Abstract

The utilization of nanoparticle-blended cement while producing concrete or mortar is gaining immense significance nowadays, mainly on account of the improvements in the long-term durability characteristics of the composites. The feasibility of using cement blended with nano-\(\hbox {TiO}_{2}\) particles to produce less permeable or impermeable mortar and concrete of sufficient strength and durability requirements was investigated in the present study. The composite cement includes Ordinary Portland Cement replaced with \(\hbox {TiO}_{2}\) nanoparticles at 0%, 2%, 4%, 6%, 8% and 10% quantities by weight. The properties studied include heat of hydration, compressive strength, bond strength, water absorption, permeability and sorptivity of mortar or concrete specimens. The roughness and surface defects of coarse aggregates greatly alleviated due to the incorporation of nano-\(\hbox {TiO}_{2}\) particles in concrete specimens. The rate of heat evolution increased during early stages of hydration owing to the high fineness and additional reactive surfaces induced from the nano-\(\hbox {TiO}_{2}\) particles blended in cementitious composite. Additionally, with reference to strength and durability characteristics, the nano-\(\hbox {TiO}_{2}\)-blended composites performed relatively better than the control samples. The role of blended nano-\(\hbox {TiO}_{2}\) cement composites in reducing the interconnected matrix porosity of concrete is discussed briefly, providing evidences from scanning electron microscope (SEM) observations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The idea of blending nanoparticles with cement is the most recent development in the field of concrete technology, which has prompted producing concrete or mortar of relatively higher strength and durability characteristics [1]. The revival of blended cements containing nanoparticles for making structural concrete is a welcome change and is a natural consequence of developments in global research. Researchers who were then accustomed to a natural sequel of testing only strength characteristics are now a part of major paradigm shift focusing on multi-criteria performance parameters with emphasis on durability characteristics of concrete. Apprehensions on use of nanoparticles in concrete are justified by conducting laboratory tests and practical case studies utilizing nanoparticles in concrete [2,3,4].

The goal of a concrete mix design is to have fine materials filling in the gaps between the coarse constituents. Thus, several researchers investigated on amending the pore structure offered by cementitious materials in concrete at micro- to nano-metre scale by incorporating nanoparticles at suitable proportions that take part in the hydration reactions to make substantial contribution to the mechanical strength and durability characteristics of concrete [5, 6]. Researchers proposed to improve the concrete micro-structure by utilizing pozzolanic nanoparticles such as nano-\(\hbox {SiO}_{2}\), nano-\(\hbox {CaCO}_{3}\) and nano-\(\hbox {Al}_{2}\hbox {O}_{3}\) that aid by hydrating continuous lamellae of C–S–H gel within the matrix [7,8,9]. Alternatively, nanoparticles such as nano-\(\hbox {TiO}_{2}\), nano-\(\hbox {Fe}_{2}\hbox {O}_{3}\) and nano-clays (bentonite/kaolinite) served as nano-scale functional filler materials to provide nucleation sites for cement hydration resulting in improved composite micro-structure [10,11,12].

Nano-\(\hbox {TiO}_{2}\)-blended cement composites have many advantages, the most significant being the inoculation effect that can prevent the growth of algae and molds (multi-cellular filaments) over the composite surfaces by means of intramural photocatalytic reactions [13]. The other benefits include enhanced aesthetic appearance, durability and depollution properties [14, 15]. Nazari and Riahi (2011) [16] reported that by partial replacement of \(\hbox {TiO}_{2}\) nanoparticles with cement up to 3% by weight, the C–S–H gel formation accelerated owing to increased amount of crystalline \(\hbox {CaOH}_{2}\) formation during the onset stages of hydration. Owing to the blending of nano-\(\hbox {TiO}_{2}\) particles within cement pastes, Chen et al (2012) [17] observed reduction in initial and final setting times and an increase in standard consistency with increasing percentage of nano-\(\hbox {TiO}_{2}\) particles in cement pastes. Meng et al (2012) [18] substantiated that due to modifications in calcium hydroxide (CH) orientation index at the inter-facial transition zone (ITZ), there was significant improvement in the strength characteristics of nano-\(\hbox {TiO}_{2}\)-blended cement mortars. Feng et al (2013) [19] provide evidences of reduced nano-roughness of nano-\(\hbox {TiO}_{2}\)-admixed hardened cement pastes compared with control samples through atomic force microscopy. Several literature proclaim that nano-modification of cement composites by incorporating nano-\(\hbox {TiO}_{2}\) particles enhance the workability, strength, water impermeability, drying shrinkage, NO\(_x\) mitigation, abrasion and fire resistance characteristics of composite elements [20,21,22,23,24]. Furthermore, the usage of nanoparticles in concrete has optimistic environmental impacts [13]. With significant amount of research in the context of nanoparticle-based cement composites over the times, several critical and meta-analysis-based descriptive reviews are available that spotlight on the impact of nanoparticle additives on orders of reaction with cement and mechanisms of hydration [25,26,27,28].

A careful review of literature reveals that many studies on utilization of nano-\(\hbox {TiO}_{2}\) particles in producing mortar or concrete are concerned with improving the strength and durability characteristics of the composite elements. Studies on heat of hydration of cement composites blended with nanoparticles have attracted attention in recent years. Hence, the present work aims to study the nano-\(\hbox {TiO}_{2}\) blended cement hydration and microstructure development to gain knowledge of composite cement hydration mechanisms. Additionally, the strength and durability properties of nano-\(\hbox {TiO}_{2}\) blended cement composites are evaluated to determine the quality of concrete or mortar composites for possible use in buildings or structures.

2 Materials

2.1 Cement

Ordinary Portland Cement of 43 grade conforming to IS:8112-2013 [29] standard was used throughout the experimental program. Its physical properties and chemical constituents are listed in table 1. The low-fineness 43-grade cement provides a better consistency when blended with nano-\(\hbox {TiO}_{2}\) particles compared to the fast-reacting 53-grade cement having higher specific surface area. High proportion of fines in the nano-\(\hbox {TiO}_{2}\) blended concrete/mortar mix widens the particle size distribution in comparison with plain cement concrete/mortar, increasing the water demand or standard consistency of cementitious paste.

2.2 Aggregates

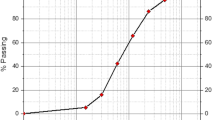

The fine aggregate employed was natural river bed sand procured from local sources. The sand was washed to remove any organic matter present in it. From sieve analysis, the grading of fine aggregate conformed to zone-II of Table 4 of IS:383-1970 (2002) [30]. Crushed quarry stones of 20 mm nominal maximum size were used as coarse aggregate in concrete. The crushed stones were cubical and angular in shape; flaky and elongated pieces were prevented. Saturated surface dry state aggregate was used during the preparation of mortar or concrete blocks. The properties of coarse and fine aggregates used are listed in table 2 and table 3 presents the grading or retention of aggregate particles on IS standard sieves.

2.3 Photocatalytic \(\hbox {TiO}_{2}\) nanoparticles

Titanium di-oxide, also known as Titania, is an off-white coloured naturally occurring inorganic element, with chemical formula \(\hbox {TiO}_{2}\) as shown in figure 1. Titanium di-oxide produced as ultrafine (nanomaterial) product is an inert and safe material engineered to have primary particles less than 1 nm. These nanoparticles have a slightly increased propensity to agglomerate with micron \((\mu )\) size particles such as cement via van der Waals attractive forces to form composite particles. In the present study the rutile-grade \(\hbox {TiO}_{2}\) was used as a substitution material for cement, whose average particle size was in the range \(2\pm 1\hbox {nm}\). Some physical properties of \(\hbox {TiO}_{2}\) nanoparticles used are listed in table 4.

3 Experimental programme

In the present study, M20 grade of concrete is considered for the reason that it is the most widely adopted grade of concrete at construction sites in India. Following the procedure mentioned in IS:10262-2009 [31], an M20 grade nominal concrete mix was designed. For a water to binder ratio \(= 0.45\), the binder to aggregate ratio so obtained was 1: 2.05: 3.10. The slump between 50 and 100 mm was adopted to achieve a workable concrete. The concrete produced was cast in standard mild steel cubes of size 150 mm by sufficiently compacting over a table vibrator. The mix proportions adopted to produce \(1\hbox { m}^3\) volume of concrete are given in table 5.

The nano-\(\hbox {TiO}_{2}\) and cement composite mortar produced had a binder to fine aggregate ratio of 1:3 (by weight). Considering the standard consistency of composite binder, the percentage of water added varied between 9.5 and 11.25% of combined mass of binder and fine aggregates based on the recommendations in IS:4031 (Part-6)-1988 (2005) [32]. The composite mortar mixes were prepared in an automated mortar mixer by mixing for about 5 min. Steel cube moulds of size 70.7 mm were used to cast the test specimens and a table vibrator was employed to sufficiently compact the mortar in the moulds. Mortar cubes were prepared using nano-\(\hbox {TiO}_{2}\) particles as cement replacement at 2%, 4%, 6%, 8% and 10% levels.

3.1 Determination of properties of fresh composite cement and concrete

The initial setting time, final setting time and standard consistency of nano-\(\hbox {TiO}_{2}\)-blended cement were determined using a Vicat’s apparatus as per IS:4031 (Part-4)-1988 (2005) [33] and IS:4031 (Part-5)-1988 (2005) [34] guidelines. Water more than the consistency results in excess water and strength reduction, and hence determination of Standard Consistency is important. The consistency is affected by the type and fineness of cement particles. Water requirement is more in cements with higher fineness values. The slump test was conducted to determine the workability of fresh concrete as per the procedure mentioned in IS:1199-1959 (1991) [35]. The ease with which concrete flows realized through slump test is dependent on the factors such as particle size distribution, moisture content of concrete ingredients, fineness of cement and the site temperature.

3.2 Determination of heat of hydration of cement composites

A heat of hydration calorimeter conforming to IS:11262-1985 [36] was used to measure the total heat of hydration of nano-\(\hbox {TiO}_{2}\)-cement composites. The standard procedure mentioned in IS:4031 (Part-9)-1988 (2005) [37] was implemented to determine the heat of hydration of nano-\(\hbox {TiO}_{2}\)-cement composites. The heat evolution profile from hydrating nano-\(\hbox {TiO}_{2}\)-blended cement composite can give insights on the temperature impacts on hydration process and optimization of nano-\(\hbox {TiO}_{2}\) dosing. The effects of controlled blending of fine nano-\(\hbox {TiO}_{2}\) particles with slightly coarser cement particles on early hydration reactions were the focus of present investigation.

3.3 Determination of properties of hardened composite concrete/mortar

The compressive strengths of composite concrete cubes of 150 mm size and composite mortar cubes of 70.7 mm size were determined as per IS:516-1959 (2006) [38] guidelines. Test was carried out on triplicate specimens of each mix proportion at 7 and 28 days age after water curing and the mean compressive strength of cubes were catalogued. To evaluate the bond strength of composite mortar with bricks, triplicate brick masonry blocks comprising 3 standard bricks bonded by mortar as a whole were casted. Brush away any dirt over the surfaces and saturate the bricks thoroughly before the mortar is pressed over the bricks in successive layers. Triplet brick prisms of size \(215\,\hbox {mm} \times 101\,\hbox {mm} \times 70\,\hbox {mm}\) and composite mortar of 1:3 binder to sand ratio (by weight) were used in the study. The typical experimental set-up for determining the bond/adhesive strength of composite mortar with bricks under shear over a compression testing machine is shown in figure 2.

3.4 Determination of durability properties of composite concrete/mortar

The water absorption capacity of composite mortar cubes of size 70.7 mm was tested at regular time intervals of 15, 30 and 45 days after curing as per the specifications of BS 1881:Part 122 (1983) [39]. Greater water absorption rates depict significant ingress of moisture into the mortar and its vulnerability to deterioration. Sorptivity test on cylindrical composite concrete blocks of size: 100 mm diameter and 50 mm height was conducted as per the specifications of ASTM C 1585-13 (2013) [40]. The typical experimental set-up for testing the sorptivity of composite concrete specimens is shown in figure 3. Sorptivity of concrete is characterized by the tendency of the concrete to absorb and transmit water by capillarity [41]. Water permeability is the prime cause for the defects in concrete associated with several types of chemical attacks. Hence, water permeability test on composite concrete cubes of size 150 mm was carried out according to IS:3085-1965 (2002) [42] guidelines after 28 days of curing period. The co-efficient of permeability of test specimen was computed from the net quantity of water penetration using the following equation based on Darcy’s Law:

where K is the co-efficient of permeability (cm/s), A is the cross-sectional area of specimen face \((\hbox {cm}^2\)), Q is the quantity of water in millimetres percolating over the entire test period T in seconds once the steady state has been reached and H/L is the ratio of pressure head to thickness of the specimen.

3.5 Micro-structural analysis of concrete blended with \(\hbox {TiO}_{2}\) nanoparticles

In the present study, the images obtained using a scanning electron microscope (SEM) aided with energy-dispersive X-ray spectroscopy (EDS) of concrete (Mix 5) blended with \(\hbox {TiO}_{2}\) nanoparticles were analysed to determine the morphological characteristics, elemental composition and atomic weight of chemical constituents synthesized in the composite concrete. The SEM images of the samples of Mix 5 concrete were derived at different magnifications from 100\(\times \) to 25,000\(\times \). The samples, approximately, 5 mm thick chipped off from the core portion of cubes of the optimal composite concrete mix were used in the SEM analysis.

4 Results and discussion

The effects of substitution of \(\hbox {TiO}_{2}\) nanoparticles with cement on the mechanical and durability properties of mortar or concrete such as compressive strength, bond strength, water absorption, sorptivity and water permeability are discussed in detail and compared to those of conventional concrete specimens.

4.1 Properties of fresh nano-\(\hbox {TiO}_{2}\)-blended cement composite and concrete

The experimental outcomes of setting times and standard consistency of nano-\(\hbox {TiO}_{2}\) cement composite pastes at room temperature (\(28\pm 3\,{}{^{\circ }}\hbox {C}\)) are tabulated in table 6. The initial setting time was unaltered up to 4% substitution of nano-\(\hbox {TiO}_{2}\) particles with cement. However, it decreased progressively at 6%, 8% and 10% substitution levels. This is attributed to the changes in mineralogical composition of composite cement and their proportions. Similarly, the final setting times are also shortened due to accelerated hydration of cement composites. The nano-\(\hbox {TiO}_{2}\)-blended cement composites consume more water to arrive at standard consistency due to the increase in surface area of the blended mass. Hence, the water to binder (w/b) ratio = 0.45 was adopted during the mix design of M20 grade composite concrete taking into account the total water required for workable concrete and exposure temperature.

Nano-\(\hbox {TiO}_{2}\) particles allow for complex interactions within the fresh concrete, thereby affecting the rheological properties of composite concrete. They deteriorate the workability of fresh concrete; its nano-fineness and hydrophilic properties physically disperse the cement flocs and adsorb more water, consequently reducing the workability of the mix. Bleeding is also reduced because of this mechanism and nano-\(\hbox {TiO}_{2}\) particles ensure uniform dispersion of water molecules at all the fine loci of the mix. The slump of composite concrete was measured immediately after discharge from the mixer. All the mixes were cohesive and the slump of conventional concrete was found to be higher compared with that of nano-\(\hbox {TiO}_{2}\)-blended concretes (figure 4). All the blended concrete mixes met the requirement of acceptable workability. The incremental addition of nano-\(\hbox {TiO}_{2}\) particles (by 2%) reduced the slump owing to increase in the percentage of fines.

4.2 Heat of hydration of nano-\(\hbox {TiO}_{2}\)-cement composites

The cement hydration reactions, which are mostly exothermic, generate heat during the process. As the percentage of nano-\(\hbox {TiO}_{2}\) substitution increased, the early heat of hydration (heat liberation) increased in the composite system. The heat evolution curves plotted are shown in figure 5. The heat evolution boosted up to 4–5 h from unhydrated nano-\(\hbox {TiO}_{2}\)-blended cement pastes when tested in the calorimeter as per the standard procedure. Well-dispersed photocatalytic \(\hbox {TiO}_{2}\) nano-particles along with cement act as centres of crystallization and accelerate the cement hydration process. The heat release is significant during the period of rapid and massive nucleation followed by growth and precipitation of the calcium silicate hydrate (C–S–H) and CH gels. The nanofine \(\hbox {TiO}_{2}\) particles provide more nucleation sites for the the formation of acicular and interwoven crystals during hydration. The kinetics of hydration process is often influenced by the surface area of total solid phase in the composite system where the activity occurs through diffusion and dissolution of materials in the concentrated paste.

4.3 Properties of hardened nano-\(\hbox {TiO}_{2}\) cementitious composites

The cube compressive strength results of mortar and concrete produced from nano-\(\hbox {TiO}_{2}\) cementitious composites at the age of 7 and 28 days are presented in tables 7 and 8, respectively. The compressive strength development in nano-\(\hbox {TiO}_{2}\)-blended cement composites is influenced by the refinement of microstructure attributed to nano-scale \(\hbox {TiO}_{2}\) fines (nano-filler effect), modifications in the orientation index of CH crystals via internal reactions and formation of dense ITZs. It can be observed that the composite concrete cubes made of nano-\(\hbox {TiO}_{2}\)-blended cement composites attain 40–50% of design strength at an early age of 7 days itself due to accelerated hydration process. As the substitution percentage of nano-\(\hbox {TiO}_{2}\) particles increases, the compressive strength of both mortar and concrete cubes increases up to 8% substitution level and thereafter declines at 10% substitution. Such a behaviour in this context is fostered by excess fines (nanoparticles) that cause segregation and autogenous shrinkage of the mix by self-desiccation in the composite pore system of the hardened paste. The replacement of \(\hbox {TiO}_{2}\) nanoparticles is therefore not recommended beyond 10%. At 28 days, the cement composite concrete blended with 8% nano-\(\hbox {TiO}_{2}\) developed the highest strength of 24.37 MPa against the design strength of 20 MPa. Also, the rate of strength development in nano-\(\hbox {TiO}_{2}\)-blended cement composites (both mortar and concrete) was much more significant than that of the control mix (0%).

The bonding between cement mortar and the brick units is one of the significant properties that influence the overall strength of masonry construction. The bond strength of nano-\(\hbox {TiO}_{2}\)-blended cement composite mortar with bricks is presented in figure 6. The control mix mortar offered 18.47% lesser bond strength compared with that of Mix 5 composite mortar. The factors affecting mortar performance include particle size distribution of the mix, binder content, water to binder ratio, any impurities such as silt and clay content, and workmanship. Nano-\(\hbox {TiO}_{2}\) particles within the mortar mix impart chemical adhesiveness, benefitting the bonding ability of mortar.

4.4 Durability properties of nano-\(\hbox {TiO}_{2}\) cementitious composites

Water absorption and permeability are the prime causes for problems arising in concrete due to various types of chemical attacks. Experimental investigations were carried out on the test specimens to ascertain the durability-related properties such as water absorption, sorptivity and water permeability of cement composites. The water absorption test results are presented in table 9. It was evident that the mortar cubes with 10% nano-\(\hbox {TiO}_{2}\) blending were less vulnerable to water absorption. The possible reason for this behaviour is that: higher the fine particles within the mortar matrix, lesser the water absorption due to reduced pore space and denser matrix. The mortar with 10% substitution of nano-\(\hbox {TiO}_{2}\) particles exhibited 6.84% less absorption compared with that of control mix (0%) at 45 days of water immersion.

The permeability in hardened concrete is usually rendered by the entrapped air pockets within the concrete matrix due to improper placement or insufficient compaction and secondly, by the voids created due to water evaporation from freshly placed concrete. The use of admixtures such as nano-\(\hbox {TiO}_{2}\) particles allows for the placement of highly impermeable concrete. Figure 7(a) shows the pressure drop in the manometer with time of nano-\(\hbox {TiO}_{2}\)-blended concrete cubes subjected to 5 bar water pressure. Figure 7(b) shows the variations in co-efficient of permeability of concrete cubes blended with nano-\(\hbox {TiO}_{2}\) particles at various percentages. It is evident that the 10%-\(\hbox {TiO}_{2}\)-substituted mix has greater resistance for permeability and the results are in line with the trend observed, i.e. concrete with higher percentage of nano-\(\hbox {TiO}_{2}\) substitution shows reduced permeability rates. Concrete permeability influences the rate of corrosion of reinforcing bars, alkali–aggregate reaction, carbonation, freeze and thaw cycles, and so forth, which may all happen simultaneously.

The practical applicability and significance of water absorption test carried out by total immersion of mortar specimens and the permeability test, which measures the response of concrete to water pressure, are often debatable. However, in the present context, the water absorption and permeability tests determine the water-tightness of nano-\(\hbox {TiO}_{2}\)-blended cement composites as against the reference one. The driving thrust of fluids entering the concrete could be better gauged by the sorptivity test, which represents the water uptake characteristics of a porous unit at a partially saturated state by capillary action. The initial and secondary rates of water absorption from nano-\(\hbox {TiO}_{2}\)-blended concrete blocks are tabulated in table 10. Sorptivity was observed to progressively decrease with an increase in percentage of nano-\(\hbox {TiO}_{2}\) blending with cement. The initial and secondary rates of water absorption in 10% nano-\(\hbox {TiO}_{2}\)-blended composite concrete are lower by 5.50% and 6.67%, respectively, compared with that of control mix (0%) concrete. Correspondingly, figure 8 depicts the plot of absorption (I) in mm versus square root of time in seconds based on initial and secondary rates of water absorption from sorptivity specimens of nano-\(\hbox {TiO}_{2}\)-blended concrete mixes. The initial 6 h of absorption measurements denote initial rate of water absorption and the sorptivity measurements from day 1 to 7 days represent the secondary rate of water absorption. The nano-\(\hbox {TiO}_{2}\) particles fill up the micro- and macro-pores within the composite concrete and reduce the generation of \(\hbox {CaOH}_{2}\) crystals during hydration. Concrete with higher sorptivity is prone to reduced durability; hence the admixtures such as nano-\(\hbox {TiO}_{2}\) particles aid in reducing the sorptivity potential of concrete by pore-size refinement at aggregate–cement interface and break the tortuous continuity of pores via enhancement of heterogeneous microstructure.

4.5 Morphology and elemental composition of nano-\(\hbox {TiO}_{2}\)-blended concrete

SEM observations allowed recognizing significant morphological changes in the microstructure of nano-\(\hbox {TiO}_{2}\)-blended concrete (Mix 5) as presented in figure 9. In figure 9(a) one can observe densely packed microstructure with more bonded and linked hydration products. On examining the surface texture of samples, a large proportion of hydration products finer than \(10\, \upmu \hbox {m}\) with smooth surfaces are evident from the microstructure [figure 9(b)]. The sample in figure 9(c) shows platy or foil-like sub-angular fibres of C–S–H and cubical agglomerates. At higher magnification [figure 9(d)], the nano-\(\hbox {TiO}_{2}\)-blended concrete samples are composed of a significant proportion of sub-angular particles, secondary crystal growths and agglomerates (\(\approxeq \) 5–\(15\,\upmu \hbox {m}\) in size) wherein most of the voids are filled by nano-\(\hbox {TiO}_{2}\) particles, which serve as inert fillers. The nano-\(\hbox {TiO}_{2}\) particles play a major role in densification and homogenization of the microstructure at ITZ, which has considerable influence on the durability performance of concrete [figure 9(e)]. The blending of nano-\(\hbox {TiO}_{2}\) particles with cement creates extra reactive surfaces that enhance hydration at early ages, thus reducing the pore structure of composite concrete and furnishing a much uniform microstructure [figure 9(f)]. In addition, the results of EDS analysis presented in figure 10 portray the peaks and relative concentration of elements such as Ti, Ca, Si, Al, Fe, Mg, etc. that are captured in the spectrum. The peaks of Ti, Si and Ca elements denote considerable development of compounds associated with those elements. The low calcium to silica (Ca/Si) ratio of 0.823 indicates favourable C–S–H phases that lead to an increase in alkali uptake [43, 44].

5 Conclusions

The following conclusions are drawn based on the experimental results obtained from the study.

-

\(\hbox {TiO}_{2}\) nanoparticles potentially act as nano-fillers and improve the degree of concrete resistance to water permeability.

-

The compressive strengths of mortar and concrete cubes were found to increase with the increase in the percentage of substitution of \(\hbox {TiO}_{2}\) with cement up to 8%. Thereafter, the strength decreased due to increase of fines content in the mortar/concrete matrix. Hence, the recommended optimum substitution percentage is 8%.

-

Nano-\(\hbox {TiO}_{2}\) particles in the mortar mix impart chemical adhesiveness benefitting the bonding ability of mortar.

-

As the substitution percentage of \(\hbox {TiO}_{2}\) increased, the rate of water absorption and sorptivity of composite specimens decreased.

-

The heat of hydration of nano-\(\hbox {TiO}_{2}\)-blended cement composites increased due to the release of additional reactive surfaces for specific reactions with C–S–H and CH gels, along with the formation of secondary hydration compounds.

-

The cement composites produced by blending nano-\(\hbox {TiO}_{2}\) particles showed improved strength and durability performances compared with that of control mix. The presence of Ti peak in EDAX analysis serves as a primary support for its secondary compounds reducing the porosity of interconnected matrix within the composite concrete.

References

Sanchez F and Sobolev K 2010 Nanotechnology in concrete—a review. Constr. Build. Mater. 24(11): 2060–2071 https://doi.org/10.1016/j.conbuildmat.2010.03.014

Jo B W, Kim C H, Tae G and Park J B 2007 Characteristics of cement mortar with nano-\(\text{ SiO}_{2}\) particles. Constr. Build. Mater. 21(6): 1351–1355 https://doi.org/10.1016/j.conbuildmat.2005.12.020

Norhasri M S M, Hamidah M S and Fadzil A M 2017 Applications of using nano material in concrete: a review. Constr. Build. Mater. 133: 91–97 https://doi.org/10.1016/j.conbuildmat.2016.12.005

Reches Y 2018 Nanoparticles as concrete additives: review and perspectives. Constr. Build. Mater. 175: 483–495 https://doi.org/10.1016/j.conbuildmat.2018.04.214

Li G 2004 Properties of high-volume fly ash concrete incorporating nano-\(\text{ SiO}_{2}\). Cem. Concr. Res. 34(6): 1043–1049 https://doi.org/10.1016/j.cemconres.2003.11.013

Du H, Du S and Liu X 2014 Durability performances of concrete with nano-silica. Constr. Build. Mater. 73: 705–712 https://doi.org/10.1016/j.conbuildmat.2014.10.014

Nazari A, Riahi S, Riahi S, Shamekhi S F and Khademno A 2010 Influence of \(\text{ Al}_{2}\text{ O}_{3}\) nanoparticles on the compressive strength and workability of blended concrete. J. Am. Sci. 6(5): 6–9

Sato T and Beaudoin J 2011 Effect of nano-\(\text{ CaCO}_{3}\) on hydration of cement containing supplementary cementitious materials. Adv. Cem. Res. 23(1): 33–43 https://doi.org/10.1680/adcr.9.00016

Said A M, Zeidan M S, Bassuoni M T and Tian Y 2012 Properties of concrete incorporating nano-silica. Constr. Build. Mater. 36: 838–844 https://doi.org/10.1016/j.conbuildmat.2012.06.044

Staub de Melo J V and Trichłs G 2018 Study of the influence of nano-\(\text{ TiO}_{2}\) on the properties of Portland cement concrete for application on road surfaces. Road Mater. Pavement Des. 19(5): 1011–1026 https://doi.org/10.1080/14680629.2017.1285811

Khoshakhlagh A, Nazari A and Khalaj G 2012 Effects of \(\text{ Fe}_{2}\text{ O}_{3}\) nanoparticles on water permeability and strength assessments of high strength self-compacting concrete. J. Mater. Sci. Technol. 28(1): 73–82 https://doi.org/10.1016/S1005-0302(12)60026-7

Fan Y, Zhang S, Wang Q and Shah S P 2015 Effects of nano-kaolinite clay on the freeze–thaw resistance of concrete. Cem. Concr. Compos. 62: 1–12 https://doi.org/10.1016/j.cemconcomp.2015.05.001

Folli A 2011 TiO2 photocatalysis in Portland cement systems: fundamentals of self cleaning effect and air pollution mitigation. Ph.D. Thesis, University of Aberdeen, Scotland

Qin Z B, Zhang W T, Qian G P, Wu X L and Li Y 2015 The effects of different ways of adding nano-\(\text{ TiO}_{2}\) to concrete on the degradation performance of \(\text{ NO}_{2}\). Mater. Res. Innovations 19(10): 148–154 https://doi.org/10.1179/1432891715Z.0000000002127

Maggos T, Plassais A, Bartzis J G, Vasilakos C, Moussiopoulos N and Bonafous L 2008 Photocatalytic degradation of NO\(_{x}\) in a pilot street canyon configuration using \(\text{ TiO}_{2}\)-mortar panels. Environ. Monit. Assess. 136(1–3): 35–44 https://doi.org/10.1007/s10661-007-9722-2

Nazari A and Riahi S 2011 \(\text{ TiO}_{2}\) nanoparticles effects on properties of concrete using ground granulated blast furnace slag as binder. Sci. China Technol. Sci. 54(11): 3109 https://doi.org/10.1007/s11431-011-4421-1

Chen J, Kou S C and Poon C S 2012 Hydration and properties of nano-\(\text{ TiO}_{2}\) blended cement composites. Cem. Concr. Compos. 34(5): 642–649 https://doi.org/10.1016/j.cemconcomp.2012.02.009

Meng T, Yu Y, Qian X, Zhan S and Qian K 2012 Effect of nano-\(\text{ TiO}_{2}\) on the mechanical properties of cement mortar. Constr. Build. Mater. 29: 241–245 https://doi.org/10.1016/j.conbuildmat.2011.10.047

Feng D, Xie N, Gong C, Leng Z, Xiao H, Li H and Shi X 2013 Portland cement paste modified by \(\text{ TiO}_{2}\) nanoparticles: a microstructure perspective. Ind. Eng. Chem. Res. 52(33): 11575–11582 https://doi.org/10.1021/ie4011595

Ma B, Li H, Mei J, Li X and Chen F 2015 Effects of nano-\(\text{ TiO}_{2}\) on the toughness and durability of cement-based material. Adv. Mater. Sci. Eng. 2015: 583106 https://doi.org/10.1155/2015/583106

Zhang R, Cheng X, Hou P and Ye Z 2015 Influences of nano-\(\text{ TiO}_{2}\) on the properties of cement-based materials: hydration and drying shrinkage. Constr. Build. Mater. 81: 35–41 https://doi.org/10.1016/j.conbuildmat.2015.02.003

Duan P, Yan C, Luo W and Zhou W 2016 Effects of adding nano-\(\text{ TiO}_{2}\) on compressive strength, drying shrinkage, carbonation and microstructure of fluidized bed fly ash based geopolymer paste. Constr. Build. Mater. 106: 115–125 https://doi.org/10.1016/j.conbuildmat.2015.12.095

Li Z, Ding S, Yu X, Han B and Ou J 2018 Multifunctional cementitious composites modified with nano titanium dioxide: a review. Compos. Part A: Appl. Sci. Manuf. 111: 115–137 https://doi.org/10.1016/j.compositesa.2018.05.019

Rhee I, Lee J S, Kim J B and Kim J H 2018 Nitrogen oxides mitigation efficiency of cementitious materials incorporated with \(\text{ TiO}_{2}\). Materials 11(6): 877 https://doi.org/10.3390/ma11060877

Silvestre J, Silvestre N and de Brito J 2016 Review on concrete nanotechnology. Eur. J. Environ. Civ. Eng. 20(4): 455–485 https://doi.org/10.1080/19648189.2015.1042070

Sobolev K 2016 Modern developments related to nanotechnology and nano engineering of concrete. Front. Struct. Civ. Eng. 10(2): 131–141 https://doi.org/10.1007/s11709-016-0343-0

Han B, Zhang L, Zeng S, Dong S, Yu X, Yang R and Ou J 2017 Nano-core effect in nano-engineered cementitious composites. Compos. Part A: Appl. Sci. Manuf. 95: 100–109 https://doi.org/10.1016/j.compositesa.2017.01.008

Lau D, Jian W, Yu Z and Hui D 2018 Nano-engineering of construction materials using molecular dynamics simulations: prospects and challenges. Compos. B: Eng. 143: 282–291 https://doi.org/10.1016/j.compositesb.2018.01.014

IS:8112-2013 2013 Ordinary Portland cement, 43 grade – specifications. Bureau of Indian Standards, New Delhi

IS:383-1970 2002 Specification for coarse and fine aggregates from natural sources for concrete. Bureau of Indian Standards, New Delhi

IS:10262-2009 2009 Guidelines for concrete mix design proportioning. Bureau of Indian Standards, New Delhi

IS:4031 (Part-6)-1988 2005 Determination of compressive strength of hydraulic cement (other than masonry cement). Methods of physical tests for hydraulic cement, part 6. New Delhi: Bureau of Indian Standards

IS:4031 (Part-4)-1988 2005 Determination of consistency of standard cement paste. Methods of physical tests for hydraulic cement, part 4. New Delhi: Bureau of Indian Standards

IS:4031 (Part-5)-1988 2005 Determination of initial and final setting times. Methods of physical tests for hydraulic cement, part 5. New Delhi: Bureau of Indian Standards

IS:1199-1959 1991 Methods of sampling and analysis of concrete. Bureau of Indian Standards, New Delhi

IS:11262-1985 1985 Specification for calorimeter for determination of heat of hydration of hydraulic cement. Bureau of Indian Standards, New Delhi

IS:4031 (Part-9)-1988 2005 Determination of heat of hydration. Methods of physical tests for hydraulic cement, part 9. New Delhi: Bureau of Indian Standards

IS:516-1959 2006 Method of tests for strength of concrete. Bureau of Indian Standards, New Delhi

BS 1881:Part 122:1983 1983 Testing concrete: method for determination of water absorption. British Standards Institution, London

ASTM C 1585-13 2013 Standard test method for measurement of rate of absorption of water by hydraulic-cement concretes. ASTM International, PA

Hall C 1989 Water sorptivity of mortars and concretes: a review. Mag. Concr. Res. 41: 51–61 https://doi.org/10.1680/macr.1989.41.147.51

IS:3085-1965 2002 Methods of test for permeability of cement mortar and concrete. Bureau of Indian Standards, New Delhi

Kunther W, Ferreiro S and Skibsted J 2017 Influence of the Ca/Si ratio on the compressive strength of cementitious calcium-silicate-hydrate binders. J. Mater. Chem. A 5(33): 17401–17412 https://doi.org/10.1039/C7TA06104H

Rossen J E, Lothenbach B and Scrivener K 2015 Composition of CSH in pastes with increasing levels of silica fume addition. Cem. Concr. Res. 75: 14–22 https://doi.org/10.1016/j.cemconres.2015.04.016

Acknowledgements

The authors wish to acknowledge the cooperation rendered by the non-teaching staff of Department of Civil Engineering, SMVITM, Bantakal, in obtaining the experimental data presented in the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naganna, S.R., Jayakesh, K. & Anand, V.R. Nano-TiO2 particles: a photocatalytic admixture to amp up the performance efficiency of cementitious composites. Sādhanā 45, 280 (2020). https://doi.org/10.1007/s12046-020-01515-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-020-01515-x