Abstract

Organic dyes utilised in textile industry possess poisonous toxins and thus are subjected to treatment to avoid being released into the environment. Several methodologies, including physical, chemical and biological methods, have been used to solve this challenge. Photocatalysis is now one of the most advanced oxidation processes, which is carried out using light and proper photocatalytic materials. Heterogeneous photocatalysis offers multiple advantages, including being environmentally acceptable, cost-effective and effective in degrading different colours and organic pollutants found in waste effluent. For the treatment of textile effluent including dye components, a variety of photocatalysts, as well as modified or composite photocatalysis, are utilised. The most promising component appears to be titanium dioxide (TiO2), and various modified variants of TiO2 exhibit increased photocatalytic activity on dye degradation. This chapter discusses the many traditional procedures for removing dyestuffs from textile effluents, as well as the photocatalysis process in detail. Photocatalysis was used to remove many dye components, which was also covered in this chapter.

Rahul Bhattacharjee and Tamoghni Mitra—Contributed equally.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

7.1 Introduction

The growth of the global population is the indicator of the development of numerous establishments leading to industrialisation for nurturing the population demands. Handicrafts and textile industries, tanneries, pulp and paper industries have all grown along with the development of industries fulfilling the requirements of essential supplies like medicine, food, fuel, etc.; produces a massive volume of coloured effluents, which is responsible for causing global environmental problems if dumped into neighbouring waterbodies without ample treatment for decolorizing the dyes. Natural colourants prepared from crushing fruits and plant products have been used extensively for fabrics colouration before globalisation, but the revolution necessitates the use of more advanced and synthetic colouring agents of many variations to fulfil the demands according to the requirement during the dyeing practices of not only in the tannery and textile industries but in the food industries and pharmaceutical industries also. Different synthetic dyes used for fabrics colouration are methylene blue, malachite green, methyl orange, etc.; causes deprivation of the aquatic environment because of their stable configurations, when dumped without appropriate precautions (Khan and Mondal 2021). There are over a million distinct types of dyes commercially available, which are frequently used in the textile industry, producing 50,100 L wastewater effluents per kilogram of finished material (Khan and Mondal 2021; Manu and Chaudhari 2002; Lai 2014). Since dyes are non-biodegradable and remain in the environment for prolonged durations, they instigate adverse consequences, such as the blocking of sunlight by the higher colour intensity in freshwater bodies, causing the death of aquatic life forms. Apart from that, it was also accountable for lessening the safety of drinking water. Considering the persistent nature of these organic molecules which are light-resistant and withstand aerobic degradation, the management of wastewater effluents containing dyes and pigments, often known as ‘new and emerging contaminants,’ is extremely challenging. Due to incomplete dye degradation during wastewater treatment, the formation of highly poisonous, carcinogenic properties bearing naphthalene, benzidine and other aromatic intermediate products are escalating (Suteu et al. 2011; Borker and Salker 2006; Dave et al. 2021; Satapathy et al. 2021; Dave 2021), requiring a method for destroying dyes and pigments contained in wastewater into simple, non-toxic molecules.

Wastewater containing dyes and colouring pigments is treated using a variety of physical, chemical, biological, electrochemical and photochemical techniques, while photocatalysis is presumed to be a reasonable solution among them for removing dissolved organic pollutants. In contrast to physical procedures (adsorption process and aslocoagulation process), When used in conjunction with photocatalysis, waste effluents may be readily transferred to other media and generally create impurities, but organic dye molecules can be mineralised into water, mineral acids and CO2. The employment of biological processes is restricted due to the long retention period and the death of living bacteria in very hazardous conditions. The chemical reactions mediated by light in the presence of a photocatalyst, a substance capable of light absorption and speeding up the reaction rate, are known as photocatalysis. A photocatalyst upon light absorption produces an electron–hole pair that triggers chemical conversions and regenerates its chemical configuration (Fox and Dulay 1993). This photocatalytic approach has captured the curiosity of experts in recent years, having the potential to address a variety of environmental concerns. This approach is widely regarded as a fantastic model for wastewater treatment and the green movement, allowing for a green economic climate. There are no oxidants required and the process takes place under normal atmospheric conditions (Khan and Mondal 2021).

7.2 Classification of Dyes

Prior to the development of synthetic dyes, there were just a few natural dyes available. As a result of the rise in yearly worldwide dye output, it has become necessary to classify dyes. According to estimates, they might be in the millions of tonnes (Gürses et al. 2016). There are numerous structural variations in dyes, making it impossible to classify them all based on just one criterion. This is also useless from a practical standpoint.

In the colour index, synthetic dyes and textile dyes may be classed based on their colour, chromophore structure and manner of application (Allen 2013; Rauf and Hisaindee 2013; Zollinger 2003). Dyes are categorised into numerous classes based on their chromophores (for example, xanthene, azo, triphenylmethane, oxazine, diphenylmethane and so on) (Rauf et al. 2011). Each colour in textile dyes has a distinct chemical structure (Christie a2014; Raman and Kanmani 2016). Their chromophoric group’s chemical structure may be used to give them a name. The chromogenic chromophore is a collection of atoms found in dye compounds that are responsible for the dye’s colour. Auxochrome is a chromophore that attaches to a group of atoms, enhancing the chromogen’s colour (Zinatloo-Ajabshir and Salavati-Niasari 2015, 2016). The most often used chromophores are (–NO2), (–C=N–), (–N=N–), (–C=O–), (–C=C–) and quinoid rings (Antoniotti and Duñach 2002). The auxochromes accessible include (–OH), (–CO2H), (–SO3H) and (–NH3) (Christie 2014; Raman and Kanmani 2016; Welham 2000). Additionally, some dyes are soluble in a variety of solvents, including basic, direct, mordant, reactive dyes and acid. Vat, azo, disperse and sulphur dyes are all examples of insoluble dyes. Nonionic and ionic dyes are classified according to their charge upon dissolution. The term ‘catalytic ionic dyes’ refers to any basic dyes, while the term ‘anionic dyes’ refers to dyes that are acidic, reactive as well as direct dyes. To put it simply, nonionic dyes are just dispersed dye in their most fundamental form. Due to the fact that dyes have a variety of applications, they may be categorised as azo dyes for dyeing polymers, sulphur dyes for dyeing cotton and drug dyes for use in the creation of pharmaceuticals and so on.

No categorisation of dyes can satisfy everyone, since many substances satisfy chemical requirements for inclusion in many groups. The following diagram (Fig. 7.1) highlights the general classification of each dye family.

7.3 Photocatalysis

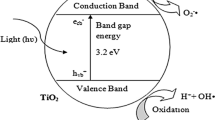

Photocatalysis is a combination of two words, i.e. photo which refers to photon and catalyst which is a substance that can change the rate of reaction. It is phenomenon in which a semiconductor utilises light energy to generate electron–hole pairs to drive chemical reactions. The catalyst that utilises the light energy to carry the reaction is known as a photocatalyst (Yang and Wang 2018).

Based on physical state of reactants, there are two sorts of photocatalysis, that is homogenous and heterogenous photocatalysis. It is possible to have homogenous photocatalysis when the reactant and semiconductor are in same state of the reaction. In heterogeneous photocatalysis, the semiconductor and reactant are in distinct phases, like, liquid, gas or solid (Ameta et al. 2018). The photocatalysis method has recently piqued the interest of scientists, who believe it has the potential to help solve a number of environmental problems. The elimination of dyestuffs from textile wastewater discharges using photocatalysis is often considered as the most successful approach. In the green movement, this strategy has been considered a paradigm and a cleaner alternative for garbage and environmental remediation. On the basis of how the reactants look in their physical state, two kinds of photocatalytic reactions may be distinguished.

-

Homogeneous photocatalysis: Homogeneous photocatalysis is the name given to photocatalytic reactions in which the reactant and the semiconductor are both in the same state of matter (solid, liquid or gas) (Manu and Chaudhari 2002).

-

Heterogeneous photocatalysis: Heterogeneous reactions are those in which the reactant and semiconductor are in various phases of the reaction cycle (Lai 2014).

Photocatalysis is defined as the acceleration of chemical transformations in the presence of a material called a photocatalyst that absorbs light and participates in the process. It forms an electron–hole pair when photons are absorbed by a component, which causes chemical reactions in reaction contributors and rejuvenates its biochemical arrangement after every series (Suteu et al. 2011).

7.3.1 The Process of Photocatalysis

One must employ a semiconductor light source or light irradiation in order to activate a solid material through photocatalysis, which is explained by ‘redox mechanism’ chemistry. All organic dyestuffs contained in a wastewater sample may be degraded using photocatalytic materials. However, the bandgap of these materials is critical. Rather than the band gap, the position of the photocatalyst's band determines the photocatalyst's oxidation or reduction strength, which in turn increases photocatalytic degradation. Several semiconductors have bandgaps that fall between 0.7 and 5 eV. Semiconductor bands are separated by a bandgap (also known as an energy gap), which is a difference in energy between a solid's conduction and valence bands. Particularly important is the use of photocatalytic processes to remove pollutants from waste, particularly those with a bandgap of 2.0–3.3 eV (Borker and Salker 2006). The photocatalyst’s surface is often where the oxidation and reduction reactions take place. Azo dye molecules are a common kind of dye used in staining applications.

The degradation of dyes has been attributed to radical species created during the photoexcitation of the semiconductor. In a broad sense, the stages involved may be shown as follows:

The deterioration of the dye is caused by an excited electron and a hole in the semiconductor. Nanotechnology has made use of many different semiconductors, with the enhanced surface area and favourable quantum size impact of most of them.

It is necessary for the photocatalytic mediated degradation of waste-produced azo dye molecules to be carried out in the presence of UV irradiation or in the presence of visible light. The steps are as follows:

-

1.

⋅OH radicals and electrons on the semiconductor’s CB largely oxidise or decrease the dye element (Dave et al. 2021).

-

2.

The darkening of the wastewater indicates the breakage of the azo link (Satapathy et al. 2021).

-

3.

⋅OH radicals trigger oxidation processes that open aromatic rings.

-

4.

Compounds including amines, short-chain organic acids and phenols are formed when aromatic rings are broken down into their constituents.

-

5.

By-products like CO2 and H2O are signs that the dye molecule has been completely degraded by photocatalysis (Dave 2021).

7.3.2 Direct Mechanism for Dye Degradation

Additional photocatalytic dye degradation processes may take place in the presence of visible light due to their tendency to absorb a part of visible light. This method includes dye excitation from the ground state (Dye) to the triplet excited state (Dye*) using visible light photons (λ > 400 nm) (Borker and Salker 2006). In this case, TiO2 is used to put an electron in the conduction band. These excitons dye varieties are then turned into a (Dye+)semi-oxidised radical cation. These trapped electrons interact with the system’s dissolved oxygen, resulting in the formation of superoxide radical anions (\({\text{O}}_{2}^{ - }\)) and hydroxyl radicals (OH−). OH− radicals have a substantial impact on oxidation of organic molecules as shown in the equations.

It's widely accepted that the dye degradation process is more heavily influenced by the indirect mechanism than by the visible light-initiated mechanism. Indirect mechanisms, on the other hand, are thought to have a much slower response time.

7.3.3 The Mechanism of Indirect Degradation of Dye

The following summarises the indirect heterogeneous photocatalytic oxidation mechanism employing semiconducting materials.

-

a.

Photoexcitation: To put it simply, a photocatalytic reaction begins when light passes through a semiconductor and moves a photoelectron from its fully-charged valence band into its empty conduction band over. In order for the photon to be absorbed, it must have an energy level (hn) equal to or higher than the semiconductor photocatalyst’s band gap. The valence band (hVB+) is left empty after the excitation process (Fox and Dulay 1993). As a consequence, as shown in the equation, a pair of electrons and holes (e/h+) is formed as a consequence.

$$ h\nu \left( {{\text{UV}}} \right) + {\text{TiO}}_{{2}} \to {\text{TiO}}_{{2}} \left( {h^{ + } \left( {{\text{VB}}} \right) + e^{ - } \left( {{\text{CB}}} \right)} \right) $$(7.10) -

b.

Ionisation of water: ⋅OH is produced as a result of a reaction between water molecules and the holes generated at the VB, as shown by

$$ h^{ + } \left( {{\text{VB}}} \right) + {\text{H}}_{{2}} {\text{O}}\left( {{\text{ads}}} \right) \to {\text{H}}^{ + } \left( {{\text{ads}}} \right) + {\text{OH}}^{ \cdot } \left( {{\text{ads}}} \right) $$(7.11)Irradiated semiconductors produce hydroxyl radicals (OH) that are very powerful oxidising agents. Depending on the structure and stability of the organic compounds, the closer the organic compounds are to the catalyst surface, the more likely they are to mineralize (Gürses et al. 2016).

-

c.

Oxygen ionosorption: To create an anionic superoxide radical (O2), the electron in the conduction (eCB) is picked up by oxygen and interacts with OH or surface-bound H2O to form the photogenerated hole (hVB+).

$$ e^{ - } \left( {{\text{CB}}} \right) + {\text{O}}_{{2}} \to {\text{O}}_{2}^{ - } \left( {{\text{ads}}} \right) $$(7.12)This superoxide ion may prevent the electron-hole recombination of TiO2, which can participate in the subsequent oxidation process as well.

-

d.

Protonation of superoxide: Upon protonation of the superoxide formed, a hydroperoxyl radical (HO2⋅) is formed, followed by hydrogen peroxide (H2O2), which is reduced to very reactive OH radicals (Allen 2013). The chain of events is shown as follows:

$$ \cdot {\text{O}}_{{2}}^{ - } + {\text{ H}}^{ + } \to {\text{ HO}}_{2}^{ \cdot } $$(7.13)$$ {\text{2 HO}}_{{2}} \to {\text{ O}}_{{2}} + {\text{ H}}_{{2}} {\text{O}}_{{2}} $$(7.14)$$ {\text{H}}_{{2}} {\text{O}}_{{2}} \to {\text{2OH}} $$(7.15)$$ {\text{OH}} + {\text{Dye}} \to {\text{H}}_{{2}} {\text{O}} + {\text{CO}}_{{2}} \left( {{\text{dye\,intermediate}}} \right) $$(7.16)$$ h^{ + } \left( {{\text{VB}}} \right) + {\text{Dye}} \to {\text{oxidation\,product}} $$(7.17)$$ e^{ - } \left( {{\text{CB}}} \right) + {\text{Dye}} \to {\text{reduction\,product}} $$(7.18)

The surface of the photoexcited semiconductor photocatalyst is often the site of oxidation and reduction reactions (Fig. 7.2).

Photodegradation mechanisms. a Direct degradation by (1) direct photolysis. b Dye-sensitisation leading to degradation through either electron (2i) or hole injection (2ii). c Indirect degradation of dyes by various photocatalytic reactions. (3i) and (3ii) involve direct oxidation/reduction of the dye by the photoexcited catalyst, while (3ii–3vi) proceed via radical intermediates. Reproduced with open access permission from ref. Pingmuang et al. (2017)

7.4 Factors Affecting Photocatalytic Performances

A number of variables influence the photocatalytic degradation process, which may be summarised as follows: The rate of reaction is affected in numerous dimensions by pH, which is an incredibly essential component. Since generated water is so complicated, it’s impossible to quantify variables like pH (Rauf and Hisaindee 2013) of the solution, catalyst dose, temperature and pollutant concentrations. Since the catalyst surface charge fluctuates with solution pH, adsorption on semiconductor material surfaces is greatly impacted. The pH of the solution has a significant impact on the pace of degradation and the overall photocatalytic dye degradation mechanism. During heterogeneous photocatalysis, the adsorption of pollutants (elements that need to be destroyed) and water molecules plays a crucial role in the degradation process. To effectively remove dyestuffs from polluted water, it is critical to figure out the optimal dose or photocatalyst loading (Zollinger 2003). It is important to consider light intensity, the type of dye component being removed, the topology of the photocatalyst, as well as the reactor layout when estimating the catalyst required for a given removal application. According to several studies, there are several reports of better dye adsorption by increasing catalyst loading. Hydrogen peroxide (H2O2) and potassium peroxydisulfate (K2S2O8), both powerful oxidising chemicals, may be added to the catalyst solution to increase the photooxidation rate (Rauf et al. 2011). Light intensity and wavelength are linked to catalytic light absorption ranges and reduce the influence of the light source on photocatalysis, in addition to aromatic chemicals in generated water having strong UV absorption. The efficiency of the photocatalytic reaction is highly reliant on basic parameters such as amount of photocatalyst and the concentration of the substrate as well as operational parameters such as temperature and pH of the reaction medium, feed flow rates, intensity and wavelength of the light, concentration of salt and ion species, etc. (Ahmad et al. 2016; Kumar and Pandey 2017). Also, the nature and structure of the photocatalyst, as well as the substrate, play a significant role in the photocatalytic process (Lin et al. 2020). Several operational parameters have been discussed further (Fig. 7.3).

7.4.1 pH

According to a technique of synthesis for nano TiO2, the surface charge characteristics of nano TiO2 and the hydroxyl radical are regulated by pH (Jyothi et al. 2014). Nano TiO2 photocatalytic activity is greatly influenced by the pH of the solution, which affects the interaction between photo-induced holes and hydroxides on the TiO2 surface. pH levels that are either neutral or high are thought to be the most favourable conditions for hydroxyl radicals (Jallouli et al. 2017). Positive holes are thought to be a major cause of oxidation processes at lower pH levels (Shifu and Gengyu 2005). The photo redox process, as well as the phenomenon of interfacial electron transport, are influenced by pH changes induced by differences in molecular charge distribution, which in turn may modify the ease of site attack and bond breaking during photocatalysis (Jyothi et al. 2014).

7.4.2 Light Intensity

The ideal light intensity must be selected in photocatalytic reactions if high efficiency is to be achieved. Increasing light intensity may boost the rate of nano TiO2 photocatalytic reaction, as the propensity of electron and hole interaction is insignificant at low-intensity levels (0–20 mW/cm2) (Mozia 2010). At low intensities of light (about 25 mW/cm2), the dissociation of charge carriers (electron-hole pairs) operates in a highly competitive with the hybridisation of charge carriers. This means that the rate of photocatalysis seems to be proportional to the square root of the intensity of light (Zangeneh et al. 2015). At extremely high intensities, the rate of reaction becomes independent of light intensity because the reaction rate is solely determined by mass transfer, which is limited by the existence of fully saturated materials at the catalyst surface for both adsorption and desorption (Lee et al. 2016).

7.4.3 Feed Flow Rate

Taking into account the flow rate of feed that is related to the time it spends in the system, it could have an effect on how well the system works. There is less exterior transfer of mass and less boundary layer rigidity in the liquid phase when flow speeds are increased over a photocatalyst that is immobilised. This could slow down pollutant degradation if flow speeds are enhanced above the ideal level (Lin and Valsaraj 2005). A high flow rate may limit penetration of light and reduce surface response efficiency because of the sheer growth in liquid viscosity and the reduction in holding time (Ananpattarachai and Kajitvichyanukul 2014).

7.5 Concentration of Reactants

According to the Arrhenius equation, increase in the concentration of contaminants in water enhances photocatalytic efficiency, which follows first-order kinetics. However, high concentrations outside the ideal range have a harmful impact on photocatalytic efficiency (Zainal et al. 2005). Because the number of active sites on the nanoparticle surface stays constant for a certain irradiation time, light intensity, catalyst dosage and at high concentrations owing to insufficient generation of reactive species, photocatalytic degradation is reduced. UV scattering increases with solution concentration and light penetration decreases as a result (Nam et al. 2002). In certain studies, it was discovered that increasing the concentration of reactants such as phosphamidon, phenol, reactive orange 14, lindane and MeO reduced the pace of decomposition (Rabindranathan et al. 2003).

7.5.1 Number of Catalysts Loading Layers on Substrate

The quantity of nano TiO2 accessible for photocatalytic reactions may be increased by coating the substrate with several layers, which can improve photocatalytic activity. However, heavy loading can reduce the process’ efficiency. Photocatalytic activity drops because the nano TiO2’s external surface blocks the internal layers, resulting in an increase in hole and electron recombination, which lowers light quantisation efficiency (Henderson 2011). The effectiveness can also be hampered by the dispersion of radical species via the layers. According to (Yu and Zhao 2000), the apparent pace was further increased by layering on up to five coats of film. When the number of coatings crossed 5, there was a slower growth.

7.6 Temperature During Catalyst Immobilisation

The temperature of the photocatalyst during immobilisation has a significant impact on the physiochemical characteristics of the immobilised film. However, lowering the calcination temperature reduces the critical loading, which has a negative impact on the coating film’s mechanical stability. However, elevating the calcination temperature significantly increases the distribution of support molecules into the nano film (Chen and Dionysiou 2006). Temperature is also important for adherence to the support.

7.6.1 Ions Species

Ionic species in water can have an impact on photocatalytic degradation (Qamar et al. 2005). Ionic chemicals have an influence on the amount of electrons photogenerated, the prevention of electron-hole recombination and the scavenging of hydroxyl radicals. It has been shown that the presence of inorganic anions (such as HCO3, \({\text{PO}}_{4}^{3 - }\), NO2, NO3, \({\text{SO}}_{4}^{2 - }\) and Cl) in water reduces photocatalytic activity since the interaction of hydroxyl radicals and holes with the inorganic ions forms inorganic radicals, which impair photocatalytic properties (Hassan et al. 2016) upon adsorption of nano TiO2 surface. The influence of inorganic anions on photocatalytic activity has been studied extensively (Ahmed et al. 2011). Bicarbonate (HCO3), carbonate (\({\text{CO}}_{3}^{2 - }\)), and chloride (Cl) ions may interfere with photocatalytic activity by interacting with the hydroxyl radical. It is possible that chloride (Cl) ions, along with other inorganic anions (e.g. NO2, HCO3, NO3, and \({\text{PO}}_{4}^{3 - }\)), might have an adverse effect on photocatalytic remediation by taking away the hydroxyl radicals and holes and producing reduced dichloride radicals (Cl2⋅) (Eq. 7.21) and reactive chloride radicals (Cl⋅) (Eq. 7.19) (Sirtori et al. 2010).

In the presence of chloride ions, the photocatalytic activity of a TiO2/graphene oxide composite immobilised on a polymeric membrane decreased from 61 to 27% (Pastrana-Martinez et al. 2015). In another investigation, the presence of chloride ions had a deleterious influence on photocatalytic degradation at acidic pH (Yap and Lim 2011).

7.7 Photocatalysis of Wastewater

Photocatalysis, a much-admired advanced oxidation process (AOP) being used for wastewater treatment for dye removal purposes, produces water and carbon dioxide, in the overall process of decomposition of organic contaminants during cleaning up industrial pollutants (Lin et al. 2020). The mechanism of photocatalysis is grounded on redox reactions and the behaviour of semiconductors (Khan and Mondal 2021). An important role is played by the semiconductor bandgap, which may be described as the amount of energy that is required to destroy all organic dyes contained in industrial effluents via photocatalysis. However, oxidation-reduction strength is strongly dependent on the photocatalyst’s band location instead of its bandgap and this has a significant effect on the degradation potential (Khan and Mondal 2021). Absorption of a wavelength containing higher energy than the bandgap creates electron-hole pairs just on the catalyst by releasing an electron in the CB and producing a positive hole in the VB, which allows photogenerated electron-hole pairs to move into more energetically advantageous locations (Lin et al. 2020). Upon exposure to UV/Vis light, semiconductor produces hydroxyl and superoxide anionic radicals, which are the principal oxidising species, able to cause the oxidation as well as mineralisation of a diverse array of organic molecules (Lin et al. 2019a, b). Diffusion and drift currents, as well as the rates of charge carrier, generated and recombined, all are having an impact on the charge separation equilibrium. The oxidation-reduction reactions taking place on the surface of the photocatalyst, causes the hole to be captured by surface water molecules, producing a reactive hydroxyl radical along with hydrogen ions, which delocalises on neighbouring water molecules, influencing the production of hydrogen peroxide (Rueda-Marquez et al. 2020). Furthermore, the generated hydroxide radicals potentially oxidise volatile elements in wastewater, such as methane (László et al. 2016).

Organic pollutant + O2 semiconductor, hv \(\to \) CO2 + H2O + inorganic ions/acids

Organic (particularly azo dyes) molecules are one of the most frequently used dyes in industries. The photocatalytic breakdown of azo dyes present in industrial effluent includes many crucial processes when exposed to UV light or visible light irradiation. The steps are:

-

(1)

When the dye component is in the CB, electrons move through it and make it oxidise or reduce itself.

-

(2)

The decoloration of effluent signifies the disruption of the azo bond.

-

(3)

Oxidation processes fuelled by ⋅OH radicals disintegrate the aromatic structure of dye molecules.

-

(4)

Amines, short-chain organic acids and phenolic substances are formed due to configuration changes and structural disintegration.

-

(5)

Carbon dioxide and water production as a by-product is the indicator of the completion of photocatalytic degradation of the dye molecule.

The output of investigations on photocatalytic remediation of wastewater is inadequate, while the majority of them are employed for synthetically produced water (Jiménez et al. 2019). The primary classes of organic pollutants include glutaraldehyde, xylene, toluene, phenol, acetic acid and naphthalene are found in produced water, while some of them are readily degraded despite having a sluggish mineralisation rate for most of the elements, which necessitates a superior remediation method (Lin et al. 2020; Hong et al. 2018). The effects of several AOPs (photocatalysis, ozonation) on the treatment of synthetic wastewater imply that photocatalysis is successful of all these AOPs strategies (Jiménez et al. 2019), with less than 20% of the organic matters like carbon (TOC) being eliminated after only four hours of treatment. Variations in the TOC removal rate were identified as minor at higher P25 TiO2 concentrations. No significant decline in TOC was seen for relatively high molecular organic materials such as grease, oil and natural organic matter in both photocatalysis and UV photolysis treatments, suggesting that the remediation of volatile, tiny organic pollutants like as toluene, naphthalene and xylene, along with the declination of phenol concentration, was verified using gas chromatograph-mass spectroscopy (Liang et al. 2011). Graphene-like TiO2 nanocomposites (rGO-TiO2) show better photocatalytic efficiency than TiO2 for treating synthetic wastewater with high salt concentrations and various compositions of intractable dissolved organic substances, with a catalytic reaction rate for only 22% TOC elimination after 5 h of treatment increasing in the order of Phenols, Acetic acid, Toluenes, Xylenes and Naphthalene (Andreozzi et al. 2018). A novel approach was used to investigate the use of vertically stacked ZnO nanorods by using substrates that are specifically designed for optimal solar photocatalytic degradation by trapping visible light of HPAM (partially hydrolysed polyacrylamide), a well-known polymeric compound with oil recovery potential. After 6 h of treatment, the elimination of 150, 100, 50 and 25 mg/L of HPAM was found to be 45%, 56%, 62% and 68%, respectively, followed a decrease of 37% and 20% of TOC during 14 h and 7 h of reactivity permitting mineralisation (Dave 2021; Neppolian et al. 2008).

Precisely, photocatalysis is a well-planned efficient method for the degradation of refractory organic substances except for the proper mineralisation of wastewater. And for further reduction of organic pollutants and photocatalytic by-products, various technologies need to be utilised in succession for wastewater treatment. Toxicity, as well as biodegradability, should be given more consideration because of their substantial impact on the designing of treatment procedures (Lin et al. 2020). For toxicity assessment (both chronic as well as acute) of wastewater contaminants that are targeted to undergo the treatment of photocatalysis, a variety of approaches have been used, including bioassays with bacteria, plants (phytotoxicity), mammalian cells (genotoxicity), microalgae and seawater as well as freshwater invertebrates (He et al. 2016; Hasegawa et al. 2014; Di 2015; Tsoumachidou et al. 2017; Saverini et al. 2012; Calleja et al. 1986). Despite the development of several assessments for the investigation of photocatalytic analysis, only a few studies have included toxicity analysis for wastewater treatment, following successful remediation in minimising wastewater toxicity (Rueda-Marquez et al. 2020). For the purposes of toxicological evaluation, the standard effective concentration (EC50) is the level of a substance present in an environmental medium that causes unfavourable effects in at least half of the participants in an experiment (Lin et al. 2020). Vibrio fischeri was utilised as an experimental organism for the assessment of acute aquatic toxicity, which is leading to the implementation of four classes of toxicity according to their effectivity: class I indicates extremely toxic level with an EC50 value of 25%; class II indicates as toxic with an EC50 range of 25–75%, class III is known as somewhat toxic having an EC50 of 75%; and class IV is non-toxic with an EC50 of more than 75%. Photocatalysis is able to reduce the toxicity of the discharge up to 13–16%, indicating the efficiency of this method in comparison to ozone and H2O2 treatment for toxicity reduction of industrial effluent (Jiménez et al. 2019).

Ozone/TiO2/UV photocatalytic oxidation was conducted in a batch mode in a laboratory-scale reaction chamber or reactor to determine the efficacy of these processes in removing pollutants and reducing the ecotoxicity of petrochemical industry-generated fluids (Corrêa et al. 2010). Vibrio fischeri and Poecilia vivipara were utilised to conduct screening for bacterial luminescence attenuation and fish toxicity, respectively, for acute toxicity analysis of the raw effluents, indicating a high toxicity level having EC50 value less than 1.55%, with lesser toxicity toward bacteria (EC50 = 30.9%), but higher toxicity induction in fish (EC50 = 1.9%), after 60 min of exposure. High tolerance of bacterial specimens to photocatalysed wastewater samples, but toxic effects in fish due to the presence of ammonia and other metal in photocatalysis treated wastewater, supports these experimental observations, insisting a post-treatment (biological treatment, sorption) for their removal (Corrêa et al. 2010). Even though distinguishing the effects of photocatalytic degradation from ozone treatment is problematic, combining photocatalysis with ozone reduces the toxicity of wastewater. Additional investigation concerning photocatalysis-induced toxicity as well as wastewater toxicity is intended to enhance the implementation of these methodologies (Lin et al. 2020; Corrêa et al. 2010).

7.8 Dye Removal From Wastewater May Be Accomplished Using a Variety of Methods

As the world's population grows, so does the growth of diverse industries to meet their demands. The quantity and volume of these operations are rapidly increasing across the world, resulting in massive volumes of coloured effluents. When these effluents are spilled into adjacent lakes and rivers without being properly treated or dyestuffs decoloured, they pose major environmental issues (Manu and Chaudhari 2002). In freshwater rivers and lakes, dyes with high colour intensity block out sunlight, killing aquatic life and plants. Water quality is also harmed, making it dangerous to drink. Because dyes are refractory organic molecules that resist aerobic digestion and are light stable, treating waste effluents containing dyestuff is particularly challenging (Suteu et al. 2011). Dyestuff-containing wastewater is treated using a variety of physical, chemical, electrochemical, biological and photochemical techniques. Treatment using photocatalytic means is one of these ways that is thought to be a viable option for removing soluble organic composites. Adsorption, advanced oxidation process (AOP), bioremediation and biodegradation, electrochemical approaches, ion exchange and membrane filtering technology are some of the dye removal technologies available. In the next section, the approaches are succinctly outlined.

7.8.1 Adsorption Technique

A common method for eliminating contaminants from waste effluent is adsorption. Numerous different metals or constituents are deposited all across the interface of a liquid or solid molecule in this surface phenomenon. Pre-treatment is not required when using liquid-phase adsorption. A well-known separation method for wastewater purification and water reuse is based on its simplicity and controllability, lower investment costs and ability to manage highly concentrated contaminants (Dąbrowski 2001). The extensive aspect of pollutant removal via the adsorption method is that no harmful components are likely to be generated during the reaction phase. When utilising adsorption methods, the decolorization operation is controlled by a variety of elements, such as the adsorbent's effective surface area, particle size, dye element-adsorbent interactions, process temperature and pH and contact length (Kumar et al. 1998). To remove dyes from wastewater, a variety of activated carbons have been utilised, including pelletised carbon, granular activated carbon (GAC), powdered activated carbon (PAC), and fibre-type activated carbon. Adsorption also involves the phase transition of pollutants into some secondary wastes, necessitating extra treatment for the proper discharge route.

7.8.2 Advanced Oxidation Process (AOP)

Textile effluent may be decolored using this method. Hydroxyl radicals (⋅OH) are one of the most potent oxidising agents and are used in this process. It is described as the generation of ⋅OH and highly reactive oxidations that particularly harm the target component. As a result of their ability to remove organic dyestuffs without creating additional elemental deposition, AOPs outperform standard physical and chemical approaches. It has been shown that ozone (O3) treatment and UV irradiation, H2O2/UV combination method, Fenton and Photo-Fenton techniques have shown increased removal efficacy and/or broken up to a less complex substance that may be quickly biodegradable (Szpyrkowicz et al. 2001). Thus, there are several combinations of AOPs, like as (Fe2+/H2O2, O3, O3/H2O2/UV, O3/UV and H2O2/UV,), that might produce superior outcomes for textile industry effluent treatment.

7.8.3 Bioremediation and Biodegradation

Biodegradation is recognised as one of the most cost-effective methods for reducing a variety of organic dye components. Various microorganisms, including algae, fungus, yeast and bacteria, have been used for the biodegradation of dyestuff. They use a variety of ways to clean wastewater, including fungal decolorization, microbial degradation, adsorption through microbial biomass and bioremediation, all of which are often used in industrial wastewater treatment (Szpyrkowicz et al. 2001; Fu and Viraraghavan 2001). Aerobic and anaerobic methodologies might be successfully applied to the treatment of textile effluents using biological methods. There are several limitations to this procedure, such as the presence of excessive harmful substances, which significantly diminish the number of active microorganisms present in the biological technique (Wallace 2001). Accordingly, despite its many advantages, the biodegradation process was not able to efficiently remove the colour from certain types of organic dyestuffs and break down their complex chemical structure.

7.8.4 Electrochemical Method

It has been shown that the electrochemical method is a viable alternative to chemical treatment for textile industrial wastewaters. Electrochemical approaches are categorised based on the electrode material utilised, the chemicals employed and the contaminant removal procedure (Riyanto et al. 2013).

Electro-oxidation is a well-established electrochemical process in which an electron serves as the primary reagent, removing organic components from textile effluents without forming any secondary harmful pollutants. Electrochemical oxidation techniques are unique in that they are simple to use, do not require additional chemicals and are a cost-effective technology that might be a superior alternative for waste-effluent treatment. Organic and hazardous pollutants in effluent water, such as dye components, are frequently torn apart by direct oxidation or indirect oxidation routes in this treatment process. Contaminants are adsorbed on the anode surface and then reduced by an electron transport process in the direct anodic oxidation technique. Strong oxidants such as hypochlorite, ozone and hydrogen peroxide, on the other hand, might be regenerated by electrochemical methods during electrolysis in the indirect oxidation mode (Khan and Mondal 2021).

Electrocoagulation is a straightforward approach that produces less sludge than other procedures (Nguyen et al. 2013). The process is explained as the formation of metal ions from anodes that have been hydrolysed into metal hydroxides, as well as the development of hydrogen (H2) bubbles at the cathode that allows the coagulated materials to float (Mollah et al. 2004). The electrocoagulation method involves three steps in order to remove contaminants from wastewater: (a) coagulants are produced in an electrolytic solution by oxidising electrodes, (b) by compressing and neutralising the diffuse double layer, pollutants are disturbed and interrupted and (c) coagulants collect contaminates that have been disturbed (Singh et al. 2014). Electrochemical methods work at a lower temperature, need no extra chemicals and produce no hazardous by-products.

7.8.5 Ion-Exchange Method

Ion exchange is a versatile process that may be used to treat polluted wastewater from a variety of industrial processes, as well as textile effluents containing a variety of complicated dyestuffs. Pollutants that are hazardous or harmful may be reduced in impact by ion exchange, which transforms them into a state that can be recycled. Resins that can exchange anions and cations with the surrounding material are known as ion exchangers. As their name implies, ion-exchange adsorbents may bind to contaminants with an opposing charge. The capacity to scatter as well as concentrate pollutants is another key feature of the ion-exchange process. An ion-exchange process can deal with reactive dyes, which are considered one of the most difficult types of dyes to work within the textile business. By employing an ion-exchange approach, it is possible to remove contaminants from waste management systems up to PPB levels (Khan and Mondal 2021).

7.8.6 Membrane Filtration Technique

While there are a variety of conventional techniques available, the membrane-based filtration process is considered to be one of the most complex technological approaches available and it is used extensively in the wastewater treatment and textile discharge treatment. On the basis of pore size and applied pressure, pressure-driven membrane filtration methods are divided into four categories: microfiltration (MF), ultrafiltration (UF), nanofiltration (NF) and reverse osmosis (RO) membranes. The semipermeable membrane has an impact on the membrane-separation concept, which is straightforward. While water molecules are allowed to pass through the semipermeable membrane, suspended particles and other pollutants are prevented from entering. Variables such as composition, material (including polymers and ceramics), surface (including homogeneous or heterogeneous, porous or dense) and shape all have an effect on the membrane filtering performance (porosity and thickness). Tertiary stage of wastewater treatment utilises membrane filtration to its fullest potential. MF and UF membranes with pore diameters ranging from 0.1 to 10 μm and 0.1–0.01 μm are utilised to extract biologically degraded products and moderately large elements from the water. To separate dye waste effluent from dissolved salts including monovalent anions and cations, NF membranes with nanopores with pore diameters typically ranging from 1 to 10 nm are utilised. Using a RO membrane with a pore capacity of 1 nm, all inorganic and organic contaminants are successfully removed from the water (Khan and Mondal 2021).

Although membrane-based operations have a number of drawbacks, including greater membrane preparation costs, incompatibility with low effluent flow rates, the need for a comparatively higher working pressure, the cost of intermittent membrane replacement and the inability to reduce dissolved solids. The membrane-separation approach, on the other end, is one of the possible wastewater treatment ways since it requires frequent cleaning and membrane-module replacement in order to maintain the efficacy of dye removal from effluent water.

7.9 Modulation of Photocatalysis of Wastewater by Dyes

7.9.1 Methyl Orange

Sodium 4-[4-(dimethylamino) phenyl] diazenyl benzene-1-sulfonate or methyl orange is also known as the universal indicator. Acidic media gives it a vivid red hue, whereas alkaline media gives it a yellow tint. Additionally, it is widely used in the chemical industry. Because of its mutagenic qualities, studies have been conducted on the treatment of effluents containing it. Photocatalytic decomposition of methyl orange in an aqueous medium was studied by He et al. (2010) using a WO3/TiO2 combination film. They studied the photocatalytic activity in relation to pH and other inorganic anions. According to the results, the clearance ratio decreased as pH increased and vice versa. Inorganic anions have two types: facilitators and inhibitors. The facilitators helped remove methyl orange, while the inhibitors slowed the process (reduced the elimination of methyl orange).

While anions such as \({\text{HCO}}_{3}^{ + }\), \({\text{NO}}_{3}^{ + }\) and \({\text{PO}}_{43}^{ + }\) interacted with water to form ⋅OH, anions such as Cl and \({\text{SO}}_{42}^{ + }\) trapped the ⋅OH and thereby hindered the elimination of methyl orange under UV irradiation. Nonmetallic components like F and S may be added to a TiO2 nanotube array, Liao et al. (2012) examined the photocatalytic degradation of methyl orange. However, calcination for two hours at 500 °C greatly enhanced the photocatalytic activity of doped TiO2 with a large aspect ratio. To treat methyl orange, N-doped TiO2 was also used to make nanotube array films. Similarly, doped TiO2 was shown to have better photocatalytic activity than undoped TiO2 (Murugan et al. 2019). To get the highest level of photocatalytic activity, N-doped TiO2 nanotubes were produced in an electrolyte solution containing 1.0 M NH4NO3 and HF. When methyl orange was exposed to visible light, nearly 80% of it was destroyed.

7.9.2 Indigo Carmine

Acid Blue 74, also known as indigo carmine (3, 3′-dioxo-2, 2′-bis-indolyden-5, 5′-disulfonic acid disodium salt), is a dye for textiles, a drug additive (tablets and capsules) and a diagnostic aid in medicine. Barrett’s oesophagus is diagnosed with the use of acetic acid and indigo carmine. Although it’s a natural colourant, the dye is very harmful to human health and may cause cancer (Barka et al. 2008). The dye has been linked to serious skin reactions and even death in certain cases of accidental ingestion. The removal of indigo carmine from contaminated effluents has been investigated. The degradation of dye was evident by the drop in COD levels and the resulting discolouration of the treated dye solution.

Depending on how much photocatalyst was employed and the concentration of dye at the start, degradation of the dye was affected. The author also concluded that TiO2 commercially available was more effective than TiO2 infused on activated carbon surfaces. According to Barka et al. (2008), Indigo carmine dye was effectively removed from non-oven fibres by using TiO2 coatings. The photocatalyst surface and dye structure were both affected by pH, which was the primary governing factor in the reaction. At a pH of less than 4, the highest dye adsorption occurred. Also investigated under outdoor light was the photocatalytic degradation of indigo carmine and the efficacy of ZnO coated with Ag2O4 (Chowdhury et al. 2020). Because of ZnO and TiO2’s slower photogenerated electron-hole pair separation rates under outdoor light, the composite was shown to have a much greater photocatalytic activity. ZnO covered with Ag2O4 destroyed indigo carmine most effectively in natural settings. Indigo carmine photocatalytic degradation was also examined by Lubis et al. utilising multiple factors of pH, concentration of photocatalyst, starting dye concentration and irradiation time (Lubis and Sitompul 2019). When the dye and photocatalyst concentrations were both 10 mg L−1 and 250 mg, the composite showed the greatest photocatalytic activity at pH 1.

7.9.3 Malachite Green

Triphenylmethane dye, sometimes known as malachite green, is a cationic dye. The chemical name for this compound is N,N-dimethylcyclohexa-2,5-dien-1-iminium chloride. It is used extensively in the leather, textile, food and paper industries as a colourant. Even in its diluted state, this dye is particularly harmful to the environment because of its carcinogenicity and long-term persistence (Chen 2011). As a result, it is critical to eliminate these chemicals before releasing them into the environment. A Bi2WO6 nanoplate was used for the photocatalytic degradation of malachite green. According to the scientists, malachite green and Bi2WO6 were used in this investigation for the first time (Tahmasebi et al. 2019). Dye and Photocatalyst concentrations of 0.1 and 1.0 g L−1 at pH2 were found to be optimal. Meena et al. used ZnO nanoparticles to successfully remove malachite green from effluent water. The cap of ZnO with EDTA was investigated to see what effect it had on photocatalysts (Meena et al. 2016). According to the results, malachite green deteriorated by 94.14%, when there is a visible source of light. According to one theory, the ZnO photocatalyst may have been more stable and more active because of the capping molecules. ZnS nanoparticles with a ZnS core/shell configuration have also been studied as an alternative to EDTA in the dissolution of malachite green under visible light. The results of UV-Vis absorption spectroscopy revealed that dye may be effectively decolored. C and Fe (III) doped TiO2 photocatalysts were studied by Ismael et al. for their synergistic effect on TiO2 photocatalysts (Ismael 2020). Adding co-doping to TiO2 made it more able to absorb visible light and make electrons and holes separate, which led to more malachite green being broken down. For the photocatalytic breakdown of malachite green, Ca-doped ceria nanoparticles have recently been used as well. At 35 °C with a dye concentration of 0.6 g L−1 and a photocatalyst concentration of 0.1 g, 93% dye degradation was observed after 90 min of UV irradiation (Amar et al. 2020).

7.9.4 Rhodamine B

Rhodamine B ([9-(2carboxyphenyl)-6-diethylamino-3xanthenelidene] diethylammonium chloride) is a brilliant red xanthene dye that is often used in food colouring. It is most often used as a water-based tracer dye. Fluorescence microscopy, flow cytometry and labelling acid-fast bacteria are just a few of the biotechnological uses for Rhodamine B as an analytical reagent. Despite this, rhodamine B has been banned as a food colourant because of its long-term toxicity and carcinogenic properties. The removal of rhodamine B from polluted water has been studied. TiO2 photocatalyst immobilised on silicone was used to decolorize rhodamine B. For best results, the TiO2 concentration should be 210.7 g/L−1(Kim and Park 2006). A round disc TiO2/Ti photoelectrode with a wedge shape was developed by scientists in a photoelectrocatalytic reactor. Using a wedge construction may have enhanced light utilisation while also carrying more pollutants to the electrode for treatment. In 60 min, the wedge surface electrode removed 100% of the dye, whereas in 150 min, it removed 93% of the COD (Li et al. 2011). Some indigenously manufactured photocatalysts, including TiO2NWs, TiO2 coated multi-walled carbon nanotubes (MWCNTs) and ZnO, were used in the photocatalytic degradation of rhodamine B. Compared with the other two photocatalysts, TiO2NWs had the greatest degrading efficiency of 96.44% (Khan and Mondal 2021). Rhodamine B may be efficiently removed from water samples using simple photocatalysis at room temp using indigenously generated BaWO4. Barium nitrate and sodium tungstate were used to manufacture the photocatalyst (Khan and Mondal 2021). The authors’ proposed process for dye degradation is as follows:

7.9.5 Methylene Blue

3,7-bis(dimethylamine)-phenothiazin-5-ium-chloride or methylene blue, also known as methylthionium chloride. This colourant is also commonly utilised in the pharmaceutical industry. It's injected intravenously to stain surgical tissues, monitor CSF leakage and help treat vasodilatory shock, among other things (Diaz-Uribe et al. 2018). However, when dye-laden water from industry and medical institutes is dumped into water bodies without treatment, it is a significant cause of environmental contamination, resulting in harmful results. It is also used in a variety of industries such as plastics, food, rubber, paper, textile and cosmetics.

As a result, it is imperative that these dye elements be removed from the wastewater before it is disposed of in the environment. Adeleke et al. investigated the photocatalytic degradation of methylene blue dye by ZnO/NiFe2O4 nanocomposites under UV light (Adeleke et al. 2018). To fabricate the solid-state nanocomposites, the co-precipitated NiFe2O4 and ZnOwere oxidised for 10 h at 800 °C. According to the researchers, the dye was eliminated as a result of the synthesis of h+ and ⋅OH ions during the photocatalytic activity. The following equations were used by the authors to explain how the dye degrades:

Photocatalytic removal of methylene blue dye by nano TiO2 has been studied by Bastruck et al. Catalyst dose, pH impact, starting dye concentration and irradiation intensity were all aspects that were optimised in this research as well (Basturk et al. 2019). According to the findings, 66% dye degradation was achieved at pH 6.5 and 9, a catalyst dosage of 0.25 g L−1 and an irradiation of 50 Wm-2. The photocatalytic impact of TiO2 and graphene oxide was also studied by several researchers. It was found that the GO/TiO2 complexes may be employed to degrade methylene blue in synthetic wastewater. When 200 mg of GO/TiO2 composites (containing GO by 15% weight percent) were added to 200 mL of synthetic wastewater with an initial pH of 8, degradation rates of about 95% were found after 2.5 h (Anwer et al. 2019; Nemiwal et al. 2021) (Fig. 7.4).

7.10 Conclusion

Organic as well as inorganic colouring agents, whether ionic or nonionic, are extensively used in several industries today; and a lack of effective treatment for these dyes is producing serious environmental concerns owing to their negative impact on the ecosystem and society. New environmental laws governing the discharge of dyestuffs into the environment are implemented to resolve this issue, while experts are working in the development of new processes for budget-friendly and environment-friendly wastewater treatment, one of which is photocatalysis (homogenous photocatalysis and heterogeneous photocatalysis) participating in both direct and indirect dye degradation mechanism(photoexcitation, followed by ionisation and oxygen ionosorption and lastly protonation of superoxide). pH, light intensity, feed flow rate, the concentration of reactants, number of catalysts loading layers on the substrate, temperature during catalyst immobilisation and ionic species have the potency to influence photocatalytic degradation of dyestuffs. The development of innovative composite materials and enhanced photocatalysts should be the focus of future research to increase the efficiency of dyestuff removal and degradation. Even though different dye removal techniques exist, such as (i) adsorption, (ii) advanced oxidation process (AOP), (iii) bioremediation and biodegradation, (iv) electrochemical method, (v) ion exchange, (vi) membrane filtration technique; photocatalysis is modulated for successful wastewater treatment following degradation of industrial dyes, namely methyl orange, indigo carmine, malachite green, rhodamine B and methylene blue.

References

Adeleke J et al (2018) Photocatalytic degradation of methylene blue by ZnO/NiFe2O4 nanoparticles. Appl Surf Sci 455:195–200

Ahmad R et al (2016) Photocatalytic systems as an advanced environmental remediation: recent developments, limitations and new avenues for applications. J Environ Chem Eng 4(4):4143–4164

Ahmed S et al (2011) Influence of parameters on the heterogeneous photocatalytic degradation of pesticides and phenolic contaminants in wastewater: a short review. J Environ Manage 92(3):311–330

Allen RL (2013) Colour chemistry. Springer Science & Business Media

Amar IA et al (2020) Photocatalytic degradation of malachite green dye under UV light irradiation using calcium-doped ceria nanoparticles. Asian J Nanosci Mater 3(1):1–14

Ameta R et al (2018) Photocatalysis, in advanced oxidation processes for waste water treatment. Elsevier, pp 135–175

Ananpattarachai J, Kajitvichyanukul P (2014) Kinetics and mass transfer of fixed bed photoreactor using N-doped TiO2 thin film for tannery wastewater under visible light. Chem Eng 42

Andreozzi M et al (2018) Treatment of saline produced water through photocatalysis using rGO-TiO2 nanocomposites. Catal Today 315:194–204

Antoniotti S, Duñach E (2002) Direct and catalytic synthesis of quinoxaline derivatives from epoxides and ene-1, 2-diamines. Tetrahedron Lett 43(22):3971–3973

Anwer H et al (2019) Photocatalysts for degradation of dyes in industrial effluents: opportunities and challenges. Nano Res 12(5):955–972

Barka N et al (2008) Photocatalytic degradation of indigo carmine in aqueous solution by TiO2-coated non-woven fibres. J Hazard Mater 152(3):1054–1059

Basturk E, Işık M, Karatas M (2019) Removal of aniline (methylene blue) and azo (reactive red 198) dyes by photocatalysis via nano TiO2. Desalin Water Treat 143:306–313

Borker P, Salker A (2006) Photocatalytic degradation of textile azo dye over Ce1−xSnxO2 series. Mater Sci Eng B 133(1–3):55–60

Calleja A, Baldasano J, Mulet A (1986) Toxicity analysis of leachates from hazardous wastes via microtox and Daphnia magna. Toxicity Assessment 1(1):73–83

Chen Y et al (2012) Photodegradation of malachite green by nanostructured Bi2WO6 visible light-induced photocatalyst. Int J Photoenergy 2011

Chen Y, Dionysiou DD (2006) Effect of calcination temperature on the photocatalytic activity and adhesion of TiO2 films prepared by the P-25 powder-modified sol–gel method. J Mol Catal a: Chem 244(1–2):73–82

Chowdhury MF et al (2020) Current treatment technologies and mechanisms for removal of indigo carmine dyes from wastewater: a review. J Mole Liquids:114061

Christie R (2014) Colour chemistry. Royal Society of Chemistry

Corrêa AX et al (2010) Use of ozone-photocatalytic oxidation (O3/UV/TiO2) and biological remediation for treatment of produced water from petroleum refineries. J Environ Eng 136(1):40–45

Dąbrowski A (2001) Adsorption—from theory to practice. Adv Coll Interface Sci 93(1–3):135–224

Dave S et al (2021) Mathematical modeling and surface response curves for green synthesized nanomaterials and their application in dye degradation. Photocatalytic Degradation Dyes:571–591

Dave S, Dave S, Das J (2021) Photocatalytic degradation of dyes in textile effluent: a green approach to eradicate environmental pollution. In: The future of effluent treatment plants. Elsevier, pp 199–214

Di Ç (2015) Optimization of suspended photocatalytic treatment of two biologically treated textile effluents using TiO2 and ZnO catalysts

Diaz-Uribe CE et al (2018) Photocatalytic degradation of methylene blue by the Anderson-type polyoxomolybdates/TiO2 thin films. Polyhedron 149:163–170

Fox MA, Dulay MT (1993) Heterogeneous photocatalysis. Chem Rev 93(1):341–357

Fu Y, Viraraghavan T (2001) Fungal decolorization of dye wastewaters: a review. Biores Technol 79(3):251–262

Gürses A et al (2016) Classification of dye and pigments. In: Dyes and pigments. Springer, pp 31–45

Hasegawa MC et al (2014) COD removal and toxicity decrease from tannery wastewater by zinc oxide-assisted photocatalysis: a case study. Environ Technol 35(13):1589–1595

Hassan M, Zhao Y, Xie B (2016) Employing TiO2 photocatalysis to deal with landfill leachate: current status and development. Chem Eng J 285:264–275

He J et al (2010) Photocatalytic removal of methyl orange in an aqueous solution by a WO3/TiO2 composite film. Korean J Chem Eng 27(2):435–438

He Y et al (2016) Construction of the elements based on lifted multiwavelet and its applications. Integr Ferroelectr 172(1):132–141

Henderson MA (2011) A surface science perspective on TiO2 photocatalysis. Surf Sci Rep 66(6–7):185–297

Hong S et al (2018) Photolysis of glutaraldehyde in brine: a showcase study for removal of a common biocide in oil and gas produced water. J Hazard Mater 353:254–260

Ismael M (2020) Enhanced photocatalytic hydrogen production and degradation of organic pollutants from Fe(III) doped TiO2 nanoparticles. J Environ Chem Eng 8(2):103676

Jallouli N et al (2017) Photocatalytic degradation of paracetamol on TiO2 nanoparticles and TiO2/cellulosic fiber under UV and sunlight irradiation. Arab J Chem 10:S3640–S3645

Jiménez S et al (2019) Produced water treatment by advanced oxidation processes. Sci Total Environ 666:12–21

Jyothi K, Yesodharan S, Yesodharan E (2014) Ultrasound (US), ultraviolet light (UV) and combination (US + UV) assisted semiconductor catalysed degradation of organic pollutants in water: oscillation in the concentration of hydrogen peroxide formed in situ. Ultrason Sonochem 21(5):1787–1796

Khan AA, Mondal M (2021) Effective materials in the photocatalytic treatment of dyestuffs and stained wastewater. In: Photocatalytic degradation of dyes. Elsevier, pp 91–111

Kim DS, Park YS (2006) Photocatalytic decolorization of rhodamine B by immobilized TiO2 onto silicone sealant. Chem Eng J 116(2):133–137

Kumar A, Pandey G (2017) A review on the factors affecting the photocatalytic degradation of hazardous materials. Mater Sci Eng Int J 1(3):1–10

Kumar V et al (1998) Decolorization and biodegradation of anaerobically digested sugarcane molasses spent wash effluent from biomethanation plants by white-rot fungi. Process Biochem 33(1):83–88

Lai CW et al (2014) An overview: recent development of titanium oxide nanotubes as photocatalyst for dye degradation. Int J Photoenergy 2014

László B et al (2016) Photo-induced reactions in the CO2-methane system on titanate nanotubes modified with Au and Rh nanoparticles. Appl Catal B 199:473–484

Lee KM et al (2016) Recent developments of zinc oxide based photocatalyst in water treatment technology: a review. Water Res 88:428–448

Li K et al (2011) Degradation of rhodamine B using an unconventional graded photoelectrode with wedge structure. Environ Sci Technol 45(17):7401–7407

Liang X, Zhu X, Butler EC (2011) Comparison of four advanced oxidation processes for the removal of naphthenic acids from model oil sands process water. J Hazard Mater 190(1–3):168–176

Liao HD et al (2012) Synthesis and photoelectrocatalytic property of two-nonmetal-codoped TiO2 nanotube arrays with high aspect ratio. Adv Mater Res

Lin H, Valsaraj KT (2005) Development of an optical fiber monolith reactor for photocatalytic wastewater treatment. J Appl Electrochem 35(7):699–708

Lin L et al (2019a) Enhanced visible light photocatalysis by TiO2-BN enabled electrospinning of nanofibers for pharmaceutical degradation and wastewater treatment. Photochem Photobiol Sci 18(12):2921–2930

Lin L et al (2019b) Adsorption and photocatalytic oxidation of ibuprofen using nanocomposites of TiO2 nanofibers combined with BN nanosheets: degradation products and mechanisms. Chemosphere 220:921–929

Lin L et al (2020) Treatment of produced water with photocatalysis: recent advances, affecting factors and future research prospects. Catalysts 10(8):924

Lubis S, Sitompul DW (2019) Photocatalytic degradation of indigo carmine dye using α-Fe2O3/bentonite nanocomposite prepared by mechanochemical synthesis. In: IOP conference series: materials science and engineering. IOP Publishing

Manu B, Chaudhari S (2002) Anaerobic decolorisation of simulated textile wastewater containing azo dyes. Biores Technol 82(3):225–231

Meena S, Dipti V, Das B (2016) Photocatalytic degradation of malachite green dye by modified ZnO nanomaterial. Bull Mater Sci 39(7):1735–1743

Mollah MY et al (2004) Fundamentals, present and future perspectives of electrocoagulation. J Hazard Mater 114(1–3):199–210

Mozia S (2010) Photocatalytic membrane reactors (PMRs) in water and wastewater treatment. A review. Separation Purification Technol 73(2):71–91

Murugan C et al (2019) Improving hole mobility with the heterojunction of graphitic carbon nitride and titanium dioxide via soft template process in photoelectrocatalytic water splitting. Int J Hydrogen Energy 44(59):30885–30898

Nam W, Kim J, Han G (2002) Photocatalytic oxidation of methyl orange in a three-phase fluidized bed reactor. Chemosphere 47(9):1019–1024

Nemiwal M, Zhang TC, Kumar D (2021) Recent progress in g-C3N4, TiO2 and ZnO based photocatalysts for dye degradation: strategies to improve photocatalytic activity. Sci Total Environ:144896

Neppolian B et al (2008) Degradation of textile dye by solar light using TiO2 and ZnO photocatalysts. J Environ Sci Health Part A Toxic/hazard Subst Environ Eng 34:1829–1838

Nguyen DD, Ngo H, Yoon Y (2013) A new hybrid treatment system of bioreactors and electrocoagulation for superior removal of organic and nutrient pollutants from municipal wastewater. Biores Technol 153C:116–125

Pastrana-Martinez LM et al (2015) Graphene oxide based ultrafiltration membranes for photocatalytic degradation of organic pollutants in salty water. Water Res 77:179–190

Pingmuang K et al (2017) Composite photocatalysts containing BiVO4 for degradation of cationic dyes. Sci Rep 7(1):1–11

Qamar M, Saquib M, Muneer M (2005) Photocatalytic degradation of two selected dye derivatives, chromotrope 2B and amido black 10B, in aqueous suspensions of titanium dioxide. Dyes Pigm 65(1):1–9

Rabindranathan S, Devipriya S, Yesodharan S (2003) Photocatalytic degradation of phosphamidon on semiconductor oxides. J Hazard Mater 102(2–3):217–229

Raman CD, Kanmani S (2016) Textile dye degradation using nano zero valent iron: a review. J Environ Manage 177:341–355

Rauf M, Hisaindee S (2013) Studies on solvatochromic behavior of dyes using spectral techniques. J Mol Struct 1042:45–56

Rauf M, Meetani M, Hisaindee S (2011) An overview on the photocatalytic degradation of azo dyes in the presence of TiO2 doped with selective transition metals. Desalination 276(1–3):13–27

Riyanto E, Norazizi N, Mohamed R (2013) Textiles industries wastewater treatment by electrochemical oxidation technique using metal plate. Int J Electrochem Sci 8:11403–11415

Rueda-Marquez JJ et al (2020) A critical review on application of photocatalysis for toxicity reduction of real wastewaters. J Clean Prod 258:120694

Satapathy S et al (2021) Mechanistic aspects and rate-limiting steps in green synthesis of metal and metal oxide nanoparticles and their potential in photocatalytic degradation of textile dye. In: Photocatalytic degradation of dyes. Elsevier, pp 605–630

Saverini M et al (2012) Genotoxicity of citrus wastewater in prokaryotic and eukaryotic cells and efficiency of heterogeneous photocatalysis by TiO2. J Photochem Photobiol B 108:8–15

Shifu C, Gengyu C (2005) Photocatalytic degradation of organophosphorus pesticides using floating photocatalyst TiO2·SiO2/beads by sunlight. Sol Energy 79(1):1–9

Singh S, Srivastava VC, Mall ID (2014) Electrochemical treatment of dye bearing effluent with different anode–cathode combinations: mechanistic study and sludge analysis. Ind Eng Chem Res 53(26):10743–10752

Sirtori C et al (2010) Effect of water-matrix composition on trimethoprim solar photodegradation kinetics and pathways. Water Res 44(9):2735–2744

Suteu D, Zaharia C, Malutan T (2011) Removal of orange 16 reactive dye from aqueous solutions by waste sunflower seed shells. J Serb Chem Soc 76(4):607–624

Szpyrkowicz L, Juzzolino C, Kaul SN (2001) A comparative study on oxidation of disperse dyes by electrochemical process, ozone, hypochlorite and Fenton reagent. Water Res 35(9):2129–2136

Tahmasebi N, Maleki Z, Farahnak P (2019) Enhanced photocatalytic activities of Bi2WO6/BiOCl composite synthesized by one-step hydrothermal method with the assistance of HCl. Mater Sci Semicond Process 89:32–40

Tsoumachidou S et al (2017) Greywater as a sustainable water source: a photocatalytic treatment technology under artificial and solar illumination. J Environ Manage 195:232–241

Wallace TH (2001) Biological treatment of a synthetic dye water and an industrial textile wastewater containing azo dye compounds. Virginia Tech

Welham A (2000) The theory of dyeing (and the secret of life)

Yang X, Wang D (2018) Photocatalysis: from fundamental principles to materials and applications. ACS Appl Energy Mater 1(12):6657–6693

Yap P-S, Lim T-T (2011) Effect of aqueous matrix species on synergistic removal of bisphenol-A under solar irradiation using nitrogen-doped TiO2/AC composite. Appl Catal B 101(3–4):709–717

Yu J, Zhao X (2000) Effect of substrates on the photocatalytic activity of nanometer TiO2 thin films. Mater Res Bull 35(8):1293–1301

Zainal Z et al (2005) Removal of dyes using immobilized titanium dioxide illuminated by fluorescent lamps. J Hazard Mater 125(1–3):113–120

Zangeneh H et al (2015) Photocatalytic oxidation of organic dyes and pollutants in wastewater using different modified titanium dioxides: a comparative review. J Ind Eng Chem 26:1–36

Zinatloo-Ajabshir S, Salavati-Niasari M (2015) Nanocrystalline Pr6O11: synthesis, characterization, optical and photocatalytic properties. New J Chem 39(5):3948–3955

Zinatloo-Ajabshir S, Salavati-Niasari M (2016) Facile route to synthesize zirconium dioxide (ZrO2) nanostructures: structural, optical and photocatalytic studies. J Mol Liq 216:545–551

Zollinger H (2003) Color chemistry: syntheses, properties, and applications of organic dyes and pigments. Wiley

Conflict of Interest

The authors declare no conflict no interest among themselves.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Bhattacharjee, R. et al. (2022). Effective Materials in the Photocatalytic Treatment of Dyestuffs and Stained Wastewater. In: Dave, S., Das, J. (eds) Trends and Contemporary Technologies for Photocatalytic Degradation of Dyes. Environmental Science and Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-08991-6_7

Download citation

DOI: https://doi.org/10.1007/978-3-031-08991-6_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-08990-9

Online ISBN: 978-3-031-08991-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)