Abstract

This paper considers the problem of the control system transient process quality improvement, which is very important in thermal engineering even now. The way of improvement under consideration is the use of a predictive control algorithm. The control algorithm described is a PID control law with a first order filter and a linear prediction module; the control system is also equipped with an auto-tuning module, that allows to retune the system if necessary. The auto-tuning module uses a fast auto-tuning algorithm calculating the process model parameters using the process reaction of a rectangular impulse. The PID algorithm coefficients are calculated using indirect optimality indexes. The system works with a typical thermal process with a second order transfer function with a time delay. Calculations and simulation of the system are carried out in Mathcad and Matlab/Simulink. Some examples are considered, the predictive control system performance is estimated and recommendations on the prediction time interval determination are given. These recommendations may be further used while developing this system using modern controllers and controller programming software.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Nowadays in many industries the demands to the control system performance are rather strict. For example, the temperature of the superheated steam at thermal power units can change in a very narrow interval. The things mentioned mean that the performance of the control system should be high and it is still important to improve the performance. There are some features of control plants and processes that can influence the control system performance badly, and one of them is the time delay. It is typical for some processes, for example, for thermal processes at thermal power plants, heating systems, industrial thermal technologies, etc.

Generally, two ways can be used to improve the control system performance. First, one can use a more advanced control algorithm (for example, one can use PID instead of PI and so on), second, one can use a more complex control system structure, for example, a cascade system [1, 2]. The cascade systems are standard engineering solution in many cases nowadays, for example, at thermal power plants [3], but they have certain drawbacks in comparison with single-loop systems. Single-loop systems are easy to use and tune, there are a lot of tuning methods and auto-tuning algorithms [2, 4] that may be easily implemented by means of modern programmable controllers. That is why, from the one side, the abilities of the standard linear control algorithms are under-used, and from the other side, it is possible to improve the performance of the single-loop systems using auto-tuning algorithms [4] and predictive algorithms [1, 5]. This paper is going to consider a single-loop control system with a predictive PID-controller, auto-tuning module and a thermal process.

There are a lot of adaptation and auto-tuning methods [2, 4, 6, 7], all of them have their advantages and disadvantages. In order to get the process model and tune the control system the method may use the process transient response [2] or frequency response [2, 4] or more complicated things such as artificial neural networks [8]. In this paper a method described in [4] will be used, this method is called AT-1 and it has two important advantages, it allows to get coefficients of the considerably complex model (the second order with the time delay and the four coefficients may be determined independently) and it works faster than other methods because it performs only one iteration. This method was used earlier in some systems where the process model was used, for example, in a single-loop control system with a PID-algorithm, a thermal process and a Smith predictor [9].

Predictive control systems are widely described in the technical literature, for example, in [1, 5, 6]. There are a lot of articles considering using the predictive systems with the thermal processes [5, 7, 8, 10, 11], and all of them show that the predictive systems of various kinds are effective for thermal processes. But generally they use either rather complex algorithms, such as MPC [11] or neural networks [8]. Some articles consider standard linear control algorithms, such as [10, 12, 13], but they do not consider the systems with the PID control law with filters, although these systems are typical for industry [2, 4]. In this situation it seems logical to consider a control system with the predictive PID control law with a filter. Such systems with the second order filters were briefly considered in [14], but the PID law with the first order filter is even more widely used.

This article considers a single-loop control system with a PID control law with the first order filter. The system is equipped with an auto-tuning module using the fast auto-tuning algorithm AT-1 and works with a typical thermal process.

2 System Description and Problem Statement

As has already been mentioned, the paper considers a single-loop control system with a PID control law and an auto-tuning module. The PID is equipped with a first order filter. The prediction module is in the feedback. The structure of the system is given in Fig. 1.

The PID control law with the first order filter has the following transfer function:

where: \(K_{p}\) – the gain of the PID control law, \(T_{i}\) – the integrating time constant, \(T_{d}\) – the derivative time constant, \(T_{f}\) – the filter time constant. Tuning methods for this control law are described in many books and papers, for example, in [2, 4, 15]. In this paper we will use the method based on the ideas shown in [4, 16], the method will be described below.

The process model has the second order transfer function with the time delay:

where: \(K_{mod}\) – the gain of the process model; \(T_{1mod}\), \(T_{2mod}\) – the time constants of the process model; \(\tau_{mod}\) – the delay time of the process model.

The system shown in Fig. 1 operates as a common single-loop system with a PID control algorithm in the normal working mode. If it is necessary to retune the system one switches the switch shown in Fig. 1 from position 1 to position 2 and the auto-tuning module began to work. The general structure of the auto-tuning module is shown in Fig. 2.

The general working algorithm of the autotuning module is simple. The relay forms the rectangular impulse on the input of the process. The impulse response goes to the Calc1 module and the module calculates the coefficients of the process model with the transfer function (2). Then the coefficients are sent to the Calc2 module that calculates the PID-law parameters, the transfer function of the PID-law is (1). The PID parameters are calculated using indirect frequency optimality indicators. The calculation methods mentioned are described in detail in [4, 16].

The prediction module operates according to the linear prediction algorithm, described by the following formula [10, 12, 13, 16]:

where: \(y\left( t \right)\) – the process output signal (see Fig. 1), \(y^{\prime}\left( t \right)\) – the derivative of the process output signal, \(y_{pred} \left( t \right)\) – the output of the prediction module, \(\tau_{pred}\) – the prediction time. The linear prediction algorithm was chosen because it is simple, easy to implement by means of modern controller programming systems and generally provides good results.

There is an undetermined parameter \(\tau_{pred}\) in the linear prediction algorithm. In the papers, for example, [10, 12, 13] there are recommendations on how to choose this parameter. Although these recommendations are given for the P, PI and the so-called ideal PID-algorithm (or the PID-algorithm with the derivative term without the filter at all). This kind of PID-algorithm is not typical for the modern controllers, where the PID-algorithms with the first order filter or the second order filter are normally used. The PID-law with the prediction module and the second order filter is considered in [14], but it is impossible to say that the recommendations for this case will work properly for the PID-algorithm with the second order filter.

So, the problem statement can be represented as follows. One should consider the control system shown in Fig. 1 and described above and study how the prediction module influences the system transient process quality. If the influence is positive it is necessary to give recommendations (at least approximate) on how to choose the prediction time interval \(\tau_{pred}\). The process under consideration is a typical thermal process with the transfer function (2).

3 The Process Characteristics

The process under consideration has transfer function (2), this kind of transfer function is typical for non-integration thermal processes, for example, in the temperature control sections. Several processes with different time constants and delay times were considered during the preliminary calculations, Table 1 shows the parameters of some of them. The table shows the parameters of the process (line “Process”) and parameters of the model (line “Model”) obtained by the auto-tuning module using the method described in [2, 4].

An example of the step response of process 1 and the model of the process are given in Fig. 3. As one can see from the figure the curves almost coincide with each other so the auto-tuning system works efficiently. The step responses of this type are rather wide-spread in thermal power engineering [3, 17].

4 PID Algorithm Tuning and Transient Processes

First let us consider an ordinary single-loop system with a PID control law with a first order filter, the transfer function (1) is given above. The calculation of the control law parameters are carried out by the auto-tuning module on the basis of the method based on [2] and described in [4, 18]. The method is based on the fact that the vector of the frequency response of the closed optimally tuned system is always in the more or less same position if the frequency is the resonance one (or close to it). So, one can give the magnitude and the phase of the vector and consider them as the indirect frequency optimality criteria, and the auto-tuning module calculates the PID-law coefficients that can provide the stated frequency response vector position on the resonance frequency. The parameters calculated are given in Table 2. The parameters provide a damping ratio value of 0.9.

The transient processes in the closed loop system with the PID control law are given in Fig. 4 and 5. Figure 4 shows the system response when the set point changes.

Figure 5 shows the system response to the step signal on the input of the control process.

From the given processes we can see that the system provides the above mentioned damping ratio.

5 Control System with the Predicitive PID Algorithm

When one considers the control system with the PID control law with a prediction module one faces a very important question of how to choose the prediction time interval. The use of the prediction module helps to provide higher transient process quality but the improvement of the quality depends on the value of the time interval. It is logical to assume that the value of the time interval may depend on the process model. There are some recommendations in the literature, for example, [10, 12, 13, 19] that generally state that the prediction time interval \(\tau_{pred}\) should be where \(\tau_{pred} = 0.2\left( {T_{1mod} + T_{2mod} } \right)\). The problem is that this recommendation is for the systems with the predictive PID-law without the filter. As it has already been checked, the formula does not work for the PID control algorithm with the second order filter, the time interval obtained by means of this formula is too high and the control system becomes unstable [14]. That is why it is necessary to check the recommendations for the control system under consideration.

In order to estimate the transient process quality in the predictive system let us obtain the transient processes for various values of the prediction time interval. The transient processes are obtained for the case when the single step is on the input of the control process. The transient processes for the system with process 1 (see Table 1) are given in Fig. 6.

As one can see from the processes given in Fig. 6 even a considerably small prediction time (such as 2 s) may provide quality improvement and the longer the prediction interval the better the transient process quality is. The problem observed is the same as the problem with the system with the PID with the second order filter: when the prediction time interval is too high, one can see high frequency oscillations in the transient process and with a higher prediction time interval the process may become unstable. Even if the process is stable high frequency oscillations are highly undesirable, because they influence the reliability of the equipment badly.

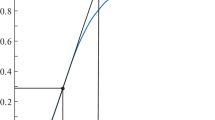

In order to explain the high frequency oscillations let us obtain the Nyquist curves for the open systems with and without the prediction. The curves are obtained for the system with process 1 and given in Fig. 7.

From Fig. 7 one can see that because of the introduction of the prediction module the Nyquist curve on low frequencies becomes farther from the point with coordinates \(\left( { - 1,j0} \right)\) and it becomes closer to the point on high frequencies.

If one calculates the prediction time interval according to the recommendations given in [10, 12, 13, 19], for example, for the system with process 1, one obtains the following:

It is possible to see from Fig. 6 that the high frequency oscillations start to appear when \(\tau_{pred} = 8\;{\text{s}}\) and it means that the prediction time interval obtained (\(19.06 \;{\text{s}})\) is too high and the system is unstable if this value is used. For the system with process 1 \(\tau_{pred} = 6\;{\text{s}}\) is optimal. Let us compare the transient processes in the systems with and without the prediction. The processes are shown in Fig. 8. The quality indexes are shown in Table 3.

In Table 3 \(y_{din}\) is the dynamic deviation (the maximal deviation from the set point), \(t_{tran}\) is the duration of the transient process (in seconds) and \({\Psi }\) is the damping ratio. One can see that the use of the prediction module improves the quality considerably. Calculations for other processes gives the same results. Now it is necessary to formulate at least approximate recommendations on the calculation of the prediction time interval so that the auto-tuning module could calculate the prediction time as well.

Using the calculations obtained one can conclude that the optimal prediction time interval for the case under consideration is equal to the time delay (or a little bit lower to be on the safe side, but not higher). The preliminary formula may be as follows:

This formula may be easily used in programming controllers using modern software, for example, CODESYS [20]. The authors plan to test the system described using real hardware and software in the future.

6 Conclusion

In this paper the authors considered the control system with the predictive PID control law with the first order filter and estimated its efficiency for the system for the thermal processes with time delay. The system described is effective and provides the considerable transient process quality improvement. The authors also formulated the recommendation on the calculation of the prediction time interval \(\tau_{pred}\) for this system, the formula obtained may be easily implemented using modern controller programming software. The advantage of the developed system is that it does not require to install any additional equipment, so the only work that has to be carried out is improving the controller program.

References

Hu, Y., Jia, X., Lei, X., Hou, P., Bai, J.: Multiple model switching DMC-PID cascade predictive control for SCR denitration systems. In: 2018 Chinese Automation Congress, pp. 2573–2577 (2018). https://doi.org/10.1109/CAC.2018.8623613

Rotach, V.: Automatic Control Theory. MPEI Publishing House, Moscow (2004)

Bilenko, V.A.: Multi-loop automatic control systems with several control inputs and their application for maintaining steam temperature in once-through boilers. Therm. Eng. 58(10), 850–858 (2011). https://doi.org/10.1134/S004060151110003X

Kuzishchin, V.F., Tsarev, V.S.: Algorithms for accelerated automatic tuning of controllers with estimating the plant model from the plant response to an impulse disturbance and under self-oscillation conditions. Therm. Eng. 61(4), 281–290 (2014). https://doi.org/10.1134/S0040601514040041

Ping, M., Qian, Z., Nannan, L.: Study of a dynamic predictive PID control algorithm. In: 2015 Fifth International Conference on Instrumentation and Measurement, Computer, Communication and Control, pp. 1418–1423 (2015). https://doi.org/10.1109/IMCCC.2015.302

Zhou, K., Yu, H.: Application of fuzzy predictive-PID control in temperature control system of Freeze-dryer for medicine material. In: 2011 Second International Conference on Mechanic Automation and Control Engineering, pp. 7200–7203 (2011). https://doi.org/10.1109/MACE.2011.5988712

Wang, Y., Zou, H., Tao, J., Zhang, R.: Predictive fuzzy PID control for temperature model of a heating furnace. In: 2017 36th Chinese Control Conference, pp. 4523–4527 (2017). https://doi.org/10.23919/ChiCC.2017.8028070

Du, C., Ling, H.: Generalized predictive control algorithm applied to thermal power units based on PID neural network. In: 2010 2nd International Conference on Advanced Computer Control, pp. 38–42 (2010). https://doi.org/10.1109/ICACC.2010.5486737

Kuzishchin, V.F., Merzlikina, E.I., Van Va, H.: Study of the efficiency of the control system with smith predictor using a simulator based on controller owen PLC. In: 2nd International Conference on Industrial Engineering, Applications and Manufacturing, pp. 1–4 (2016). https://doi.org/10.1109/ICIEAM.2016.7910912

Pikina, G.A., Kuznetsov, M.S.: Tuning methods for typical predictive control algorithms. Therm. Eng. 59(2), 154–158 (2012). https://doi.org/10.1134/S0040601512020139

Marzaki, M.H., Jalil, M.H.A., Shariff, H.M., Adnan, R., Rahiman, M.H.F.: Comparative study of Model Predictive Controller (MPC) and PID Controller on regulation temperature for SSISD plant. In: 2014 IEEE 5th Control and System Graduate Research Colloquium, pp. 136–140 (2014). https://doi.org/10.1109/ICSGRC.2014.6908710

Pikina, G.A.: Implementation of the predictive control principle in automatic control systems. In: XII Russian Conference on Control Problems, pp. 200–211 (2014)

Pikina, G.A., Pashchenko, F.F.: The predictive principle in control systems with standard lows. Procedia Comput. Sci. 150, 403–409 (2014)

Merzlikina, E., Van Va, H., Farafonov, G.: Automatic control system with an autotuning module and a predictive PID-algorithm for thermal processes. In: 2021 International Conference on Industrial Engineering, Applications and Manufacturing, pp. 525–529 (2021). https://doi.org/10.1109/ICIEAM51226.2021.9446467

Zhang, W., Yang, M.: Comparison of auto-tuning methods of PID controllers based on models and closed-loop data. In: Proceedings of the 33rd Chinese Control Conference, pp. 3661–3667 (2014). https://doi.org/10.1109/ChiCC.2014.6895548

Kuzishchin, V.F., Merzlikina, E.I., Van Va, H.: Indirect frequency optimality indicators for automatic tuning of controllers: consideration of the dependence on the process model parameters. Bull. MPEI 6, 106–114 (2019)

Ismatkhodzhaev, S.K., Kuzishchin, V.F.: Enhancement of the efficiency of the automatic control system to control the thermal load of steam boilers fired with fuels of several types. Therm. Eng. 64(5), 387–398 (2017). https://doi.org/10.1134/S0040601517050032

Kuzishchin, V.F., Petrov, S.V.: A procedure for tuning automatic controllers with determining a second-order plant model with time delay from two points of a complex frequency response. Therm. Eng. 59(10), 779–786 (2012). https://doi.org/10.1134/S0040601512100084

Pikina, G.A., Kuznetsov, M.S.: Typical predictive control algorithms. Therm. Eng. 58(4), 336–341 (2011). https://doi.org/10.1134/S0040601511040100

Programming software CODESYS. https://www.codesys.com/

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Merzlikina, E., Sviridov, G., Van Va, H. (2022). Control System with a Predictive PID-Controller with a First-Order Filter: Estimation of the Efficiency for Thermal Proceses. In: Radionov, A.A., Gasiyarov, V.R. (eds) Advances in Automation III. RusAutoCon 2021. Lecture Notes in Electrical Engineering, vol 857. Springer, Cham. https://doi.org/10.1007/978-3-030-94202-1_10

Download citation

DOI: https://doi.org/10.1007/978-3-030-94202-1_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-94201-4

Online ISBN: 978-3-030-94202-1

eBook Packages: EngineeringEngineering (R0)