Abstract

In this Chapter, a wind-based multigeneration system is designed, developed and analyzed. The proposed system is evaluated through energy and exergy approaches. For the potential implementation of the system, a case study is conducted by considering the needs and wind data of the Caribbean island nation of Antigua and Barbuda. The excess power occurring during the energy off-peak time of the region is utilized to compress and store air into underwater balloons. If the wind speed is not sufficient enough to provide enough energy, the energy stored in compressed air is extracted via gas turbines. Thermal waste energy occurring during the air compression process is stored and introduced to compressed air before the expansion process to increase the carried energy further while decreasing the losses throughout the integrated system. The thermal energy is also partially utilized in a thermal water desalination unit to produce fresh water from seawater for the region. The performance of the proposed system is evaluated through various parametric studies. The study results show that the proposed system is capable of providing 51.36 MW of net electric power while operating with overall energy and exergy efficiencies of 39.49% and 37.62%, respectively. Furthermore, the system offers 9818 tons of fresh water for the region on a monthly basis.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Global warming and its associated impacts on nature, e.g. water scarcity, increasing fire threats, drought, salt level increase in soil, higher wildlife extinction rates and infectious diseases, is addressed as one of the primary threats to the existence of the living species by many authorities (https://www.un.org/en/chronicle/article/health-effects-global-warming-developing-countries-are-most-vulnerable, https://ec.europa.eu/clima/change/consequences_en, https://www.canada.ca/en/services/environment/weather/climatechange/causes-effects.html). The increase in the heat-trapping greenhouse gases in the atmosphere causes temperature rise and eventually change in climate pattern on a local and global level. Due to its long resistance in the atmosphere, carbon dioxide (CO2) emissions primarily from human activities are known as the main driver of the on-going global warming and its side impacts on the planet earth. Since the industrial revolution, the energy needs of humankind to sustain the life and living standards have been increasing cumulatively. Fossil fuels were and still are the main source to meet this energy demand. Today, about 80% of the global energy supply is from fossil fuels (https://www.capp.ca/energy/world-energy-needs/). Figure 1 shows the ratios of the greenhouse gas emissions (GHGs) for different gases. Fossil fuels and its related activities, e.g. extraction, processing and burning, are responsible from 65% of global CO2 emissions. Therefore, the primary objective for mitigation of global warming is to be the development of efficient and environmentally benign energy technologies.

Global greenhouse gas emissions ratios (Data from https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data)

Conventional fossil fuel-based energy technologies cause economic and ecological problems due to unstable fuel prices and emitting large amount of CO2 when combusted. On the other hand, renewable resources, i.e. wind and solar, are more than enough to make the energy supply nature-friendly. However, intermittent characteristics of these resources raise concerns in terms of reliability. This can be mitigated/avoided by correct approaches to the renewable energy systems. The most common one is to store the obtained energy when it is abundant and offer to the service when it is needed. The selection of the correct energy storage system is also critical. For instance, pumped hydro is recognized as the most commonly used method for energy storage forming almost 95% of energy storage systems operating across the globe (https://www.hydropower.org/factsheets/pumped-storage). On the other hand, this approach may not be feasible in every cases due to geographical and topographical restrictions. Chemical energy storage in the form of hydrogen is another promising method to store energy effectively and nature-friendly. In this case, the excess electricity can be used in the hydrogen production via electrolysis of water, and then the produced hydrogen can be converted back to electricity via fuel cells without any harm to the nature. As a mechanical energy storage method, compressed air energy storage systems (CAESs) is an alternative nature-friendly approach that is commonly investigated. In CAES, the excess energy is used to compress the air into a storage medium, which can be an underground cavern, or a balloon located under the surface of water. When it is needed, the energy is reproduced by the expansion of the compressed air through gas turbines. Use of underwater balloons may provide the advantage of utilizing from the hydrostatic pressure; thus, the instant pressure drops and decency of the storage medium can be achieved without any extra effort. Main drivers to consider renewable energy together with energy storage can be summarized as follows:

-

To provide power on demand in case renewable resources are insufficient;

-

To harness more energy from renewable resources;

-

To decrease CO2 emission rates of power sector by penetrating more clean energy to grid;

-

To manage the problems associated with intermittency of the renewable resources.

In the scope of a more sustainable planet, the production of electricity from wind energy is one of the most promising and, consequently, one of the fastest growing renewable-based electricity generation methods. In 2000, the global installed wind capacity was 17.6 GW, and global electricity production from wind was about 30 GWh (https://www.nrel.gov/docs/fy01osti/29436.pdf). In 2020, these ratios reached to 743 GW of global wind capacity and global wind-based electricity production of 1590 GWh (https://ourworldindata.org/renewable-energy). Figure 2 shows the global renewable-based electricity generations trends with respect to sources from 2000 to 2020. Wind turbine can be located as on-shore and off-shore. Off-shore wind power generation plants can enjoy higher wind speeds and larger wind blades diameters that allows to generate electricity at higher rates compared to the on-shore applications. Nonetheless, off-shore wind-based electricity production has much higher capital and operational costs. Due to this, about 93% of the global installed wind capacity is on-shore. The energy in the form of kinetic energy from moving air is converted to mechanical energy via wind turbines and eventually to electricity via generator taking place in the body of the wind turbine set-up.

Global renewable based electricity by sources from 2000 to 2020 (Data from https://ourworldindata.org/renewable-energy)

The selection of site with a favorable weather pattern is critical for effective operation of wind turbines. In this regard, the minimum wind speed of 12–14 km/h, which is also known as cut-in speed, is addressed to turn turbine blades to capture energy from blowing wind and produce the useful output of electricity (https://www.nrcan.gc.ca/sites/www.nrcan.gc.ca/files/canmetenergy/files/pubs/WindEnergy_buyersguide_ENG.pdf). The size of the wind turbine blades, wind speed and air density are some major parameters that define the amount of energy produced by wind turbines. Higher wind speeds mean to more energy available in the wind and electricity production via wind turbines at higher rates. However, wind turbines are designed to cope with certain wind speeds. In this regard, a cut-out wind speed is defined for safe operation of wind turbines that vary by turbine design (up to 80 km/h) (https://www.energy.gov/eere/articles/how-do-wind-turbines-survive-severe-storms). This is the maximum wind speed that wind turbines are capable of bearing if every single components in the system in cooperation, but in practice, wind turbines are stopped operating before reaching these ranges to remain in a safe zone.

Another important parameter that defines the energy extraction ratio from wind is the Betz limit. Similar to Carnot cycle efficiency in thermodynamics, stating that all energy provided to a heat engine cannot be turned into useful output and partially must be rejected to the environment, Betz limit defines the limits of extracting energy from wind. According to Albert Betz, theoretical maximum efficiency of a wind turbine cannot exceed 59.3%; meaning that only 59.3% of the kinetic energy can be used for spinning wind turbines to generate electricity (Ragheb and Ragheb 2011). In practice, wind turbines cannot reach to this efficiency, and commonly practiced wind turbine efficiencies falls between 35 and 45% range (https://css.umich.edu/factsheets/wind-energy-factsheet). It should be noted that the Betz limit defines the maximum kinetic energy that can be turned into mechanical energy by a wind turbine. Since the desired useful output from wind power plants is electricity, the efficiency of other system components, i.e. gearbox and generator, must be considered while calculating the electrical output of wind turbines.

In this study, the system developed is evaluated within the scope of a case study for which Antigua and Barbuda is selected as the region for the potential implementation of the system. Antigua and Barbuda is an island nation with a total population of 96,286 (https://datacommons.org/place/country/ATG#Environment). The country consists of two main islands and several small islands covering an area of 443 square kilometers (km2) in total (Vinet and Zhedanov 2011). For its energy, the country relies on imported fossil fuels, and heavy fuel oil is the main source used for the electricity production in the country. Due to this, the country struggles with unstable and high energy prices (0.4 US$/kWh) as well as high CO2 emission rates (http://www.apua.ag/customer-service/rates/). The drinking water sector in Antigua and Barbuda is reliant on seawater desalination through reverse osmosis, and fresh water production consumes about 36 GWh of electricity annually, which corresponds to around 12% of the total electricity consumption in the country (https://www.worlddata.info/america/antigua-barbuda/energy-consumption.php). Hydropower, geothermal, and bioenergy resources are all said to be unavailable in the country. On the other hand, the country has a good solar insulation, and the capacity of power generation from wind is reported as 400 MW for the region (Samuel 2021). Figure 3 shows the average wind speed of Antigua and Barbuda for the corresponding months. The specific objectives of the study are listed as follows:

Monthly average wind speed and air temperature of Antigua and Barbuda (https://www.weather-atlas.com/en/antigua-and-barbuda/codrington-climate#wind)

-

To design and develop a wind-based multigeneration integrated energy system;

-

To conduct a thermodynamic analysis on the system and determine energy and exergy efficiencies of the system;

-

To evaluate the system performance through parametric studies by considering primary design and operational parameters;

-

To conduct a case study for a potential implementation of the system in Antigua and Barbuda by considering regional parameters.

2 System Description

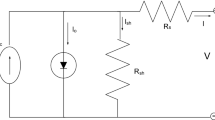

Within the scope of the current study, a wind based integrated energy systems is investigated through thermodynamic approaches. The developed system utilizes from wind as a primary energy source. The excess energy likely to occur during the off-peak time of the energy demand is stored via compressed air energy storage (CAES) system located underwater. Further, the waste heat occuring from the air compression process is stored in a thermal energy storage (TES) tank, and later introduced to the compressed air before the expansion through gas turbines. Lake/river water is utilized as a cooling agent to manage the temperature between the compression stages and store the thermal energy in the TES tank. After use in the interheaters to increase the carried energy within the compressed air before the expansion, the water is released back to its environment with acceptable temperatures to avoid any potential thermal pollution. The integrated system also comprises a thermal desalination system to produce fresh water from seawater, for which the required thermal energy is provided from the excess heat from the air compression process. The system consists of 100 wind turbines with a blade radius of 50 m. The energy analysis of the system is performed by considering an average wind speed of 8 m/s and a power coefficient of 49%. Figure 4 illustrates the system diagram. Antigua and Barbuda is selected as a region to evaluate the system as a case study. Table 1 presents the energy overview of the country. Table 2 presents the specifications considered in the analysis of the system.

A wind based integrated power system (Adapted from Karaca et al. (2021))

2.1 System Analysis

The proposed system is evaluated through energy and exergy approaches. Thermodynamic balance equations for corresponding sub-components are presented in Table 4 in accordance with the state points as illustrated in Fig. 4. The following assumptions are considered while conducting the thermodynamic analysis of the system:

-

The steady state and adiabatic operations in the pumps, compressors and turbines.

-

The reference temperature and pressure for air: 25 °C and 101.3 kPa.

-

The reference temperature and pressure for water: 17 °C and 101.3 kPa.

-

The reference state temperature and pressure for seawater: 20 °C and 101.3 kPa.

-

The isentropic efficiency of 85% for pump, compressor and turbine operations.

-

The potential pressure losses throughout the system are neglected.

-

The potential and kinetic energy changes are neglected.

The specific exergy of a given state point can be calculated by

Both compressor (including pump) and turbine isentropic efficiencies can be computed by

The exit temperature for the isentropic compressor operation can be identified by (k = 1.4)

For the multistage water desalination unit, mass balance equation is as follows [e.g., Demir and Dincer 2017]:

where \(\dot{m}_{sw} ,\) \(\dot{m}_{b} , \dot{m}_{des} ,X_{sw} , X_{b}\) are fed seawater mass flow rate, brine mass flow rate, desalinated product mass flow rate, fed seawater salinity, and brine salinity, respectively. Table 3 presents the values of the variables used in the analysis of the multistage water desalination unit.

The temperature increase during the air compression process is managed by intercoolers between the stages in which lake/river water is utilized as a cold stream fluid. The thermal energy absorbed by the fluid is conveyed and stored into a thermal energy storage tank (TES). During the discharging period where wind speed is not high enough to produce enough power, the energy in the TES tank is utilized in interheaters to further increase the carried energy by the compressed air before expanding through gas turbines to generate power. The effectiveness of the heat exchangers taking place in the aforementioned cycle is written as

where \(\dot{Q}_{actual}\) is the actual heat transfer, and \(\dot{Q}_{max}\) is the maximum possible heat transfer between hot and cold stream in the heat exchangers.

where subscript of “hs” indicates the hot stream, and “cs” is for the cold stream. \(c_{p}\) is the specific heat capacity (kJ/kgK) of the corresponding fluid at the corresponding state properties.

or

Here, \(\dot{Q}_{max}\) will be the minimum value obtained from these two equation. By employing the presented equations, the effectiveness of the heat exchangers operating in the compressed air cycle is evaluated as in a range between 0.612 and 0.955. The value of the 0.612 is obtained in the intercoolers, whereas the effectiveness of the interheaters is evaluated as 0.955.

Both energy and exergy efficiencies of the system are evaluated as charging phase and discharging phase. For the charging phase, in which the energy storage is implemented, the energy efficiency can be written as

where \(\dot{W}_{net}\) represents the net power output from the system, \(\dot{Q}_{ca}\) is the energy storage in the form of compressed air, \(\dot{Q}_{Tes}\) is the thermal energy storage in the TES tank and \(\dot{W}_{wind}\) is the available wind power hitting the wind turbines. Table 4 shows thermodynamic balance equations written for the each sub-components taking place in the overall system.

The net power of the system during the charging phase can be defined as

where \(\dot{W}_{wt}\) represents the wind turbines’ power output, and \(\dot{W}_{comp}\) is for the compressor power input needed for the CAES. Power output from the wind turbine and total wind power crossing from the area swept by turbine blades can be determined by

where \(N_{wt}\) represents the number of wind turbines, \(C_{{p_{wt} }}\) is the power coefficient of the wind turbine and \(\eta_{wt}\) is the wind turbine efficiency regarding the gearbox and generator efficiencies. It is important to note that wind turbines operate with wind speed in certain ranges to provide an effective and safe operation. Therefore, turbine speed (\(V_{wt}\)) and wind speed \((V_{w}\)) are defined separately. In the analysis of the system, the maximum wind speed that the turbine can cope with is assumed as 11 m/s. Beyond this value, the turbine operates at a constant speed up until 25 m/s. After this, wind turbine stops working to avoid potential damages. Table 5 presents the thermodynamic properties of each state points shown in Fig. 4.

The exergy efficiency of the charging phase can be defined as

For the discharging phase, energy and exergy efficiencies can be determined by

The integrated system’s overall energy and exergy efficiencies can be calculated by

Table 6 presents the variables taking place in the efficiency analysis. The purpose of using multiple sub-systems is to harvest more useful output from the overall energy input. Thus, the effectiveness of the renewable energy can be increased by utilizing more from abundant renewable resources. In this regard, energy efficiency of a conventional wind power plant is defined to provide a better picture of the benefit of the integrated renewable power systems. The energy efficiency for a conventional power plant can be defined as

3 Results and Discussion

In this section, the results of the study are presented and discussed with figures. Engineering Equation Solver (EES) software has been used in the thermodynamic, energy and exergy analysis of the system. The system performance is evaluated through various parametric studies by considering primary design and operational parameters. Antigua and Barbuda is considered as potential region to implement the system; thus wind data from the region is considered in the monthly-based analysis of the system. In the current state, the country produces its electricity from heavy fuel oil (HFO). Potential impact and performance analysis for the replacement of the existing systems with the integrated system is discussed. The total power produced by 100 wind turbines is evaluated as 85.12 MW at a wind speed of 8 m/s. On a monthly basis, the system is capable of providing 9818 tons of fresh water. Overall energy and exergy efficiencies of the system are evaluated as 39.49% and 37.62%, respectively. Figure 5 shows the exergy destruction rates in the major system components. Total exergy destruction rate throughout the system is evaluated as 15,033 MW. According to the thermodynamic analysis results, the highest exergy destruction rates are observed in the interheaters 1 and 2 with a value of 2858 MW. Exergy destruction is the loss of work potential. Therefore, it is possible to extract more useful output by decreasing the exergy destruction rates. In this specific case, high exergy destruction in intercoolers can be mitigated by lowering the temperature difference between hot and cold stream. Table 7 presents the performance results of the developed integrated renewable energy system.

Figure 6 shows the monthly basis electricity production of the integrated system. July and January are evaluated as the most productive period of the year in this regard. For the corresponding periods, the electricity productions become 48.9 MWh and 44.5 MWh per month, respectively. The similar result is expected for energy storage ratios since higher electricity production via wind may allow to dedicate higher portion of the produced electricity to energy storage via CAES. September, October and November are the least productive period of the year in the region.

Figure 7 presents the potable water production in accordance with monthly basis average wind speed (see Fig. 1). In this regard, the most productive period of the year is evaluated as July with a total fresh water production of 7833 tons, where the average wind speed of the region is reported as 7.42 m/s. The lowest fresh water production rates are obtained for October with a value of 3386 tons. It should be noted that thermal energy for water desalination process is from the excess heat occurring during the period of energy storage via CAES. For off-peak time, 60% of electricity produced by wind turbine is considered as excess power and utilized for the energy storage. Therefore, average wind speed for the corresponding periods of the year greatly impacts the freshwater production ratios.

Note that integrated systems allow to harness more energy from renewable resources. In this regard, comparative assessment of the integrated system with a conventional wind power plant is presented in Fig. 8 to provide a better understanding. Up to 11 m/s, it is considered that the wind turbine operates with the wind speed. Then, the turbine operates with a constant speed 11 m/s up until the wind speed 15 m/s. After this, the turbine stops working to avoid potential damages. The power coefficient factor is varied for different wind speeds, for which the \(C_{p}\) values provided in Neill and Hashemi (2018) for corresponding wind speeds are used. Due to the determined operational limit of the wind turbine, the power production becomes stable after the wind speed of 11 m/s. However, the efficiency of the plant decreases since the output from the system becomes stable while the wind energy increases with higher wind speeds. At a wind speed of 11 m/s, the system is capable of producing 156 MW of electrical power. On the other hand, it is found that integrated system performs higher energy efficiency (39.49%) than that of a conventional wind power plant (35.28%). According to this results, it is evaluated that the integrated system offers around 12% increase in the harnessing energy from the wind compared conventional wind power plant. Figure 9 presents the energy and exergy efficiencies of the integrated system for different operational phases with respect to wind speeds. Exergy efficiency of the discharging phase becomes slightly higher than the energy efficiency due to the decrease in the denominator of the exergy efficiency definition for the corresponding phase.

The annual electricity need of Antigua and Barbuda is reported as 308 GWh (See Table 1, which totally relies on imported heavy fuel oil. The country also produces its potable water from seawater via reverse osmosis where electricity required is from HFO-based power plants. The analysis of the proposed system indicates that the system is capable of 745.66 GWh clean energy production for the region, which is well above the country’s annual electricity demand. Beyond making the country totally energy independent and consuming clean energy, the potential implementation of the proposed system may make Antigua and Barbuda an energy exported in the Caribbean region.

4 Conclusions

In the scope of the current study, thermodynamic analysis of a wind-based integrated energy system is conducted. The performance of the study is investigated through various parametric studies. The findings of the conducted study can be summarized with couple bulleted points as follows:

-

At a wind speed of 11 m/s, the electrical power output of the system 156 MW;

-

At an average wind speed of 8 m/s, the potable water production is about 9618 tons/month;

-

Overall energy and exergy efficiencies of the system are evaluated as 39.49% and 37.62%, respectively;

-

Compared to conventional wind power plant, the integrated system is capable of harnessing 12% more energy from wind.

In closing, conventional fossil fuel-based energy production and consumption activities are the primary contributors to global warming and its devastating impacts on the planet. Furthermore, having depleting sources and unstable prices make fossil fuel and energy relying on these sources even more problematic. Therefore, renewable-based effective and nature-friendly energy systems become a necessity for all if a cleaner, safer, and more stable environment is demanded.

Abbreviations

- A :

-

Area, m2

- ex:

-

Specific exergy, kJ/kg

- \(\dot{E}x_{d}\) :

-

Exergy destruction rate, kW

- h:

-

Specific enthalpy, kJ/kg

- Ir:

-

Solar irradiation, kW/m2

- \(\dot{m}\) :

-

Mass flow rate, kg/s

- \(\dot{Q}\) :

-

Heat rate, kW

- s:

-

Specific entropy, kJ/kgK

- \(\dot{S}_{{gen}}\) :

-

Entropy generation rate, kW/K

- \(\dot{W}\) :

-

Work rate, kW

- X:

-

Salination, g/kg

- η :

-

Energy efficiency

- Ψ :

-

Exergy efficiency

- \(\rho\) :

-

Density, kg/m3

- \(\epsilon\) :

-

Effectiveness

- CAES:

-

Compressed air energy storage

- EES:

-

Engineering Equation Solver

- HFO:

-

Heavy fuel oil

- GHG:

-

Greenhouse gas

- TES:

-

Thermal energy storage

References

Antigua and Barbuda—Place Explorer—Data Commons (2021). [Online]. Available https://datacommons.org/place/country/ATG#Environment. Accessed 27 Sept 2021

Azhar MS, Rizvi G, Dincer I (2017) Integration of renewable energy based multigeneration system with desalination. Desalination 404:72–78

Causes and effects of climate change - Canada.ca. [Online]. Available: https://www.canada.ca/en/services/environment/weather/climatechange/causes-effects.html. Accessed 26 Sept 2021

Codrington, Antigua and Barbuda—Detailed climate information and monthly weather forecast | Weather Atlas. [Online]. Available: https://www.weather-atlas.com/en/antigua-and-barbuda/codrington-climate#wind. Accessed 25 Sept 2021

Demir ME, Dincer I (2017) Development of an integrated hybrid solar thermal power system with thermoelectric generator for desalination and power production. Desalination 404:59–71

Energy consumption in Antigua and Barbuda (2021). [Online]. Available https://www.worlddata.info/america/antigua-barbuda/energy-consumption.php. Accessed 27 Sept 2021

European Union (n.d.) Climate change consequences. European Union-Climate Action. Retrieved from https://ec.europa.eu/clima/change/consequences_en. Accessed 26 Sept 2021

“Global Greenhouse Gas Emissions Data | US EPA.” [Online]. Available: https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data. [Accessed: 26-Sep-2021].

How Do Wind Turbines Survive Severe Storms? | Department of Energy (2021). [Online]. Available: https://www.energy.gov/eere/articles/how-do-wind-turbines-survive-severe-storms. Accessed 26 Sept 2021

“IEAWind Energy Annual Report 2000"Available: https://www.nrel.gov/docs/fy01osti/29436.pdf. [Accessed: 27-Sep-2021].

“International Hydropower Association.” [Online]. Available: https://www.hydropower.org/factsheets/pumped-storage. [Accessed: 27-Sep-2021].

Karaca AE, Dincer I, Nitefor M (2021) An integrated renewable energy based plant with energy storage for a sustainable community. Sustain Energy Technol Assessments 45:101217

Kasotia P (n.d.) The health effects of global warming: developing countries are the most vulnerable. United Nations. Retrieved from https://www.un.org/en/chronicle/article/health-effects-global-warming-developing-countries-are-most-vulnerable

Land area—SaskWind (2021) [Online]. Available: https://www.saskwind.ca/land-area. Accessed 27 Sept 2021

Neill SP, Hashemi MR (2018) Offshore wind. In: Fundamentals of ocean renewable energy, pp 83–106

NRCAN. Stand-alone wind energy systems: a buyer’s guide. Retrieved from https://www.nrcan.gc.ca/sites/www.nrcan.gc.ca/files/canmetenergy/files/pubs/WindEnergy_buyersguide_ENG.pdf

Our Energy Needs: World Energy Consumption & Demand | CAPP. [Online]. Available: https://www.capp.ca/energy/world-energy-needs/. Accessed 26 Sept 2021

Ragheb M, Ragheb AM (2011) Wind turbines theory-the betz equation and optimal rotor tip speed ratio. Fundam Adv Top Wind Power 1(1):19–38

Rates—Antigua Public Utilities Authority (APUA) (2021). [Online]. Available: http://www.apua.ag/customer-service/rates/. Accessed 27 Sept 2021

Renewable Energy—Our World in Data (2021). [Online]. Available: https://ourworldindata.org/renewable-energy. Accessed 26Sept 2021

Samuel HA (2021) A review of the status of the interconnection of distributed renewables to the grid in CARICOM Countries | Climate Technology Centre & Network. [Online]. Available: https://www.ctc-n.org/resources/review-status-interconnection-distributed-renewables-grid-caricom-countries. Accessed 27 Sept 2021

Vinet L, Zhedanov A (2011) A “missing” family of classical orthogonal polynomials. J Phys A Math Theoret 44(8). Available at https://doi.org/10.1088/1751-8113/44/8/085201/meta

Wind Energy Factsheet | Center for Sustainable Systems (2021). [Online]. Available https://css.umich.edu/factsheets/wind-energy-factsheet. Accessed 26 Sept 2021

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Karaca, A.E., Dincer, I. (2022). A Wind Energy-Based Cogeneration System for Energy and Fresh Water Production. In: Uyar, T.S., Javani, N. (eds) Renewable Energy Based Solutions. Lecture Notes in Energy, vol 87. Springer, Cham. https://doi.org/10.1007/978-3-031-05125-8_22

Download citation

DOI: https://doi.org/10.1007/978-3-031-05125-8_22

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-05124-1

Online ISBN: 978-3-031-05125-8

eBook Packages: EnergyEnergy (R0)