Abstract

The work studied the effect of various media (water vapor, ammonia, and isopropanol in air) on the electrical characteristics of ZnO thin films. In all cases, changes in the electrical characteristics of the films were observed, but the nature of these changes was different. In the presence of ammonia vapor at room temperature, the film current almost doubled. Moreover, the adsorption process is more inertial than the desorption one. The same films at room temperature do not react to propanol vapors in the ambient air. At a temperature of 373 K, the sensitivity to propanol increases considerably. Films are sensitive to moisture at room temperature. However, in comparison with the reaction to ammonia, the reaction to water vapor is more inertial and the sensitivity is lower. The difference in the values and temperatures of the sensitivity of zinc oxide films to different adsorbates allows us to consider them as sensitive elements for multisensors.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Zinc oxide thin films

- Electrical characteristics of thin films

- Ammonia sensitivity

- Sensitivity to propanol

- Sensitive to moisture

1 Introduction

Nanosized films are actively used as transparent electrodes for solar cells, LEDs and other optoelectronic devices, and sensitive elements of gas sensors.

Zinc oxide nanosized films, in particular, are actively used in electronics as transparent electrodes for solar cells [1], light-emitting diodes [2], lasers, photodetectors, and other optoelectronic devices [3]. Recently, such films are actively used also as sensitive elements for sensors of various gases [4,5,6]. All of these and many other applications of zinc oxide are possible due to its physical properties. Zinc oxide is a wide-gap semiconductor (3.3–3.4 eV [6]) of the n-type. The advantage is the direct band gap transition of its energy structure, a fairly high value of the binding energy of excitons [6], and broad optical absorption band. Its insolubility, chemical stability, and good catalytic activity are also important for applications in catalysis and gas sensors.

Nanoscale forms of this material are actively used due to the enhancement of interesting existing features and to the acquisition of new ones. In the nanoscale form, its catalytic and sensory properties are intensified, which leads to a decrease in the working temperature of such processes. Various types of zinc oxide nanoforms can be obtained by both physical and chemical methods, among which there are enough simple and cheap ones [3, 7,8,9,10]. The sol–gel method was chosen for producing thin zinc oxide films as a simple and cheap method, allowing the introduction of various additives in the production process, for an example, to change the structure, doping, and, consequently, to improve its functional characteristics.

In this work, the effect of various media (water vapor, ammonia, and isopropanol in air) on the electrical characteristics of such films was studied. The ammonia vapors impact control is important in monitoring human health, the food industry, food trade, and agriculture. The usage of isopropanol widespread for cleaning beginning from electronics up to the service industry also requires the control of its vapors in such workplaces. Taking into account the effect of moisture on the components of electronic elements based on zinc oxide is also useful in industries and everyday life.

2 Methods

The investigated zinc oxide films were obtained from aqueous solutions of zinc acetate with the addition of polyvinyl alcohol as a structuring additive. The initial solutions were applied to the prepared glass substrates. The resulting preparatives were annealed in a muffle furnace. The method for producing films is described in detail in [10].

The films had a porous nanoscale structure, which was confirmed by SEM studies and is shown in Fig. 1. In addition to porosity, a certain fractality of the film structure is noticeable. Zinc oxide films obtained from zinc acetate by the sol–gel method by the authors of [11] In general, the structure looks like being composed of nanosized agglomerates up to 50–100 nm in diameter. Such a developed porous structure with a large surface area is preferable for adsorption-sensitive sensor elements. It provides good contact with the detected substances, and, therefore, a noticeable response when interacting with them.

The electrical characteristics: current–voltage characteristics (CVC), dark current temperature dependence (DCTD), and the conductivity kinetics of the films were measured in an atmosphere of dry air and in atmospheres containing water vapor, ammonia, and isopropyl alcohol. The atmosphere under study was formed in the measuring chamber by introducing a portion of the detected gas into the atmosphere of specially dried air.

3 Results and Discussion

Investigations of the current–voltage characteristics were carried out to elucidate the dominant mechanism of conduction in zinc oxide films in air and with the addition of water or ammonia vapors to the research chamber.

Figure 2 shows the current–voltage characteristics of a zinc oxide film, which were measured in an air atmosphere at temperatures of 290 K (curve 1) and 420 K (curve 2) and in the presence of water vapor at a temperature of 290 K (curve 3). In an air atmosphere at temperatures of 290 K (curve 1), the CV characteristic of the studied zinc oxide film has an exponential dependence. This dependence is typical for the barrier mechanism of current flow. The CV characteristic in an air atmosphere at a temperature of 420 K shows the current flow values higher almost on the order of magnitude (at the same voltage values), and in addition, the degree of its superlinearity is less than at room temperature. This behavior indicates an increase in the concentration of electrons in the conduction band of the ZnO film with increasing temperature. Therefore, the effect of intercrystalline barriers on the current flow with increasing temperature is less pronounced.

It can be seen that in an atmosphere containing water vapor (Fig. 2, curve 3), the electrical conductivity shows higher values in comparison with the electrical conductivity in dry air. Similar results obtained on zinc oxide films are known in the literature [12] and are explained by the dissociative adsorption of water on the surface of the ZnO film. Water is absorbed on zinc oxide in both molecular and dissociative form. Dissociative adsorption on nanosized forms of ZnO mainly occurs on oxygen vacancies, which adsorb and neutralize hydroxyl groups OH− [13].

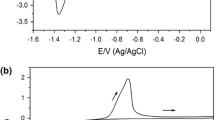

In an atmosphere with ammonia vapor, the electrical conductivity of the studied zinc oxide films also differed from this indicator in dry air. Figure 3 shows the CV characteristic of a zinc oxide film in dry air (curve 1) and in air with ammonia vapor (curve 2). The exponential character of the dependence, as well as its straightening in the coordinates. ln I ~ U^(1/4), indicates the above-barrier Schottky emission through thin intercrystalline barriers [14] as the dominant mechanism of current transfer in the film.

In ammonia vapor, the CVC of the ZnO film (curve 2 in Fig. 3) is almost an order of magnitude higher than in air. This is especially noticeable in the region of low voltages.

In works [12, 15] it was shown that the stable configuration of NH3 during adsorption on the surface of zinc oxide is the binding of the nitrogen atom (N) with the surface zinc atom (Zn). In this case, even at ambient temperature (~300 K) [15], charge transfer to the ZnO surface is observed. Molecular chemisorption of NH3 occurs on the ZnO surface, in which ammonia molecules become donors of charge carriers. As a result, the equilibrium surface bending of the energy bands decreases and the conductivity of thin zinc oxide films increases.

The temperature dependences of the current of zinc oxide films were studied in dry air, in atmospheres with water vapor, ammonia, and isopropyl alcohol in the temperature range 290–723 K.

Figure 4 shows the DCTD of ZnO films in dry air (1–2–3) and in the presence of water vapor (4–5–6). Electrical conductivity was measured both when the sample was heated (Sections 1–2) and when it was cooled (Section 3).

In the atmosphere of dry air, the conductivity grows exponentially with temperature increasing wherein the dependence shows several sections with different activation energies. The minimal growth in conductivity is observed in the temperature range 290–320 K with conductivity activation energy of about 0.1 eV. These values correspond to the shallow donors’ contribution to the conductivity, often caused by surface defects. The conduction activation energies in other areas (E1, E2, and E3) are presented in Table 1. Their numerical values (0.35–0.5) eV being close to each other are less than half the band gap of zinc oxide. In such cases, electrical conductivity is controlled by intercrystalline potential barriers, and its mechanism can be explained by the semiconductor model with large-scale potential relief fluctuations described in [16].

The current temperature dependence measured in the presence of water vapor has some specific features. So, on DCTD, when the film is heated, there are Sects. 4 and 5, in which the electrical conductivity increases with temperature. Between them there is a section of abnormal temperature dependence 322–395 K, where the electrical conductivity decreases with temperature growth. A similar dependence was observed on thin films of ZnO [17] and SnO2 [18] in a humid environment. This anomaly can be explained by desorption of physically adsorbed water and hydroxyl groups present on the surface of oxides in a humid atmosphere. In this case, on the surface of the ZnO film, the number of adsorption centers for oxygen increases, which, being adsorbed, captures electrons from the conduction band, thereby leading to a reduction in current flow. A further rise in temperature stimulates desorption of oxygen, and, as a consequence, an increase in conductivity. The possibility of using zinc oxide films as adsorption-sensitive elements of gas sensors, can be clarified by conductivity kinetic studies during the periodic filling the measuring chamber with dry air and gas for detection.

Figure 5 shows the relaxation of the current in the ZnO film with periodic admission of water vapor and dry air into the chamber. The studies were carried out at a constant voltage of 200 V. As it can be seen, the resistance of the film decreases by more than five times when water vapor is let into the atmosphere of the chamber. When dry air is let in, the resistance value is restored to its initial value. Both processes are quite inertial and last 6–8 min. Using the classic sensitivity formula

(where Ro is the film resistance in air; R is the film resistance in water vapor), the sensitivity of the zinc oxide film to water vapor was calculated.

Similar measurements of current relaxation and sensitivity calculations were performed for other voltages in the range (50–320) V. The dependence of the sensitivity of the ZnO film to water vapor on the applied voltage is shown in Fig. 6. It can be seen that with an increase of the applied voltage, the sensitivity increases, reaches a maximum at a voltage of 200 V and is 0.37 in relative units.

The relaxation of the current with periodic admission of ammonia vapor or dry air into the measuring chamber is shown in Fig. 7. In the presence of ammonia vapor, the current in the ZnO film almost doubles. The adsorption of ammonia is a fairly fast-response process. The current reaches 90% of its stationary value (tresp—response time) in about 48 s. After admitting dry air into the chamber, the current decreases almost to its initial value. This process, which actually reflects the ammonia desorption is more inertial than the adsorption process. The recovery time (trel is the time during which the current falls by 90% of its stationary value) is about 180 s.

From the relaxation curves measured at different values of the applied voltage, the sensitivity of the ZnO film to ammonia vapor was calculated. The dependence of the sensitivity on the applied voltage is shown in Fig. 8. It can be seen that the value of the sensitivity reaches its maximum at a voltage of 250 V and is 0.82 in relative units.

The isopropyl alcohol vapor influence on the conductivity of the studied zinc oxide films was additionally studied. Figure 9 shows the current relaxation measurements in the ZnO film with periodic filling of isopropyl alcohol vapors and dry air into the measuring chamber. As it can be seen, at room temperature (Fig. 9, curve 1), the change in the electrical conductivity of the film in the presence of isopropanol vapor is very small. However, when the ZnO film is heated, its sensitivity to isopropanol vapor increases and already at a temperature of about 363 K; it reaches 0.41 relative units (Fig. 9, curve 2). This indicator is comparable to the sensitivity of the studied ZnO films to water and ammonia vapors. The change in electrical conductivity upon contact of the films with ammonia, as well as the reverse process, occurs rather quickly; the response time can be considered equal to 60–70 s. However, the kinetic dependences show that the current does not reach its initial value during the observation time (180 s for each process). This indicates the formation of stronger chemical bonds between the isopropanol molecule and the surface at an elevated temperature (393 K) compared to the interaction at room temperature.

The result obtained is probably due to the more complex structure of the isopropyl alcohol (C3H7OH) molecule as compared to the H2O and NH3 molecules and requires further study. It may be interesting for the application of the same film in the joint control of several pollutants. In this case, local heating of a part of the sensitive element for isopropanol detection can be used.

4 Conclusion

In the studies carried out in all cases, changes in the electrical characteristics of the studied films were observed, but the nature of these changes differs and depends on the nature of the interaction of the adsorbate with the previously adsorbed oxygen.

In the presence of ammonia vapor at room temperature, the current in the film has almost doubled. Moreover, the adsorption process is quite inertial in contrast to the desorption process. The films’ sensitivity was at the level of 0.82 relative units.

These same films at room temperature do not react to propanol vapors in the ambient air. However, as the temperature of the layers increases, their electrical conductivity increases. At a temperature of 373 K, the sensitivity to propanol S is 0.41 relative units.

The films have also been noticed to be sensitive to moisture at room temperature. However, compared to the reaction to ammonia, the reaction to water vapor was more inertial and the sensitivity was at the level of 0.37 relative units.

The difference in the values and temperature of the sensitivity of zinc oxide films to different adsorbates allows considering them as a sensitive elements of the multisensors.

References

He S, Zou X, Sun Z, Teng G (2013) Influence of precursor solution’s concentration on double-layer ZnO structure and solar cell’s performance. Mater Lett 91:258–260. https://doi.org/10.1016/j.matlet.2012.09.112

Rahman F (2019) Zinc oxide light-emitting diodes: a review. Opt Eng 58(1):010901. https://doi.org/10.1117/1.OE.58.1.010901

Kołodziejczak-Radzimska A, Jesionowski T (2014) Zinc oxide-from synthesis to application: a review. Materials (Basel) 7(4):2833–2881. https://doi.org/10.3390/ma7042833

Sun Y-F, Liu S-B, Meng F-L, Liu J-Y, Jin Z, Kong L-T, Liu J (2012) Metal oxide nanostructures and their gas sensing properties: a review. Sensors 12:2610–2631

Carpenter MA, Mathur S, Kolmakov A (2013) Metal oxide nanomaterials for chemical sensors. Springer Science & Business Media, New York

Jagadish C, Pearton SJ (eds) (2006) Zink oxide bulk, thin films and nanostructures. Elsevier, Amsterdam

Sadraei R (2016) A simple method for preparation of nano-sized ZnO. Res Rev: J Chem (RRJCHEM) 5(2):45–49

Rawat A, Soni U, Malik RS, Pandey SC (2018) Facile synthesis of UV blocking nano-sized Zinc Oxide and Polymethyl-methacrylate polymer nanocomposite coating material. Nano-Struct Nano-Obj 16:371–380. https://doi.org/10.1016/j.nanoso.2018.09.002

Maroufa S, Beniaiche A, Guessas H, Azizi A (2017) Morphological, structural and optical properties of ZnO thin films deposited by dip coating method. Mater Res 20(1):88–95. https://doi.org/10.1590/1980-5373-MR-2015-0751

Chebanenko AP, Filevska LM, Grinevych VS, Bulyga YI, Brytavskyi IV, Smyntyna VA (2021) The conductivity mechanisms of ZnO thin films structured using polyvinyl alcohol. In: Fesenko O, Yatsenko L (eds) Nanomaterials and nanocomposites, nanostructure surfaces, and their applications. NANO 2020. Springer Proceedings in Physics, vol 263. Springer, Cham. https://doi.org/10.1007/978-3-030-74741-1_27

Krasteva LK, Dimitrov DT, Papazova KI, Nikolaev NK, Peshkova TV, Moshnikov VA, Gracheva IE, Karpova SS, Kaneva NV (2013) Synthesis and characterization of nanostructured zinc oxide layers for sensor applications. Semiconductor 47(4):586–591

Kovalenko MV (2017) Electronic energy structure, optical-spectral and sensory properties of ZnO-based nanostructures. Ph.D. thesis, Lviv (in Ukrainian)

Noei H, Qiu H, Wang Y, Löffler E, Wöll C, Muhler M (2008) The identification of hydroxyl groups on ZnO nanoparticles by infrared spectroscopy. Phys Chem Chem Phys 10:7092–7097

Pikus GE (1972) Fundamentals of the theory of semiconductor devices, Nauka (in Russian)

Nancy AA, Rai PK, Jeyaprakash BG (2018) Understanding ammonia adsorption and charge transfer process on ZnO using experimental and DFT approach. Mater Chem Phys 214:540–547. https://doi.org/10.1016/j.matchemphys.2018.04.101

Bonch-Bruevich VL, Zvyagin IP, Kuiper R, Mironov AG, Enderline R, Esser B (1981) Electronic theory of disordered semiconductors. Nauka (in Russian)

Nakagawa M, Mitsudo H (1986) Anomalous temperature dependence of the electrical conductivity of zinc oxide thin films. Surf Sci 175:157–176

Harrison PG, Willett MI (1989) Tin oxide surfaces: electrical propertis of tin oxide gel: nature of the surface species controlling the electrical conductance in air as a function of temperature, I. Chem Soc Faraday Trans 1 85(8):1921–1932

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Chebanenko, A.P., Filevska, L.M., Grinevych, V.S., Smyntyna, V.A. (2023). Electrical Characteristics of Nanosized ZnO Films, Obtained Using Polyvinyl Alcohol, in Different Atmospheres. In: Fesenko, O., Yatsenko, L. (eds) Nanomaterials and Nanocomposites, Nanostructure Surfaces, and Their Applications . Springer Proceedings in Physics, vol 279. Springer, Cham. https://doi.org/10.1007/978-3-031-18096-5_17

Download citation

DOI: https://doi.org/10.1007/978-3-031-18096-5_17

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-18095-8

Online ISBN: 978-3-031-18096-5

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)