Abstract

Environmental issues such as climate change, global warming and energy supplies need to augment existing power generation facilities and have got the attention to develop gasification of biomass source, solar energy, wind energy etc. Biomass corresponds to various kinds of recently dead and living plant cell, anatomy, morphology and composition of which is distinct for different parts and species of plant (Shafizadeh, 1982).

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Introduction

Environmental issues such as climate change, global warming and energy supplies need to augment existing power generation facilities and have got the attention to develop gasification of biomass source, solar energy, wind energy etc. Biomass corresponds to various kinds of recently dead and living plant cell, anatomy, morphology and composition of which is distinct for different parts and species of plant (Shafizadeh, 1982).

Municipal residues, wastes, forestry, agricultural residues and dedicated energy crops are the major raw materials for renewable energy generation. Wastes are now typically less expensive to supply to end point users, and will like to play an important role in early development of renewable energy demand. However, analyses of future demand for renewable energy indicate that these are not able to meet the required production in future. Thus dedicated energy crops will be required to meet the demands of a growing renewable energy market. At present scenario, biomass globally supplies about 50 EJ (1 exajoule = 1018 J) that is 10 % of annual primary energy consumption at global level (IEA Report, 2006).

Worldwide biomass ranks fourth as an energy resource, providing approximately 14 % of the world’s energy needs; biomass is the most important source of energy in developing nations, providing 35 % of their energy (Sudha and Ravindranath, 1999).

Biomass is carbon lean fuel as the carbon released during combustion in the form of CO2 is fixed during plant growth by photosynthesis. Wood is a highly efficient biomass fuel but it is too valuable to be used for power generation and in timber industry it is better used as a construction material. So the plant residue bagasse, animal dung, stacks of maize, husks of rice, coconut and renewable perennial biomass of herbaceous plants are major feedstock for energy production.

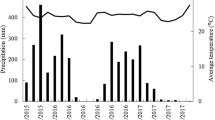

Vetiver is perennial grass of family gramineae commonly known as Kasa. It is hydrophytes, often dominant in fresh-water swamps, flood plains and on stream banks. However, it can also grow well under alternating very wet and very dry conditions, at average temperatures of 25 °C-35 °C (Seaforth and Tikasingh, 2002). Indian Railways has 114,500 kilometres (IRYB, 2009–10) of total track over a route of 65,000 kilometres and to prevent soil erosion from the elevated track with respect to ground level, on both sides of it vetiver is grown. Major quantity of vetiver grass leaves are burnt by rural people for cooking and oil extraction industry; it harms the atmosphere releasing carbon dioxide as a major green house gas. Combustion of fossil fuel produces substantial greenhouse gases (GHG) and toxic gases such as CO2, CH4, SO2, NOx and other pollutants, causing global warming and acid rain (Meng et al., 2006a). So production of power and energy resource from biomass via sustainable method lower the emission of environmentally prejudicious gases like SO2 and NOx and mitigates environmental issue and challenges such as global acid formation, global warming etc. (IEA Report, 2006; Jenkins et al., 1998; Malkina et al., 2002; Rezaiyan et al., 2005).

Chemical composition of biomass constitutes carbon as a major element together with a mixture of organic molecules containing hydrogen, oxygen, nitrogen and also small amount of alkaline earth, alkali and heavy metals. In nature hemicelluloses comprise roughly one-fourth to one-third of the most plant materials and some important applications of these polysaccharides have been demonstrated during the past two decades. Hemicelluloses show a potential fermentation feedstock for the production of sugars, furfural and used as an additive in paper-making, pharmaceutical, cosmetic and food areas (Fenden et al., 2002; Sun and Tomkinson, 2002). A novel product like hydrogel has been also exploited since hemicelluloses are, in their native form, responsible for the interaction with water (Gabrielii et al., 2000). In addition, with a chemical modification, a hydrophobic film from maize bran hemicelluloses has been created as a bioplastic (Fenden et al., 2002).

Hemicellulose samples from the vetiver grass is an arabinoxylan mainly consisting of a backbone of 1, 4-linked xylopyranosyl units. The (1 → 4)-xylopyranose backbone is substituted on O-2 and/or O-3 by single residue or short chains. These branches may be single arabinose residue, single glucuronic acid residue or a short chain of sugar residues containing arabinose, xylose and galactose. So it shows a great potential to use as energy production (Oraphin et al., 2004). There is absolute contingency to augment utilization of biomass by tapping the wastes, unused plants and its residue. Conventional crops production used for energy can also be accelerated, with considerate account of land availability and food demand. Ligninocellulosic crops could be produced on coastal, devalued and ancillary agricultural lands and furnish the bulk of biomass resources.

Experiment

Plants of vetiver grass (Fig. 1) were collected from Banaras Hindu University campus and separated into three categories: stems, leaves and total plants. These were dried at 110 °C in the oven for 24 hrs and then ground in a mixer-grinder and sieved (mesh no. 18–100).

Experimental Setup

The schematic diagram of experimental set up of the pyrolysis of biomass is represented in Fig. 2 and the role of different components of experimental set up is mentioned in Table 1.

Schematic diagram of the pyrolysis experimental set up (1. Nitrogen gas; 2. Microprocessor-based temperature controller; 3. Temperature indicator; 4. Split-open furnace; 5. Reactor; 6. Thermocouple; 7. Thermowell; 8. Condenser cum cooler; 9. Gas bubbler; 10. Digital gas flow meter; and 11. Gas sampler)

Pyrolysis of Biomass

At first 10 g powder of vetiver grass was taken in the fabricated quartz reactor and it was flushed out by nitrogen for 30 minutes to replace the air present in reactor. Now the temperature of reactor was increased at a rate of 5˚C/min from room temperature to 500 °C. Gas flow rate was measured with the help of digital gas flow meter until production of gas completely stopped. The pyrolysed gas produced was collected in a gas sampler and it was analyzed with the help of a Nucon gas chromatograph (model no. 5765) equipped with pora pack Q column, methanizer and FID detector under the following conditions: Carrier gas – Nitrogen, Fuel gas – Hydrogen, Oven temp – 60 °C, Detector and injector temperatures – 80 °C each, Methanizer temperature – 300 °C and Gas sample size – 500 μl.

In the second experimental series, catalytic effect of Na2CO3 on the gas flow rate and amount of gas released on different separated parts of vetiver grass was analyzed. 10 g powder of vetiver grass was thoroughly admixed with 10 ml of 1 % Na2CO3 solution and dried in oven at 110 °C for overnight. Ten gram of dried material was taken into the reactor and pyrolysis was done as described above.

In third experimental series, the optimum concentration of Na2CO3 for the pyrolysis of stem part of vetiver grass was determined.

In fourth experimental series, water gas was produced and measured by passing steam over char residue obtained by pyrolysis of the stem of vetiver grass at 426 °C. Steam was generated from water introduced at the rate of 0.33 ml/min with the help of a syringe pump.

In fifth experimental series, activated char was prepared using char residue obtained by pyrolysis of stem treating with 10 % H2SO4 for six hours, followed by washing with distill water to remove H2SO4 and drying at 110 °C. Further, activation of acid treated and dried char was carried out by passing CO2 gas at 400 °C.

In sixth experimental series, activated char was used to remove Cr+6 from the prepared standard solution of K2Cr2O7 (40 ppm). One gram of the activated char was taken in conical flask having 100 ml of solution. The content of the flask was shaken on electric shaker and at the interval of 1 hr Cr+6 content was analyzed with the help of atomic spectrophotometer.

Gasification of Char by Production of Water Gas

After pyrolysis of stem of vetiver grass at 500 °C when gaseous product stopped coming out, the gasification of the char was carried out by passing steam over char residue at 426 °C. Steam was generated from water introduced at the rate of 0.33 ml/min with the help of a syringe pump. The flow rate of the generated water gas was measured with the help of a digital gas flow meter.

Determination of Calorific Value of Biomass

Calorific values of powdered material of stem, leaves and total plant were determined separately with the help of a bomb calorimeter.

Result and Discussion

Analysis of Gas Collected on Pyrolysis of Vetiver Grass

Composition analysis of the gas sample collected on pyrolysis of the vetiver grass was carried out with the help of a gas chromatograph. Methane (CH4) and carbon dioxide (CO2) were found as major amounts, whereas carbon monoxide (CO) was found in trace amount. Composition of different gaseous products with their weight % is given in Table 2.

Calorific Value of Vetiver Grass

Calorific values of different parts of vetiver grass were determined in a bomb calorimeter. The experimental data obtained in the present study is compared with the values reported in literature for different biomass in Table 3. It can be seen that the present data is comparable to reported data. It is very clear from the table that the calorific value of stem part of vetiver grass is very high in comparison to total plant and leaves.

Pyrolysis of Powdered Material of Various Parts of Vetiver Grass

Figure 3 shows the flow rate of gas generated on pyrolysis of various parts of the vetiver grass at different temperatures. It can be seen from the figure that the pyrolysis of various parts of vetiver grass started generating gases at 114.7 °C and stopped around 400 °C. In case of total plant and stem of the vetiver grass initially slower rate of gas generation occurred with increase in temperature and then it increased rapidly resulting in two maxima in both the cases at different temperatures and a minimum at 262.3 °C. For total plant the maxima occurred at 245 °C and 295 °C on the other hand for stem the maxima occurred at 147.5 °C and 307.4 °C. Whereas, the pyrolysis of leaves start generating gases at 180.3 °C and stopped at 426.3 °C resulting in a single maximum at 278.7 °C.

During pyrolysis of biomass highest flow rate was observed at 295 °C, 311 °C and 278 °C for vetiver plant, stem and leaves respectively. Gas flow rate in case of leaves shows less variation. It may have occurred due to presence of less amount of lignin-cellulosic material in cell wall in leaves compared to stem. Hemicellulose, cellulose and lignin decompose typically in the temperature ranges of 200–400, 275–400 and 200–500 °C, respectively (Hirunpraditkoon and Garcia, 2008). Pyrolysis of lignin started at lower temperature than that of cellulose, which covers a rather wide temperature interval (Liu et al., 2008). The principal component of vetiver grass was reported as cellulose (ca. 30–35 %), hemicelluloses (ca. 40 %) and lignin (ca. 10 %) (Pawadee et al., 2003). Amount of lignin, cellulose and hemicellulose varies with different parts of the plant. Stem of plant is stiffer than leaves due to presence of lignin and leaves mainly composed of hemicellulose and cellulose. In the studies of alpha cellulose pyrolysis, significant weight loss was observed at 247-280 °C due to dehydration (Chang et al., 2011). In case of pyrolysis of stem and total plant of vetiver grass, gas flow rate goes down at 262.3 °C which may be due to endothermic dehydration of constituent components (cellulose).

Yield of char obtained for plant, stem and leaves were 0.4182 g/g, 0.3411 g/g and 0.4061 g/g of biomass, respectively. Assuming ideal gas law, the weight of gas produced was 0.1707 g/g, 0.2086 g/g and 0.1722 g/g of biomass of total plant, stem and leaves, respectively. Thus the amount of tar, water and other liquid products was calculated by the difference, equal to 0.4111 g/g, 0.4503 g/g and 0.4217 g/g of total plant, stem and leaves, respectively.

Effect of Catalyst (Na2CO3) on Pyrolysis of Powdered Material of Various Parts of Vetiver Grass

Few inorganic salts like carbonate, chromates and chlorides show propitious effect on the rate of pyrolysis reaction (Rabah and Eldighidy, 1989). Among alkali catalyst Na2CO3 has better catalytic effect compared to other catalyst for biomass pyrolysis (Meng et al., 2006b). Catalysts reduce the tar content and also improve the gas product quality. Figure 4 shows the flow rate of gas generated on pyrolysis of varhious parts of the vetiver grass admixed with Na2CO3 catalyst at different temperature. It can be seen from Fig. 4 that the pyrolysis of various parts of vetiver grass started generating gases at 114.7 °C and stopped around 400 °C. In case of total plant and leaves of the vetiver grass, initially slower rate of gas generation occurred with increase in temperature and then it increased rapidly resulting in two maxima in both the cases at different temperatures and a common minimum at 311.5 °C. For total plant the maxima occurred at 270.5 °C and 327.9 °C on the other hand for leaves the maxima occurred at 278.7 °C and 344.3 °C. It should be noted that contrary to without catalyst, with catalyst leaves show two peaks, whereas for stem single maximum occurred at 245.9 °C. Variation in the maxima occurred due to its constituent composition.

Alvarez and Vazquez (2004) reported the peak of pyrolysis temperature at 300 °C for the hemicellulose and 360 °C for the pure cellulose without catalyst. The present experimental data with catalyst show that the maxima shift toward low temperature compared to the reported values by Alvarez and Vazquez (2004).

Yields of char obtained with 1 % Na2CO3 treated total plant, stem and leaves were 0.3842 g/g, 0.3754 g/g, and 0.4332 g/g of biomass respectively. Assuming ideal gas law the weight of gas produced was 0.1942 g/g, 0.2170 g/g and 0.1863 g/g for 1 % Na2CO3 treated total plant, stem and leaves, respectively. Thus the amount of tar, water and other liquid products was calculated by the difference equal to 0.4216 g/g, 0.4076 g/g and 0.3805 g/g of 1 % Na2CO3 treated total plant, stem and leaves, respectively. The data show that on treatment of biomass with Na2CO3 produced more amount of gas and less amount of tar in comparison to without catalyst. The temperature range for maximum gas production with catalyst is very narrow (200-300 °C) as compared to without catalyst (262-377 °C) for stem. Therefore, stem was selected for further studies.

Optimization of Catalyst Concentration for Pyrolysis of Stem of Vetiver Grass

Optimum concentration of catalyst is necessary to minimize the cost of biomass pyrolysis process. Figure 5 shows the effect of catalyst concentration on flow rate of gas generation on pyrolysis of stem of vetiver grass at different temperatures. It can be seen from the figure that the pyrolysis of the stem started generating gases at 114 °C and stopped around 450 °C. In case of 0.5 % and 1.5 % Na2CO3 treated stem of the vetiver grass initially slower rate of gas generated and with increase in temperature it increased rapidly resulting in two maxima in both the cases at different temperatures and a minimum at 311.5 °C and 295.1 °C, respectively. For 0.5 % Na2CO3 treated stem of the vetiver grass the maxima occurred at 278.7 °C and 327.9 °C, on the other hand for 1.5 % Na2CO3 treated stem the maxima occurred at 286.9 °C and 311.5 °C. Whereas, the pyrolysis of 1.0 % Na2CO3 treated stem of the vetiver grass started generating gases at 147.5 °C and stopped at 409.8 °C resulting in a single maximum at 245.9 °C.

Yields of char obtained for 0.5 %, 1 % and 1.5 % Na2CO3 treated stem were 0.3488 g/g, 0.3754 g/g and 0.3578 g/g of biomass, respectively. Assuming ideal gas law, the weight of gas produced was 0.2296 g/g, 0.2170 g/g and 0.2184 g/g for 0.5 %, 1 % and 1.5 % Na2CO3 treated stem, respectively. Thus the amount of tar, water and other liquid products was calculated by the difference equal to 0.4216 g/g, 0.4076 g/g and 0.4238 g/g of 0.5 %, 1 % and 1.5 % Na2CO3 treated stem, respectively.

It is to be noted that in all the cases of Na2CO3 treated samples, comparable total amount of gases were produced. However, maximum gas flow rate occurred at the lowest temperature of 245.9 °C for 1 % Na2CO3 treated stem of the vetiver grass in comparison to other samples.

Water Gas Production

When steam was passed over red hot char left after pyrolysis (4.127 g) at 426 °C, water gas is produced as per following equation:

The flow rate of water gas produced with time is plotted in Fig. 6. A maximum flow rate of 9.44 ml/min of water gas resulted at 21 minutes of the start of the experiment. The gas production stopped after 110 minutes of continuous experiment when reducible carbon in the char is exhausted. A total of 390 ml of water gas was produced at ambient temperature and pressure.

Removal of Chromium

Activated carbon prepared from char remained after pyrolysis was utilized for waste water treatment for Cr+6 removal. The results of chromium removal is shown in Fig. 7. Adsorption of chromium is initially increased rapidly and then it becomes constant with increase of time. The optimum time for adsorption was observed 240 min. It can be seen from Fig. 7 that removal efficiency of chromium is highest for activated carbon which was treated with H2SO4 after char was prepared from stem powdered material. The powdered materials treated with H2SO4 and activated by carbon dioxide show relatively higher efficiency to remove chromium with respect to the activated carbon prepared without treatment with H2SO4 and CO2. Carbon dioxide molecules can diffuse into the narrower micro pores where the nitrogen molecules cannot diffuse because of the increase in the diffusion rate of the gas molecules and the absence of diffusion barrier.

Since nitrogen has a pore penetrator function, carbon dioxide deepens and widens pores, especially at high temperatures. That is it increases the ratio of mesopore volume. Because carbon dioxide gas reacts with elementary graphite micro crystals in the carbon structure and it removes carbon atoms burning at the pore sides during activation, it leaves an activated carbon having a more defective structure that contained different types of pores (Guzel and Tez, 1993).

Conclusion

Vetiveria zizanoides is grown deliberately to prevent soil erosion, typically at the borders of agricultural lands and sides of the railway track, since this plant does not hinder the growth and nutrient uptake of other plants. At the end of summer season stem of vetiver is burnt as it has negligible market value at present.

In this study, it is found that vetiver grass stem has high calorific value compared to other biomass feedstock used for energy production; therefore there is much potential of it to be used as energy crop for bio-energy. Due to the seasonal burning of vetiver grass stem, carbon dioxide is released which is a harmful greenhouse gas. It can be reduced by using vetiver grass as bio-energy. The activated carbon prepared from char obtained after pyrolysis can be used to control waste water pollution and fuel cell. As India is developing agricultural nation, finding productive uses for waste biomass is a great asset for the country, especially when it contributes to the area of energy production.

References

Chang, A.C.C., Chang, H.F., Lin, F.J., Lin, K.H. and Chen, C.H. (2011). Biomass gasification for hydrogen production. International Journal of Hydrogen Energy, 36: 14252-14260.

Chaikumpollertb, O., Methacanona, P. and Suchiva, K. (2004). Structural elucidation of hemicelluloses from vetiver grass. Carbohydrate Polymers, 57: 191-196.

Fenden, E., Granet, R., Zerrouki, R., Krausz, P., Saulinier, L., Thibault, J.F., Rosier, J. and Petit, C. (2002). Hydrophobic films from maize bran hemicelluloses. Carbohydrate Polymers, 49: 1-12.

Gabrielii, I., Gatenholm, P., Glasser, W.G. and Kenne, L. (2000). Separation, characterization and hydrogel-formation of hemicellulose from aspen wood. Carbohydrate Polymers, 43: 367-374.

Guzel, F. and Tez, Z. (1993). The characterization of the micropore structures of some activated carbons of plant origin by N2 and CO2 adsorptions. Separation Science and Technology, 28: 1609-1627.

Hirunpraditkoon, S. and Garcia, A.N. (2009). Kinetic study of vetiver grass powder filled polypropylene composites. Thermochimica Acta, 482: 30-38.

IEA (International Energy Agency). IEA bioenergy annual report (2006). http://www.energytech.at/pdf/iea_bereport06.pdf.. Accessed 5 January 2013.

Indian Railways Year Book (2009-2010). Ministry of Railways, Government of India. 2011. Retrieved 26 December 2012.

Indiasolar Web. http://www.indiasolar.com/cal-value.htm. Accessed 5 January 2013.

Jenkins, B.M., Baxter, L.L., Miles Jr, T.R. and Miles, T.R. (1998). Combustion properties of biomass. Fuel Process Technol, 54: 17-46.

Liu, Q., Wang, S., Zheng, Y., Luo, Z. and Cen, K. (2008). Mechanism study of wood lignin pyrolysis by using TG–FTIR analysis. Journal of Analytical and Applied Pyrolysis, 82: 170-177.

Malkina, I.G. and Pykh, Y.A. (2002). Sustainable energy resources, technology and planning. WIT Press, Southampton (UK).

Meng, N., Leung, D.Y.C., Leung, M.K.H. and Sumathy, K. (2006a). An overview of hydrogen production from biomass. Fuel Process Technology, 87: 461-472.

Meng, N., Leung, M.K.H., Sumathy, K. and Leung, D.Y.C. (2006b). Potential of renewable hydrogen production for energy supply in Hong Kong. International Journal of Hydrogen Energy, 31: 1401-1412.

Methacanona, P., Chaikumpollertb, O., Thavornitia, P. and Suchiva, K. (2003). Hemicellulosic polymer from vetiver grass and its physicochemical properties. Carbohydrate Polymers, 54: 335-342.

Rabah, M.A. and Eldighidy, S.M. (1989). Low cost hydrogen production from waste. International Journal of Hydrogen Energy, 14: 221.

Rezaiyan, J. and Cheremisinoff, N.P. (2005). Gasification technologies – A primer for engineers and scientists. CRC Press (Taylor & Francis Groups), Boca Raton (FL).

Seaforth, C. and Tikasingh, T. (2002). Final report: A study for the development of a handbook of selected Caribbean herbs for industry.

Shafizadeh, F. (1982). Introduction to pyrolysis of biomass. Journal of Analysis and Applied Pyrolysis, 3: 283-305.

Sudha, P. and Ravindranath, N.H. (1999). Land availability and biomass production potential in India. Biomass and Bioenergy, 16: 207-221.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Capital Publishing Company

About this chapter

Cite this chapter

Kumar, A., Prasad, R. (2015). Production of Renewable Energy and Waste Water Management from Vetiver Grass. In: Raju, N., Gossel, W., Ramanathan, A., Sudhakar, M. (eds) Management of Water, Energy and Bio-resources in the Era of Climate Change: Emerging Issues and Challenges. Springer, Cham. https://doi.org/10.1007/978-3-319-05969-3_14

Download citation

DOI: https://doi.org/10.1007/978-3-319-05969-3_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-05968-6

Online ISBN: 978-3-319-05969-3

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)