Abstract

This chapter studies sedimentation of suspensions treated as continuous media. Sedimentation processes are studied from two perspectives; a discrete approach and a continuum approach, in which dynamic processes are established. This chapter uses the continuum approach and presents the concept of an ideal suspension and an ideal thickener. Suspensions described by solid concentration, solid component velocity and fluid component velocity constitute the sedimentation process provided they obey the mass conservation equations. Sedimentation can be performed in batches or continuously. Batch sedimentation is studied first and the Modes of batch sedimentation are established. These observations are extended to continuous processes. Finally the capacity of an ideal continuous thickener is derived. Kynch sedimentation theory, besides correctly describing the behavior of incompressible suspensions, forms part of the more general theory of compressible materials. The exercise of constructing solutions to Kynch sedimentation processes allows for a better understanding of the sedimentation of compressible pulps. Anyone wanting to understand the phenomenological theory of sedimentation must first master Kynch sedimentation processes.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

To have the ability to predict the different modes particle will settle from a suspension under the effect of gravity, sedimentation processes must be studied from a fundamental point of view. We have seen in previous chapters that particulate systems can be viewed from two different approaches. Chapter 4 analyzes sedimentation with a discrete approach, in which the laws of mechanics are applied to individual particles in the system. Discrete sedimentation has been successful to establish constitutive equations for the sedimentation properties of a certain particulate material in a given fluid. Nevertheless, to analyze a sedimentation process and to obtain behavioral pattern permitting the prediction of capacities and equipment design procedures, the continuum approach must be used. The theory we present in this chapter uses this approach and is based on the works of Kynch (1952) and those of Concha and Bustos (1991) and Bustos et al. (1999).

5.1 Concepts of an Ideal Suspension and an Ideal Thickener

Consider a mixture of solid particles in a fluid contained in a vessel, and assume that the suspension satisfies all the requirements to be considered a super-imposed continuous media. The assumptions are:

-

1.

All solid particles are of the same size, form and density and are small with respect to the vessel in which they are contained.

-

2.

The solid and the fluid are incompressible.

-

3.

There is no mass transport between solid and the fluid.

-

4.

The solid–fluid relative velocity in the mixture is a function of the solid concentration only.

-

5.

The solid concentration is the same in all cross-sections of the vessel.

Assumption 1, together with assumption 3, allows establishing a unique settling velocity to all particles; Assumption 2 establishes constant material densities for the suspension components; Assumption 4, key to Kynch’s theory, is a constitutive assumption for the settling velocity that makes unnecessary the use of the momentum balances.

Mixtures fulfilling assumptions 1–4, receive the name of ideal suspension (Shannon and Tory 1966; Bustos and Concha 1988; Concha and Bustos 1992) and may be considered a superposition of two continuous medium. The ideal suspension is a model of great utility. It has, in mechanics, a similar connotation that the ideal gas has in thermodynamics. The ideal suspension does not exist really, but many materials behave as ideal suspensions in certain special cases. The Theory of Mixtures predicts the behavior of an ideal suspension that describes, with good approximation, the settling of a suspension of small glass beads (Shannon and Tory 1966; Davies et al. 1991), the sedimentation of un-flocculated copper concentrates and diluted un-flocculated flotation tailings of many metallic and non-metallic ores (Concha 2001).

In general, the solid concentration of a suspension is function of the three dimensions of space, but assumption 4 allows describing the suspension with one space dimension only, that is, the concentration depends on one space dimension and on time. This assumption defines the concept of and ideal thickener as a vessel with no wall effect (Shannon and Tory 1966; Bustos et al. 1990a; Concha and Bustos 1992), where the feed, the underflow and the overflow are represented as surface sources or surface sinks.

All models related to sedimentation use the concept of ideal thickener, irrespectively if they use ideal or real suspensions. The reason for this is that the modeling of thickeners feed and discharge mechanism, including the rakes, are to complicated and, that in spite of that, measurements (Becker 1982) have shown that concentration distribution in an industrial thickener is approximately one-dimensional. See Fig. 5.1.

Concentration distribution in an industrial thickener treating copper tailings (Becker 1982)

5.2 Field Equations

Sedimentation of an ideal suspension may be described by the following field variables: (1) the solid concentration, as volume fraction of solids, \( \varphi (z,t) \), (2) the solid component velocity \( {\varvec{v}}_{{\varvec{s}}} (\varphi) \) and (3) the fluid component velocity \( {\varvec{v}}_{{\varvec{f}}} (\varphi) \). These field variables must obey the mass conservation equations (3.34) and (3.35) :

where \( {\varvec{q}}(\varphi, t) \) is the volume average velocity.

Solutions to these conservation equations are generally discontinuous. This means that discontinuities may appear in the suspension and that Eqs. (5.1) and (5.2) are valid only in those regions where the variables are continuous. At discontinuities they must be replaced by the mass jump conditions [Eq. (3.38)]:

where \( \sigma \) is the rate of propagation of the discontinuity in the direction normal to the discontinuity surface and \( \left[ \circ \right] \) is the difference of value of the variable at each side of the discontinuity.

If the sedimentation vessel is an ideal thickener, all equations reduce to one space dimension, then:

where \( u = v_{s} - v_{f} \) is the relative solid fluid velocity.

Define the new variable solid flux density by the product of the velocity \( v_{s} \) and concentration \( \varphi \), that is, \( f(\varphi ) = \varphi v_{s} (\varphi ) \). In terms of the solid flux density the field equations, for regions where the variables are continuous are:

and at discontinuities:

where \( f = q\varphi + \varphi (1 - \varphi )u. \)

Since discontinuities imply non-uniqueness in the solution, a certain criterion should be used to select the admissible solutions. One of these criteria is Lax entropy condition (Bustos and Concha 1988):

5.2.1 Batch and Continuous Sedimentation

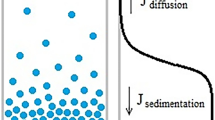

Sedimentation can be performed in a batch or continuous manner. Batch sedimentation is usually used in the laboratory. The suspension is introduced in a graduate cylinder with closed bottom, see Fig. 5.2a. The suspension is allowed to settle under the effect of gravity and the water-suspension interface is recorded as a function of time. The ideal thickener, for the batch case, is called settling column and is depicted in Fig. 5.2b.

If a pulp of solid volume fraction \( \varphi_{0} \) is introduced in a column of volume \( V = A \times L \), where A is the column cross-section and L the suspension height, the total solid mass M and solid volume per unit area W in the column are:

Continuous sedimentation is performed in a cylindrical vessel called continuous thickener, with a feedwell at the top and rakes at the bottom of the tank. Figure 5.3 represents a schematic view of the original Dorr thickener.

A volume feed rate \( Q_{F} (t) \) with concentration \( \varphi_{F} (t) \) enters through the feedwell and an underflow rate \( Q_{D} (t) \) with concentration \( \varphi_{D} (t) \) leaves the thickener at the bottom and center of the tank. At the top and periphery of the tank clear water leaves through the overflow launder at volume flowrate of \( Q_{O} (t) \).

The solid volume flux in and out of the thickener are given by \( F = Q_{F} \varphi_{F} \;{\text{and}}\; \, D = Q_{D} \varphi_{D} \). The ratio of the solid volume flux to the thickener cross section S is the solid volume flux density, or just solid flux density, so that the solid feed and underflow flux densities are:

The volume average velocity q of the pulp is:

A macroscopic balance in the thickener at steady state gives:

5.3 Batch Kynch Sedimentation Process

When an ideal suspension settles under the effect of gravity in a settling column, the following steps can be distinguished:

-

(a)

Before settling begins, the suspension is homogenized by agitation obtaining a suspension of constant concentration.

-

(b)

When sedimentation starts, all particles settle at the same velocity forming a water-suspension interface that moves at the velocity of the solid particles. This step is called hindered settling because the presence of other particles hinders the settling of an individual particle. See Fig. 5.4. There are special cases, noted by Bürger and Tory (2000), where during a short time not all particles settle at the same velocity.

-

(c)

Particles that reach the bottom of the column very rapidly cover the whole column cross sectional area. This material, with concentration \( \varphi_{\infty } \), is called sediment. The particles in the sediment start piling up moving the interface between the sediment and the suspension at a constant characteristic upward velocity. See Fig. 5.4.

-

(d)

At a given time \( t = t_{c} \), called critical time, the interface water-suspension meets with the interface sediment-suspension at a critical height \( z = z_{c} \). These coordinate \( \left( {z_{c} ,t_{c} } \right) \) define the critical point were sedimentation ends.

Based on the description of batch sedimentation, we can add the following assumptions to the 5 general assumptions given at the beginning:

-

1.

There is no inflow or outflow of suspension from the settling column, therefore the volume average velocity q = 0.

-

2.

The suspension has an initial constant concentration \( \varphi_{0} \).

-

3.

The final sediment concentration is \( \varphi_{\infty } \).

Under these addition assumptions, Eqs. (5.4) and (5.5) may be written, for regions where the variables are continuous, in the form:

where \( f_{bk} \) is called Kynch batch flux density function and is a constitutive equation to be determined experimentally.

At discontinuities Eq. (5.14) is not satisfied and is replaced by the Rankin-Hugoniot condition (Bustos and Concha 1988; Concha and Bustos 1991):

However, discontinuous solutions, satisfying (5.14) at points of continuity and (5.16) at discontinuities, are in general not unique, therefore an additional criterion, or entropy principle, is necessary to select the physically relevant discontinuous solution. This solution is called entropy weak solution.

One of these entropy criteria is the Oleinik jump entropy condition, requiring that:

An interpretation of this entropy condition indicates that (5.17) is satisfied if, and only if, in a \( f_{bk} (\varphi )\;{\text{versus}}\;\varphi \) plot, the chord joining the point \( \left( {\varphi^{+},\,f_{bk} (\varphi^{ + } )} \right) \) and \( \left( {\varphi^{ - } ,\,f_{bk} (\varphi^{ - } )} \right) \) remains above the curve \( f_{bk} (\varphi ) \) for \( \varphi^{ + } < \varphi^{ - } \) and below the curve \( f_{bk} (\varphi ) \) for \( \varphi^{ + } > \varphi^{ - } \). See Fig. 5.5.

Discontinuities satisfying (5.16) and (5.17) are called shocks. If, in addition,

are satisfied, the discontinuity is called contact discontinuity.

Initial and boundary conditions for the conservation law expressed by Eqs. (5.14) to (5.17) are:

where concentrations \( \varphi_{L} ,\;\varphi_{0} \;y\,\varphi_{\infty } \) are all constant. Kynch batch flux-density functions should obey the following conditions:

Equations (5.14)–(5.21) form an initial-boundary value problem called Batch Kynch Sedimentation Process (BKSP) (Bustos and Concha 1988).

5.3.1 Solution to the Batch Kynch Sedimentation Process

Equation (5.14) may be written in the form:

Since \( f_{bk} (0) = f_{bk} (\varphi_{\infty } ) = 0 \), initial and boundary conditions (5.19) and (5.20) may be written as initial conditions only:

Summarizing, we can state that sedimentation of ideal suspensions may be represented by the volume fraction of solids \( \varphi (z,t) \) and the Kynch batch flux density function \( f_{bk} (\varphi ) \). These two functions constitute a BKSP if, in the region of space \( 0 \le z \le L \) and time \( t > 0 \), they obey Eq. (5.22) where variables are continuos and Eqs. (5.16) and (5.17) at discontinuities. Additionally they must satisfy the initial conditions (5.23).

-

(a)

Solution by the method of characteristics

Written in this form, a BKSP can be treated as an initial value problem and may be solved by the method of characteristics for constant initial values. According to Courant and Hilbert (1963), straight lines, called characteristics can be drawn in the \( \left( {z,t} \right) \) plane, where Eq. (5.22) is valid. These lines obey the following conditions:

Here \( {{dz(\varphi ,t)} / {dt}} \) represents the propagation velocity of concentration waves of constant value \( \varphi \) in the (z,t) domain. Since \( \varphi \) is constant along these lines, \( f_{bk}^{\prime } (\varphi ) \) is also constant and the characteristics are straight lines.

As an example, take the case with initial concentration \( \varphi_{0} < \varphi_{\infty }^{**} \), where \( \varphi_{\infty }^{**} \) is the point where a tangent drawn from point \( \left( {\varphi_{\infty } ,\,f_{bk} (\varphi_{\infty } )} \right) \) cuts Kynch flux density curve. See Fig. 5.6. Since the initial values for \( z < 0 \), \( 0 \le z \le L \) and \( z > L \) are constant, characteristic starting from the ordinate axis are parallel straight lines with slope given by \( f_{bk}^{\prime} (0),\;f_{bk}^{\prime} (\varphi_{0} )\;{\text{and}}\;f_{bk}^{\prime} (\varphi_{\infty } ) \) respectively. On the other hand, we can see that \( f_{bk}^{\prime} (0),\;f_{bk}^{\prime} (\varphi_{0} )\;{\text{ and}}\;f_{bk}^{\prime} (\varphi_{\infty } ) \) are lines tangent to Kynch flux density curve at \( \varphi = 0 ,\; \, \varphi = \varphi_{0} \) and \( \varphi = \varphi_{\infty } \). Where these lines intersect, the solution is no longer unique and discontinuities, with slope \( \sigma \left( {0,\varphi_{0} } \right) \) and \( \sigma \left( {0,\varphi_{\infty } } \right) \), are formed in the form of cords drawn from \( \left( {0,\,f_{bk} (0)} \right)\;{\text{ to}}\; \, \left( {\varphi_{0} ,\,f_{bk} (\varphi_{0} )} \right) \) and \( \left( {\varphi_{0} ,\,f_{bk} (\varphi_{0} )} \right) \, \;{\text{to}}\; \, \left( {\varphi_{\infty } ,\,f_{bk} (\varphi_{\infty } )} \right) \) respectively. See Fig. 5.6.

-

Modes of Sedimentation

In his work Kynch (1952) mentioned modes of sedimentation as manners in which a suspension may settle, but without giving a specific meaning to them. Precise description of this concept was given by Bustos and Concha (1988) and Concha and Bustos (1991) who defined Modes of Batch Sedimentation (MBS) as the different possible BKSP, that is, as the possible entropy weak solutions to the batch sedimentation problem that can be constructed for a given initial data and Kynch flux density function. There are 7 MBS for Kynch flux density functions with at most two inflection points (Bustos et al. 1999).

The type of MBS depends on how the zones of constant concentration \( \varphi_{0} \;{\text{ and}}\; \, \varphi_{\infty } \) are separated after sedimentation is complete. Figures 5.7 and 5.8 show the 7 Modes of Batch Sedimentation, including the flux density function, settling plot and concentration profile.

-

MBS-1 A shock. The supernatant-suspension and the suspension sediment are both shocks meeting at the critical time \( t_{c} \). See Fig. 5.7a.

-

MBS-2 The rising shock is replaced, from bottom to top, by a contact discontinuity followed by a rarefaction wave. This MBS can occur only with a Kynch Batch flux density function with one inflection point. See Fig. 5.7b.

-

MBS-3 A rarefaction wave. In this case no cord can be drawn from \( \left( {\varphi_{0} ,\,f_{bk}^{\prime} (\varphi_{0} )} \right) \) to \( \left( {\varphi_{0}^{*} ,\,f_{bk}^{\prime} (\varphi_{0}^{*} )} \right) \) and the contact discontinuity becomes a line of continuity. This MBS can occur only with a Kynch Batch flux density function with one inflection point. See Fig. 5.7c.

-

MBS-4 Two contact discontinuities separated by a rarefaction wave. See Fig. 5.8a.

-

MBS-5 One rarefaction wave followed by a contact discontinuity. See Fig. 5.8b.

-

MBS-6 One rarefaction wave followed by a convex shock. This mode occurs if the inflection points a and b are on the left of the minimum in Kynch flux density curve and the tangency point \( \left( {\varphi_{t} ,\,f_{bk} (\varphi_{t} )} \right) \) of a line drawn from \( \left( {0,\,f_{bk} (0)} \right) \) to the Kynch flux density curve is in the range \( a < \varphi_{t} < b \), and the initial concentration is in the interval \( \varphi_{t} < \varphi_{0} < b \). See Fig. 5.8c.

-

MBS-7 One shock followed by a contact discontinuity and a curved shock. This mode occurs if the inflection points a and b are on the left of the minimum in Kynch flux density curve and the tangency point \( \left( {\varphi_{t} ,\,f_{bk} (\varphi_{t} )} \right) \) of a line drawn from \( \left( {0,\,f_{bk} (0)} \right) \) to the Kynch flux density curve is in the range \( a < \varphi_{t} < b \), and the initial concentration is \( \varphi_{0} > b \). See Fig. 5.8d.

In all cases independently of the type of MSB, the final state is a sediment of concentration \( \varphi_{\infty } \). The height of the sediment is given by a mass balance as:

5.4 Continuous Kynch Sedimentation Process

Figure 5.9 shows a continuous thickener showing the feedwell and rakes.

It has been established that four zones exists in a continuous thickener.

-

Zone I.

Zone I correspond to clear water, which is located in the region above and outside the feed well

-

Zone II.

Below the clear water zone a region of constant concentration forms. This zone is called hindered settling zone and has a concentration called conjugate concentration.

-

Zone III.

Under the hindered settling zone, a transition zone takes the conjugate concentration to the sediment concentration. This can happen through a shock wave, a rarefaction wave or a combination of them.

-

Zone IV.

Finally, we have the sediment zone, a zone of constant and final concentration (Fig. 5.10).

5.4.1 Solution to the Continuous Kynch Sedimentation Process

Based on the description of continuous sedimentation, we can add the following assumptions to the 5 general assumptions given at the beginning:

-

1.

The outflow velocity of suspension from the ideal thickener is \( q(t) = Q_{D} (t)/S \).

-

2.

The suspension has an initialconcentration distribution \( \varphi_{I} \left( z \right) \).

-

3.

Solids never enter zone I, that is, the domain of the solution is \( 0 \le z \le L \), where \( L \) is the base of the feedwell.

Under these additional assumptions, Eqs. (5.4) and (5.5) may be written, for regions where the variables are continuous, in the form:

and (5.5) for discontinuities:

The jump condition must satisfy Oleinik jump entropy condition:

Summarizing, we can state that the continuous sedimentation of ideal suspensions in an ideal thickener may be represented by the volume fraction of solids \( \varphi (z,t) \), the volume average velocity \( q(z,t) \) and the continuous Kynch flux density function \( f_{k} (\varphi ) \). These functions constitute a Continuous Kynch Sedimentation Process (CKSP) if, in the region of space \( 0 \le z \le L \) and time \( t > 0 \) where the variables are continuous, the obey Eqs. (5.26) and (5.27), and at discontinuities they obey Eqs. (5.28) and (5.29).

-

Solution by the Method of Characteristics

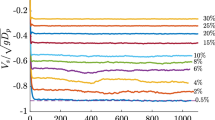

In the majority of cases, Kynch batch flux density functions are functions with one infection point only at \( \varphi_{a} \). If \( \varphi_{\infty } \) is the concentration at the end of the sedimentation process, the Kynch flux density function must obey the following properties. See Fig. 5.11.

Equation (5.27) shows that \( q = q(t) \) is independent of the z coordinate. In the rest of this work we will assume that q is a constant independent of time (steady state).

Solutions to the CKSP are straight lines, called characteristics, drawn in the \( \left( {z,t} \right) \) plane, where Eq. (5.26) is valid. These lines obey the following conditions:

Here \( {{dz(\varphi ,t)} /{dt}} = f_{k}^{\prime} \left( \varphi \right) \) represents the propagation velocity of concentration waves of constant value \( \varphi \).

-

Modes of continuous sedimentation

Mode of Continuous Sedimentation (MCS) are the different possible CKSP, that is, the possible entropy weak solutions to the continuous sedimentation problem that can be constructed for a given initial data and Kynch flux density function (Bustos et al. 1999). Since these MSC depend entirely on the Kynch flux density function and on the initial conditions, it is necessary to choose these material properties and conditions.

We will consider the following initial conditions:

From Eq. (5.27), the value of \( \varphi_{L} \) is obtained by solving the implicit equation:

where \( f_{F} \) is the feed solid flux density function. In case Eq. (5.36) admits more than one solution \( \varphi_{L} \), the relevant one is selected by the physical argument that the feed suspension is always diluted on entering the thickener, as shown by Comings et al. (1954).

For a Kynch flux density function with one inflection point, the important parameters are shown in Figs. 5.12 and 5.13 for two values of the volume average velocity q.

The type of MCS depends on how the zones of constant concentration \( \varphi_{0} \, \;{\text{and }}\;\varphi_{\infty } \) are separated after sedimentation is complete. Three MCS exist for a flux density function with one infection point (Concha and Bustos 1992).

-

MCS-1 A shock separating two zones of continuous sedimentation \( \varphi_{L} \;{\text{ and }}\;\varphi_{\infty } \). See Fig. 5.14a.

-

MCS-2 A contact discontinuity separating two zones of continuous sedimentation \( \varphi_{L} \, \;{\text{and}}\; \, \varphi_{\infty } \). See Fig. 5.14b.

-

MCS-3 A rarefaction wave separating two zones of continuous sedimentation \( \varphi_{L} \, \;{\text{and}}\; \, \varphi_{\infty } \). See Fig. 5.14c.

The fact that the exact location and propagation speed of the sediment-suspension interface level is always known, permits to formulate a simple control model for the transient continuous sedimentation. It can be shown (Bustos et al. 1990b) that the steady state corresponding to an MCS-1 can always be recovered after a perturbation of the feed flux density by solving two initial-boundary value problems at known times and with parameters \( q \, \;{\text{and}}\; \, \varphi_{L} \) that can be calculate a priori. See Fig. 5.15.

Control of continuous sedimentation after Bustos et al. (1990b)

5.4.2 Steady State of an Ideal Continuous Thickener

In MCS-1 and MCS-2 the thickener overflows, empty or attain a steady state, while in MCS-3 no steady state can be attained:

-

(a)

A MCS-1 can reach a steady state if \( f_{k}^{\prime} \left( \infty \right) > 0\;{\text{and}}\;\varphi_{L} = \varphi_{s} \), where \( \varphi_{s} \) is defined in Fig. 5.12. See Fig. 5.16.

-

(b)

A MCS-2 can reach a steady state if \( f_{k}^{\prime} \left( {\varphi_{\infty } } \right) < 0\;{\text{ and}}\; \, \varphi_{L} = \varphi_{M}^{**} \), so that \( \sigma \left( {\varphi_{L} ,\varphi_{L}^{*} } \right) = f_{k}^{\prime} \left( {\varphi_{M} } \right) = 0 \) and a contact horizontal discontinuity forms. \( \varphi_{M} \) corresponds to the concentrations of the maximum point in the flux density curve and \( \varphi_{M}^{**} \) to its conjugate concentration. See Fig. 5.17.

-

Capacity of an Ideal Continuos Thickener

At steady state, from Eq. (5.26):

with boundary conditions \( z = 0,\;f_{k} (\varphi (0)) = q\varphi_{D} ,\;z = L,\;f_{k} (\varphi (L)) = f_{F} \), where \( f_{F} \) is the feed flux density function. Then,

Substituting (5.39) into (5.40) yields:

Since the mass flow to the thickener is \( F = \rho_{s} Q_{F} \varphi_{F} \) and the solid flux density is defined by \( f_{F} = - Q_{F} \varphi_{F} /S \), we can write:

Defining the Unit Area \( UA = S/F \), where S is the thickener cross sectional area:

Replacing this expression into Eq. (5.40) yields an equation for the Unit Area.

We have seen that for a MCS-1 at steady state, \( \varphi_{L} = \varphi_{s} \;{\text{and}}\;\varphi_{D} = \varphi_{\infty } \), then from (5.43):

and for a MCS-2, \( \varphi_{L} = \varphi_{M}^{**} \;{\text{and}}\;\varphi_{D} = \varphi_{M} \), then from (5.43):

Kynch sedimentation theory, besides describing correctly the behavior of incompressible suspensions, forms part of the more general theory of compressible materials. The exercise of constructing global weak solutions to Kynch Sedimentation Processes in graphical form, allows a better understanding of the sedimentation of compressible pulps. Every person willing to understand the phenomenological theory of sedimentation must first master Kynch Sedimentation Processes.

References

Becker, R. (1982). Continuous thickening, design and simulation, Eng. Thesis, University of Concepcion, Chile (in Spanish).

Bürger, R., & Tory, E. M. (2000). On upper rarefaction waves in batch settling. Powder Technology, 108, 74–87.

Bustos, M. C., & Concha, F. (1988). On the construction of global weak solutions in the Kynch theory of sedimentation. Mathematical Methods in the Applied Sciences, 10, 245–264.

Bustos, M. C., Concha, F., & Wendland, W. (1990a). Global weak solutions to the problem of continuous sedimentation of an ideal suspension. Mathematical Methods in the Applied Sciences, 13, 1–22.

Bustos, M. C., Paiva, F., & Wendland, W. (1990b). Control of continuous sedimentation of ideal suspensions as an initial and boundary value problem. Mathematical Methods in the Applied Sciences, 12, 533–548.

Bustos, M. C., Concha, F., Bürger, R., & Tory, E. M. (1999). Sedimentation and thickening: Phenomenological foundation and mathematical theory (pp. 111–148). Dordrecht: Kluwer Academic Publishers.

Comings, E. W., Pruiss, C. E., & De Bord, C. (1954). Countinuous settling and thickening. Industrial and Engineering Chemistry Process Design and Development, 46, 1164–1172.

Concha, F. (2001). Filtration and separatilon manual, Ed. Red Cettec, Concepción, Chile.

Concha, F., & Bustos, M. C. (1991). Settling velocities of particulate systems, 6. Kynch sedimentation processes: Batch settling. International Journal of Mineral Processing, 32, 193–212.

Concha, F., & Bustos, M. C. (1992). Settling velocities of particulate systems, 7. Kynch sedimentation processes: Continuous thickening. International Journal of Mineral Processing, 34, 33–51.

Courant, R., & Hilbert, D. (1963). Methods of mathematical physics (Vol. 2), Interscience. New York, p. 830.

Davies, K. E., Russel, W. B., & Glantschnig, W. J. (1991). Settling suspensions of colloidal silica: Observations and X-ray measurements. Journal of the Chemical Society, Faraday Transactions, 87, 411–424.

Kynch, G. J. (1952). A theory of sedimentation. Transactions of the Faraday Society, 48, 166–176.

Shannon, P. T., & Tory, E. M. (1966). The analysis of continuous thickening. Society of Mining Engineers of AIME, 2, p. 1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Concha A., F. (2014). Kynch Theory of Sedimentation. In: Solid-Liquid Separation in the Mining Industry. Fluid Mechanics and Its Applications, vol 105. Springer, Cham. https://doi.org/10.1007/978-3-319-02484-4_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-02484-4_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-02483-7

Online ISBN: 978-3-319-02484-4

eBook Packages: EngineeringEngineering (R0)