Abstract

This paper investigates the feature attribution in remaining useful life (RUL) prediction model of cryogenic ball bearing. The RUL prediction model is constructed based on artificial neural network (ANN) by using the TensorFlow platform for training the degradation curve of bearing. To train the models, 5 run-to-failure (RTF) data of cryogenic ball bearings were used. The experiment was driven to 3,600rpm with 20kN axial load and 2.5kN radial load for accelerated life test (ALT) of bearing. 6 sensor data (motor input current, bearing outer race torque, test bearing temperature, and support bearing top and bottom temperature) were used in each case. Before training, min-max scaler was used to avoid biased toward a specific range of values. The model has 3 hidden layers with 0.25 dropout for each. Mean absolute percentage error (MAPE) and Root mean square error (RMSE) were used for evaluating the model. By applying SHapley Additive exPlanations (SHAP), it was confirmed that the current is the most attributing feature for the RUL prediction model, then the torque. Temperature also attributes to the model in order of distance away from the test bearing.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Bearing is one of the most basic mechanical elements, with 45% of total equipment failures [1]. Accordingly, research in the diagnosis and prediction of bearings’ failure through machine learning is being actively conducted for equipment maintenance. Most studies use vibration data for ordinary bearings [2], so these have a limitation that cannot be immediately applied to bearings with special driving conditions. Ding et al. [3] demonstrated the effectiveness of using multiple sensors measuring vibration, torque, and temperature for predicting the degradation of slewing bearing which extremely low rotational speed with heavy load. In the case of ball bearings in cryogenic environment, solid lubricants are used in the cryogenic ball bearing cage instead of the oil or grease that are typically used to lubricate ordinary ball bearings. Kwak et al. [4] proposed a friction model that incorporates the hydrodynamic effect of cryogenic fluids, which showed a significant difference compared to existing models that did not consider such effects. As the instability of the ball bearings’ cage is a major cause of bearing damage [5], Choe et al. [6] investigated the effect of different cage clearances and rotation speeds on the cryogenic ball bearing cage’s dynamic behavior, which the design parameters are significantly different compared to ordinary bearings. Furthermore, considering the experiment by Yang et al. [7] which showed that combining temperature and vibration signals can highly suspect ball bearing failure due to cage damage, it is expected that thermal signals may have different feature importance in revealing degradation of cryogenic ball bearings compared to ordinary bearings.

It is possible to construct a practical life prediction model for cryogenic ball bearing when the features that reflect the characteristics of the bearing are learned. However, cryogenic ball bearings are difficult to obtain a sufficient amount of data due to the large time and cost of data acquisition. So it is difficult to define the data to be acquired for building fault diagnosis and life prediction models except for the bearing experts. Therefore, this study evaluates the features attribution for predicting remaining useful life (RUL) of cryogenic ball bearings. Run-to-failure (RTF) data were obtained from the reliability evaluation experiment of the bearing used for constructing the RUL model. The feature rankings will be discussed for predicting RUL of cryogenic ball bearing.

2 Feature Evaluation Process

2.1 Experimental Setup

Figure 1a shows the cryogenic ball bearing test rig [8], which has the form of a piping and instrumentation diagram (P&ID) as shown in Fig. 2 [9]. Each Pneumatic cylinder is installed at the upper and center adjust constant loads in axial and radial direction. A cryogenic environment can be simulated by filling the chamber with liquid nitrogen (LN2). The bearing of RTF data is a deep groove ball bearing (model 6314) for cryogenic use. It consists cage made of PTFE and others are SUS440C with satisfying the same precision class 5 according to the ISO(International Standards Organization) standard 492, internal clearance grade C4 (Fig. 1b) [6]. Axial and radial loads are measured by load cells (SLS-2T, curiosity technology, Korea). The LN2’s inlet mass flowrate is measured by Coriolis-type mass flow meter (CMF025M, Emerson Electric, USA), and the LN2 inlet, outlet and chamber pressure is measured by pressure transmitter (A-10, WICA, Korea). To measure the test bearing’s outer race temperature, support bearing top and bottom temperature, K-type thermocouples are applied. Current data is acquired from inverter (SOHO55VD4Y, Seoho Electric, Korea) analog output port. Bearing torque is obtained through a load cell (DBCM-30, Bongshin, Korea) with the same principle as [6]. All data was collected by DAQ (NI-9215, National Instruments, USA) with a sampling of 1.

The experiment was conducted under the condition of a constant load of 20 kN in the axial direction and 2.5 kN in the radial direction with 3,600 rpm. RTF data was collected from 5 bearings for each, and the failure threshold was set based on a microphone sensor and the characteristic frequency [10]. After the experiment, a spall on the outer race can be seen, as shown in the red box of Fig. 1c.

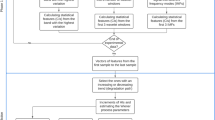

2.2 Model Definition

Artificial neural network (ANN) was applied for RUL prediction with TensorFlow platform and Python (Fig. 2). The model consist of three hidden layers with rectified linear unity (ReLU) activations function. The ReLU function is defined such that it outputs 0 for input values less than 0, and for input values greater than or equal to 0, the output is equal to the input value. The ReLU function is as follows:

The function h(x) in the above equation represents the ReLU function, and x represents the input value. Additionally, to prevent overfitting, 25% dropout is applied between each layers of the ANN model. The specification of constructed model is shown in Table 1, and the output value of a node in a layer is expressed as follows:

Here, \({x}_{i}\) is the i-th input value, \({w}_{ij}\) is the weight between the i-th input value and the j-th hidden layer, \({b}_{i}\) is the bias of the i-th hidden layer, h is the activation function (ReLU), and \({y}_{out}\) represents the output value of the i-th hidden layer.

To build the RUL prediction model, 6 sensors’ data (motor input current, test bearing outer race temperature, outlet temperature, support bearing top/bottom temperature and test bearing torque) are used as the features as shown in Fig. 3. Min-max normalization was applied for each features to prevent from getting biased toward a specific range of values. Min-max normalization is expressed as follows:

The min-max normalization defined above was applied individually to each sensor data. In this case, the max and min values of the sensor data were extracted from the dataset used for training, and \(x^{\prime}\) represents the normalized data.

Of the 5 cases of RTF data, 4 cases were used as training data, and the remaining 1 case was used as test data for model evaluation. 20% of the training data was used as validation data. To label the RUL result for each data point, first predicting time (FPT) to the failure threshold point was divided at regular intervals. The model was trained under the conditions of 20 batch size and 100 iterations. The learning rate was 0.001 and the weight of each node was updated by applying adaptive moment estimation (Adam).

2.3 Feature Attribution

Theoretically, the more features a model learns, the higher the complexity and the better its performance. However, if it learns actual data, the adoption of too many features can increase the learning time and the performance is also reduced by the noise of data (curse of dimensionality). Therefore, SHapley Additive exPlanations (SHAP) framework [11] was used to confirm each feature attribution for RUL prediction. SHAP is a technique for evaluate the importance of feature based on Shapley value (Eq. 4). When all features sets are \(F\), a feature subset \(S\) which satisfies \(S\subseteq F\) is required in all cases. If \({f}_{S\cup \left\{i\right\}}\) is a model currently learned by feature, and \({f}_{S}\) is a model learned by suppressing the feature, the Shapley value is as follows.

3 Results

Figure 4 presents the actual and predicted RUL using the same data as in Fig. 3, which was not used for training. The FPT seems to be almost exactly defined, but it can be seen that the predicted RUL value rapidly decreases after FPT. The mean absolute percentage error (MAPE) was 5.478 and the root mean square error (RMSE) was 3.974. This model has room for improvement in terms of predictive accuracy, however, as this study focused on feature selection through feature attribution evaluation, the methods to enhance the model’s predictive accuracy were not included.

When the Shapley value is positive, it has a positive effect on deriving prediction results and vice versa for negative [11]. In the case of the RUL prediction model, where the result value decreases according to the system’s degradation, the negative value means more important feature for RUL prediction. It was confirmed that the motor’s input current is the most dominant feature in building the cryogenic ball bearing RUL prediction model (Fig. 5). Table 2 shows the minimum Shapley value for each feature (Fig. 6).

4 Discussion

Figure 4 shows the section where the prediction result changes rapidly after FPT. It is considered as lack of significant train data in the failure section due to low sampling [12]. Therefore, the sampling or sampling technique itself must be utilized for more accurate RUL prediction.

In Table 2, it can be seen that the influence of current and torque, which can immediately affected by bearing movement, were the strongest. In addition, the order of temperature attribute can be seen that the value is different depending on the distance from the data acquisition point to test bearing. The Shapley value of T.B. temp. which is measured directly by the test bearing was the highest, followed by Out. temp., the LN2 outlet from the chamber where the test bearing was installed. Then S.B-t temp., the temperature of support bearing located just below the chamber. S.B-b temp. was the last which is furthest from test bearing. In other words, there is a difference in the attribution score depending on the distance from test bearing, which can be considered as the failure didn’t arise due to other elements in test rig.

Considering that temperature showed relatively low attribution compared to current and torque, it can be inferred that features related to the mechanical properties, such as current and torque, contribute significantly to the RUL prediction of both cryogenic and ordinary ball bearings. However, in real industrial settings with high noise levels and system complexity, adding meaningful features such as T.B. temp. can be useful for enhancing the practicality of the RUL prediction model. Therefore, future research will consider the dynamics of the mechanical system affected by cryogenic ball bearings and select more sensors in proper locations. Additionally, features such as vibrations, similar to those used in [7], can be added to evaluate attribution to the model. By selecting appropriate features through further study, it will be possible to construct a more practical data-based RUL prediction model.

5 Conclusions

The study was conducted to evaluate the importance of each feature to predict RUL of the cryogenic ball bearing by comparing the Shapley value. An ANN-based RUL prediction model was constructed using RTF data of 5 cases obtained for cryogenic ball bearing reliability experiments. There are a total of 6 features used, all of which are acquired with sampling of 1. In the order of current, torque, T.B. temp., S.B-t temp., Out. temp., and S.B-b-temp. has attributed to the RUL prediction result. In particular, in the case of temperature feature, the attribution of the RUL prediction result differs depending on the physical distance from test bearing, so it can be judged that the test bearing failed due to the fault itself, rather than failure of other elements. In actual industries may produce fault signals depending on the complex relationship between each element, so the selecting data to be acquired should be in consideration of the dynamics of the system.

Abbreviations

- \(A\) :

-

Motor input current (Current)

- \({T}_{o}\) :

-

Outlet temperature (Out. temp.)

- \({\tau }_{t}\) :

-

Test bearing torque (Torque)

- \({T}_{t}\) :

-

Test bearing temperature (T.B. temp.)

- \({T}_{st}\) :

-

Support bearing top temperature (S.B-t temp.)

- \({T}_{sb}\) :

-

Support bearing bottom temperature (S.B-b temp.)

- RUL:

-

Remaining useful life

- RTF:

-

Run-to-failure

References

Zheng, Z., Wang, F., Gong, G., Yang, H., Han, D.: Intelligent technologies for construction machinery using data-driven methods. Autom. Constr. 147, 104711 (2023)

Zhang, H., et al.: An unsupervised intelligent fault diagnosis research for rotating machinery based on NND-SAM method. Meas. Sci. Technol. 34(3), 35906 (2022)

Ding, P., Wang, H., Dai, Y.: A clustering-based framework for performance degradation prediction of slewing bearing using multiple physical signals. ASCE-ASME J Risk Uncertainty Eng. Syst. Part B: Mech. Eng. 5(2), 020908 (2019)

Kwak, W., Lee, J., Lee, Y.B.: Theoretical and experimental approach to ball bearing frictional characteristics compared with cryogenic friction model and dry friction model. Mech. Syst. Signal Process. 124, 424–438 (2019)

Kannel, J.W., Snediker, D.K.: The hidden cause of bearing failure (analytical modeling for performance prediction). Mach. Des. 49, 78–82 (1977)

Choe, B., Lee, J., Jeon, D., Lee, Y.: Experimental study on dynamic behavior of ball bearing cage in cryogenic environments, part I: effects of cage guidance and pocket clearances. Mech. Syst. Signal Process. 115, 545–569 (2019)

Yang, Y., et al.: Experimental study on vibration characteristics due to cage damage of deep groove ball bearing. Tribol. Int. 185, 108555 (2023)

Lee, Y.B., Choe, B., Lee, J.K., Ryu, S.J., Lee, B.: Bearing test apparatus for testing durability of bearing. U.S. Patent No. 9714883, 201 (2017)

Kwak, W.: Failure Criteria and Life Model to Verify the Reliability of Cryogenic Rolling Bearings, pp. 70–72. Ph.D. University of Science and Technology, Daejeon, Republic of Korea (2023)

Park, J., Kim, S., Choi, J.H., Lee, S.H.: Frequency energy shift method for bearing fault prognosis using microphone sensor. Mech. Syst. Signal Process. 147, 107068 (2021)

Lundberg, S.M., Lee, S.I.: A unified approach to interpreting model predictions. In: Advances in Neural Information Processing Systems 30 (2017)

Demir, S., Mincev, K., Kok, K., Paterakis, N.G.: Data augmentation for time series regression: applying transformations, autoencoders and adversarial networks to electricity price forecasting. Appl. Energy 304, 117695 (2021)

Acknowledgments

This study was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) with the project title “Development of platform technology and operation management system for design and operating condition diagnosis of fluid machinery with variable devices based on AI/ICT” (No. 2021202080026D). The authors thank them for their contribution to this study.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

An, B., Ha, Y., Lee, Y., Kwak, W., Lee, Y. (2024). Investigation on Feature Attribution for Remaining Useful Life Prediction Model of Cryogenic Ball Bearing. In: Chu, F., Qin, Z. (eds) Proceedings of the 11th IFToMM International Conference on Rotordynamics. IFToMM 2023. Mechanisms and Machine Science, vol 139. Springer, Cham. https://doi.org/10.1007/978-3-031-40455-9_25

Download citation

DOI: https://doi.org/10.1007/978-3-031-40455-9_25

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-40454-2

Online ISBN: 978-3-031-40455-9

eBook Packages: EngineeringEngineering (R0)