Abstract

Microalgae and cyanobacteria are photosynthetic microorganisms that can be used to bioremediate anthropogenic pollutants from air, water and soil. These organisms can remediate several anthropogenic pollutants, such as carbon dioxide, nitrates and phosphates, heavy metals, pharmaceuticals, pesticides and persistent organic pollutants. The biomass generated in this process can be used as a feedstock source for the production of a multitude of valuable biobased products and applications. Polymers, resins, binders, lubricants, and coatings are some of the promising examples. This chapter provides an overview of the entire process: bioremediation using microalgae and production of value-added products, based on a biorefinery concept, focusing on circular economy and sustainability. Essential aspects of legislation and regulations are also approached.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

2.1 Introduction

Microalgae is a diverse group of prokaryotic and eukaryotic photosynthetic microorganisms living in different environments. Microalgae include prokaryotic blue-green algae (cyanobacteria) and eukaryotic microalgae (diatoms and green algae). These organisms use light energy and carbon dioxide as carbon source and, through metabolic processes, convert them into various biopolymers such as proteins, nucleic acids, lipids, and polysaccharides, releasing molecular oxygen in the process. They produce a wide range of compounds, some of which have potential commercial value. Depending on species, microalgae and cyanobacteria produce different biomolecules, and, depending on the growth conditions, these biomolecules might vary in composition and concentration. This versatility is reflected in the remarkable number of products and applications that can be developed.

Microalgae and cyanobacteria have been cultivated for decades, but only a limited number of species have been commercially used, mainly for pigments production and food and feed supplements. The most commercially used species are Chlorella, Spirulina, Dunaliella, Haematococcus, Nannochloropsis, tetraselmis and Isochrisis.

Despite their versatility, resilience, and potentialities, a consolidated and accepted microalgae cultivation system is not yet implemented worldwide. Many factors contribute to this reality: the many decades of established and implemented fossil economy, the confidence from investors, the initial costs of the investment, the downstream processing challenges, and the acceptance and willingness of all the stakeholders (political, industry, civil society). In recent years, the number of microalgae production units has increased and represents a significant step towards a sustainable resource for the future. These aspects will be further discussed in the following sections of this chapter.

2.2 Brief History

The importance of microalgae in wastewater treatment was recognised several decades ago. At the beginning of the twentieth century, the first studies focused on nitrogen/phosphorus uptake alongside oxygenation potential. Early studies on wastewater treatment using algal pond systems were developed in the mid-1950s; these systems were used to study algal growth and photosynthetic oxygen production to assist with bacterial degradation of Biological Oxygen Demand (BOD). In the 1960s, researchers began to focus on nutrient removal from sewage and wastewater, such as nitrates and phosphates. At the beginning of the 1970s, a 300 m2 pilot plant was built and operated for algae wastewater treatment (Borowitzka 2013) and semicontinuous cultures of microalgae began to be studied for their ability to remove heavy metals, such as cadmium, chromium and mercury, from wastewaters.

The concern with environmental degradation by chemicals is not new. Several reports from the late 1960s and during the decade of 1970s state the problem of persistent pesticides in the environment and the impact on human health. And in this period, many reports were published to address the issue of their presence in underground and superficial waters, mainly using microalgae in the process. A notable a paper published in 1976 reported the removal of two herbicides (amitrole and atrazine), from water, by four microalgae species (Chlorella pyrenoidosa, Scenedesmus quadricauta, Chlamydomonas reinhardtii, and Euglena gracilis). During the decade of 1980s, many studies on the uptake of nitrogen and phosphorus from wastewater by microalgae were undertaken. The studies on this subject have been constant over many decades (PierreChevalier 1985, Hammouda et al. 1995, Shi et al. 2007, Eroglu et al. 2012, Ferrando and Matamoros 2020, Castellanos-Estupinan et al. 2022).

Much progress has been made in understanding many aspects of microalgal biology and physiology, nutrition, and cultivation conditions. Less research has focused on the uptake and removal of emerging contaminants. But one of the significant limitations of an implemented microalgae system, limiting further expansion, is the high cost of investment and cost-effective harvesting of biomass and extraction of compounds (downstream process).

In the last three decades, researchers have studied harvesting and extraction techniques involving physical (centrifugation, sedimentation, filtration, flotation, etc.) and chemical processes (e.g. flocculation). However, these are energy-demanding processes, and some chemical processes use toxic chemicals (Hoang et al. 2022). Academy and public research institutions, companies, and government agencies have funded research projects focused on the field of microalgae technology. Nevertheless, it still requires much knowledge and innovation, particularly in the engineering field applied to the downstream processing steps.

The history of each field of science is of great importance since one can analyse what was done by the peers in previous decades, what remained to be studied, what failed, and why it was not moved forward. In the case of the removal of pollutants from the environment, although there was some level of concern in previous decades, it was only more recently that public opinion, governments, world organisations, and companies are more willing to protect the environment by restoration and with more ecological alternatives.

2.3 Microalgae Bioremediation: An Effective Approach Towards Environment Restoration

Globally, the emissions of greenhouse gas of which, carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O), as well as surface and groundwater contamination by organic and metal pollutants, are the major global environmental issues that have captured the attention of scientists, environmentalists and legislators (Sundarrajan et al. 2019). Various physical-chemical methods have thus been proposed. While they are effective, such methods require expensive chemicals and energy-intensive equipment, rendering the treatment costs high and limiting their large-scale application (Danouche et al. 2021).

2.3.1 Application of Microalgae in CO2 Mitigation

Sequestration of CO2 can be achieved by using physicochemical and/or biological approaches. Currently, the main abiotic approaches employed for the mitigation of CO2 include physicochemical adsorption (Song et al. 2019), direct injection into the deep ocean, old coal mines, oil wells, geological formations such as saline aquifers, and CO2 mineral carbonation. However, some drawbacks are associated with these approaches, for instance, the control of the physicochemical adsorption process is generally difficult, and the sorbent materials are generally expensive and non-renewable. Additionally, the injection of CO2 into geological formations presents significant challenges in terms of space requirements and potential leakage over time (Zeng et al. 2011). Naturally, microalgae capture photons from the sun’s energy to convert CO2 dissolved in water (as free CO2, bicarbonate (HCO3−), carbonate (CO32−), and carbonic acid (H2CO3)) to produce organic molecules through the process of photosynthesis (Eze et al. 2018; Fu et al. 2019). As reported by Zhou et al. (2017), microalgae have a high growth rate and a photoautotrophic efficiency 10–50 times higher than that of terrestrial plants, which makes the capture of CO2 using microalgae as one of the most promising approaches (An et al. 2021). A number of Chlorophyceae species have exhibited a high capacity for CO2 sequestration. The most studied species for CO2 fixation from flue gases belong to Chlorella genus, such as C. vulgaris, C. fusca, C. sorokiniana, C. pyrenoidosa and C. kessleri (Kong et al. 2021). The detailed mechanisms of CO2 fixation and nitrogen assimilation in microalgae are described in Fig. 2.1.

2.3.2 Application of Microalgae in Wastewater Treatment

Phycoremediation, or the use of microalgae for the remediation of wastewater or contaminated aquatic ecosystems by organic or metallic pollutants, has recently emerged as a promising, efficient, economical and environmentally friendly strategy compared to other physicochemical processes (Danouche et al. 2020; Singh et al. 2021a, b). The use of wastewater as a culture medium for microalgae is an innovative concept particularly suited to tertiary wastewater treatment. Indeed, microalgae can assimilate a wide range of inorganic contaminants as well as some organic pollutants, besides their capacity to accumulate heavy metals (HMs).

Phycoremediation of Inorganic Pollutants

In wastewater treatment systems, microalgae can use several inorganic pollutants during their growth, such as nitrogen, phosphates, chlorides, sulfates and other inorganic pollutants, and may have a major role as intermediates in metabolic activity (Abdel-Raouf et al. 2012). Several studies have highlighted the possibility of using wastewater as a source of nutrients for the cultivation of microalgae, allowing both the elimination of the pollution load and the production of biomass at low cost (Fal et al. 2021). On the other hand, the ability of microalgae to eliminate and detoxify HMs is the result of adaptation mechanisms developed over centuries of evolution in contaminated environments (Ubando et al. 2021). These mechanisms are subdivided into metabolism-dependent and metabolism-independent pathways. Extracellular biosorption of HMs refers to a physicochemical property of the microalgae cell surface that binds to HMs ions independently to the cellular metabolism. However, HMs biosorption into extracellular polymeric substances (EPS) formed by microalgae under conditions of stress is a metabolism-dependent process (Naveed et al. 2019). It has been reported that the biosorption efficiency varies depending on the genus and the species of microalgae (Kumar et al. 2015a, b). For instance, the growth of C. sorokiniana and S. obliquus in media contaminated with Pb(II), Cd(II), Cu(II) and Cr(VI) was significantly different (Danouche et al. 2020). This can be attributed to the physiology of the strain, in particular, the cell wall composition (Baudelet et al. 2017). In contrast, bioaccumulation is a metabolism-dependent mechanism. It consists of an intracellular accumulation of HMs into the cytosolic compartment through passive and/or active transport across the cell membranes (Chojnacka 2010). According to Pérez-Rama et al. (2002), the bioaccumulation of Cd(II) using Tetraselmis suecica was a biphasic process, assisted in the first phase by an adsorption to proteins or polysaccharides, followed by an energy-dependent accumulation to the cytosol. The intracellular mitigation of toxic HMs may involve the chelation by metallothioneins (Balzano et al. 2020), phytochelatins (Gómez-Jacinto et al. 2015), poly-phosphates (Wang and Dei 2006), the compartmentalisation in the vacuole (Shanab et al. 2012), chloroplast (Hanikenne et al. 2009) and mitochondria (Mendoza-co et al. 2005) or the biotransformation via an enzymatic reaction such the biotransformation of Cr(VI) to Cr(III) by strains of C. vulgaris through an enzymatic reaction catalysed by the chromate reductase (Lee et al. 2017; Yen et al. 2017). Figure 2.2 depicts the intracellular and extracellular mitigation pathways for HMs using microalgae.

Phycoremediation of Organic Pollutants

Although microalgae are classified as autophotrophic organisms, some species have a heterotrophic metabolism, and under certain conditions, some microalgae strains are able to grow in mixotrophic mode. This trophic particularity allows microalgae cells to use the carbons contained in organic pollutants and to ensure the bioremediation of contaminated aquatic ecosystems (Zhou et al. 2017). It has been reported that many microalgae strains have the capability of removing a range of organic pollutants such as polycyclic aromatic hydrocarbon (Semple et al. 1999), synthetic dyes (Bhardwaj and Bharadvaja 2021), pharmaceuticals and personal care products (Hena et al. 2021), pesticides and other emerging contaminants (Maryjoseph and Ketheesan 2020).

Based on the above considerations, we can infer that the benefits of phycoremediation technology are to allow both CO2 capture through photosynthesis and to remove nutrients and xenobiotics from wastewater. Thus, the resulting biomass can be used as a raw material for several valuable products depending on their composition and the type of pollutant to which it has been exposed. For example, it can be used for the production of biofuels, animal feed, fertilisers, pharmaceuticals, biosurfactants, proteins, pigments and many other valuable products, that can be extracted from microalgae.

Microalgae production could be integrated into a biorefinery to achieve greater economic potential.

2.4 Microalgae Biomass: Valorisation within a Biorefinery Concept

Like a traditional petroleum refinery, a biorefinery converts feedstock into energy and several chemicals. The process entails different technologies and can be applied for processing different raw materials. There are several types of biorefineries based on biobased feedstock or waste source, end-products and conversion technologies. Potential organic feedstock sources include corn, potato, cellulosic biomass, forestry, agricultural waste, food waste and algae. The variety of possible organic raw materials implies a rich diversity of potential chemicals. Bioethanol, biogas, lignin, secondary metabolites, carbohydrates, lipids and proteins are some of the products that can be obtained using the biorefinery concept (Espinoza Pérez et al. 2017). To obtain this variety, different conversion processing technologies are required. Biorefinery conversion techniques can involve different separation technologies such as thermochemical conversion, chemical conversion and biochemical conversion (Sankaran et al. 2018).

There are three different phases of development of a biorefinery depending upon feedstock and products. Phase I converts a single raw material into one main product using a fixed process. The Phase II biorefinery also processes a single raw material but is capable of producing various products with diverse processing technologies. The biorefinery processes using single raw material sources can lead to food competition, land use issues and environmental impact (Espinoza Pérez et al. 2017; Sankaran et al. 2018). Phase III biorefinery uses a mixture of biomass from different sources, such as whole-crop, lignocellulose and microalgae, that allows the production of many biobased industrial products using different processing technologies. Phase III, the most advanced form of biorefinery, is also an engineering challenge due to the complexity involved. Some of these constraints are related to product separation and purification.

Among the various biomass sources, microalgae are a very promising and remarkable feedstock for the biorefinery process; they do not compete with food, do not require arable land, and can be used for air and water cleaning processes. Large-scale microalgae production requires a high initial investment, especially for the installation of photobioreactors, and production costs; these include high-power consumption, artificial light illumination, the CO2 feed, the cultivation medium, and nitrates and phosphates. To save water and decrease production costs, microalgae can be used in wastewater treatment stations; they can also be integrated into different industrial production units such as cement, paper, textile, tannery and dairy. An integrated system requires the full use of waste and exhaust gases.

The biorefinery process consists of the separation of different fractions, such as lipids, minerals, carbohydrates and secondary metabolites. That separation process should not cause damage to the other fractions. Microalgae are rich in lipids, but during the separation process is possible to obtain many other products that can be also transformed into value-added products (pigments, polyunsaturated fatty acids (PUFAs), toxins, and polysaccharides) or may be used to produce bioplastics, for instance. Microalgae biorefinery is divided into several stages which can be categorised into upstream and downstream processes. The upstream processing is determined by the strain selection, carbon dioxide supply, light source and intensity, and nutrients, such as nitrogen and phosphorus sources.

2.4.1 Upstream Production Systems

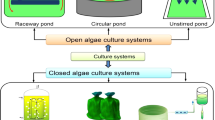

The production of microalgal biomass, and derived products, is highly dependent on the cultivation production systems. The choice of production system is particularly important for bioremediation applications, as large-scale algae production requires high initial capital investment. Broadly speaking, there are two main types of production system for microalgae; the open pond system or closed systems (Fig. 2.3).

2.4.1.1 Open Systems

Open ponds are systems that allow large-scale production for commercial purposes. Open ponds have various sizes, shapes and types of turbulence. Their construction is often dictated by local conditions and available materials and can be constructed of plastic, bricks, concrete, or adobe. Open ponds include lakes and lagoons, raceway ponds, paddle-wheel-driven open raceway ponds, circular ponds and Inclined and cascaded systems. Open systems generally present some shortcomings in relation to control over process parameters. These systems offer little or no guarantee on the control of the operational variables (temperature and incident light intensity). The contamination by other microorganisms that may occur during the process and the low efficiency of CO2 utilisation due to lack of agitation of the flow and poor gas exchange in the culture medium compromise the overall algal growth rates.

-

Natural ponds. It is a naturally selective system, the type of species and strain is closely linked to the soil and climatic conditions of the region, generally being a low-cost, monospecies that can be grown almost all year round. In these systems, the risk of contamination is very high due to its open characteristics.

-

Raceway ponds (also known as high-rate algal ponds). These are open-air extensive cultivation systems, in the form of a racetrack, shallow, with mixing undertaken by a paddlewheel that distributes nutrients homogeneously to the microalgae. Generally, they are built with low-cost materials, cement, clay and white plastic to facilitate light capture.

-

Circular ponds. Since these systems present an inefficient configuration compared with raceway ponds, they are rarely used for commercial purposes. However, in some countries, such as Japan, Taiwan and Indonesia, this process is widely used to produce biomass.

-

Inclined and cascaded systems. In these systems, the turbulence is generated by gravity and the crop moves from the top to the bottom of an inclined suspended surface. This process is particularly interesting because the flow is highly turbulent, and the thin culture layers improve light absorption, and produce a greater concentration of cells. However, this system has a high evaporation rate, increased sedimentation of the cells under low turbulence mixing regimes and a high energy consumption compared to other pond systems.

The major disadvantages of open systems are essentially the high evaporation rates, the difficulties of temperature control and the high risk of contamination. In general, open cultivation systems produce less biomass per unit area compared to closed photobioreactors.

Although research to develop cultivation systems for microalgae has focused more on closed cultivation systems, today’s large-scale industries rely more on open systems for economic reasons; they are cheaper to maintain, easier to operate and require less energy. However, only a small number of algae species can be successfully cultivated in outdoor systems due to contamination, which directly compromises productivity.

Due to the several problems associated with open culture systems, there is a particular interest in closed photobioreactors which, offer more efficiency and more advantages over open culture systems. These advantages include better results in terms of efficiency in photosynthesis; greater capacity for CO2 removal; versatility in terms of the culture medium; production is not seasonal; the absence or reduction of contaminations; ease of monitoring operational variables such as temperature, pH and CO2; greater incidence of light on the culture medium. The photobioreactors can be exposed to sunlight or artificial light, the latter offers better control over the process variables.

2.4.1.2 Closed Systems

Closed photobioreactor systems strongly limit any direct exchange of contaminants into the cultivation medium. The algae and cultivation medium flows within the transparent walls of the reactor to reach the cultured cells. Photobioreactors are classified according to their mode of operation and design. Some examples include tubular vertical and horizontal, shaking tank photobioreactors, helical tubular, flat plate photobioreactors, and photobioreactors mixed by air “airlifts”.

Although photobioreactors have limitation of contamination as the main advantage, this may not be completely achievable, except in some designs specifically developed for this purpose. They are also more expensive than open systems.

-

Vertical Tubular Photobioreactors. Since the first invention of photobioreactors in 1950, several models have been developed. The construction cost of this system is very high; however, its maintenance and monitoring are very economical. The vertical stacked system presents a higher concentration of cells and a higher productivity thanks to the gentle and controlled agitation of the mixture which is obtained through the injection of compressed air. Furthermore, vertical tubular photobioreactors are compatible with the majority of microalgae species. The disadvantage of this system is that it has a lower efficiency of sunlight incidence, an issue that can easily be circumvented by applying artificial lighting.

-

Horizontal tubular photobioreactors. Horizontal tubular photobioreactors were the best solution to solve the problem of sunlight incidence in vertical tubular systems. The horizontal orientation of the tubes increases the capacity to absorb the incidence of light. However, this system also has some difficulties in the O2 removal and in the CO2 supply, also the increase of the light absorption capacity implies the growth of the installation area of the tubes.

-

Flat photobioreactors. These are systems with large, transparent panels, which can be made of glass or polycarbonate, arranged vertically or at an inclined angle. The light intensity is easily controlled due to the possibility of directing the panels in different directions and at different angles. This system has received special attention from the scientific community, which considers it to be a promising system thanks to the light conversion efficiency and productivity per unit area.

-

Airlift photobioreactors. These are cylindrical tubes with two interconnecting zones, one of which is called a “riser”, where the gas mixture is spread, while the other zone, the “downcomer”, does not receive the gas. This system stands out for having high levels of mass transfer. The pneumatic agitation caused by the injection of CO2 at the bottom of the tank increases the velocity of the medium circulation, which in turn increases the efficiency of the microalgae growth.

2.4.2 Downstream Processing

After the cultivation stage, the upstream processing ends, and the downstream processing begins. Typically, downstream processing involves several stages: harvesting of biomass through centrifugation, filtration or flocculation, drying, product extraction, purification and conversion processes. These operation units account for 50–60% of the total costs in the microalgae multi-product biorefinery, with harvesting accounting for at least 20% of these costs ('t Lam et al. 2018; Xu et al. 2020). Microalgae cultures are dilute suspensions, typically varying from 0.5 to 5 g L−1, depending on species, making harvesting a challenge. Common harvesting and dewatering methods encompass centrifugation, filtration, sedimentation, flotation and flocculation. The latter include chemical, biological and electro-flocculation.

After the dewatering process, the microalgae biomass will be subjected to drying processes such as spray drying, solar drying, convective and freeze drying (Chen et al. 2015).

The extraction of high-value products such as lipids, pigments, secondary metabolites, and others can be performed using either wet or dry biomass. The extraction processes vary depending on the products. Some microalgae species can have thick and multilayered walls, silicified, and wall-bound exopolysacharides membranes implying a reduced extraction efficiency. Therefore, appropriated pre-treatment methods are often required before extraction takes place. Cell disruption can be achieved through soaking, maceration, bead-beating, sonification, alkaline lysis, etc. (Catherine Dupré et al. 2020).

After the pre-treatment steps, the biomass can be converted into several products. Extraction methods include conventional solvent extraction, supercritical fluid extraction, enzyme extraction, subcritical water extraction, among others (Catherine Dupré et al. 2020).

2.4.2.1 Production of High-Value Products and Applications

A variety of products and compounds can be extracted and isolated from microalgae biomass: biopolymers, lipids, bioactive compounds, proteins and carbohydrates, which can be applied in a multitude of applications (Table 2.1). The currently existing applications on the market focus on food, feed, nutraceuticals, cosmetics and pharmaceuticals with several companies commercialising different microalgae products. Few are focused on the chemical industry, and the potentialities are vast and could extend into new areas.

Biopolymers, such as polyhydroxy butyrate (PHB) have been identified in some marine and freshwater microalgae species. They are used in the food industry, pharmaceutical industry, environmental remediation and medical devices. Polyhydroxyalkanoates (PHAs) are biodegradable biopolyesters produced by microorganisms, including microalgae. With properties like those of polyethylene and polypropylene, they can be processed similarly to fossil-based thermoplastics, including injection moulding, extrusion and blow moulding. PHAs are generally produced by heterotrophic bacteria, natural or artificially modified bacteria, such as Cupriavidus necator, recombinant Escherichia coli., Ralstonia sp., Halomonas sp., among several others {Khatami, 2021 #1}(Khatami et al. 2021); it is known that at least 75 distinct genera synthesise PHAs (Reddy et al. 2003). The intracellular levels accumulated can reach 90% of the cell’s dry weight under conditions of nutrient stress (Reddy et al. 2003). At present, more than 160 different monomer units have been identified, and their molecular weight ranges from 50,000 to a million Da (Taguchi and Matsumoto 2021; Vermeer et al. 2022). The variation in the composition of the monomeric units implies a diversity of chemical and physical properties. Microalgae are an alternative to the production of bacterial PHA. PHAs such as PHB can be stored by microalgae and cyanobacteria as reserves of energy material in response to nutritional stress. Excess carbon and nutrient depletion growth conditions lead to the production of these polyesters by these microorganisms. Microalgae species Chlorella sp., Scenedesmus sp., and Spirulina sp. are three species capable of producing PHB (Da Silva et al. 2018; García et al. 2020; Selvaraj et al. 2021). Large quantities of carbon source, such as glucose, are required to produce PHAs, which represents 50% of the total costs of production (Costa et al. 2019). This limitation can be overcome using waste feedstock from industrial waste streams.

Spider silk proteins, such as spider fibroins or spidroins, are another interesting biomaterial that can be obtained from the cultivation of microalgae. The recombinant spider silk proteins have similar properties to those of natural spider silk. This biomaterial has extraordinary properties, such as toughness, strength, elasticity, and biocompatibility, exceeding those of other natural and synthetic materials such as steel, and textile fibres, including Kevlar-like super fibres. Potential applications include biomedical (scaffolds and tissue engineering), hydrogel formation, constructing fibres and electronics.

Genes encoding recombinant spidroin have been expressed in Chlamydomonas reinhardtii. (João Vitor Dutra Molino et al. 2016).

Microalgae lipids provide a potential and attractive alternative to crude oil and a source of building blocks for many interesting chemicals. Many microalgae species can produce large amounts of lipids depending on culture parameters, such as light intensity and nitrates concentration. Several reports on lipid production indicate a production range of up to 80% of dry weight (Encarnação et al. 2018, Hess et al. 2018). These microalgal oils are a great source of feedstock chemicals. Lubricants (Farfan-Cabrera et al. 2022), resins (Hidalgo et al. 2019), additives, polyols and polyurethanes (Peyrton et al. 2020), coatings (Decostanzi et al. 2018), plasticisers and surfactants (Pleissner et al. 2015) are some of the potential products.

Regarding biofuel applications, the development has been at a lab and pilot scale. The conversion of microalgae lipids to biodiesel is performed by a transesterification process in which triglycerides react with monoalcohol (methanol or ethanol) in the presence of acid or alkali catalyst to produce fatty acid methyl esters (FAME) and glycerol as a side product. The two most imposing barriers and limitations to the scale-up of this technology to produce biofuels are the downstream processing costs and the bioprocessing.

Companies, industries, and governments should invest in the circular economy, stimulating the transition for a biobased and green economy. The development has been supported by several National, European and International projects. The European Commission has launched ambitious programmes boosting these transitions (Table 2.2).

2.5 Legislation Framework and Regulations/Policy and Legal Framework

Biobased products are non-food goods, fundamental in a Circular Bioeconomy, which can help to reduce CO2 and pollution (EuropeanCommission n.d.). They are derived from renewable raw materials. When these are obtained from microalgae biomass used in cleaning processes, as the present chapter discusses, special attention to the legislation applicable to them should be verified. Despite the importance attributed to those products by the Regulatory Entities, and some progress has been made, there is still a long way ahead for better clarification of the rules. For instance, the Legislation for Biobased products in the EU and USA should guarantee standards and measurements which allow the industries to make them available in terms of sustainability. Depending on the type of biobased products, details in quality control still need to ensure better products and to achieve high acceptance by the Market. It would be ideal that the EU and USA, among others, develop harmonised standards for such products to reduce trade barriers and foster a more broad market. However, until now, limited research has been conducted on biobased products derived from microalgae used in bioremediation, and this could drive some constraints on the companies due to some toxic contaminants not yet well evaluated or unknown.

Before we go further in detail on the legislation available, we must highlight some considerations. Regarding biobased materials from microalgae, it is important to identify the products produced and what will be the targeting industry. Thus, it is possible to organise and orient the application of the available legislation. Until now, the well-established bioproducts obtained from algae (macroalgae) were alginates, agar and carrageenans (phycocolloid production), almost exclusively from seaweeds (macroalgae brown and red) and other biopolymers, such as starch, cellulose, chitin and PHA (biodegradable plastic). It is consensual that in these last years, the growth in the production of microalgae introduced a new perspective in the biotransformation and production of different new biomaterials, which require a more detailed look at the possibilities. Moreover, as referred to above in this chapter, the production of high-value products include biopolymers, carbohydrates, lipids, phycobilins, pigments, proteins, polyhydroxyalkanoates, and many more compounds. Resins, coatings, binders, and bioplastics are the main industrial applications as well biofertilisers, food and feed, pharmaceuticals, cosmetics and products for personal care. Even bioplastics which can be converted to produce high-value final products such as medical equipment, prosthetics and scaffolds, will add a new perspective market for these biobased products. Therefore, the legislation available should reflect clear information to be followed, if different from the biobased obtained from plants, for instance. Other interesting microalgae products include the bioactive oligosaccharides (extracted by enzymatic methods), biopigments for food supplements (carotenoids and xanthophylls) or for paints, and cosmetic bioactive compounds for skincare (ex. Porphyridium cruentum extract) and γ-linoleic acid or alguronic acid from Chlorella extract. For all of the cited products, the legislation used is the same that should be followed for other similar products from different sources. Fertilisers or soil improvers, feed, energy or fuels, soap, and building or packaging materials are some of the possible examples.

Nevertheless, the main concern for biobased materials production for various applications requires intensive regulatory work in order to protect human health and the environment from harmful fractions of waste, especially if the start material is microalgae previously used for wastewater bioremediation. The legal maximum of residues should be cautious, especially because, in certain cases, some of them are unknown. Despite this, the legislation for Agro-food, Cosmetics and Pharmaceutics have already a list of contaminants that should be avoided, and when admitted, the low amounts of them need to be reevaluated cycling, face to the evolution of data provided by science.

Nevertheless, the companies, when preparing a submission to obtain clearance of the material, should evaluate, for instance, which are the appropriate food simulants to be used to estimate the potential for migration and found to prove to authorities that the substance is stable for an intended application that involves a specific type of food, cosmetic or a pharmaceutical purpose. Generally speaking, it may be necessary to demonstrate the suitable purity of a product with respect to the potential presence of possible contaminants such as, for instance, algal biotoxins and mycotoxins, toxic organic compounds such as dioxins and polychlorinated biphenyls, or inorganic compounds already regulated in various materials as human and veterinary medicine residues, heavy metals, nitrates and pesticides.

For instance, a scientific risk assessment carried out by the Scientific Committee for Consumer Safety (SCCS) in Regulation (EC) No. 1223/2009, in order to address potential risks for human health, lays down a system of restrictions and bans on the use of certain substances in cosmetics based classified as carcinogenic, mutagenic or toxic for the reproduction (CMR), of category 1a, 1b or 2, under Part 3 of Annex VI to Regulation (EC) No. 1272/2008. Substances classified as endocrine disruptors are only banned or restricted automatically in cosmetics if they are also classified as CMR. Actually, some substances classified as endocrine disruptors derived from plants are still found in certain cosmetic products, but this issue should be reviewed for the safety of consumers once scientists continue to link endocrine-disrupting chemicals to various diseases and disorders such as cancer, infertility and obesity.

The legislation here referred to below is representative of the most detailed data that should be consulted before submitting for Market Authorization in EU and in the USA biobased products obtained from microalgae used in the bioremediation of wastewater from different sources (Tables 2.3 and 2.4).

In summary, eco-innovation is a priority on the international agenda, and, despite this, all the regulation available is mainly for biobased products other than microalgae derivatives. The tailored production of microalgae biomass and the respective bio-products still have barriers and constraints, mainly in the understanding of the levels and types of contaminants that sometimes could be under-evaluated in the current legislation. Better and more active involvement of the companies in a green intervention will contribute to a stable policy framework with greater harmonisation and coordination around the world, together with a simplification of complex national regulations, which provides more transparency for relevant stakeholders in knowing how sustainable are their products.

Also, national and international programmes and research funding will push forward the development and innovation of these technologies. Moreover, the fact that the alternative products are considered green and biobased is not guaranteed that they have not a similar negative impact on the environment and human health as their conventional counterparts. Therefore, more research is needed to mitigate the potential impacts.

As a final note, the biorefinery concept can transform the linear economy through a biobased circular economy which is an integrated concept that envisages the cascade use of biomass from different sources.

References

Abdel-Raouf N, Al-Homaidan AA, Ibraheem IBM (2012) Microalgae and wastewater treatment. Saudi J Biol Sci 19:257–275. https://doi.org/10.1016/j.sjbs.2012.04.005

Adam S, Santhanam KPP, Kumar SD, Prabhavathi P (2015) Bioremediation of tannery wastewater using immobilized marine microalga Tetraselmis. J Mar Biol Oceanogr 4:1

An Y, Nan M, Chern S, Ilankoon IMSK (2021) Analysis of direct and indirect quantification methods of CO 2 fixation via microalgae cultivation in photobioreactors: a critical review. Renew Sust Energ Rev 137:110579. https://doi.org/10.1016/j.rser.2020.110579

Balzano S, Sardo A, Blasio M, Chahine TB, Anno FD, Sansone C, Brunet C (2020) Microalgal Metallothioneins and Phytochelatins and their potential use in bioremediation. Front Microbiol 11:1–16. https://doi.org/10.3389/fmicb.2020.00517

Baudelet PH, Ricochon G, Linder M, Muniglia L (2017) A new insight into cell walls of Chlorophyta. Algal Res 25:333–371. https://doi.org/10.1016/j.algal.2017.04.008

Bhardwaj D, Bharadvaja N (2021) Phycoremediation of effluents containing dyes and its prospects for value-added products: a review of opportunities. J Water Process Eng 41:102080. https://doi.org/10.1016/j.jwpe.2021.102080

Borowitzka MA (2013) In: M. A. B. a. N. R (ed) Energy from microalgae: a short history. Springer Science, Moheimani

Castellanos-Estupinan MA, Carrillo-Botello AM, Rozo-Granados LS, Becerra-Moreno D, Garcia-Martinez JB, Urbina-Suarez NA, Lopez-Barrera GL, Barajas-Solano AF, Bryan SJ, Zuorro A (2022) Removal of nutrients and pesticides from agricultural runoff using microalgae and cyanobacteria. Water 14:4

Catherine Dupré HDB, Campos MG, Delattre C, Encarnação T, Fauchon M, Gaignard C, Hellio C, Ito J, Laroche C, Legrand J, Michaud P, Pais AACC, Pierre G, Serive B, Watanabe MM (2020) Microalgal biomass of industrial interest: methods of characterization. Handbook on characterization of biomass, biowaste and related by-products. C. e. a. Dupré, Springer, Cham

Cesário MT, Da Fonseca MMR, Marques MM, De Almeida MCMD (2018) Marine algal carbohydrates as carbon sources for the production of biochemicals and biomaterials. Biotechnol Adv 36(3):798–817

Cesario TM, da Fonseca MMR, Marques MM, de Almeida MCMD (2018) Marine algal carbohydrates as carbon sources for the production of biochemicals and biomaterials. Biotechnol Adv 36(3):798–817

Cezare-Gomes EA, Mejia-da-Silva LDC, Perez-Mora LS, Matsudo MC, Ferreira-Camargo LS, Singh AK, de Carvalho JCM (2019) Potential of microalgae carotenoids for industrial application. Appl Biochem Biotechnol 188(3):602–634

Chen C-L, Chang J-S, Lee D-J (2015) Dewatering and drying methods for microalgae. Dry Technol 33(4):443–454

Chojnacka K (2010) Biosorption and bioaccumulation-the prospects for practical applications. Environ Int 36:299–307. https://doi.org/10.1016/j.envint.2009.12.001

Costa SS, Miranda AL, de Morais MG, Costa JAV, Druzian JI (2019) Microalgae as source of polyhydroxyalkanoates (PHAs) - a review. Int J Biol Macromol 131:536–547

Da Silva CK, Costa JAV, De Morais MG (2018) Polyhydroxybutyrate (PHB) synthesis by Spirulina sp. LEB 18 using biopolymer extraction waste. Appl Biochem Biotechnol 185(3):822–833

Danouche M, El Arroussi H, Bahafid W, El Ghachtouli N, El Arroussi H, Bahafid W, An NEG (2021) An overview of the biosorption mechanism for the bioremediation of synthetic dyes using yeast cells. Environ Technol Rev 10:58–76. https://doi.org/10.1080/21622515.2020.1869839

Danouche M, El Ghachtouli N, El Baouchi A, El Arroussi H (2020) Heavy metals phycoremediation using tolerant green microalgae: enzymatic and non-enzymatic antioxidant systems for the management of oxidative stress. J Environ Chem Eng 8:104460. https://doi.org/10.1016/j.jece.2020.104460

Decostanzi M, Lomege J, Ecochard Y, Mora AS, Negrell C, Caillol S (2018) Fatty acid-based cross-linkable polymethacrylate coatings. Prog Org Coat 124:147–157

Encarnação T, Arranja CT, Cova TFGG, Pais AACC, Campos MG, Sobral AJFN, Burrows HD (2018) Monitoring oil production for biobased feedstock in the microalga Nannochloropsis sp.: a novel method combining the BODIPY BD-C12 fluorescent probe and simple image processing. J Appl Phycol 30:2273–2285

Encarnacao T, Palito C, Pais A, Valente AJM, Burrows HD (2020) Removal of pharmaceuticals from water by free and imobilised microalgae. Molecules 25:16

Encarnacao T, Santos D, Ferreira S, Valente AJM, Pereira JC, Campos MG, Burrows HD, Pais A (2021) Removal of imidacloprid from water by microalgae Nannochloropsis sp. and its determination by a validated RP-HPLC method. Bull Environ Contam Toxicol 107(1):131–139

Eroglu E, Agarwal V, Bradshaw M, Chen XJ, Smith SM, Raston CL, Iyer KS (2012) Nitrate removal from liquid effluents using microalgae immobilized on chitosan nanofiber mats. Green Chem 14(10):2682–2685

Espinoza Pérez AT, Camargo M, Narváez Rincón PC, Alfaro Marchant M (2017) Key challenges and requirements for sustainable and industrialized biorefinery supply chain design and management: a bibliographic analysis. Renew Sust Energ Rev 69:350–359

European Commission (n.d.) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A new Circular Economy Action Plan For a cleaner and more competitive Europe COM/2020/98 final. https://ec.europa.eu/growth/industry/sustainability/circular-economy_en

Eze VC, Velasquez-orta SB, Hernández-garcía A, Monje-ramírez I, Orta-ledesma MT (2018) Kinetic modelling of microalgae cultivation for wastewater treatment and carbon dioxide sequestration. Algal Res 32:131–141. https://doi.org/10.1016/j.algal.2018.03.015

Fal S, Benhima R, El Mernissi N, Kasmi Y, Smouni A, El Arroussi H (2021) Microalgae as promising source for integrated wastewater treatment and biodiesel production. Int J Phytoremediation 1–13. https://doi.org/10.1080/15226514.2021.1920572

Farfan-Cabrera LI, Franco-Morgado M, Gonzalez-Sanchez A, Perez-Gonzalez J, Marin-Santibanez BM (2022) Microalgae biomass as a new potential source of sustainable green lubricants. Molecules 27:4

Ferrando L, Matamoros V (2020) Attenuation of nitrates, antibiotics and pesticides from groundwater using immobilised microalgae-based systems. Sci Total Environ 703:134740

Francavilla M, Trotta P, Luque R (2010) Phytosterols from Dunaliella tertiolecta and Dunaliella salina: a potentially novel industrial application. Bioresour Technol 101(11):4144–4150

Fu J, Huang Y, Liao Q, Xia A, Fu Q, Zhu X (2019) Bioresource technology photo-bioreactor design for microalgae: a review from the aspect of CO2 transfer and conversion. Bioresour Technol 292:121947. https://doi.org/10.1016/j.biortech.2019.121947

García G, Sosa-Hernández JE, Rodas-Zuluaga LI, Castillo-Zacarías C, Iqbal H, Parra-Saldívar R (2020) Accumulation of PHA in the microalgae Scenedesmus sp. under nutrient-deficient conditions. Polymers 13(1):131

Gómez-Jacinto V, García-Barrera T, Gómez-Ariza JL, Garbayo-Nores I, Vílchez-Lobato C (2015) Elucidation of the defence mechanism in microalgae Chlorella sorokiniana under mercury exposure. Identification of Hg-phytochelatins. Chem Biol Interact 238:82–90. https://doi.org/10.1016/j.cbi.2015.06.013

Gomez-Loredo A, Benavides J, Rito-Palomares M (2016) Growth kinetics and fucoxanthin production of Phaeodactylum tricornutum and Isochrysis galbana cultures at different light and agitation conditions. J Appl Phycol 28(2):849–860

Hammouda O, Gaber A, Abdel-Raouf N (1995) Microalgae and wastewater treatment. Ecotoxicol Environ Saf 31:205–210

Hanikenne M, Merchant SS, Hamel P (2009) Transition metal nutrition: a balance between deficiency and toxicity, the chlamydomonas sourcebook. 333–399. https://doi.org/10.1016/B978-0-12-370873-1.00018-6

Hena S, Gutierrez L, Crou J (2021) Removal of pharmaceutical and personal care products (PPCPs) from wastewater using microalgae : a review. J Hazard Mater 403. https://doi.org/10.1016/j.jhazmat.2020.124041

Hess SK, Lepetit B, Kroth PG, Mecking S (2018) Production of chemicals from microalgae lipids—status and perspectives. Eur J Lipid Sci Technol 120(1):1700152

Hidalgo P, Navia R, Hunter R, Gonzalez ME, Echeverria A (2019) Development of novel bio-based epoxides from microalgae Nannochloropsis gaditana lipids. Compos Part B-Eng 166:653–662

Hoang AT, Sirohi R, Pandey A, Nizetic S, Lam SS, Chen WH, Luque R, Thomas S, Arici M, Pham VV (2022) Biofuel production from microalgae: challenges and chances. Phytochem Rev

Ibuot A, Dean AP, Mcintosh OA, Pittman JK (2017) Metal bioremediation by CrMTP4 over-expressing Chlamydomonas reinhardtii in comparison to natural wastewater-tolerant microalgae strains. Algal Res 24:89–96

João Vitor Dutra Molino TLA, Ferreira-Camargo LS, Croce MA, Tanaka A, Buson FX, de Freitas Ribeiro P, Campos-Salazar AB, Antonio EP, Maizel AS, Siratuti VM, Costa C, Wlodarczyk SR, de Souza Lima R, Mello FN, Mayfield SP, Carvalho JCM (2016) Chimeric spider silk production in microalgae: a modular bionanomateria. Res Ideas Outcomes 2:e9342

Khatami K, Perez-Zabaleta M, Cetecioglu Z (2021) Pure cultures for synthetic culture development: next level municipal waste treatment for polyhydroxyalkanoates production. J Environ Manag 305:114337

Kong W, Shen B, Lyu H, Kong J, Ma J (2021) Review on carbon dioxide fixation coupled with nutrients removal from wastewater by microalgae. J Clean Prod 292:125975. https://doi.org/10.1016/j.jclepro.2021.125975

Koutra E, Economou CN, Tsafrakidou P, Kornaros M (2018) Bio-based products from microalgae cultivated in digestates. Trends Biotechnol 36(8):819–833

Kumar D, Santhanam SP, Jayalakshmi T, Nandakumar R, Ananth S, Devi AS, Prasath BB (2015a) Excessive nutrients and heavy metals removal from diverse wastewaters using marine microalga Chlorella marina (Butcher). Indian J Geo-Mar Sci 44(1):97–103

Kumar KS, Dahms HU, Won EJ, Lee JS, Shin KH (2015b) Microalgae—a promising tool for heavy metal remediation. Ecotoxicol Environ Saf 113:329–352. https://doi.org/10.1016/j.ecoenv.2014.12.019

Lee L, Hsu CY, Yen HW (2017) The effects of hydraulic retention time (HRT) on chromium (VI) reduction using autotrophic cultivation of Chlorella vulgaris. Bioprocess Biosyst Eng 40:1725–1731. https://doi.org/10.1007/s00449-017-1827-6

Li H, Li H, Meng F, Zhang B, Lin Y, Wu J, Wang G, Zheng Y (2020) The biodegradation of Para-xylene in seawater by a newly isolated oceanic microalga Rhodomonas sp. JZB-2. J Water Process Eng 36:101311

Maryjoseph S, Ketheesan B (2020) Microalgae based wastewater treatment for the removal of emerging contaminants: a review of challenges and opportunities. Case Stud Chem Environ Eng 2:100046. https://doi.org/10.1016/j.cscee.2020.100046

Mendoza-co D, Loza-tavera H, Herna A, Moreno-sa R (2005) Sulfur assimilation and glutathione metabolism under cadmium stress in yeast, protists and plants. FEMS Microbiol Rev 29:653–671. https://doi.org/10.1016/j.femsre.2004.09.004

Muthukumar ASE, Ajithkumar TT, Kumaresan S, Balasubramanian T (2012) Biodiesel production from marine microalgae chlorella marinaand Nannochloropsissalina. J Pet Technol Altern Fuels 3:58–62

Naveed S, Li C, Lu X, Chen S, Yin B, Zhang C, Ge Y (2019) Microalgal extracellular polymeric substances and their interactions with metal(loid)s: a review. Crit Rev Environ Sci Technol 49:1769–1802. https://doi.org/10.1080/10643389.2019.1583052

O'Neil GW, Gale AC, Nelson RK, Dhaliwal HK, Reddy CM (2021) Unusual shorter-chain C35 and C36 alkenones from commercially grown Isochrysis sp. Microalgae. J Am Oil Chem Soc 98:757–768

Parvin Molazadeh NK, Rahimi MR, Nasiri A (2015) Adsorption of lead by microalgae Chaetoceros Sp. and Chlorella Sp. from aqueous solution. J Commun Health Res 4(2):114–127

Pérez-Rama M, Abalde Alonso J, Herrero López C, Torres Vaamonde E (2002) Cadmium removal by living cells of the marine microalga Tetraselmis suecica. Bioresour Technol 84:265–270. https://doi.org/10.1016/S0960-8524(02)00045-7

Peyrton J, Chambaretaud C, Sarbu A, Averous L (2020) Biobased polyurethane foams based on new polyol architectures from microalgae oil. ACS Sustain Chem Eng 8(32):12187–12196

PierreChevalier JLN (1985) Wastewater nutrient removal with microalgae immobilized in carrageenan. Enzym Microb Technol 7:621–624

Pleissner D, Lau KY, Zhang CW, Lin CSK (2015) Plasticizer and surfactant formation from food-waste and algal biomass-derived lipids. ChemSusChem 8(10):1686–1691

Reddy CS, Ghai R, Rashmi, Kalia VC (2003) Polyhydroxyalkanoates: an overview. Bioresour Technol 87(2):137–146

Ruiz-Dominguez MC, Cerezal P, Salinas F, Medina E, Renato-Castro G (2020) Application of box-Behnken design and desirability function for green prospection of bioactive compounds from Isochrysis galbana. Appl Sci-Basel 10:8

Sankaran R, Show PL, Nagarajan D, Chang JS (2018) Exploitation and biorefinery of microalgae. Waste Bioref Potential Perspect:571–601

Schuler LM, Santos T, Pereira H, Duarte P, Gangadhar KN, Florindo C, Schulze PSC, Barreira L, Varela JCS (2020) Improved production of lutein and beta-carotene by thermal and light intensity upshifts in the marine microalga Tetraselmis sp. CTP4. Algal Res-Biomass Biofuels and Bioproducts 45

Selvaraj K, Vishvanathan N, Dhandapani R (2021) Screening, optimization and characterization of poly hydroxy butyrate from fresh water microalgal isolates. Int J Biobased Plast 3(1):139–162

Semple KT, Cain RB, Schmidt S (1999) Biodegradation of aromatic compounds by microalgae. FEMS Microbiol Lett 170:291–300. https://doi.org/10.1111/j.1574-6968.1999.tb13386.x

Shanab S, Essa A, Shalaby E (2012) Bioremoval capacity of three heavy metals by some microalgae species (Egyptian isolates). Plant Signal Behav 7. https://doi.org/10.4161/psb.19173

Shi J, Podola B, Melkonian M (2007) Removal of nitrogen and phosphorus from wastewater using microalgae immobilized on twin layers: an experimental study. J Appl Phycol 19(5):417–423

Singaram VNJ (2022) Enhanced biodiesel production by optimizing growth conditions of Chlorella marina in tannery wastewater. Fuel 316:123431

Singh DV, Bhat RA, Upadhyay AK, Singh R, Singh DP (2021b) Microalgae in aquatic environs: a sustainable approach for remediation of heavy metals and emerging contaminants. Environ Technol Innov 21:101340. https://doi.org/10.1016/j.eti.2020.101340

Singh PK, Bhattacharjya R, Saxena A, Mishra B, Tiwari A (2021a) Utilization of wastewater as nutrient media and biomass valorization in marine Chrysophytes- Chaetoceros and Isochrysis. Energy Convers Manage-X 10:100062

Song C, Liu Q, Qi Y, Chen G, Song Y, Kansha Y (2019) Absorption-microalgae hybrid CO2 capture and biotransformation strategy-a review. Int J Greenhouse Gas Control 88:109–117. https://doi.org/10.1016/j.ijggc.2019.06.002

Sundarrajan P, Panchamoorthy K, Greetham D, Joseph A (2019) A review on cleaner production of biofuel feedstock from integrated CO2 sequestration and wastewater treatment system. J Clean Prod 210:445–458. https://doi.org/10.1016/j.jclepro.2018.11.010

't Lam, G. P., M. H. Vermue, M. H. M. Eppink, R. H. Wijffels and C. van den Berg (2018). "Multi-product microalgae biorefineries: from concept towards reality." Trends Biotechnol 36(2): 216–227

Taguchi S, Matsumoto K (2021) Evolution of polyhydroxyalkanoate synthesizing systems toward a sustainable plastic industry. Polym J 53(1):67–79

Tiwari BMA (2021) Cultivation of Anabena variabilis, Synechococcus elongatus, Spirulina platensis for the production of C-phycocyanin, C-phycoerythrin and Thalassiosira, Skeletonema, Chaetoceros for fucoxanthin. Syst Microbiol Biomanufacturing 1:356–361

Ubando AT, Africa ADM, Maniquiz-Redillas MC, Culaba AB, Chen WH, Chang JS (2021) Microalgal biosorption of heavy metals: a comprehensive bibliometric review. J Hazard Mater 402:123431. https://doi.org/10.1016/j.jhazmat.2020.123431

Vermeer CM, Bons LJ, Kleerebezem R (2022) Production of a newly discovered PHA family member with an isobutyrate-fed enrichment culture. Appl Microbiol Biotechnol

Wang W, Dei RCH (2006) Metal stoichiometry in predicting Cd and Cu toxicity to a freshwater green alga Chlamydomonas reinhardtii. Environ Pollut 142:303–312. https://doi.org/10.1016/j.envpol.2005.10.005

Wang YJ, Meng FP, Li H, Zhao SL, Liu QQ, Lin YF, Wang GS, Wu JY (2019) Biodegradation of phenol by Isochrysis galbana screened from eight species of marine microalgae: growth kinetic models, enzyme analysis and biodegradation pathway. J Appl Phycol 31(1):445–455

Xu Z, Wang H, Cheng P, Chang T, Chen P, Zhou C, Ruan R (2020) Development of integrated culture systems and harvesting methods for improved algal biomass productivity and wastewater resource recovery—a review. Sci Total Environ 746:141039

Yen H, Chen P, Hsu C, Lee L (2017) The use of autotrophic Chlorella vulgaris in chromium (VI) reduction under different reduction conditions. J Taiwan Inst Chem Eng 74:1–6. https://doi.org/10.1016/j.jtice.2016.08.017

Zeng X, Danquah MK, Dong X, Lu Y (2011) Microalgae bioengineering: from CO2 fixation to biofuel production. Renew Sust Energ Rev 15:3252–3260. https://doi.org/10.1016/j.rser.2011.04.014

Zhou W, Wang J, Chen P, Ji C, Kang Q, Lu B, Li K, Liu J, Ruan R (2017) Bio-mitigation of carbon dioxide using microalgal systems: advances and perspectives. Renew Sust Energ Rev 76:1163–1175. https://doi.org/10.1016/j.rser.2017.03.065

Acknowledgements

The authors acknowledge the Fundação para a Ciência e a Tecnologia (FCT) through the project PTDC/BTA-GES/2740/2020_NABIA. The Coimbra Chemistry Centre (CQC) is supported by the FCT through the projects UIDB/00313/2020 and UIDP/00313/2020. CDRSP is financed by national funds through the FCT/MCTES (UIDB/00481/2020 & UIDP/00481/2020). We are grateful for funding from PTScience which is supported through the programmes CENTRO-05-4740-FSE-001526 and FEDER.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Encarnação, T. et al. (2023). Bioremediation Using Microalgae and Cyanobacteria and Biomass Valorisation. In: Encarnação, T., Canelas Pais, A. (eds) Marine Organisms: A Solution to Environmental Pollution?. Environmental Challenges and Solutions. Springer, Cham. https://doi.org/10.1007/978-3-031-17226-7_2

Download citation

DOI: https://doi.org/10.1007/978-3-031-17226-7_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-17225-0

Online ISBN: 978-3-031-17226-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)