Abstract

In Singapore, large volumes of excavated soils from the construction industry are sustainably re-purposed in land reclamation projects as fill material. The excavated soils are trucked to Staging Ground (SGs), where they are received and categorized into two broad groups (“Good Earth” and “Soft Clay”). The soil type categorization is traditionally done using properties such as particle size distribution (PSD) and water content (w). However, due to the heterogeneity of soils and non-uniform mixing during the excavation and truck loading process, the actual excavated soils in each truckload received at the SGs may vary. As such, visual checks of each truck are presently implemented at the SGs, which is labour-intensive and can be subjective. Therefore, an objective rapid classification method is required at the SGs. This can be achieved through an innovative system using computer vision complemented by in-situ probe measurement to perform non-destructive and instantaneous soil classification on-site. An accurate classification of excavated soils is critical in maximizing the recovery and reuse of natural resources in land reclamation projects for long-term sustainability. This paper presents the assessment of rapid soil testing methods that are suitable for integration with a recently developed novel rapid soil classification using computer vision. The objective of this complementary soil parameter measurement is to enhance the soil type prediction accuracy, as well as the capability to detect soil type with depth. The methods that are deemed suitable are the four-probe soil electrical resistivity measurement, cone penetration test (CPT) and moisture content test using time-domain reflectometer (TDR).

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Computer vision technique

- Cone penetration test

- Electrical resistivity

- Rapid and non-destructive

- Soil classification

1 Introduction

1.1 Background

Staging Grounds (SGs) in Singapore performs two main roles—receiving excess excavated soil from construction sites, as well as supplying suitable fill material for land reclamation projects. Unwanted excavated soils are transported via dump trucks (Fig. 1) from construction sites to SGs located along the coast of Singapore. Subsequently, the soil is loaded onto barges and transported to land reclamation sites to be used as infill material. For proper use and appropriate treatment methods, the type of the excavated soils must be identified. With hundreds of trucks arriving at the SGs daily, SG operators are looking into ways to improve the quality of inspection and optimization of on-site operations in classifying soil received.

Excavated soils received at the SGs can be broadly classified into two groups, namely “Good Earth” and “Soft Clay”, despite the varying geologies over Singapore. Soil classification is made largely based on Particle Size Distribution (PSD) and water content. According to the SGs’ classification criteria, “Good Earth” soils contain at least 65% by weight of coarse particles (>63 μm) and water content of less than 40%. “Good Earth” soils generally have a higher percentage of coarse particles and relatively low water content.

On the other hand, soils categorized as “Soft Clay” have a higher percentage of fine particles, or a high water content, or both. These soils experience slow gain in shear strength and large settlement over time, requiring more costly ground improvement techniques to be effectively used as the infill material.

1.2 Current Classification Methods

Housing and Development Board (HDB) operates two Staging Grounds (SGs) in Singapore with daily throughput of thousands of truckloads. The current practice of soil classification primarily uses the borehole log information obtained before the excavation activities. After excavation, the excavated soil will be loaded onto trucks which were tagged with “Good Earth” (GE), or “Soft Clay” (SC) based on soil information obtained earlier. When truck arriving at the SGs, the weigh-bridge operator will perform a quick visual inspection of the soil in the truck via Closed-Circuit Television (CCTV) camera. In the case where the soil in the truck tagged with “Good Earth” label was found to have a visibly high water content, it would be downgraded to a “Soft Clay” soil.

The current practice fails to account for the highly varying geological formations in some parts of Singapore, and possible mixing of different soil types during the excavation activities on-site. Substantial amount of “Good Earth” soils may have been misclassified as “Soft Clay” soils. In this case, the relatively useful sandy soil that could have been used for revetment bunds were inefficiently utilized as general infill material, which is a waste of resources. On the other hand, there may be an occasion that “Soft Clay” was mistaken as “Good Earth” of which no treatment was conducted, which resulted in poor foundation and/or excessive settlement.

This calls for a need to improve the soil classification operation at the SGs. In addition, the current system is also very time-consuming and labour-intensive. Hence, a rapid in-situ soil classification method that is automatic, non-destructive and objective is explored for suitable use at the SGs. The research on the development of such method using non-destructive techniques was conducted on a near-full scale, and the initial version using computer vision technique was successfully developed [1].

2 Literature Review

2.1 Previous Research

In the first version of such rapid classification method, an Artificial Neural Network (ANN) model was established using back-propagation network tested with 40 soil samples collected from Tanah Merah Staging Ground (TMSG). It was found that the trained ANN model was able to differentiate between “Good Earth” and “Soft Clay” soils in less than a minute.

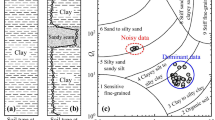

This has led to further research on using Grayscale Co-Occurrence Matrix (GLCM) textural features as inputs (Contrast, Correlation, Entropy), Generalized Delta learn rule and Sigmoid transfer function to refine the ANN model. A further 101 soil images and samples were obtained and used for training, which led to an improved version of ANN model. Comparing the predicted soil type against the actual soil type (determined by conventional laboratory testing), it was observed that the optimal improved ANN model occurs at 25,000 learning iterations with an overall prediction accuracy of 85% on the selected representative soil images (Fig. 2).

However, this current improved version of the ANN model and its associated hardware system can only capture data of the top surface of the soil mass in the truck, and does not consider the variation of soil type with depth that may be possibly present beneath the surface. This paper presents a complementary scheme, that make use of additional soil parameters determined in-situ that can complement the computer vision system to obtain a better soil classification of soil at various depth in the truck. Apparent resistivity, moisture content and CPT strength were chosen to be possible soil parameters.

2.2 Apparent Resistivity

By Ohm’ Law, the apparent resistivity of soil ρ (in a two-electrode soil box method) can be calculated based on the following Eq. (1):

where V = potential difference between two electrodes, I = current, and L and A are the length and area of the conducting cross section of soil. Wet to moist sand has a typical apparent resistivity of 20–200 Ωm, while that of clay ranges from 1 to 20 Ωm [2].

2.3 Moisture Content

Time-Domain Reflectometer (TDR) is an instrument which is capable to measure in-situ moisture content and provide results almost instantaneously. By sending out a fast-rise voltage pulse through the waveguides, wave propagation distance and speed are used to calculate the velocity of propagation, where the apparent dielectric constant can be derived. This apparent dielectric constant is subsequently used to estimate the volumetric moisture content drawn from a relationship supported by calibration data from numerous sources. A linear relationship was established, as shown in Eq. 2 [3], to relate volumetric moisture content, θv, and apparent dielectric constant, εra

2.4 Cone Penetrometer Test (CPT)

Cone penetration testing (CPT) is a common soil profiling technique and is a quick and convenient testing method that may be suitable for rapid on-site soil classification. CPT is performed by inserting a cone into the soil mass. CPT tip resistance qt is generally approximated by the cone tip resistance qc at shallow soil depth [4] where pore water pressure is ignored, which is applicable in the context of this application where the expected measuring depth is <1.5 m.

3 Methodology

3.1 Experimental Setup

A series of tests were performed to investigate the feasibility of the three soil parameter determination (apparent resistivity, moisture content, CPT strength) in classifying soils at the SGs. The experimental setup mainly consists of a near-full scale soil box with metal and plywood walls measuring 180 (L) × 1200 (W) × 1200 mm (H) (see Fig. 3), sensors (discussed in further sections), soil mass filled up to a thickness of about 1000–1200 mm thick in the soil box, and a frame with actuators to push the sensors into the soil mass.

3.2 Apparent Resistivity Using Wenner’s Array

Four electrodes were arranged with equal spacing, and current is passed through the outer two electrodes (A and B). Potential difference between the two inner electrodes (C and D) is measured (Fig. 4).

The apparent resistivity is calculated using the following Eq. 3:

where ρ = apparent resistivity (Ωm), a = electrode spacing (m), b = depth of electrode (m) and R = resistance (Ω), which is given by potential difference (∆V) divided by current (I).

3.3 Moisture Content Using TDR

The TDR sensor is inserted into the soil mass together with the other sensors. As the volumetric moisture content measured is the average value across the entire waveguide length, the value is taken to be at the mid-point of the waveguides. The volumetric moisture content is measured and stored using a commercial datalogging software.

3.4 In-House CPT Cone

CPT was performed using an in-house CPT cone, and data is captured continuously every second. The CPT cone is 40 mm in diameter with a 60° tip and a shaft of 40 mm diameter and 120 mm length. It measures both tip and shaft resistances via the installed strain gauges. The penetration rate of the CPT cone during measurement is 8 mm/s, which is much lower than the standard rate of 20 ± 5 mm/s used in field CPT test to ensure better sensitivity in a soil mass with shallow thickness in this case.

4 Results and Discussion

Five (5) number of tests were conducted for this study. The configuration of the tests is listed in Table 1.

4.1 Homogeneous Soil (Test 1 with GE and Test 2 with SC)

The apparent resistivity and moisture content with depth for Test 1 (GE) and Test 2 (SC) are plotted in Fig. 5. Soil parameter data is captured from 400 to 1200 mm depth.

Apparent resistivity is intuitively inversely proportional to moisture content, as a higher moisture content would allow more ions to carry electrical charges and conduct electricity. As the top part of soil mass is usually drier and uneven (presence of voids), apparent resistivity registered is comparatively higher.

Comparing the results of the two soil types, it can clearly be seen that GE soils have higher range of apparent resistivity and lower range of moisture content than SC soils. These range of values can be used as guiding values for distinguishing between the two.

Figure 6 shows the cone tip and shaft resistances as well as the friction ratio with depth for GE and SC. It is to be noted that shaft resistance values are much smaller than tip resistance values. Due to overburden pressure, soil at the bottom experiences greater stresses. Hence, tip resistance is found to be increasing with depth for GE, while that for SC is much less prominent, which is consistent with the understanding for sandy and clayey soils respectively. The two soil types can also be clearly distinguished from the difference in friction ratio (1% for sandy soil GE, 4–6% for clayey soil SC).

4.2 Layered Soil (Test 3 with GE-SC and Test 4 with SC-GE)

The apparent resistivity and moisture content with depth for Test 3 and Test 4 are plotted in Fig. 7, where GE-SC refers to “Good Earth” soil atop of “Soft Clay” soil, while SC-GE refers to “Soft Clay” soil atop of “Good Earth” soil.

From Fig. 7, the layering feature of the soil mass can be identified by the sudden change in resistivity and moisture content. It can be identified that GE soils show a higher range of apparent resistivity and lower range of moisture content than SC soils. For example, in SC-GE where GE soil is atop SC soil, apparent resistivity drops from 300 Ωm to less than 100 Ωm at lower depth, while the moisture content increases from ~15% at the top, to ~40% at the greater depth.

Figure 8 shows the tip and shaft resistances as well as the friction ratio with depth for Test 3 and 4. Tip resistance is found to be increasing with depth for GE (sandy soil), while that for SC (clayey soil) is much more uniform. The difference in friction ratio is also very apparent (1% for sandy soil GE, 4–8% for clayey soil SC). Again, the layering feature of soil mass can be identified from these plots.

5 Conclusion

This paper has presented the preliminary findings from the three soil parameter determination: (i) apparent resistivity, (ii) moisture content, and (iii) CPT strength with the objective of complementing the newly-developed rapid soil classification technique using computer vision to classify excavated soils into “Good Earth” or “Soft Clay”. This near-full scale proof-of-concept has shown the feasibility of the above three methods to distinguish between the two different soil types and identify certain foreign material located within the soil.

Further testing will be performed to obtain more data for calibration of models to further refine the range of soil property values for “Good Earth” and “Soft Clay” soils. An actual full-scale testing will be conducted to capture data with test dimensions that resemble actual operations at the SGs.

In future, the soil parameter determination can be combined with the existing computer vision method at the SGs to improve operational productivity, optimize use of excavated soils and contribute to the long-term sustainability for land reclamation projects and the construction industry in Singapore.

References

Aw YJE, Koh JW, Chew SH, Tan SED, Cheng LM, Yim HMA, Ang LJL, Chua KE (2020) Application of computer vision technique for rapid soil classification. In: 10th International Conference on geotechnique, construction materials and environment. Melbourne, Australia

Department of Army, U.S. Army Corps of Engineers (2015) Geophysical exploration for engineering and environmental investigations, scholar’s choice

Knappett J, Craig RF (2020) Craig’s soil mechanics. CRC Press

Topp GC, Ferré T (2005) Time-domain reflectometry. In: Encyclopedia of soils in the environment. Elsevier, pp 174–181

Acknowledgements

This research is supported by the Singapore Ministry of National Development and the National Research Foundation, Prime Minister’s Office under the Cities of Tomorrow (COT) Research Programme (COT Award No. COT-V3-2019-1). Any opinions, findings and conclusions or recommendations expressed in this paper are those of the author(s) and do not reflect the views of the Singapore Ministry of National Development and National Research Foundation, Prime Minister’s Office, Singapore.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Eugene Aw, Y.J. et al. (2023). Field Trial to Rapidly Classify Soil Using Computer Vision with Electric Resistivity and Soil Strength. In: Atalar, C., Çinicioğlu, F. (eds) 5th International Conference on New Developments in Soil Mechanics and Geotechnical Engineering. ZM 2022. Lecture Notes in Civil Engineering, vol 305. Springer, Cham. https://doi.org/10.1007/978-3-031-20172-1_18

Download citation

DOI: https://doi.org/10.1007/978-3-031-20172-1_18

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-20171-4

Online ISBN: 978-3-031-20172-1

eBook Packages: EngineeringEngineering (R0)