Abstract

This study proposes a new modified ACI 318-08 formula based on machine learning (ML) to forecast better the compressive strength of Concrete-Filled Steel Tube (CFST) columns. The prediction ML model is established from 663 experimental samples. CFST columns’ ultimate compressive strength results show differences when comparing experiments with the current calculation formulas using the Linear Regression algorithm to modify the original ACI 318-08 formula by determining the regression coefficient or slope coefficient and the required intercept value. The prediction model with the updated ACI 318-08 formula yields a more reliable CFST column ultimate compressive strength.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- ACI 318-08

- CFST columns

- Linear regression

- Machine learning

- Ultimate compressive strength

- Structural design

1 Introduction

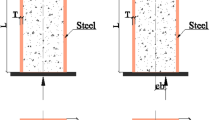

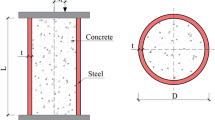

The finest Civil Engineering structures are circular Concrete-Filled Steel Tube (CFST) columns. Steel sheets, W-section steel, or tubes may support a steel–concrete composite structure. Concrete-filled or concrete-coated steel structures are linked to work.

Several studies have examined CFST columns’ advanced behavior. ACI 318-08 [1] is the most frequent country-specific standard for CFST column strength. Recently, numerous research employing ABAQUS simulation analysis software presented improved equations to compute compressed circular CFST columns, such as Nguyen et al. [2], Pham et al. [3,4,5,6] found that regular and high-strength concrete affects CFST column axial compression. Nguyen and Pham’s FEM-ABAQUS nonlinear behavior study of CFST columns yields reliable findings. Nguyen et al. [7] showed finite element software's power in parameter characteristics utilizing Ansys DesignXplorer, an integrated Ansys Workbench program. In Nguyen et al. [8] study, parametric design is used to build steel sections with strength and beauty. Industry and offshore use circular CFST columns. Tran et al. [9] analyzed an offshore wind turbine using plasticity. Kim et al. [10] built a concrete-filled double-skin steel tube column using two concentric steel pipes of various diameters (CFDST). Concrete grades and diameter/thickness ratios were evaluated. Concrete double-layer steel tube (CFDST) columns function better with an adequate inner steel tube profile ratio. Nguyen et al. [11] employed a unique fiber plastic hinge technique to examine how residual load and shear deformation affect the nonlinear inelastic behavior of 2D steel frames. These approaches are accurate and numerically stable. However, they can only be utilized for one data; hence the planned formula modification has not been done yet. Lack of coverage factor (big data fields) leads to high accuracy. With such obstacles, modern approaches have been studied. Thai [12] reviews machine learning. Jayalekshmi et al. [13] and Zarringol et al. [14] found this useful for time factor data issues with multiple mathematical models. Le et al. [15] employed several machine-learning methods to predict the CFST column's axial compressive load capability.

This research shows that linear regression can predict CFST circular column strength. ACI 318-08 formula increases the axial compressive strength of 663 circular CFST column experimental samples. [2]. The model shows a substantial disparity between observed axial compressive strength and ACI 318-08’s formula. The loop and intercept coefficients are needed to modify the original formula ACI 318-08 to produce more reliable results for CFST columns’ ultimate compressive strength.

2 ACI 318-08 Standard

The following formula determines the strength of axial compression of CFST according to the ACI 318-08 standard [1]:

where \(A_{c}\), \(A_{s}\), and \(A_{tube}\) are the cross-sectional areas of concrete, reinforced steel, and steel tube, respectively; \(f_{co}{\prime}\) is the cylindrical compressive concrete strength; \(f_{y}^{s}\) is the reinforced steel yielding stress; and \(f_{y}^{tube}\) is the steel tube yielding stress.

3 Establish a Prediction Model

3.1 Create and Review Data

The input data is the geometrical dimensions and material strength of 663 samples [2] a. CFST column compressive strength is output. Figure 1 shows a new dataset with one column of axial compressive strength obtained from Eq. (1).

Test setup of CFST columns (Su et al. [16]) and data reconstruction

The new data label in Fig. 1 shows the difference in the CFST column axial compressive strength. This research must also address this. This dataset has no noise components when summarizing the data and checking for missing data.

Next, we created prediction models using the cross-sectional geometric dimensions, concrete and steel tube strengths, and CFST columns' axial compression capacity.

3.2 Prediction Model

Section 3.1 prepares the prediction model. Cross-sectional shape and steel and concrete tube strength are inputs. The experiments and formula ACI 318-08 [1] (Ntest and N[1]) provide the CFST columns’ axial compressive strength values.

The prediction model is unchanged. The original dataset is split into 20% testing and 80% training. Figure 2 shows the axial compression strength of 663 samples after analysis from the study of Nguyen et al. [17].

Compare the value of axial compressive strength N (kN) of CFST Columns as determined by actual test (Ntest) and standard ACI 318-08 [1] (N[1])

Figure 2 shows a considerable discrepancy, requiring model change. N[1] is the ultimate strength predicted by ACI 318-08 [1] using input parameters, and Ntest is the compression strength from testing. Figure 3 illustrates calibration.

Procedure using a linear regression model to calibrate formulas to determine the axial compressive strength of 663 CFST column samples [5]

Figure 3 depicts the new ACI 318-08 formula technique. The linear regression error is high when predicting the experimental findings for CFST column ultimate strength (Ntest kN) and Eq. (1) (N[1] kN). Thus, the correlation matrix with a coefficient of 0.98 indicates that Ntest kN and N[1] kN must be considered together. Linear regression is used to create the new ACI 318-08 formula N, displayed in Fig. 3 and Eq. (2). Slope multiplies N[1] kN. The intercept coefficient is applied to minimize N[1] kN and Ntest kN error.

4 Results and Discussions

This effort shows again that machine learning can solve engineering problems by utilizing massive volumes of data. It helps [1] estimates match experimental data. Equation (1) becomes Eq. (2). The CFST column axial compression strength curve in Fig. 4 is closer to the Ntest curve than the previous one in Fig. 2.

Correcting CFST columns’ axial compressive strength using ACI 318-08 [1] fitting with experimental data

The new formula based on ACI 318-08 [1] is proposed as follows:

Some experimental specimens show contradictory projected outcomes. Unprocessed data may cause this issue. We utilize all experimental data without prejudice to demonstrate machine learning algorithms’ capability. This study's simplistic Linear Regression technique may reduce prediction accuracy.

The modified ACI 318-08 formula [Eq. (2)] is obtained by using the Linear Regression method to 663 circular CFST columns’ ultimate strength based on the previous formula and experimental testing. Figure 5 shows that the anticipated (0.965) and observed (0.961) axial compressive strength models have virtually relative standard deviation R2. The circular CFST column ultimate compressive strength prediction model is trustworthy since the standard deviation R2 for training and test data is more significant than 95%. In real structural engineering, we require dependable and accurate experimental data sets to use Machine Learning algorithms to enhance the accuracy and dependability of existing design standard formulae.

5 Conclusion

We use circular CFST columns to demonstrate that, using massive data, machine learning (ML) can anticipate structural behavior. Machine learning verifies the present formula ACI 318-08. A natural raw dataset of 663 circular CFST columns predicts their eventual strength. CFST columns’ ultimate compressive strength is inaccurately calculated using the ACI 318-08 formula. The Linear Regression technique readily innovates the ACI 318-08 formula, producing Eq. (2) with more excellent reliability [1]. Accurate prediction requires reliable specimen testing. Random Forest Regression, Support Vector Regression, K-nearest Neighbor Regression, and Artificial Neural Network may solve this prediction problem.

References

ACI 318-08: Building code requirements for structural concrete: ACI Farmington Hills, MI, USA (2014)

Nguyen P-C, Pham D, Tran T, Nghia-Nguyen T (2021) Modified numerical modeling of axially loaded concrete-filled steel circular-tube columns. Eng Technol Appl Sci Res 11(3):7094–7099

Pham D-D, Nguyen P-C, Nguyen D-L, Le H-A (2020) Simulation of concrete-filled steel box columns. In: ICSCEA 2019, Springer, pp 359–366

Pham D-D, Nguyen P-C (2020) Finite element modelling for axially loaded concrete-filled steel circular tubes. In: CIGOS 2019, innovation for sustainable infrastructure. Springer, pp 75–80

Behavior analysis and design of concrete-filled steel circular-tube short columns subjected to axial compression. arXiv preprint arXiv:2107.06488 (2021)

Pham D, Nguyen P, Le H (2019) Normal and high strength concrete-filled steel box columns under axial compression. In: Proceedings of the 17th international symposium on tubular structures, ISTS2019

Nguyen T-T, Nguyen P-C, Tran VT, Pham DD, Benabou L (2021) Reliability analysis of concrete-filled steel tube columns under axial compression. In: AIP conference proceedings. AIP Publishing LLC

Nguyen T-T, Nguyen P-C, Nguyen HTP (2023) Golden ratio application in the optimization of cold-formed steel sections. In: ICSCEA 2021. Springer, pp 837–845

Tran T-T, Hussan M, Kim D, Nguyen P-C (2020) Distributed plasticity approach for the nonlinear structural assessment of offshore wind turbine. Int J Naval Archit Ocean Eng 12:743–754

Kim S-E, Papazafeiropoulos G, Truong V-H, Nguyen P-C, Kong Z, Duong N-T, Pham V-T, Vu Q-V (2021) Finite element simulation of normal–strength CFDST members with shear connectors under bending loading. Eng Struct 238:112011

Nguyen P-C, Tran T (2021) Impacts of residual stress and shear deformation on 2D steel frames using fiber plastic hinge element: nonlinear behavior and strength. SN Appl Sci 3(7):1–22

Thai H-T (2022) Machine learning for structural engineering: a state-of-the-art review. Structures 38:448–491

Jayalekshmi S, Jegadesh J, Goel A (2018) Empirical approach for determining axial strength of circular concrete filled steel tubular columns. J Inst Eng (India): Series A 99(2):257–268

Zarringol M, Thai H-T, Thai S, Patel V (2020) Application of ANN to the design of CFST columns. Structures 28:2203–2220

Le T-T, Asteris PG, Lemonis ME (2021) Prediction of axial load capacity of rectangular concrete-filled steel tube columns using machine learning techniques. Eng Comput 1–34

Su M, Cai Y, Chen X, Young B (2020) Behaviour of concrete-filled cold-formed high strength steel circular stub columns. Thin-Walled Struct 157:107078

Nguyen T-T, Nguyen P-C (2023) K-fold cross-validation technique for predicting ultimate compressive strength of circular CFST columns, ICSCEA 2021. Springer, pp 867–874

Acknowledgements

The authors gratefully acknowledge the financial support from the Scientific Research Fund of Van Lang University, Vietnam. This research is also funded by the Ministry of Education and Training (MOET), Vietnam, under the grant number B2023–MBS–03.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Nguyen, TT., Nguyen, PC. (2023). Improving the Accuracy of ACI 318-08 Design Standard for Predicting Strength of CFST Columns Using Machine Learning. In: Long, B.T., et al. Proceedings of the 3rd Annual International Conference on Material, Machines and Methods for Sustainable Development (MMMS2022). MMMS 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-31824-5_3

Download citation

DOI: https://doi.org/10.1007/978-3-031-31824-5_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-31823-8

Online ISBN: 978-3-031-31824-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)