Abstract

Currently, worldwide, research on the production of cementitious composites with self-cleaning properties (using the photocatalytic character of TiO2) is an area of real interest. The aim of this paper was to present a synthesis of the results of experimental research on the influence of the addition of TiO2 nanoparticles on the physical-mechanical properties of cement composites based on white cement micro-concrete. Both the results of research reported to date and experimental ones have shown that the properties of concrete are positively influenced, as long as the amount of nanoparticles is not in excess. Research has indicated an increase in mechanical resistances, more pronounced in the first 7 days. The increase in tensile bending strength as a result of the addition of TiO2 nanoparticles, experimentally recorded, is a maximum of 7% for testing at 7 days of age and a maximum of 4.5% for testing at 28 days of age, respectively. The increase in compressive strength due to the addition of TiO2 nanoparticles, experimentally recorded, is a maximum of 3.6% for the 7-days tests and a maximum of 2% for the 28-days tests, respectively. In the case of an excess of TiO2 nanoparticles, or their insufficiency, the effect on the properties of the micro-concrete is the opposite.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

At present, worldwide, the general research directions are aiming to identify the possibilities for the most sustainable use of building materials and to identify new opportunities for improving performance and durability, simultaneously with as little impact as possible on the environment. Cementitious composites produced with the addition of TiO2 nanoparticles come to meet these directions by their specificity in exploiting the photocatalytic property of TiO2 nanoparticles, thus obtaining a high-performance, durable material with self-cleaning capacity and increased resistance to the development of microorganisms on its surface, for use in the construction field.

With regard to the influence of TiO2 nanoparticles on the hardened-state micro-concrete, by adding or replacing a part of cement with different amounts of TiO2 nanoparticles, the mechanical properties of concrete are improved both due to the smaller CH crystal sizes and the formation of a larger and better organized amount of C-H-S gel [1]. It also increases freeze-thaw resistance, abrasion resistance and resistance to the action of chemical agents. The excess addition of TiO2 nanoparticles decreases the performance of the compound relative to the control sample. This phenomenon is strictly conditioned by the ratios in which the raw materials are used, because if the amount of TiO2 nanoparticles is added in excess, the performance of the composite is influenced in a decreasing way [1].

There are some controversies regarding the mechanical strength of this type of cementitious composite. Some research shows that they are not negatively influenced up to a maximum of 6% addition of TiO2 nanoparticles [2], while others reduce this threshold to 5%, 3% [3] or even 1% [4].

A large number of experimental research has indicated that compressive strength increases with the increase of nanoparticles regardless of age of maturation, with 1% being optimal, but there are also reports which show that compressive strength decreases with the increasing percentage of TiO2 [5].

On the other hand, haste in the maturation process of the micro-concrete was constantly noted. Compared to the control sample (without nano-TiO2 content), the composite material with TiO2 nanoparticles addition showed an increase in compressive strength recorded at 7 days of age and a smaller increase in compressive strength between 7 and 28 days [5].

According to the literature, the compressive strength is directly influenced by the content of TiO2 nanoparticles and increases, up to a certain concentration threshold, with the increase in the content of TiO2 nanoparticles. Thus, research has shown increases in compressive strength for: 2% nano-TiO2, at the age of 28 days [6]; 0.5%, 1%, 1.5%, and 2% TiO2, (water/cement ratio, w/b = 0.4), 1% being the optimal percentage [7]; 1%, 3%, and 5% TiO2 (w/b = 0.42) at 28 days of age [8]; 1% TiO2 [9]; 0.5%, 1%, 1.5% and 2% TiO2, at the age of 7, 28 and 90 days, 1% optimal (when hardening in water), 2% optimal (when hardening in lime water) [10]; 1%, 2%, 3%, 4% and 5% TiO2, (w/b = 0.4), at 28 days of age, 4% being the optimal percentage [11, 12]. According to other researchers, the compressive strength decreases with the increase in the amount of nanoparticles, respectively, with the introduction of 1%, 2%, 3%, 4% and 5% TiO2 nanoparticles [13].

In terms of bending tensile strength, the use of TiO2 nanoparticles of 1% and 3% relative to the amount of cement increased bending tensile strength, while 5% decreased it, with 1% being optimal [8]. Other research has shown that the bending resistance increases with the increase in the amount of nanoparticles upon the introduction of 1%, 2%, 3%, 4%, and 5% TiO2 (w/b = 0.38) at 7, 14, 28 and 90 days of age, with 4% being the optimal percentage [14, 15]. Increased bending resistances are also reported by other authors, at the introduction of 0.5%, 1%, 1.5% and 2% TiO2 (w/b = 0.4) at water hardening 1% being the optimal percentage of TiO2 nanoparticles addition, and at lime water hardening, 2% being the optimal percentage [16, 17]. Li et al. and Nazari and Riahi also confirm the increase in bending resistance, at the introduction of 1% and 3% TiO2 (w/b = 0.42), at the age of 28 days, 1% being the optimal percentage [18], respectively 1%, 2%, 3%, 4% and 5% TiO2 (w/b = 0.4) at the age of 2, 7 and 28 days [11, 12].

In terms of water absorption, this parameter decreases with increasing the content of TiO2 nanoparticles addition for: 2% nano-TiO2, at the age of 28 days [6]; 1%, 2%, 3%, 4% 5% TiO2 (w/b = 0,38), at the age of 7, 14, 28, and 90 days (4% optimal) [14, 15]; 0.5%, 1%, 1.5%, 2% TiO2, (w/b = 0,4), and at the age of 7, 28 and 90 days, about 0.5% considered optimal [16]; 0.5%, 1%, 1.5%, 2% TiO2 (w/b = 0,4), and at the age of 28 and 90 days, [19, 20]; 1%, 2%, 3%, 4% 5% TiO2 (w/b = 0,4), and at the age of 7 and 28 days 4% is the percentage of the optimal [11, 12]. There are also authors whose studies show increased water absorption with increased content of TiO2 nanoparticles, as follows: 1%, 2%, 3%, 4% and 5% TiO2, (w/b = 0.4), at the age of 2 days [19, 20] or at the introduction of 0.5%, 1%, 1.5%, and 2% TiO2, (w/b = 0.4), at the age of 7 days [19, 20] (Table 1).

In all cases, regardless of conditioning temperature and age, mechanical strength of the cementitious composites increased to a content of 2% TiO2, after which they decrease [21]. Also, the decrease in conditioning temperature negatively influences mechanical resistances for all cases 0–5% TiO2 [21].

In terms of porosity, some studies show that it decreases with increasing content of TiO2 nanoparticles, at the introduction of TiO2 nanoparticles by up to 10% [21], others show its increase at the introduction of more than 5% TiO2 [22].

Reduced density and porosity, increased mechanical variation due to the rapid formation of hydration products, implicitly influences durability [21, 23,24,25,26,27].

In conclusion, based on the results of the researches presented in the literature, the influence of the introduction of nano-TiO2 in cementitious binders causes changes in the physical-mechanical performance, but an optimal content of TiO2 nanoparticles cannot be accurately assessed to ensure a general improvement in composite performance.

The aim of this paper is to present research carried out for the analysis of the influence of nano-TiO2 addition into the mass of cementitious composites of micro-concrete has on their physical and mechanical performances.

2 Materials and Methods

2.1 Raw Materials

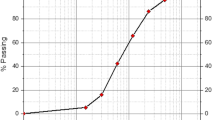

The materials used in the preparation of the nano-TiO2 addition micro-concrete were: white Portland cement CEM I 52.5 R, Degussa P25 TiO2-nanoparticles, aggregates granular class 0–4 mm and 4–8 mm, 6 mm and 19 mm PVA fibres and water.

2.2 Preparation and Conditioning

Five micro-concrete with nano-TiO2 addition mixtures have been prepared with a percentage content of TiO2 nanoparticles of 0% (control sample), 2%, 3%, 4% and 5%, with the following ratios (Table 2).

After all the constituent materials have been pre-conditioned, water and sand were mixed together for 30 s at the speed of 140 ± 5 rpm. A dry pre-mixing of cement with TiO2 nanoparticles followed, after which a mechanical mixing with the water and sand was started. In the composition thus obtained, the two types of fibers were added during mixing. After the addition of the fibers, mixing followed for 30 s at a speed of 285 ± 10 rpm. A break of 60 s was initiated, followed by a mechanical mixing for 60 s at a speed of 285 ± 10 rpm.

On the newly obtained mixture, the fresh-state density has been measured, after which the mixture was poured into prismatic, 40 × 40 × 160 mm, metallic molds in order to assess the following parameters: apparent density in hardened state, mechanical strength (flexural and compressive strength) and water absorption (Fig. 1a). 24 × 85 × 130 mm samples were also prepared in order to assess the density of the material and water absorption at different time intervals, porosity, mechanical properties (flexural strength after freeze–thaw cycles and flexural strength after thermal shock), mortar adhesion and white degree (Fig. 1b).

The samples thus obtained were conditioned for 24 h in molds, at 90% humidity and 20 °C temperature, in the dark. After the 24 h the samples were demolded and immersed completely in water for 27 days, at the temperature of 20 °C, also in a dark environment.

Until testing, the samples were stored in laboratory conditions, in the absence of light. Laboratory equipment was used to test the samples: press for resistance determination, Pull-off apparatus for adhesion determination, portable leukometer type WSB-1 for white degree determination, as well as heat-regulating oven.

2.3 Testing Methods

The measurements of physical and mechanical properties carried out, followed the tests in order to assess the following parameters: bulk density in the fresh state (EN 12,350-6) [28], the apparent density in hardened state (EN 12,350-7) [29], water absorption (EN 14,617-1) [30], porosity (EN 1936) [31], flexural strength (EN 12,390-5) [32], compressive strength (EN 12,390-3) [33], bending strength (EN 14,617-2) [34], freeze-thaw (EN 14,617-5) [35], thermal shock resistance (EN 14,617-6) [36] adhesion of mortar paste (EN 1015-12) [37] and the degree of white (parameter measured using a portable leukometer type WSB-1).

3 Results and Discussions

3.1 Apparent Density in Fresh and Hardened State

The results regarding both the apparent density in fresh state (measured after mixing stopped) and the apparent density in hardened state (measured at 28 days) are shown in Fig. 1. It is observed that an increasing or decreasing trend in the values recorded in the case of the introduction into the cementitious mixture of TiO2 nanoparticles cannot be identified. This behavior cannot be motivated otherwise than by the heterogeneity of the degree of dispersion of TiO2 nanoparticles in the cement mass. The experimental results however eloquently indicate an increase in the fresh apparent density of the composites into which the photosensitive nanoparticles were introduced, an increase due to their distribution in the pores of the cementitious matrix, thus resulting in a more dense material (Fig. 2a). In the case of the hardened state density assessment for matured samples 28 days after casting, a slight decrease in the density of composites with 2% and 4% TiO2 content, and an increase in composites with 3% and 5% TiO2 content is observed compared to the control sample, which could indicate, in correlation with the specifications in the literature [22], the difficulty of achieving a homogeneous distribution of nanoparticles the existence of agglomeration areas of nanoparticles, simultaneously with areas characterized by increased porosity (Fig. 2b).

3.2 Water absorption

The results of water absorption for saturated samples are shown in Fig. 3. The results on the amount of water absorbed according to the duration of immersion (1 h, 8 h, 24 h, 48 h and 72 h respectively) are shown in Fig. 4.

In terms of the water absorption of the samples with nano-TiO2 addition, there may be a tendency for the development of the values shown depending on the amount of TiO2 nanoparticles that are introduced into the mass of the cementitious binder, whichever is the lower, resulting in a matrix with a content of 2% TiO2 nanoparticles, and the maximum value in the matrix with a content of 5% TiO2 nanoparticles (Fig. 2). This behavior cannot be motivated otherwise than by the heterogeneity of the degree of homogeneity of the composites, respectively, by the distribution of TiO2 nanoparticles in the cement mass and by the degree of pore filling with these nanoparticles.

Regarding the amount of water absorbed according to the duration of immersion (1 h, 8 h, 24 h, 48 h and 72 h respectively) of the cementitious samples containing TiO2 nanoparticles, this has an increasing trend. Thus, it increases, with increasing immersion time, for all mixtures, regardless of the percentage of TiO2 nanoparticles introduced into the binder (Fig. 3).

3.3 Porosity

The porosity results are shown in Fig. 5. The sample containing 2% TiO2 nanoparticles was found to have a lower open porosity compared to the control sample.

For samples with a percentage content of 3% TiO2, 4% TiO2 and 5% TiO2, they have a higher open porosity relative to the control sample, value increasing with the increase in the content of TiO2 nanoparticles.

3.4 Bending strength

The results regarding the bending tensile strength at 7 and 28 days are shown in Fig. 6. It was observed that both at 7 days and 28 days of age, the recorded bending tensile strength increases, compared to the control sample, for the mixture with 2% TiO2 nanoparticles. For composites containing higher amounts of TiO2, this parameter decreased as the amount of TiO2 nanoparticles increased, which is consistent with existing specifications in the literature [21].

3.5 Compressive Strength

The compressive strength results at 7 and 28 days are shown in Fig. 6. With regard to the compressive strength of mixtures with TiO2 nanoparticles addition, the 7-day test shows an increasing trend in the parameter followed by the increase in the amount of nanoparticles to the percentage of 3% TiO2, after which the value of compressive strength decreases with the increase in the percentage of nanoparticles (Fig. 7a). This increase in compressive strength can be considered a sign of the acceleration of the hardening process, a conclusion that is in correlation with some specifications in the literature [5]. The 28-day test also shows an increase in the value of compressive strength with the increase in the percentage of nanoparticles, but this time up to the percentage of 4% TiO2, after which the compressive strength decreases (Fig. 7b).

3.6 Flexural Strength and Influence of the Environment Conditions

The flexural strength results are shown in Fig. 8. Although a trend in the evolution of the values recorded in the introduction of different percentages of TiO2 nanoparticles cannot be identified, the highest value was obtained in the sample with a content of 2% TiO2 nanoparticles and the lowest value in the sample with 3% TiO2 nanoparticles.

On the other hand, it was found that the exposure of cementitious composites, matured, to 25 freeze-thaw cycles induces a decrease in their performance by 2.5–11% compared to samples not exposed to these environmental conditions (Fig. 9a and Fig. 10).

The action of external stress in the form of thermal shock resulted in a reduction in flexural strength by 1.2–2.8% compared to samples not exposed to these environmental conditions (Fig. 9b and Fig. 10). In the case of a sample containing 4% nanoparticles, the percentage loss is likely to be high due to the inhomogeneity of the sample (Fig. 10).

3.7 Adhesion of the Mortar to the Cementitious Composite Support

As for the adhesion of the mortar to the cementitious composite support with TiO2 nanoparticles addition, it increases as the amount of nano-TiO2 in the samples increases, up to the percentage of 3% of nanoparticles introduced, after which it decreases (Fig. 11). However, it can be pointed out that, regardless of the amount of nanoparticles introduced into the binder, the adhesion to the concrete support has values above the limit of 0.5 N/mm2, a limit generally imposed as a minimum condition for plastering/finishing materials.

However, the fact that the adhesion to the substrate of composites with 4% and 5% nano-TiO2, respectively, is lower than the control composition (0% nano-TiO2), may be an indicator of the maximum amount of nanoparticles that can be introduced into the cement mass, so that this performance is not negatively influenced.

3.8 White Degree

The results regarding the evaluation of the degree of whiteness are shown in Fig. 12. As expected, the degree of white increases continuously as the amount of nano-TiO2 in the cementitious binder increases, this is a very well-known effect and reported in the literature [38], being called “chalk-effect”. A more obvious white degree increase is observed for the 2% nano-TiO2 samples, followed by a slower increase for the 3% and 4% nano-TiO2 samples, as evidenced by the graphic representation (Fig. 11).

4 Conclusions

The aim of this work was to analyze the influence that the introduction of TiO2 nanoparticles in a cementitious composite matrix based on white Portland cement has on its physical and mechanical performances.

Experimental results show that:

-

There was no general increase or decrease in the density in the hardened state (28 days after casting), but neither in the saturation water absorption of the samples, probably due to the inhomogeneous degree of dispersion of TiO2 nanoparticles in the cementitious mass. However, an increase in fresh-state apparent density was observed, an increase due to their distribution in the pores of the samples, resulting in a densification of the material;

-

The amount of water absorbed according to the immersion duration (1 h, 8 h, 24 h, 48 h and 72 h respectively) of the samples containing TiO2 nanoparticles has an increasing trend. Thus, it increases with increasing immersion time, in the case of all compositions, regardless of the percentage of TiO2 nanoparticles introduced into the mixtures;

-

Mechanical properties increase at the introduction of 2% TiO2 nanoparticles (for bending tensile strength at 7 and 28 days) and at the introduction of up to 3% and 4% in the cement matrix (for compressive strength at 7 and 28 days respectively), after which they decrease. Thus the induction of more than 4% nanoparticles of TiO2 is not motivated;

-

The flexural strength under the conditions of exposure of the samples to certain environmental factors is reduced by 2.5–11% in the case of samples exposed to freeze–thaw cycles and by 1.2–2.8% compared to samples not exposed to these conditions;

-

The adhesion of the mortar to the support samples with TiO2 increases as the amount of nano-TiO2 in the samples increased, up to the percentage of 3% of nanoparticles introduced, after which it decreases.

References

Ma, B., Li, H., Mei, J., Li, X., Chen, F.: Effects of nano-TiO2 on the toughness and durability of cement-based material. Adv. Mater. Sci. Eng. 2015, 583106 (2015)

Zhang, S.M.-H., Tanadi, D., Li, W.: Effect of photocatalyst TiO2 on workability, strength, and self-cleaning efficiency of mortars for applications in tropical environment. In: 35th Conference on Our World in Concrete & Structures, Singapore (2010)

Janus, M., Zając, K.: Concretes with photocatalytic activity, high performance concrete technology and applications. INTECH (2016).

Sorathiya, J.V., Shah, S.G., Kacha, S.M.: Effect on Addition of nano “titanium dioxide” (TiO2) on compressive strength of cementitious concrete. In: International Conference on Research and Innovations in Science, Engineering & Technology, vol. 1. Birla Vishvakarma Mahavidyalaya, Gujarat (2017)

Rashad, A.M.: A synopsis about the effect of nano-titanium dioxide on some properties of cementitious materials - a short guide for civil engineer. Rev. Adv. Mater. Sci. 40, 72–88 (2015)

Salemi, N., Behfamia, K., Zaree, S.A.: Effect of nanoparticles on frost durability of concrete. Asian J. Civ. Eng. (BHRC) 15(3), 411–420 (2014)

Nazari, A., Riahi, S., Riahi, S., Shamekhi, S.F., Khademno, A.: Benefits of Fe2O3 nanoparticles in concrete mixing matrix. J. Am. Sci. 6(4), 102–106 (2016)

Zhang, M., Li, H.: Pore structure and chloride permeability of concrete containing nano-particles for pavement. Constr. Build. Mater. 25(2), 608–616 (2011)

Li, H., Xiao, H., Guan, X., Wang, Z., Yu, L.: Chloride diffusion in concrete containing nano-TiO2 under coupled effect of scouring. Compos.: Part B 56, 698–706 (2014)

Soleymani, F.: The filler effects TiO2 nanoparticles on increasing compressive strength of limestone aggregate-based concrete. J. Am. Sci. 8, 734–737 (2012)

Nazari, A., Riahi, S.: The effect of TiO2 nanoparticles on water permeability and thermal and mechanical properties of high strength self-compacting concrete. Mater. Sci. Eng. A 528(2), 756–763 (2010)

Nazari, A., Riahi, S.: RETRACTED: splitting tensile strength of concrete using ground granulated blast furnace slag and SiO2 nanoparticles as binder. Energy Build. 43(4), 864–872 (2011)

Keivan, A., Keivan, A., Behfarnia, K.: The effects of TiO2 and ZnO nanoparticles on physical and mechanical properties of normal concrete. Asian J. Civ. Eng. (BHRC) 14(4), 517–531 (2013)

Jalal, M., Fathi, M., Farzad, M.: Effects of fly ash and TiO2 nanoparticles on rheological, mechanical, microstructural and thermal properties of high strength self compacting concrete. Mech. Mater. 61, 11–27 (2013)

Jajal, M., Ramezaianpour, A.A., Pool, M.K.: Effects of titanium dioxide nanopowder on rheological properties of self compactingconcrete. J. Am. Sci. 8(4), 285–288 (2012)

Nazari, A.: The effects of curing medium on flexural strength and water permeability of concrete incorporating TiO2 nanoparticles. Mater. Struct. 44(4), 773–786 (2011)

Soleymani, F.: Assessments of the effects of limewater on water permeability of TiO2 nanoparticles binary blended limestone aggregate-based concrete. J. Am. Sci. 7(11), 7–12 (2011)

Jayapalan, A.R., Lee, B.Y., Kurtis, K.E.: Efect of nano-sized titanium dioxide on early age hydration of portland cement. Nanotechnol. Constr. 3, 267–273 (2009)

Kaykha, M.M., Soleymani, F.: The filler effects of TiO2 nanoparticles in concrete. J. Am. Sci. 7(12), 158–161 (2011)

Soleymani, F.: Assessments of the effects of limewater on water permeability of TiO2 nanoparticles binary blended palm oil clinker aggregate-based concrete. J. Am. Sci. 8(5), 698–702 (2012)

Chen, J., Kou, S., Poon, C.: Hydration and properties of nano-TiO2 blended cement composites. Cement Concr. Compos. 34(5), 642–649 (2012)

Essawy, A.A., El Aleem, A.A.: Physico-mechanical properties, potent adsorptive and photocatalytic efficacies of sulfate resisting cement blends containing micro silica and nano-TiO2. Constr. Build. Mater. 52, 1–8 (2014)

Ma, B., Li, H., Mei, J., Ouyang, P.: Effect of nano-TiO2 addition on the hydration and hardening process of sulphoaluminate cement. J. Wuhan Univ. Technol.-Mater. Sci. Edn. 30, 768–773 (2015)

de Mendiburu, F.: agricolae: Statistical Procedures for Agricultural Research. R package version 1.3-3 (2020). https://CRAN.R-project.org/package=agricolae

Firmino, H.C., et al.: Antifungal activity of TiO2-CeO2 nanofibers against Candida fungi. Mat. Lett. 283, 128709 (2021)

Šebesta, M., Nemček, L., Urík, M., Kolenčík, M., Bujdoš, M., Hagarová, I., Matúš, P.: Distribution of TiO2 nanoparticles in acidic and alkaline soil and their accumulation by Aspergillus niger. Agronomy 10(11), 1833 (2020)

Burduhos Nergis, D.D., Vizureanu, P., Corbu, O.: Synthesis and characteristics of local fly ash based geopolymers mixed with natural aggregates. Rev. Chim. 70(4), 1262–1267 (2019)

SR EN 12350-6: 2019 - Tests on fresh concrete. Part 6: Density

SR EN 12390-7: 2019 - Tests on reinforced concrete. Part 7: Density of reinforced concrete

SR EN 14617-1:2013 - Agglomerated stone. Test methods. Part 1: Determination of apparent density and ab-sorption of water

SR EN 1936:2007 - Methods of testing natural stone. Determination of actual and apparent density and total and open porosity

SR EN 12390-5: 2019 - Test on reinforced concrete. Part 5: bending strength of specimens

SR EN 12390-3:2019 - Încercare pe beton întărit. Partea 3: Rezistența la compresiune a epruvetelor

SR EN 14617-2:2016 - Agglomerated stone. Test methods. Part 2: Determination of bending strength (tensile strength)

SR EN 14617-5:2012 - Agglomerated stone. Test methods. Part 5: Determination of frost-thaw resistance

SR EN 14617-6:2012 - Agglomerated stone. Test methods. Part 6: Determination of thermal shock resistance

SR EN 1015-12:2016 - Methods of testing mortars for masonry. Part 12: determination of adhesion of reinforced plastering and gluing mortars on supports

Cassar, L.: Nanotechnology and photocatalysis in cementitous materials. In: NICOM’2, pp. 1–7 (2015)

Acknowledgements

This paper was financially supported by the Project “Entrepreneurial competences and excellence research in doctoral and postdoctoral programs - ANTREDOC”, project co-funded by the European Social Fund financing agreement no. 56437/24.07.2019

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Grebenișan, E., Hegyi, A., Lăzărescu, AV., Szilagyi, H., Florean, C. (2022). Influence TiO2 Nanoparticles Addition on the Physico-Mechanical Performances of Micro-concrete. In: Moldovan, L., Gligor, A. (eds) The 15th International Conference Interdisciplinarity in Engineering. Inter-Eng 2021. Lecture Notes in Networks and Systems, vol 386. Springer, Cham. https://doi.org/10.1007/978-3-030-93817-8_17

Download citation

DOI: https://doi.org/10.1007/978-3-030-93817-8_17

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-93816-1

Online ISBN: 978-3-030-93817-8

eBook Packages: EngineeringEngineering (R0)