Abstract

Much of the analysis on the viability of biomass to energy focuses on the implications of utilizing biomass feedstocks on energy and food pathways, land use and the environment. However, to more accurately assess biomass energy potential, analysis also needs to include political economy and logistical constraints, such as institutional barriers, existing policies, and collection and delivery infrastructure. To demonstrate the importance of introducing such constraints into an assessment model, a biomass analysis conducted for New Jersey in 2007 is used as a case study. In this assessment, biomass potential for the state was calculated with and without political economy and logistical constraints. The case study shows that introducing political economy and logistical constraints have a significant impact on the estimated quantities of Class 1 biomass feedstocks available for energy production. In the New Jersey case, 35 % of total estimated biomass resources were unavailable for bioenergy generation when considering political economy and logistical constraints in the assessment model.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

8.1 Introduction

Methodologies used to estimate biomass energy potential have evolved over the last several decades. Early studies made simple assumptions regarding land use and the amounts of residue recoverable from agricultural production and forestry management for use in bioenergy production (McKeever 2002) [7, 14, 15, 17, 20, 21]. More recent studies employ more sophisticated models to explicitly simulate various scenarios that include environmental, technical, and economic assumptions, such as energy prices, food costs, land use and other environmental factors [1, 3–6, 8–10, 19]. In the recent United Kingdom Energy Research Centre report, Energy from Biomass: the Size of the Global Resource [16], ninety global studies on biomass potential were reviewed. Many of the studies reviewed in this report impose assumptions governing land or land use. To a lesser extent these studies also incorporate assumptions or constraints regarding yield and production capacity, sustainability, environmental impacts, and economic and market factors. However, realistic political economy and logistical constraints such as institutional factors, existing policy frameworks and collection infrastructure that impact the utilization of biomass feedstocks and the feasibility of installing alternative biomass-to-energy conversion technologies, are absent.

In this chapter, we review a state-level biomass-to-energy assessment conducted in New Jersey to demonstrate the effect of political economic and logistical considerations on estimates of energy generation potential [2]. The assessment is expansive, incorporating thirteen biomass-to-energy conversion technologies and forty potential biomass feedstocks. Biomass-to-energy generation simulations were supported by the development of a novel Bioenergy Calculator.Footnote 1 This tool allows decision makers to evaluate the sensitivity of energy generation estimates to various political economy, logistical and technological parameters affecting the availability and conversion of biomass feedstocks into energy. Political economy constraints in the model encompass assumptions regarding existing policies and logistical (i.e., feedstock collection, aggregation and distribution) or institutional barriers that limit or support the diversion of biomass resources into energy production systems. Qualitative assumptions are also made regarding the commercialization status or market readiness of alternative energy production technologies.

The physical quantities of biomass feedstocks were estimated (on a dry tonnage basis) at the state level and for each of New Jersey’s 21 counties based on the collection of extensive secondary data. These estimates represent theoretical maxima in the Bioenergy Calculator or, in other words, the upper bounds for feedstock quantities potentially suitable for bioenergy generation. Subsequent calculations discounted these maxima by considering political economy and logistical barriers that limit or preclude the use of each biomass feedstock for bioenergy production. The resulting feedstock balances, termed “practically recoverable feedstocks”, total only 65 % of the theoretical dry tonnage maxima. The New Jersey case study therefore demonstrates the sensitivity of biomass evaluations to assumptions regarding institutional capacity, feedstock aggregation and distribution infrastructure, and regulatory/policy considerations.

To set the context for the New Jersey biomass-to-energy assessment, the following section provides a brief policy background on the role of bioenergy in the state’s recent energy master plan. This is followed by a more detailed description of the data collection methodologies, structure of the Bioenergy Calculator and estimates of New Jersey’s biomass energy potential after consideration of political economy and logistical constraints. The chapter concludes with a discussion of the results and policy recommendations.

8.2 The Role of Renewable Energy in Achieving New Jersey’s Energy Goals

New Jersey has taken significant steps to increase the development and utilization of renewable energy resources through legislation, mandatory greenhouse gas (GHG) emission reduction programs, incentives, and regional collaborations. In February 2007, Governor Jon Corzine issued Executive Order 54, requiring that 20 % of the state’s electricity be derived from Class 1Footnote 2 renewable resources by 2020. The executive order also outlined targets for reducing GHG emissions [18]. In 2011, the New Jersey State Energy Master Plan (EMP), for the first time, incorporated renewable energy strategies, including biomass utilization [12]. These strategies are designed to meet several goals, including the adoption of a Renewable Portfolio Standard (RPS) requiring that 22.5 % of the state’s energy needs be met from renewable sources by 2021. The EMP further specifies a target of 900 MW of biopower as part of the State’s 2020 RPS.Footnote 3 The EMP further recognizes the importance of enabling public policies to achieve these goals, stating that “both State and federal mandates regarding the use of renewables are predicated on the need to establish worthwhile public policy goals to support renewable energy technology.”Footnote 4

Within the context of New Jersey’s total energy generation portfolio, renewable energy generation lags far behind other energy resources (i.e., nuclear, natural gas and coal). In 1997, renewable energy sources accounted for 2.8 % of New Jersey’s total energy generation. In 2011, renewables accounted for only 1.2 %, demonstrating that growth in the renewable sector has not kept pace with the increased energy demands of the state [23]; New Jersey ranks 46th in the country in terms of renewable electricity net generation [24]. To meet future demand, New Jersey’s growth rate of renewable energy will therefore have to increase substantially over current levels. As noted in the EMP, meeting renewable energy goals will require policies that ensure significant energy conservation, energy efficiencies, and high growth in renewable energy sources.Footnote 5

New Jersey has established economic incentives along with renewable energy standards, to encourage the development and utilization of alternative energy. The New Jersey Board of Public Utilities (NJBPU) Office of Clean Energy establishes and implements the majority of renewable energy programs for the state. From 2009–2012, BPU approved $1.2 billion for energy-efficiency and renewable energy initiatives (an increase of $475 million over the 2005–2008 allocation). In 2011, the Office of Clean Energy expended over $380 million to provide New Jersey residents, municipalities and businesses with incentives to install energy efficient and renewable energy technologies [13]. New Jersey also offers numerous financial incentives for alternative fuel and alternative fuel vehicles in the form of rebates and tax exemptions. In addition to the energy programs operated by BPU, the New Jersey Economic Development Authority offers a suite of “Clean Energy Solutions” programsFootnote 6 that offer grants and low-cost financing.

New Jersey currently has no financial incentives to support the development of alternative fuel infrastructure to serve the general public, which will be needed if the state intends to effectuate the transition to alternative fuel vehicles and associated infrastructure. The Alternative Fuel Infrastructure Rebate provides only limited funding to eligible local governments, state colleges and universities, school districts, and governmental authorities for the purchase and installation of refueling infrastructure for alternative fuels. Lack of public access to alternative fuels will impede the state’s goals of alternative fuel use and greenhouse gas reductions. However, New Jersey has instituted a number of regulations designed to support emissions reductions and use of alternative fuel and vehicles which include biodiesel fuel use rebates, emissions reductions requirements, low emission vehicle standards and plug-in hybrid electric vehicle promotion.

To advance biomass energy use in an environmentally responsible and sustainable manner, and as mandated by existing legislation and NJBPU regulations, the Department of Environmental Protection is developing an objective and systematic process of sustainability determinations that will facilitate environmental permitting of qualified biomass projects meeting the sustainability criteria of: (1) superior environmental performance (including meeting state-of-the-art (SOTA) air quality standards); (2) socioeconomic sustainability; and (3) reduction of greenhouse gas emissions.Footnote 7

8.3 Assessment of Biomass Energy Potential for New Jersey

The assessment of biomass energy potential for New Jersey was completed in 2007 and provided critical information to the NJBPU as it incorporated bioenergy potential into the state’s energy master plan. The 2011 EMP was the first version to contain information and recommendations on the development and utilization of bioenergy to meet state energy demands, necessitating baseline information on biomass feedstocks and practical estimates of potential bioenergy generation. The objectives of the biomass assessment were therefore to:

-

(1)

assess the characteristics and quantity of New Jersey’s biomass resources;

-

(2)

assess technologies (commercially or near commercially available) that are capable of producing biopower or biofuels from New Jersey’s biomass resources;

-

(3)

develop the first statewide mapping of waste/biomass resources and bioenergy potential; and,

-

(4)

develop policy recommendations for creating a bioenergy industry in New Jersey [2].

Since no previous assessment of biomass feedstocks and bioenergy potential had ever been conducted for New Jersey, a method was required to guide the collection and analysis of a substantial amount of data. In addition, a decision support tool was needed to calculate energy potential based: (1) estimated biomass feedstock quantities, (2) availability of suitable bioenergy generation technologies, and (3) previously described political economic and logistical constraints. These were foundational elements in the development of the Bioenergy Calculator and are detailed in the following sections.

8.3.1 Feedstock Assessment

The feedstock assessment efforts concentrated on collecting existing data on quantity and location for each type of biomass identified as a potentially significant feedstock for energy production. The data was evaluated for validity and completeness, and additional data collected as needed to fill existing gaps. This data was then used for assessing conversion technologies to identify the most promising and efficient technologies in terms of feedstock needs and cost per unit of fuel/energy production.

The methodology for identification of the type and quantity of biomass resources involved the following steps:

-

1.

Identify all types of biomass resources in New Jersey that are suitable for bioenergy production.

-

2.

Identify, by county, the quantity and location of the resources

-

3.

Place these resources into categories that are identified by similar feedstock characteristics and common type of energy conversion technologies.

-

4.

Determine factors that could reduce the availability of these resources for use as a bioenergy feedstock.

-

5.

Create a screening function in the database to eliminate those resources or percentages of resources that are not realistically able to be used.

Public data (as of September 2006) on biomass resources for each New Jersey county (21) was collected to determine an estimated total biomass quantity for the state of New Jersey. The characteristics and quantities of forty of New Jersey’s biomass resources were divided into five categories based on their physical characteristics: sugars/starches, lignocellulosic biomass, bio-oils, solid wastes, and other waste (i.e. animal waste). Sugars/starches are traditional agricultural crops and food processing residues suitable for fermentation using first generation technologies. Lignocellulosic biomass is clean, woody and herbaceous material from a variety of sources including: agricultural residues, cellulosic energy crops, food processing residues, forest residues, mill residues, urban wood waste (wood from urban forests, used pallets) and yard waste. Bio-oils are traditional edible oil crops and waste oils suitable for conversion to biodiesel, including soybean oil, used cooking oil (“yellow grease”) and grease trap waste (“brown grease”). Solid wastes are primarily lignocellulosic biomass that may be contaminated or commingled with other biomass types. This category includes the biomass component of municipal solid waste (MSW), construction and demolition (C&D) wood, food wastes, non-recycled paper and recycled materials. Other Wastes are biomass wastes that are generally separate from the solid waste stream, including animal waste, wastewater treatment biogas and landfill gas. This data was entered into the biomass resource database which forms the foundation of the bioenergy calculator.

In addition, the geographic distribution of biomass feedstocks were mapped using GIS technology to facilitate analysis of the logistics and practicality of collection and aggregation. The assessment concluded that an estimated 8.2 million dry tons of biomass is produced in New Jersey annually, representing the theoretical or upper bound for biomass feedstocks available for bioenergy generation (see Fig. 8.1). The most abundant feedstocks in the state are from lignocellulosic sources and landfilled biomass. These feedstocks are also the most difficult to collect (lignocellulosic) and the most bound by political economic restraints (landfilled biomass).

8.3.2 Technology Assessment

There are many bioenergy technologies currently available or in the pipeline that are capable of converting New Jersey biomass resources into bioenergy. For the purposes of this study only biofuel and biopower were considered. Bio-heat applications were not included in the assessment since these are typically “captive” opportunities in biomass based industries like forest products, and are therefore limited in New Jersey.

Biofuel technologies are often classified as either first or second generation technologies. Ethanol and biodiesel, as examples, are considered first generation biofuels. A significant advantage of these fuels is the ease of their incorporation into existing petroleum infrastructure. Currently, they are the only renewable option for liquid transport fuels. The downside with first generation biofuels is limited scalability, economically unviable, impacts on grain supply for food, and uncertainty of indirect land use change effects. Second generation biofuel R&D efforts are focused on increasing the range of feedstocks from which to produce biofuels and reducing the biomass to liquid fuel conversion costs. Three second generation technology platforms are under development:

-

Biochemical pathway: conversion of cellulose to fermentable sugars to multiple alcohol fuels

-

Thermochemical pathway: conversion of biomass to syngas and synthesis to multiple fuels

-

Purification of biogas (landfill gas and anaerobic digester gas) into biomethane for transportation fuels (as a compressed or liquefied gas)

These technologies require significant private and public money investment in R&D, but they offer great potential for fossil fuel displacement.

Four conversion technologies are generally considered the most appropriate for biopower applications. These are as follows:

-

Direct combustion is the primary form of biomass utilization for power generation. It is a mature technology that is applied broadly in industrial combined heat and power (CHP) and stand-alone grid power applications.

-

Gasification has received significant public and private sector investment and numerous technologies are commercially available. Although this technology is much less widely deployed relative to direct combustion, it is considered a major technology platform for future biopower development.

-

Pyrolysis is less developed than either direct combustion or gasification, but is the subject of moderate technology development and commercialization activities. One company (DynaMotive) is constructing a 200 tpd power plant in Canada.

-

Anaerobic Digestion is commonly practiced in wastewater treatment plants and increasingly on animal farms. Landfill gas is also a product of natural anaerobic digestion in landfills. Power and CHP are the most common applications.

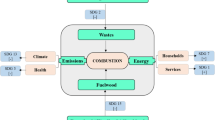

In an effort to identify the technologies that would be most applicable to New Jersey’s biomass resources, a technology evaluation analysis was conducted using the following criteria (Fig. 8.2):

-

Certain technologies are not well developed yet and/or are likely to be applicable primarily to niche applications. These were excluded from detailed analysis.

-

Though there are many biomass feedstocks that could be used with a particular conversion technology, in practice, certain feedstocks are better suited to certain conversion processes. Technologies that could more efficiently utilize New Jersey feedstocks were given priority.

-

Given the wide range of technologies within a particular “platform” (e.g., types of biomass gasification reactors), the analysis focused on broad technology platforms with similar characteristics. Representative feedstock-conversion-end use pathways were selected for the economic analysis.

-

Technologies were assessed on a Market Readiness scale to determine their location along the development/commercialization continuum. The scale was defined as five points (1) Research and Development stage; (2) Demonstration stage; (3) Market Entry stage; (4) Market Penetration stage; and (5) Market Maturity stage.

The evaluation process yielded thirteen technologies deemed feasible for the conversion of New Jersey’s biomass feedstocks into biofuel or biopower. The selected technologies were divided into five major categories: Direct Combustion, Thermo-Chemical Conversion, Fermentation, Anaerobic Digestion and Physio-Chemical Conversion (see Fig. 8.3).

Energy generation data for the thirteen selected bioenergy technologies, which takes into consideration advances in energy output and efficiency over time, was calculated. Estimated energy potential included energy produced using current or near-term technologies appropriate for each feedstock resource. All the resource and technology data was integrated with other information (e.g. technology process efficiencies and yields). A unique bioenergy calculator was then developed to aggregate all biomass and technology information and to automatically calculate energy generation potential for each county in New Jersey.Footnote 8 The database is designed to analyze the biomass resource data and technology assessment data in an interactive fashion and can be updated and modified. A screening tool embedded in the database (described in next section) allows for sensitivity analyses to be conducted on the estimates of recoverable biomass and energy potential. This also tempered estimates of energy generation potential through incorporation of existing political economic and logistical constraints.

8.3.3 Political Economic and Logistical Screening Process

Considering a variety of political economy factors to arrive at an estimate of the realistic quantity of biomass in the state available for energy conversion was an important step in the New Jersey assessment. First, all biomass currently going to the state’s seven incinerators were removed from the assessment, reflecting a state policy priority to maintain the flow of feedstocks into these facilities. Keeping the incinerators functioning to the end of their useful life was a priority in terms of maintaining a viable financial model. In addition, incinerated waste is considered a Class 2 resource and the focus of state biomass policy is only on utilization of Class 1 resources. The total amount of waste going to incinerators per year is 688,012 dry tons and was not included in the analysis.

A screening process that considered political economy/logistics criteria for Class 1 biomass resources was incorporated to determine the proportions of each existing biomass resource that are “practically recoverable” for energy production based on several considerations (Fig. 8.4). First, is/can the biomass be collected? A well established collection and delivery infrastructure is in place to manage New Jersey’s municipal solid waste. However, for some biomass resources (i.e., agricultural and forestry residues) new or significantly modified collection systems would be required. The development of additional waste management systems would require economic incentives to encourage adaptation of existing waste collection operations or the development of new systems. Economic incentives would also be needed to incentivize the owners of collection operations to add to or divert a portion of their fleet for these purposes. This screen removed 910,000 dry tons of biomass.

The second screening criterion focused on is the biomass sortable (or is sorting needed)? Further source separation policies are needed if New Jersey is to take advantage of wastes that are now not fully separated, such as food waste and C&D wood. This will require a change in policy and behavior for businesses and residents which may be difficult to achieve. The elimination of 330,000 dry tons of biomass resources due to inadequate or non-existent sorting logistics does not, of course, preclude their inclusion in the future should policy or behavioral adaptations promote needed waste separation.

The final screening criterion was does the biomass have a valuable alternative use? As a prime example, much of New Jersey’s urban waste biomass is recycled and used in alternative markets. These markets are well established and may, at least in the present day, provide higher economic returns than would be realized if the biomass was diverted into bioenergy production. This screen resulted in the largest quantity of biomass being removed—1,460,000 dry tons.

8.4 Results

Of the estimated 8.2 million dry tons (MDT) of Class 1 biomass produced annually in New Jersey (see Table 9.1), nearlyFootnote 9 three-quarters of New Jersey’s biomass is produced directly by the state’s population in the form of solid waste (e.g. municipal waste). The majority of New Jersey’s biomass is concentrated in the counties of central and northeastern New Jersey due to the large populations in those counties. Landfill gas is considered a Class 1 resource and the major source of renewable energy in the state.

Based on the screening process described previously, of the 8.2 MDT of biomass, approximately 5.5 MDT (65 %) could ultimately be available to produce energy, in the form of power or transportation fuels. The 35 % reduction in biomass volume reflects the exclusion of materials due to political economic or logistical constraints and demonstrates the clear importance of evaluating existing infrastructure limitations, policy priorities, and logistical realities during the evaluation and formation of bioenergy production alternatives.

Energy generation estimates were developed that account for the “practically recoverable” amounts of biomass available in each feedstock category after the screening process, and capable of being converted to energy by current or near-term technologies appropriate for each resource. All resource and technology data were integrated with other information (e.g. technology process efficiencies and yields) within the Bioenergy Calculator. The calculator is designed to analyze the biomass resource and technology assessment data in an interactive fashion and can be updated and modified. The screening tool embedded in the database allows for sensitivity analyses to be conducted on the estimates of recoverable biomass and energy potential based on political economy changes or scenario alternatives.

The Bioenergy Calculator yields projected biopower and biofuel estimates for 2007, 2010, 2015, and 2020. It is currently being updated to 2025. “Typical” moisture and energy content and/or yield assumptions for each resource were developed and used to calculate dry weights needed to estimate total bioenergy potential. The results showed that New Jersey’s 5.5 MDT of available Class 1 biomass resources could deliver up to 1,124 MW of power (equivalent to approximately 9 % of New Jersey’s current electricity consumption) or 311 million gallons of gasoline equivalent (roughly 5 % of current transportation fuel consumed), if appropriate policies, technologies and infrastructure were in place to produce the bioenergy. This is currently not the case, and at this time only 1.2 % of the state’s energy is generated from biomass resources [22].

8.5 Policy Discussion and Conclusions

Creating an effective institutional, regulatory and feedstock supply infrastructure, as well as comprehensive strategic and tactical industry development plans is vital to the successful achievement of any state’s renewable energy goals. Based on an examination of the impacts of political economic and logistical constraints in the utilization of the state’s biomass resources, the State of New Jersey needs to establish the capacity and infrastructure required for rapid biofuels and biorefinery development and to create sustainable markets for bioenergy products. A key step for achieving the bioenergy goals and targets is for policy to focus on institutional infrastructure, regulations, market-based incentives and market transformation through technological innovation. Market transformation will take place once the technological and infrastructure capabilities exist and can function in an economically viable and environmentally sustainable fashion. Institutional infrastructure capable of supporting the development of a renewable energy industry in New Jersey is essential to achieve the goals of the state’s energy master plan. These include the establishment/appointment of a state agency with primary responsibility for the development and support of the emerging renewable energy industry. Furthermore, policy harmonization must be facilitated across all state agencies so that the state’s renewable energy goals can be successfully achieved. This effort will need to be fully integrated, include public and private partnerships, and incorporate comprehensive research, policy and marketing plans. And finally, regional partnerships with surrounding states must be built to take advantage of related programs, maximize utilization of biomass feedstock, coordinate research activities and share expertise.

Furthermore, since the assessment results showed that 75 % of New Jersey’s biomass is produced directly by the state’s population, in the form of solid waste (e.g. municipal waste), this leads to a recommendation that New Jersey pursue the development of energy from waste industry. Energy from waste in New Jersey is particularly attractive because waste disposal costs are high and waste collection and consolidation infrastructure is already in place. Agriculture and forestry management comprise the majority of the remaining biomass produced in New Jersey and, therefore, are also important potential energy sources. The biomass from agricultural sources includes both crops and crop residues. The use of agricultural crops for energy production would require the decision to convert the current food supply chain into energy production, which could have other major policy implications. Crop residues, however, are generally underutilized and undervalued, which should allow for an easier decision to use these resources. In the case of energy crop production, New Jersey would need to decide whether to maintain current crop varieties (i.e. corn, soybean, hay, etc.), or introduce new crops that would be better suited for energy production (e.g. Poplar or switchgrass).

The results of the New Jersey bioenergy analysis demonstrates the importance of considering the influence of political economy and logistical constraints when developing and optimizing assessment models. It illuminates potentially large biases that may result from the exclusion of these constraints, thus generating dramatically misleading results.

Notes

- 1.

The Bioenergy Calculator is accessible at: http://bioenergy.rutgers.edu/biomass-energy-potential/default.asp.

- 2.

Class One Renewable Energy definition as provided by NJDEP: Class I renewable energy is defined as electricity derived from solar energy, wind energy, wave or tidal action, geothermal energy, landfill gas, anaerobic digestion, fuel cells using renewable fuels, and, with written permission of the New Jersey Department of Environmental Protection (DEP), certain other forms of sustainable biomass.

- 3.

New Jersey Energy Master Plan [12, p. 1].

- 4.

New Jersey Energy Master Plan [12, p. 86].

- 5.

New Jersey Energy Master Plan [12, p. 103].

- 6.

- 7.

New Jersey Energy Master Plan [12, pp. 102–103].

- 8.

The calculator programming was developed by Navigant Consulting.

- 9.

This does NOT include biomass that is currently used for incineration or sewage sludge because these are not classified as Class I renewable feedstocks in New Jersey.

References

Birur, D.K., Hertel, T.W., Tyner, W.E.: The biofuels boom: implications for world food markets. Center for Global Trade Analysis, Department of Agricultural Economics, Purdue University, 2007

Brennan, M.F., Schilling, B.J., et al.: Assessment of Biomass Energy Potential in New Jersey, 2007-1. New Jersey Agricultural Experiment Station, New Brunswick (2007)

Capehart, T., Richardson, J.: Food Price Inflation: Causes and Impacts. Congressional Research Service, The Library of Congress, Washington, DC (2008)

Elobeid, A., Hart, C.: Ethanol expansion in the food versus fuel debate: how will developing countries fare? J. Agric. Food Ind. Organ. 5(2), 86 (2007)

Gulen, G., Shenoy, B.: Supporting biofuels: a case study on the law of unintended consequences. Working draft, center for energy economics, bureau of economic geology, Jackson School of Geosciences, University of Texas at Austin (2007)

Helbling, T., Mercer-Blackman, V., Cheng, K.: Commodities boom, riding a wave. Finance Dev. 45(1), 10–15 (2008)

Hitzhusen, F., Jeanty, P.W.: Inventory and Economic Assessment of Ohio Biomass for Energy. Renewable Energy Conference, Piketon, Ohio (2007): McKeever, D.B.: Inventories of Woody Residues and Solid Wood Waste in the United States. USDA Forest Service, Forest Products Laboratory, Madison (2002)

Laurance, W.F.: Switch to Corn Promotes Amazon Deforestation. Science 318:1721b (2007)

Lazear, E.P.: Testimony of Edward P. Lazear Chairman, Council of Economic Advisors, before the Senate Foreign Relations Committee. http://foreign.senate.gov/testimony/2008/LazearTestimony080514a.pdf (2008). Accessed 14 May 2008

Masters, M.W.: Testimony of Michael W. Masters, Managing Member/Portfolio Manager, Masters Capital Management, LLC, before the Committee on Homeland Security and Governmental Affairs, United States Senate. http://hsgac.senate.gov/public/files/052008Masters.pdf(accessedJuly2008) (2008). Accessed 20 May 2008

McKeever, D.B.: Inventories of Woody Residues and Solid Wood Waste in the United States. USDA Forest Service, Forest Products Laboratory (2002)

New Jersey Energy Master Plan: http://nj.gov/emp/docs/pdf/2011FinalEnergyMasterPlan.pdf (2011)

New Jersey Clean Energy Program: http://www.njcleanenergy.com/files/file/Library/2012%20Final%20Budget%20Order%2012-14-11.pdf (2012)

Pennsylvania Biomass Working Group: Pennsylvania Biomass Assessment. http://www.pabiomass.org/inventory.html (2008). Accessed 7 Nov 2008

Sherman, A.R., Montpelier, V.: Vermont Wood Fuel Supply Study: An Examination of the Availability and Reliability of Wood Fuel for Biomass Energy in Vermont. Biomass Energy Resource Center, Montpelier (2007)

Slade, R., Saunders, R., Gross, R., Bauen, A.: Energy from biomass: the size of the global resource. Imperial College Centre for Energy Policy and Technology and UK Energy Research Centre, London. www.ukerc.ac.uk/support/tiki-downloadfile.php (2011).

Smith, B.W., Patrick D.M., John S.V., Scott A.P.: Forest Resources of the United States. General Technical Report NC-241, Forest Service, North Central Research Station, St. Paul, MN: USDA, 2003

State of New Jersey: http://www.state.nj.us/infobank/circular/eojsc54.htm (2007)

The World Bank: Addressing the Food Crisis: The Need for Rapid and Coordinated Action, 2008

U.S. Department of Energy: Roadmap for Agriculture Biomass Feedstock Supply in the United States. U.S. Dept. of Energy, Washington, DC (2003)

United States Department of Agriculture and the United States Department of Energy: Biomass as feedstock for a bioenergy and bioproducts industry: the technical feasibility of a billion-ton annual supply. http://www.osti.gov/bridge (2005)

U.S. Department of Energy, Energy information administration. Available at: http://www.eia.gov/renewable/state/newjersey/ (viewed October, 2012)

U.S. Department of Energy, Energy Information Administration: http://www.eia.gov/renewable/state/newjersey/pdf/newjersey.pdf (2012)

U.S. Department of Energy, Energy Information Administration: http://www.eia.gov/renewable/state/ (2012)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this paper

Cite this paper

Brennan-Tonetta, M., Hochman, G., Schilling, B. (2014). Impact of Political Economy and Logistical Constraints on Assessments of Biomass Energy Potential: New Jersey as a Case Study. In: Pinto, A., Zilberman, D. (eds) Modeling, Dynamics, Optimization and Bioeconomics I. Springer Proceedings in Mathematics & Statistics, vol 73. Springer, Cham. https://doi.org/10.1007/978-3-319-04849-9_8

Download citation

DOI: https://doi.org/10.1007/978-3-319-04849-9_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-04848-2

Online ISBN: 978-3-319-04849-9

eBook Packages: Mathematics and StatisticsMathematics and Statistics (R0)