Abstract

At present, the traditional robot grinding has some shortcomings in output constant force control. As a result, the output force on the grinding object is frequently instable. Improper force can damage the object during grinding and lead huge economic loss. Therefore, how to improve the accuracy of the output force of robot grinding, has become an urgent problem to be solved. In this paper, aim to improve the grinding force control accuracy, a new control framework which is suitable for cylinder driven grinding device is proposed. The control framework is applied to control the cylinder output force of the grinding device, thereby improving the control ability of the high-precision grinding process robot. In the framework, a PID controller with nonlinear differential gain parameters is used, and parameters are optimized by using the Particle Swarm Optimization Algorithm (PSO). The proposed control method, based on the model of the actual cylinder driven grinding device, is verified in MATLAB. The results show that it controls the actual force of the grinding object near the ideal force accurately. The overshoot of the output force on the grinding object is zero and the system stability is very good.

Funded by National Natural Science Foundation of China(62173190, U1913207).

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

1.1 A Subsection Sample

Grinding is a finishing process. It is widely used in high-precision design, such as fan blades [1], aerospace, automobiles [2], medical supplies [3], gear wheel [4], bone-cutting operation [5,6,7] and other high-tech and sophisticated fields [8]. Robot grinding is mainly used for workpiece surface grinding, sharp corners deburring, weld grinding, holes of internal cavity deburring and other scenarios [9]. So, if the robot’s cutting force is not properly controlled in the grinding process, it may cause irreversible damage to the grinding object. And it will give rise to unimaginable terrible consequences when a large error robot grinding is used in the high precision requirements fields. In recent years, with the increasing demand for efficient and economical flexible precision machining equipment, it is urgent to realize robot high-precision grinding. So, the research of high-precision robot grinding technology is of great value to achieve technological breakthroughs in industrial automation and even other fields [10].

Automated grinding requires not only precise position control, but also flexible force mixing control [11]. At present, the research on the flexible control of robot grinding mainly focuses on the following two aspects. One is the active compliance, achieved by force/position hybrid control and impedance control of the robot control algorithm [12]. The other is the passive compliance whose buffering is realized by using compliance mechanisms such as abrasive bands and so on [13]. It is noteworthy that, although good robustness is eventually obtained, the active compliance control of the mechanical arm generally has problems such as complex control algorithms and complicated realizing processes [14]. The passive compliance avoids the rigid contact between the grinding device and the grinding object. It is natural obedience. Not only due to low accuracy requirements of the robot, but also the force control and position control are decentralized, passive compliance has a wider application prospect in the industrial field. However, passive compliance control method has low accuracy and long response time for the output force, so it is not suitable for high precision grinding [15].

Therefore, focusing on the basic problems of passive compliance robot high-precision grinding control, we carried out research on improving the control accuracy of grinding device output force. In this paper, based on the model of an actual cylinder driven grinding device, a new controller with nonlinear differential gain is designed. Parameters optimization is made by introducing The Particle Swarm Optimization Algorithm (PSO) to obtain a more accurate output force of the grinding device. The new controller is expected to significantly improve the grinding accuracy and effectively reduces the probability of damage to the grinding objects.

The other components of this paper are as follows. Section 2 describes the mechanism model of the cylinder driven grinding device through the grinding tool dynamic model and the cylinder model respectively. Section 3 discusses the establishment of a nonlinear PID controller for the force output of the cylinder driven grinding device, and how to obtain the optimal PID controller parameters by introducing the Particle Swarm Optimization Algorithm. Section 4 simulates and verifies the control effect, and compares it with the original controller. And Sect. 5 summarizes the work and prospects finally (Table 1).

2 Mechanism Model of the Grinding Device

2.1 Grinding Tool Dynamics Model

The research object is a two-part grinding device, one is a cylinder and the other is a grinding tool. The device is equipped with force sensor and inclination sensor. Force sensor is used to obtain the force on the tool. Inclination sensor measures angle between gravity and the direction perpendicular to the contact surface in real time. A pressure regulating valve is selected as the pressure difference regulating actuator of the system.

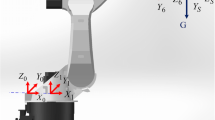

When the force or inclination changes, the pressure regulating valve will change its output voltage. Then, the air pressure on both sides of the cylinder piston will be adjusted, and the pressure difference will make the piston displaced. Since the expand and contract of the tool relates to the piston displacement, the air pressure difference can indirectly control the output force of the device. The appropriate output force control can maintain the grinding force constantly. The force analysis of the grinding tool during operation is shown in Fig. 1.

According to Newton’s Second Law, we can obtain the kinetic equation of the grinding device as follows:

where M0 can be obtained by weighing, f can be obtained by identifying friction forces at different speeds, and Fd is calculated as follows:

2.2 Cylinder Model

The research object is a two-part grinding device, one is a cylinder and the other is a grinding tool. The device is equipped with force sensor and inclination sensor. Force sensor is used to obtain the force on the tool. Inclination sensor measures angle between gravity and the direction perpendicular to the contact surface in real time. A pressure regulating valve is selected as the pressure difference regulating actuator of the system.

Cylinders have obvious nonlinear properties, and it is difficult to model a nonlinear system directly. Therefore, by taking the pressure regulating valve and the cylinder as a whole, the model form U to Pd is established. This model greatly reduces the difficulty and error of modeling.

By comparing the fitting results of different order transfer equations, the second-order model of the optimal fitting system is finally obtained as follows:

where the parameters are as follows: a = 0.008, b = 0.048, c = 1.601 [15].

In summary, the grinding device system model used in this paper is as follows:

3 Control of the Output Force of the Grinding Device

3.1 Control Framework Based on a Nonlinear Differential Gain PID Controllers

The input Fn0 is set value of constant grinding force on the grinding object in the actual operation process. Fd0(s) is calculated by the model shown in Sect. 2. Pd(s) is measured value of the air pressure. We want to get a grinding device that can realize the function of constant force grinding. This means that the device can restore the expected value Fn0 in a short time after the force on the grinding object fluctuates. In order to meet this condition, we must ensure that Fd(s) follows Fd0(s) efficiently in the simulation experiment.

The PID controller is used and it ensures that the actual value of the output force follows the ideal value quickly and stably. At the same time, PID controller can reduce the possibility of overshoot damage to the grinded object. When the controller receives the ideal value and actual values of the output force, it will use the error between the two to calculate a correction value. The correction value can make the actual value gradually approach the ideal value and eliminate the error in a short period of time.

In order to adjust the output force of the grinding tool, the controller is designed as a nonlinear differential gain PID controller and is optimized by PSO. It can increase the damping ratio and improve the dynamic response efficiency of the output force under the condition of ensuring that the natural frequency is unchanged. According to the principle of PID control system, an equation can be construct as follows:

where e(t) is calculated as follows:

The nonlinear part K is a function of e(t), so Eq. (5) can be seen as adding a nonlinear sector to the general PID. The structural diagram of the nonlinear differential gain PID control system is shown in Fig. 3.

Since the response of the grinding device is basically without overshoot, it is only necessary to slowly increase the parameters of the differential sector to suppress overshoot. Therefore, the differential gain equation is constructed as follows:

where the parameters ad, bd, cd, dd are all positive real numbers. The adjustment error e(t) is positively correlated with the differential gain and the output control amount. So, it can effectively make the system quickly tend to the target value (Fig. 2).

3.2 Controller Parameter Selection Based on the Particle Swarm Optimization Algorithm

The parameters of the differential gain are expected to adjust to an optimal state, in which the controller will have the best output force following effect. There are seven parameters in the designed nonlinear differential gain PID controller altogether. What’s more, the interaction between each parameter is completely complex. The results obtained by using the general optimization algorithm are instable. Therefore, we choose to use the Particle Swarm Optimization Algorithm. The PSO has high stability, and can accurately identify the optimal regions that can meet the needs of the particle swarm in complex particle interactions. Moreover, the PSO is efficient and has relatively simple implementation.

Therefore, the whole controller is used as the optimized object in this paper. Thus, the optimal parameter can be founded through continuous evolutionary iteration of the algorithm.

4 Simulation Experiments

4.1 Simulation Configuration and Methods

In this paper, Simulink is used for simulation experiments. Generally grinding work is usually slow and smooth and the acceleration of the grinding tool is small. So, the effect of acceleration on the calculation of the ideal output force is ignored in the simulation experiment.

In the simulation experiment, the parameters of the system are configured as follows:

-

Assignment

Before starting the experiment, some parameters in the whole device were given specific values (Table 2):

Table 2. The parameters of the device -

Classification

In this paper, three grinding scenarios are set up as follows:

-

a)

Scenario 1: Grinding objects from plane to slope: α only mutations and no continuous changes.

-

b)

Scenario 2: Grinding objects from plane to arc: α both mutations and monotonous continuous changes.

-

c)

Scenario 3: Grinding objects have only an arc surface: α no mutations and only nonmonotonic continuous changes.

-

a)

-

Particle Swarm Optimization Algorithm:

The parameters of the controller before optimization [15] are shown as follows (Table 3):

Table 3. The parameters of the original controller

The relevant parameter settings for using the Particle Swarm Optimization Algorithm are showed as follows (Table 4):

To prevent overshoots from appearing, we set a penalty for overshooting that is greater than a penalty for not overshooting. After the program runs, the changes of objective function are shown in Fig. 4(a).

After optimizing the parameters of the controller using the Particle Swarm Optimization Algorithm, we get the results as follows (Table 5):

As the iteration increases, the variation curves of each parameter are shown in the Fig. 4 and Fig. 5.

To test its control performance in different grinding states, we conduct a virtual simulation experiment on the model according to the three scenarios proposed in the previous section. We use scenario 1 to compare the effect before the controller parameter optimization and the effect after.

-

a)

Scenario 1: Fig. 6(a) is the following result of Fn before parameter optimization, and Fig. 6(b) is the following result of Fn after parameter optimization.

From the comparison of Fig. 6(a) and Fig. 6(b), it can be seen that after optimizing the parameters, the performance of PID controller has been proved. When the α suddenly changes, not only the response time becomes faster, but also the accuracy of following the set point becomes higher. The control effect of the constant force is significantly higher than that of the PID controller Using the original parameters. Therefore, the optimization, Using the PSO, can indeed significantly improve the following effect of the actual output force of the grinding device on the ideal output force.

-

b)

Scenario 2: In Scenario 2, the effect of the actual value following the ideal value is shown in Fig. 6(c).

-

c)

Scenario 3: In Scenario 3, the effect of the actual value following the ideal value is shown in Fig. 6(d).

From the following results of the above three scenarios, when the α is unchanged or continuously changed, the control method designed in this paper can accurately control the force received by the grinding object around the set constant force. When the angle α mutation occurs, there will be a small mutation in the force of the grinding object. The size of the mutation is positively correlated with the size of the α mutation. But the nonlinear differential gain PID controller adjusts it to the size of the set value in less than a second. In actual industrial production, the angle mutation is unusual, so the presence of the mutation has less impact on the accuracy of the grinding process.

Control result of actual force on the grinding object: (a) The original parameter Fn following result in scenario 1; (b) The optimized parameter Fn following result in scenario 1; (c) The optimized parameter Fn following result in scenario 2; (d) The optimized parameter Fn following result in scenario 3.

5 Conclusion

This paper studies how to more effectively realize the constant force grinding based on cylinder control. Firstly, the entire system’s two parts, the grinding tool and the cylinder, are respectively modeled. Then a framework based on the nonlinear differential gain PID controller is build. The parameters are optimized using the Particle Swarm Optimization Algorithm. Finally, the optimized controller’s advantage, can get a more accurate control and faster response to the constant force following effect, is verified through simulation experiments. However, there is shortcoming in this paper. The operating environment of the simulation experiment is very ideal. In actual operation process, there will be other uncontrollable factors that affect the system. Therefore, the following effect of the controller in real work needs to be verified by further practical experiments.

References

Chong, Z., Xie, F., Liu, X.J., et al.: Design of the parallel mechanism for a hybrid mobile robot in wind turbine blades polishing. Robot. Comput.-Integr. Manuf. 61, 101857-1–101857-9 (2020)

Pereira, B., Griffiths, C.A., Birch, B., Rees, A.: Optimization of an autonomous robotic drilling system for the machining of aluminum aerospace alloys. Int. J. Adv. Manuf. Technol. 119, 2429–2444 (2021). https://doi.org/10.1007/S00170-021-08483-4

Preciado, D., Wilson, E., Fooladi, H., Sang, H., Cleary, K., Monfaredi, R.: A new surgical drill instrument with force sensing and force feedback for robotically assisted otologic surgery. J. Med. Dev. 11(3), 031009 (2017). https://doi.org/10.1115/1.4036490

Klingelnberg GmbH: Apparatus for grinding machining of gear wheel workpieces. Patent Application Approval Process (USPTO 20190329339). Politics & Government Week (2019)

Xia, G., Zhang, L., Dai, Y., Xue, Y., Zhang, J.: Vertebral lamina state estimation in robotic bone milling process via vibration signals fusion. IEEE Trans. Instrum. Measur. 71(1), 1–10 (2022). https://doi.org/10.1109/TIM.2022.3161704

Xia, G., Jiang, Z., Zhang, J., Wang, R., Dai, Y.: Sound pressure signal based bone cutting depth control in robotic vertebral lamina milling. IEEE Sens. J. 22(11), 10708–10718 (2022). https://doi.org/10.1109/JSEN.2022.3167664

Xia, G., Dai, Y., Zhang, J., Jia, B.: A method of bone cutting depth control for surgical robot based on acoustic signals. Robot 43(1), 101–111 (2021). https://doi.org/10.13973/j.cnki.robot.200035

Wu, X., Huang, Z., Wan, Y., et al.: A novel force-controlled spherical polishing tool combined with self-rotation and co-rotation motion. IEEE Access 8, 108191–108200 (2020)

Guo, W., Zhu, Y., He, X.: A robotic grinding motion planning methodology for a novel automatic seam bead grinding robot manipulator. IEEE Access 8, 75288–75302 (2020)

Zhu, D., Feng, X., Xu, X., et al.: Robotic grinding of complex components: a step towards efficient and intelligent machining–challenges, solutions, and applications. Robot. Comput.-Integr. Manuf. 65, 101908-1–101908-15 (2020)

Luo, Z., Li, J., Bai, J., Wang, Y., Liu, L.: Adaptive hybrid impedance control algorithm based on subsystem dynamics model for robot polishing. In: Yu, H., Liu, J., Liu, L., Ju, Z., Liu, Y., Zhou, D. (eds.) ICIRA 2019. LNCS, pp. 163–176. Springer, Cham (2019). https://doi.org/10.1007/978-3-030-27529-7_15

Zhang, Y.D.: Research on robot control method based on six-dimensional force sensor. Master’s degree, Huazhong University of Science & Technology (2019)

Li, J., Guan, Y., Chen, H., et al.: A high-bandwidth end-effector with active force control for robotic polishing. IEEE Access 8, 169122–169135 (2020)

Xu, X., Chen, W., Zhu, D., et al.: Hybrid active/passive force control strategy for grinding marks suppression and profile accuracy enhancement in robotic belt grinding of turbine blade. Robot. Comput.-Integr. Manuf. 67, 102047-1 (2021)

Li, P.W.: Research on constant force control method of compliance device for high precision grinding operation. Master’s degree, Naikai University (2021)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Wen duo, J., Zi feng, J., Yu, D. (2022). Constant Force Control Method of Grinding Device. In: Liu, H., et al. Intelligent Robotics and Applications. ICIRA 2022. Lecture Notes in Computer Science(), vol 13457. Springer, Cham. https://doi.org/10.1007/978-3-031-13835-5_34

Download citation

DOI: https://doi.org/10.1007/978-3-031-13835-5_34

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-13834-8

Online ISBN: 978-3-031-13835-5

eBook Packages: Computer ScienceComputer Science (R0)