites, Li6PS5 X where X = Cl, Br, and I, were determined [151]. The Li content and location, along with the mixed occupancies of the X and Li or X and S sites was modelled. For X = Cl and Br, Cl or Br was found on two S sites, whilst I was found on an independent wholly I-containing site. For X = Cl only one Li site was found, while for X = Br and I two Li sites were revealed with a distribution of Li that differs depending on X. This highlighted that the halide plays a critical role in the distribution of atoms, including the location and occupancy of Li. Ionic conductivity was found to be highest for the X = Br samples, suggesting the influence Br has on the atomic distribution to be favourable for this property [151].

These materials were also investigated using variable-temperature neutron diffraction, where the starting reagents were reacted under similar conditions to those used in the laboratory synthesis. This was to determine the optimal reaction temperatures and conditions for favourable properties and whether any intermediate highly-conducting phases were present. The notion was to explore whether synthesis temperatures could be lowered, potentially reducing manufacturing costs, or whether intermediate phases were able to provide superior ionic-conduction properties. Analysis of neutron diffraction data showed that argyrodite formation begins at relatively low temperatures around 100 °C, well below the reported synthesis temperature of 550 °C, but at temperatures around 550 °C the reagents become amorphous or nano-crystalline with all reflections from the sample disappear (Fig. 7.17). Notably, on cooling the desired phase re-condenses and on inspection it is found that the anion ordering, leading to the most conductive phase, is actually found in the re-condensed phase rather than the initially-formed phase [152]. These types of systematic studies on bulk formation shed light on which phases and synthetic routines may provide the best ionic conduction.

Structurally disordered solid-state electrolytes have been investigated using INS. Work [153] exploring low-energy vibrational dynamics of the 11B2O3–7Li2O system showed a boson peak between 2 and 10 meV. It was found that with increasing Li content the intensity and position of the boson peak changed, suggesting the presence of intermediate glass structures. More importantly, this information can be used to generate a master curve, which suggests a universal distribution of vibrational density-of-states that is composition independent, even though the structure changes markedly. Furthermore, increasing the Li content in these glasses results in chemical structure-induced densification, as fewer low-density B-containing groups are found. It is argued that the densification may arise from the same microscopic origin as the boson peak.

4.2 Lithium Diffusion