Abstract

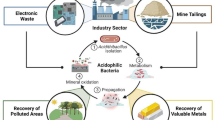

In addition to the limited availability of freshwater in arid regions, the presence of chloride in gangue or high-value minerals, possibly increased by evaporation processes, have the consequence and challenge, of carrying out biomining operations in the presence of elevated concentrations of chloride and other inorganic solutes. Examples of chemical leaching of minerals such as chalcopyrite in brackish and saline environments illustrate the potential of chloride as lixiviant and raise the question whether it is possible to combine bioleaching with chloride leaching. However, chloride inhibits bioleaching microorganisms to different degrees, while some possess physiological responses that allow them to tolerate relatively high levels of chloride. Advantages of NaCl-containing solutions for bioleaching have been published and a number of corresponding processes have been patented, but are not, as yet, used on an industrial scale. The use of chloride-tolerant strains of mineral-oxidising acidophiles together with measures to control chloride concentrations to below inhibitory levels could facilitate the development of industrial-scale biomining with brackish or saline waters.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

13.1 Introduction

13.1.1 Demand for Bioleaching in Saline/Brackish Waters to Meet Challenges

Over the past decades, bioleaching has been successfully applied to process a variety of sulfide ores that cannot be economically utilised by traditional methods. One of the challenges that biomining operations face is the need for water to run the process. In the larger context, efficiency of water usage has become a priority for global minerals industries, especially in regions with limited freshwater supplies, such as northern Chile, southern Peru, Australia, northern China, and some regions of North and South Africa, and Asia. Due to the high cost of sourcing freshwater, mining companies are searching for alternatives to freshwater in these arid regions, which often means using saline and brackish water supplies. In general, (i) waters with total dissolved salts or mineral constituents (TDS) concentration less than 3000 mg L−1 are considered freshwater; (ii) waters with 3000–10,000 mg L−1 TDS are considered to be brackish; (iii) waters containing 10,000 mg L−1 or more TDS are considered saline; (iv) groundwaters with salinity greater than seawater (about 33,000–48,000 mg L−1 TDS) are usually referred to as brines.

Even where saline or brackish waters are not used for irrigating bioheaps or dumps, biomining operations may have to deal with high TDS-containing lixiviants, since gangue minerals may dissolve and release ions, including chloride. Especially in arid regions, dissolved salts may reach very elevated concentrations, due to the evaporation of water from the heaps or dumps and due to the recycling of the raffinate or of water from tailings storage facilities. One specific source of chloride in heaps containing mixed oxidic and sulfidic copper ores may be the occurrence of atacamite (Cu2Cl(OH3)), which readily dissolves in acid and releases chloride.

13.1.2 Additional Opportunities of Bioleaching in Saline/Brackish Waters

Biomining with saline or brackish waters is not only an issue to meet the challenges described above, but also provides additional opportunities. This results from the fact that chloride has been demonstrated to promote mineral leaching under abiotic conditions by chemical means (Watling 2014). Metal chlorides are generally more soluble than corresponding sulfates. Furthermore, chloride salts appear to facilitate the diffusion of leaching agents via the formation of a more porous sulfur layer, thus improving the kinetics of the system. Consequently, there has been a number of industrial applications and smaller-scale investigations of purely chemical chloride leaching of minerals and other materials (Table 13.1).

One of the first processes using seawater for leaching was the Cuprochlor® process developed by Minera Michilla (patents CL 40891, EP 1559799B1) and then by Antofagasta Minerals (patent EP 3246420 B1). It involves agglomeration with CuCl2 and H2SO4, curing, leaching, and washing. More recently the “heap leaching method” (EP 2888380 B1) making use of chloride concentrations of 130–230 g L−1 was patented by BHP Billiton. It has been claimed that the Cuprochlor® process can be carried out with seawater directly and offers a number of advantages over bioleaching including higher recoveries and lower leaching times for secondary copper sulfides.

In the context of the most relevant applications, copper leaching from sulfidic ores, the leaching power is related to the fact that chloride ligand stabilises both cuprous and cupric ions (Watling 2014), thus avoiding cuprous ion disproportionation to cupric and elemental copper, and making it available for a cupric/cuprous redox cycle. The cupric ion in turn plays a crucial role, for example, in the mechanism of chalcopyrite leaching by attacking the H2S probably released from chalcopyrite (CuFeS2) under acidic conditions. Chalcopyrite is the most abundant copper mineral in the lithosphere, comprising roughly 70% of the world’s accessible copper reserve. Chalcopyrite leaches much more slowly than copper oxides and other copper sulfides such as chalcocite (Cu2S) and bornite (Cu5FeS4), and therefore improvement of chalcopyrite leaching is of high relevance.

Besides the effect on cupric and cuprous ion stability, the higher copper extraction from chalcopyrite in a chloride medium has also been associated with the lower activation energy for chalcopyrite dissolution. Chloride leaching of chalcopyrite is especially effective at elevated temperatures. The positive effect of chloride could be attributed to the formation of a more porous sulfur product thus allowing continued diffusion. A decreased passivation by sulfur layers obviously also plays a role in bioleaching of chalcopyrite.

While biomining is a proven technology to process low-grade ores, as described in sect. 13.1.1, the presence of elevated chloride concentrations can be problematic for various reasons (scarcity of freshwater, dissolution of minerals, recycling). The purely chemical processes mentioned above demonstrate the leaching power of chloride, and this raises the question whether the leaching power of chloride and microorganisms can be combined. Therefore, the application of biohydrometallurgy using seawater or saline water represents an attractive alternative for the mining industry, in particular in areas where freshwater sources are scarce. However, the efficacy of bioleaching may be compromised in the presence of saline and brackish waters as the majority of known acidophilic microorganisms are relatively intolerant of elevated concentrations of chloride (sect. 13.2.).

13.2 Inhibition of Bioleaching Microorganisms by Chloride

Given the potential advantages of bioleaching in the presence of chloride, growth, and iron or mineral oxidation of the more well-known mineral bioleaching microorganisms have been studied in media containing elevated concentrations of chloride (Zammit and Watkin 2016). It has been reported that iron oxidation activity of Acidithiobacillus ferrooxidans can be significantly (by ~50%) inhibited at concentrations of 100 mM chloride (NaCl or KCl) or even less, and more than 90% inhibited at concentrations below 200 mM (Rivera-Araya et al. 2020). Interestingly, sulfur oxidation, usually represented by oxidation of elementary sulfur, thiosulfate, or tetrathionate seems to be less affected than ferrous iron oxidation, though it should be considered that in some cases the starting pH was higher for growth with the sulfur compound than for that with iron (e.g., Zammit et al. 2012), a fact that will have influenced the inhibitory effect, as detailed below. Similar values as for At. ferrooxidans were also observed for iron oxidation of non-defined mixed cultures. Interestingly, over the years several acidophilic and halophilic or halotolerant iron-oxidising strains belonging to or related to the genus Acidithiobacillus have been isolated, e.g., from geothermal sites on islands in the Mediterranean Sea (Norris et al. 2020). Also, some Leptospirillum strains have been shown to be less sensitive to chloride than At. ferrooxidans (Zammit et al. 2012; Rivera-Araya et al. 2020), and adaptation to increased chloride levels has been reported. Thus, by L. ferriphilum Sp-Cl after prolonged incubation a redox potential of 600 mV (vs. Ag/AgCl) was still reached at ca. 600 mM chloride (WO 2010/009481A2). Acidophilic bacteria that can not only oxidise iron or sulfur, but also grow mixotrophically or heterotrophically (like Sulfobacillus thermosulfidooxidans or Ferrimicrobium acidiphilum) seem to tolerate higher chloride concentrations even without prolonged adaptation (Huynh 2021; Rivera-Araya et al. 2020). Iron oxidation by Sb. thermosulfidooxidans has been observed to be possible up to 600 mM NaCl and bioleaching of pyrite up to 400 mM NaCl (Huynh 2021). As with At. ferrooxidans, cells grown on a sulfur compound (tetrathionate) were reported to be more tolerant than ferrous iron-grown cells (Huynh 2021).

The extremely thermophilic archaea Sulfuracidifex (Sulfolobus) metallicus and Acidianus brierleyi have been reported to operate efficiently at chloride concentrations up to 1.1 M and therefore have been proposed to be “halophilic in character” (Deveci et al. 2008). Sulfolobus acidocaldarius has successfully been used for chalcopyrite leaching at 1 M NaCl, though no growth was observed under these conditions (Martins et al. 2019). On the other hand, Sa. metallicus, requiring media with less than 30 mM chloride, has been reported to be “particularly sensitive” to chloride in solution. Also, the review by Watling et al. (2016) on representatives of the genera Sulfolobus/Sulfuracidifex, Acidianus and Metallosphaera did not support activity at 1 M chloride or above, and included reports of lack of growth for two Acidianus species in the presence of 170 mM, growth “up to” 170 mM for Metallosphaera cuprina, minimum inhibitory concentrations of 320 mM chloride for several Sulfolobus species and tolerance of up to 513 mM for Sa. metallicus.

One reason for the relatively high sensitivity of acidophiles to chloride is considered to be the inside-positive membrane potential (Alexander et al. 1987). While sulfate can still be excluded from entering the cells, the inside-positive potential attracts chloride ions, thus reducing the membrane potential and favouring subsequent (or simultaneous) entry of protons, resulting in an acidification of the cytoplasm. The membrane potential is greatly affected by the pH of the external (bathing) liquor and becomes increasingly less positive and eventually negative) as the latter increases. This helps explain why the inhibitory effect of chloride is more pronounced at lower pH than at higher pH, while the inhibitory effect of cationic transition metals such as copper shows the opposite behaviour (Falagán and Johnson 2018). The pH dependency and the simultaneous effect of copper ions may explain some of the differences in the inhibitory effects referred to above.

Although bioleaching organisms are considered to be relatively tolerant to concentrations of sulfate as high as 1 M and sometimes greater, in addition to damaging the membrane potential and acidifying the cytoplasm, chloride will also contribute to the osmotic stress of the cells (Rivera-Araya et al. 2019). In addition, it has been reported that sodium chloride exposure induces oxidative stress in the cells (Rivera-Araya et al. 2019).

13.3 Responses and Adaptations to Chloride

As has been observed in neutrophilic microorganisms, acidophiles may respond to NaCl exposure by accumulating potassium and/or compatible solutes in the cells (Zammit and Watkin 2016). Genome analyses suggest that corresponding transport proteins or enzymes for the synthesis of, e.g., (hydroxy)ectoine or trehalose are present in acidophiles (Rivera-Araya et al. 2020). The formation of trehalose in response to NaCl has been reported for L. ferriphilum, Sb. thermosufidooxidans, and Acidiphilium cryptum, with L. ferriphilum additionally producing glucose, and At. thiooxidans glucose and proline, but not trehalose (Galleguillos et al. 2018). Proteomic analyses of At. caldus and Acidimicrobium ferrooxidans revealed up-regulation of proteins involved in membrane biosynthesis, in the synthesis of various amino acids possibly as a form of osmoprotectant and in CO2 fixation (Zammit et al. 2012). Other compatible solutes that have been reported for acidophiles are taurine and glycine betaine (Zammit et al. 2012).

Of particular interest are the species of Acidihalobacter, since these are not only moderately halotolerant iron- and sulfur-oxidising acidophiles, but also appear to require some chloride (Khaleque et al. 2020b) and may be designated as moderate halophiles. The first strains of Acidihalobacter prosperus (formerly Thiobacillus prosperus) were isolated from the Mediterranean island, Vulcano. Recently, Acidihalobacter aeolianus, Ah. ferrooxydans, and Ah. yilgarnensis have been described as additional species based on strains isolated from similar locations (Khaleque et al. 2020b). Based on the genome sequence of Ah. prosperus, rusticyanin I has been suggested to have a more negative surface potential possibly explaining activity at elevated chloride concentration (Dopson et al. 2017). Proteomic and transcriptomic investigations of different Acidihalobacter representatives have revealed numerous chloride effects, among them increases in the expression of genes involved in ectoine biosynthesis, ectoine uptake, and redox balance (Khaleque et al. 2020a).

Halotolerant microorganisms of the genera Acidithiobacillus, Alicyclobacillus, and Sulfobacillus were detected (by 16S rRNA gene analyses) in a mine tailings-contaminated beach in Chile, and iron-oxidising enrichment cultures were found to be active in media containing up to 1 M NaCl (Korehi et al. 2013). Alicyclobacillus sp. S09 has recently been isolated from a tailing-contaminated beach in Spain and has been shown to oxidise iron in the presence of 1.5 M NaCl (Huynh 2021). Genome analysis suggested that it is a novel species of this genus, and numerous genes predicted to be involved in iron oxidation, heavy metal and arsenic tolerance, oxidative stress response, and osmoadaptation were identified.

13.4 Bioleaching Processes in the Presence of Chloride

Based on the work on Acidihalobacter, BHP Billiton filed a patent in 2001 (AU 2002254782B2) describing a process to leach sulfide concentrates using Ah. ferrooxydans V8 or Ah. aeolianus V6 (both formerly T. prosperus) at a pH below 3 and a chloride concentration in excess of ca. 280 mM. Leaching of copper from Escondida ore by Ah. aeolianus V6 has later been claimed to be possible at 430–860 mM NaCl (Davis-Belmar et al. 2008). While most Acidihalobacter strains tend to be relatively sensitive to copper, which lowers their potential for use in biomining operations, the recently described species Ah. yilgarnensis appears to be more tolerant (Khaleque et al. 2020a).

Two patents of JX Nippon Mining & Metals, filed in 2006, focussed on an Acidithiobacillus strain able to oxidise sulfur at high chloride concentration and thereby leach copper sulfide ores (US 8497113 B2) or more specifically chalcopyrite containing copper sulfide ores using chloride concentrations between 170 and 510 mM, and concentrations of copper (II) of 8–80 mM and iron (II) of 9–90 mM, respectively (AU 002007203317B2).

In 2008, BHP Billiton filed a patent that invoked using a mixed culture of a halophilic sulfur-oxidiser and L. ferriphilum Sp-Cl to leach sulfide minerals at chloride concentrations between 40 mM and 850 mM (US 8597933). Column experiments on a chalcocite-rich ore in a corresponding system with L. ferriphilum Sp-Cl and an At. thiooxidans-like strain with chloride concentrations up to 170 mM gave extraction yields of around 80% (Davis-Belmar et al. 2014). The authors concluded that “biologically assisted leaching … in the presence of moderate chloride is achievable”, that seawater may be incorporated and the recirculation of process waters may be increased. In 2010, BHP Chile filed a patent for a two-step process in which the minerals are first treated by chemical leaching using chloride concentrations between 0.2 and 2.3 M followed by a bioleach cycle using chloride concentrations below 0.17 M (WO 2012001501A1).

Other patents in this area include one filed by Biosigma (in 2013) using Sulfobacillus thermosulfidooxidans strain Cutipay, which the company claimed allowed “up to 73.7% (increase) in copper recovery from primary sulfides mainly chalcopyrite” (AU 2013405779 B2), and another by Compañía Minera Zaldivar (2014) which did not give specific strains, but referred to Acidithiobacillus, Leptospirillum, and Sulfolobus strains adapted to high chloride concentrations in an “annexed plant of bioreactors”. According to the latter patent, the lixiviant uses Fe (II) and Fe (III) at redox potentials <550 mV (vs. Ag/AgCl) and chloride concentrations up to 5.6 M (WO 2016/26062 A1). A further patent application, filed by Universidad de Antofagasta in 2017, claimed to leach chalcopyrite by a consortium of Acidithiobacillus and Acidiphilium in the presence of 25%–100% seawater (WO 2019/126891A1).

In addition to patented developments in the minerals industry, numerous experiments on bioleaching in presence of chloride have been performed at research institutions, in many cases focussing on chalcopyrite. While relatively good leaching of chalcopyrite by At. ferrooxidans and At. thiooxidans in the presence of 100 mM NaCl had previously been described, Noguchi and Okibe (2020) reported a synergy for chalcopyrite leaching involving chemical chloride leaching and the “low-EH-bioleaching” effect at 140 mM chloride; only chemical chloride leaching was observed in the presence of 560 mM chloride. With the moderately halophilic strain Alicyclobacillus sp. S09 chalcopyrite could be leached using artificial seawater, at rates considerably faster than under abiotic conditions (Huynh 2021).

While most bioleaching work has focussed on copper, the effect of chloride has also been investigated for some other metals, including zinc. While 50 mM chloride does not appear to impede the bioleaching of sphalerite (ZnS), inhibition in the presence of 140 mM chloride has been reported. Leaching of chalcopyrite by Sb. thermosulfidooxidans is not affected by the presence of 200 mM chloride, sphalerite leaching seemed to be inhibited under these conditions (Huynh 2021). Sadeghieh et al. (2020) have reported optimal leaching of copper, nickel, and cobalt from tailings by a moderately thermophilic consortium at 45 °C in the presence of 170 mM NaCl.

13.5 Summary and Future Prospects

In arid regions, where freshwater is not readily available, it would be highly advantageous if mineral processing in general, and bioleaching in particular, could be performed using brackish water or seawater. This would not only conserve water for domestic purposes but also avoid the significant capital and operating costs involved in desalination.

Bioleaching in the presence of elevated chloride concentrations may also be necessary where there are significant amounts of gangue or valuable minerals (such as atacamite) that contain chloride, especially if the raffinate is recycled. In addition, as shown by various large-scale processes, chloride itself has a strong leaching potential and it would be tempting to combine the leaching power of microorganisms that generate acidic ferric iron leachates with the leaching power of chloride. While this has resulted in a number of patents being filed and promising investigations published that advocate bioleaching in the presence of chloride, to date no full-scale industrial operation using this strategy has been established. This raises the question as to the obstacles to bioleaching in presence of chloride.

Compared to “normal” bioleaching, an obvious problem associated with using chloride is its corrosive nature. This necessitates the use of more costly corrosion-resistant materials, a fact which would be anticipated to play a bigger role in tank bioleaching than in heap bioleaching. On the other hand, the industrial processes with chemical chloride leaching show that such materials are available at a price, that under certain conditions may be competitive. In addition, combining bioleaching with abiotic chloride leaching holds the promise of possibly using lower chloride concentrations than for a purely chemical process, thereby probably lowering somewhat the costs incurred in utilising corrosion-resistant equipment.

Another factor to consider is that seawater has a pH of ~8.4 and contains large amounts of bicarbonate alkalinity, both of which would require greater acid demand (compared to freshwater) to generate the extremely acidic liquors required for oxidative bioprocessing of sulfidic ores. Brackish waters would have similar disadvantages. In addition, these waters contain other dissolved ions which may interfere with the leaching process or the winning of the target metal(s) from the pregnant leach solution.

Chloride inhibition of typical bioleaching microorganisms, combined with simultaneous effects of metal ions and low pH, remains the major barrier to making use of bioleaching in presence of chloride on a larger scale. However, the identification of chloride-tolerant acidophiles that can also tolerate elevated concentrations of dissolved metals continues to provide new candidates for such processes. Even with such acidophiles, it will be necessary to control the chloride concentration at an appropriate level in order to avoid toxic concentrations. This may be relatively easy in tank operations, but more of a challenge in bioheaps and dumps, especially in arid regions, where evaporation will tend to increase the salt concentration in a temperature-dependent way and thus with different rates depending on time and location in the heap. (Dilution by rain water would have the opposite effect.) An aspect related to counteracting evaporation is that any excess salt separated from the raffinate in the form of brines needs to be disposed of in a sustainable way.

Despite the obstacles mentioned, there is confidence among scientists researching this area that at least for specific ores or concentrates the combination of bioleaching and abiotic chloride leaching in the near future could become a robust and economically viable strategy to win metals.

References

Alexander B, Leach S, Ingledew WJ (1987) The relationship between chemiosmotic parameters and sensitivity to anions and organic acids in the acidophile Thiobacillus ferrrooxidans. J Gen Microbiol 133:1171–1179. https://doi.org/10.1099/00221287-133-5-1171

Aylmore MG (2016) Alternative lixiviants to cyanide for leaching gold ores. In: Adams MD (ed) Gold ore processing, 2nd edn. Elsevier, pp 447–484. https://doi.org/10.1016/B978-0-444-63658-4.00027-X

Davis-Belmar CS, Nicolle JLC, Norris PR (2008) Ferrous iron oxidation and leaching of copper ore with halotolerant bacteria in ore columns. Hydrometallurgy 94:144–147. https://doi.org/10.1016/j.hydromet.2008.05.030

Davis-Belmar CS, Cautivo D, Demergasso C, Rautenbach G (2014) Bioleaching of copper secondary sulfide ore in the presence of chloride by means of inoculation with chloride-tolerant microbial culture. Hydrometallurgy 150:308–312. https://doi.org/10.1016/j.hydromet.2014.09.013

Deveci H, Jordan MA, Powell N, Alp I (2008) Effect of salinity and acidity on bioleaching activity of mesophilic and extremely thermophilic bacteria. Trans Nonferrous Met Soc China 18:714–721. https://doi.org/10.1016/S1003-6326(08)60123-5

Dopson M, Holmes DS, Lazcano M, McCredden TJ, Bryan CG, Mulroney KT, Steuart R, Jackaman C, Watkin ELJ (2017) Multiple osmotic stress responses in Acidihalobacter prosperus result in tolerance to chloride ions. Front Microbiol 7:2132. https://doi.org/10.3389/fmicb.2016.02132

Falagán C, Johnson DB (2018) The significance of pH in dictating the relative toxicities of chloride and copper to acidophilic bacteria. Res Microbiol 169:552–557. https://doi.org/10.1016/j.resmic.2018.07.004

Galleguillos PA, Grail BM, Hallberg KB, Demergasso CS, Johnson DB (2018) Identification of trehalose as a compatible solute in different species of acidophilic bacteria. J Microbiol 56:727–733. https://doi.org/10.1007/s12275-018-8176-2

Huynh ND (2021) Effect of sodium chloride on acidophilic iron- and sulfur-oxidizing microorganisms and their bioleaching activity. Doctoral dissertation. TU Bergakademie Freiberg, Germany

Khaleque HM, Fathollazadeh H, González C, Shafique R, Kaksonen AH, Holmes DS, Watkin ELJ (2020a) Unlocking survival mechanisms for metal and oxidative stress in the extremely acidophilic halotolerant Acidihalobacter genus. Genes 11:1392. https://doi.org/10.3390/genes11121392

Khaleque HN, González C, Johnson DB, Kaksonen AH, Holmes DS, Watkin ELJ (2020b) Genome-based classification of Acidihalobacter prosperus F5 (=DSM 105917=JCM 32255) as Acidihalobacter yilgarnensis sp. nov. Int J Syst Evol Microbiol 70:6226–6234. https://doi.org/10.1099/ijsem.0.004519

Korehi H, Blöthe M, Sitnikova MA, Dold B, Schippers A (2013) Metal mobilization by iron- and sulfur-oxidizing bacteria in a multiple extreme mine tailings in the Atacama Desert, Chile. Environ Sci Technol 47:2189–2196. https://doi.org/10.1021/es304056n

Martins FL, Patto GB, Leão VA (2019) Chalcopyrite bioleaching in the presence of high chloride concentrations. J Chem Technol Biotechnol 94:2333–2344. https://doi.org/10.1002/jctb.6028

Noguchi H, Okibe N (2020) The role of bioleaching microorganisms in saline water leaching of chalcopyrite concentrate. Hydrometallurgy 195:105397. https://doi.org/10.1016/j.hydromet.2020.105397

Norris PR, Davis-Belmar CS, Calvo-Bado LA, Ogden TJ (2020) Salt-tolerant Acidihalobacter and Acidithiobacillus species from Vulcano (Italy) and Milos (Greece). Extremophiles 24:593–602. https://doi.org/10.1007/s00792-020-01178-w

Rivera-Araya J, Huynh ND, Kaszuba M, Chávez R, Schlömann M, Levicán G (2020) Mechanisms of NaCl-tolerance in acidophilic iron-oxidizing bacteria and archaea: comparative genomic predictions and insights. Hydrometallurgy 194:105334. https://doi.org/10.1016/j.hydromet.2020.105334

Rivera-Araya J, Pollender A, Huynh D, Schlömann M, Chávez R, Levicán GP (2019) Osmotic imbalance, cytoplasm acidification and oxidative stress induction support the high toxicity of chloride in acidophilic bacteria. Front Microbiol 10:2455. https://doi.org/10.3389/fmicb.2019.02455

Sadeghieh SM, Ahmadi A, Hosseini MR (2020) Effect of water salinity on the bioleaching of copper, nickel and cobalt from the sulphidic tailing of Golgohar iron mine. Iran Hydrometallurgy 198:105503. https://doi.org/10.1016/j.hydromet.2020.105503

Watling HR (2014) Chalcopyrite hydrometallurgy at atmospheric pressure: 2. Review of acidic chloride process options. Hydrometallurgy 146:96–110. https://doi.org/10.1016/j.hydromet.2014.03.013

Watling HR, Collinson DM, Corbett MK, Shiers DW, Kaksonen AH, Watkin ELJ (2016) Saline-water bioleaching of chalcopyrite with thermophilic, iron(II)- and sulfur-oxidizing microorganisms. Res Microbiol 167:546–554. https://doi.org/10.1016/j.resmic.2016.05.003

Zammit CM, Mangold S, Rao Jonna V, Mutch LA, Watling HR, Dopson M, Watkin ELJ (2012) Bioleaching in brackish waters–effect of chloride ions on the acidophile population and proteomes of model species. Appl Microbiol Biotechnol 93(1):319–329. https://doi.org/10.1007/s00253-011-3731-3

Zammit CM, Watkin ELJ (2016) Adaptation to extreme acidity and osmotic stress. In: Quatrini R, Johnson DB (eds) Acidophiles. Life in extremely acidic environments. Caister Academic Press, Norfolk, UK, pp 49–62. https://doi.org/10.21775/9781910190333

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Chen, M., Schlömann, M. (2023). Mineral Bioleaching in Brackish and Saline Environments. In: Johnson, D.B., Bryan, C.G., Schlömann, M., Roberto, F.F. (eds) Biomining Technologies. Springer, Cham. https://doi.org/10.1007/978-3-031-05382-5_13

Download citation

DOI: https://doi.org/10.1007/978-3-031-05382-5_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-05381-8

Online ISBN: 978-3-031-05382-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)