Abstract

An efficient transport infrastructure system is essential for the social and economic development of a territory. It has become clear that the demographic increase and changes in the habits of the populations should be supported by a development of transport systems, often inadequate to the growing demand for mobility. Therefore, it was necessary to use technologies that would allow the design, management and monitoring of transport structures in an effective manner to ensure adequate levels of service and safety. In more recent times, this need has led to the development of new methodologies as Building Information Modeling (BIM), which is decisively influencing the construction sector, allowing for better results from an economic, management and performance point of view. The digitization of civil manufactures has changed the approach to design and in particular the use of BIM for infra-structures has led to changes of an instrumental nature in the processes related to all phases of design and construction.

This paper presents a new BIM procedure to support the management phases of a road infrastructure. It has been defined an informative model which can interface the three-dimensional model of a road pavement with a set of information related to monitoring activities.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Social and economic development of a territory is closely related to an efficient transport system. Over the years, it has become clear that the demographic increase and changes in the habits of the populations should be supported by a development of transport systems, often inadequate to the growing demand for mobility [1].

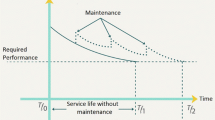

Civil structures, such as roads, bridges, dams, etc. are subjected to deterioration related to aging. Keeping track of their wear and performance conditions during exercise is essential to ensure adequate levels of comfort and safety [2]. Over time, an inadequate monitoring system entails high management costs and, in some cases, it could result in the loss of human lives. In the past and, unfortunately, even recently, tragic events have occurred, often due to the poor conditions of some components of the infrastructural works [3]. The way maintenance activities are conducted is one of the most critical aspects of management of civil works: often a manual approach is used to management information. This leads to a poor definition of the resources for life cycle management of constructions [4]. It is estimated that about 80% of the time during the Facility Management (FM) phases is used to reconstruct relevant information that is often dispersed during the pre-construction phases [5]. In this context Building Information Modeling (BIM) represents a key factor for the development of the information management process [6]. In the Architecture, Engineering and Construction (AEC) sector the adoption of BIM has resulted in significant savings during the early stages of the life cycle of a work due to the production of virtual models and an analytical approach [7]. Moreover, recent studies have shown great advantages even in the management phases [8, 9].

So far, BIM methodology has been applied mainly in the architectural and buildings construction fields where it has found considerable success, while in infrastructural one it is still at the beginning. However, widespread use of BIM in building construction has aroused growing interest also for Infrastructure ‐ Building Information Modeling (I-BIM applications) [10,11,12,13]. Up to now, contributions in literature are still few. Some researchers have analyzed various possible uses of BIM in the infrastructural field, starting from Cho et al. [14] who propose a holistic BIM library concept to integrate geometry, property, and product information into a tunnel project or Yakubi [15] who highlights obstacles for applying BIM to civil infrastructure and requisite to promote it. More recently, Fabozzi et al. [16] test a procedure to implement geotechnical information into a BIM model for a benchmark case history of tunneling in the urban area of Naples.

Acampa et al. [17] present a case study where they apply the BIM oriented design method to the underground railway extension in the metropolitan area of Catania.

Dell’Acqua et al. [18] present an overview of BIM applied to railway projects and focus on the advantages of this methodology.

Guerra de Oliviera et al. [19] suggest possible improvements in the interoperability of maintenance data of the airport’s runway of the Lamezia Terme International Airport with reference to the IFC Reference Processes.

Campisi et al. [20] give a great scientific contribution by defining a methodology to give key elements needed to design possible cycle path solutions by means the I-BIM technology.

Aritomi et al. [21] have devised a “road information model” with floor plans, profiles and cross sections based on parametric modeling of the geometry, Rebolj et al. [22] developed an updated version of the model. Lee and Kim [23] and Cho et al. [24] have developed an I-BIM methodology in the IFC format useful for geometry modeling and for archiving semantic information.

An interesting application of Heritage-BIM was proposed by Biancardo et al. [25] on an ancient road of Pompei.

In Asia and Americas, the largest number of I-BIM applications are detected, on the other hand, in Europe, Oceania and Africa, there is a lower attitude to the use of BIM in the infrastructural field [10].

On the other hand, in Italy, the Decree n.560 of 2017 makes the use of BIM method mandatory, starting from the largest tenders which often relate to infrastructures. Therefore, the need to apply BIM to infrastructures has now become urgent and important.

Use of BIM methodology facilitates design and management of a linear infrastructure because it allows to concentrate all aspects of the work in a single model, reducing possible errors and conflicts. This rationalization of processes brings benefits to public spending and increases the efficiency and profitability of the sector.

This paper presents a new BIM procedure to support the management phases of a road infrastructure. It has been defined an informative model which can interface the three-dimensional model of a road pavement with a set of information related to monitoring activities.

2 Case Study

The study concerned a section of the new SS 195, a very important infrastructure for improving the connection between the most important city and the south of Sardinia (Italy). During the construction process, the works were interrupted for a long time. In some areas, materials already installed were exposed to degradation action of atmospheric agents (see Fig. 1). A BIM model was created to support management of interventions of those road pavement sections where the criticalities were more evident.

2.1 BIM Model of the Road Pavement

A methodological approach was followed for the development of the model which led to the definition of different alternatives for achieving the set goal.

The modeling process was divided into four different macro phases. For each of these, sub-phases have been defined and specific actions and tools have been adopted. Weak interoperability between different tools and formats used was the major problems encountered (Fig. 2).

The geometric model (see Fig. 3) was created using Autodesk’s Civil3d software which follows a similar workflow of common road design softwares. The inputs for this phase were:

-

Digital terrain model;

-

Polygonal axis for creating horizontal alignment;

-

Vertical alignment.

The design drawings in CAD format were the main source of the geometric data.

A topographical survey was carried out to reconstruct digital terrain model (DTM) and returned in.dwg format.

The software allows to read the geometric entities directly from Autocad elaborations. The points are parametric entities which made possible to use the information of the elevation. It was reported in the drawing by text form, by inserting it in the corresponding Z coordinate of each point.

The main axis of the project was then imported, this was read as a 2d polyline, which was used as the basis for the creation of the “path” object, a BIM object that dynamically interacts with the other elements of the model. It allowed to define the vertical alignment of the terrain and the road, which collects various information such as elevation in curves, project speed and type of road as reported in the Ministerial Decree No. 6792 of 05/11/2001.

The vertical alignment was obtained starting from the horizontal alignment and the DTM and was defined according to the choices made during the design phase.

The typical section of the road pavement has been defined starting from predefined schemes and then modified to adapt the model to the design choices. Each section is coded according to codes that allow to assign different geometric properties and create dynamic links with the entities of the project.

The changes in the model were made by using Subassembly Composer application, a visual programming environment that allows to visually compose complex components of type section and simulate their functioning with different values and target conditions. These components are imported into civil 3d in .pkt format.

The elements created so far are combined to create the three-dimensional model of the road pavement through the “corridor” object that manages the data, linking the various standard sections (applied to the different ranges of stations) to the base lines (horizontal alignment) and to the respective vertical alignment. In other words, it manages the connection of project-specific surface and alignment data with the content of components of type section. The object includes corridor body geometry, longitudinal feature lines, and embedded surfaces. A corridor allows to define and visualize components such as:

-

feature lines which link points along point codes defined in components of type section;

-

surfaces using link codes and feature lines.

During the elaboration of the corridor the interferences present along the route (hydraulic artifacts, intersections) were carefully considered. To obtain a result that could correctly represent the road solid object it was necessary to create different regions (Fig. 4).

Corridors can be defined by setting different levels of discretization; in this case a step of 1m was chosen. In Fig. 5 a detail that highlights the coding relating to the points, connections and shapes described above is reported. The model created in this first phase was imported to Revit as a 3D solid.

2.2 The Information Model of the Road Pavement

BIM integrates the traditional 3D model of a building with all the information and properties about that building, such as design plans, product information, planning sequence and operations [26]. Therefore, the main aspect of this methodology is to produce an informative digital model that links geometric and alfa-numeric information to all the objects which compose the work. The structuring and management of a wide range of digital data and information about the status of the work creates the best conditions for conducting a “multicriteria” analysis that would allow the design and evaluation of different scenarios and intervention strategies, identifying the best combination that maximizes comprehensively the quality of the results.

In this case, the BIM authoring tool chosen for the development of the informative model was Revit by Autodesk. It is strongly oriented towards building modeling, but it allows to define very effectively data structures also in the infrastructural field. The dataset have to be able to 1) contain information relating to the type and characteristics of materials; 2) store the data relating to the surveys carried out on the pavement; 3) keep the history of the analysis and maintenance activities carried out during the operating phase.

Each element present within Revit is considered a Family. The family contains the geometric definition of the element and the parameters used for the information storage. Each instance of an element is defined and controlled by the family.

The parameters associated with different families of the project can be defined according to the discipline to which they belong. Although there are no specific sections relating to InfraBIM, it was possible to identify valid alternatives for grouping and defining the shared parameters for using in the infrastructural field.

Once the parameters have been defined, they are assigned to the families. To achieve the objective of this work, it was essential to find a field in the data set of families that contains the procedures and intervention times defined in the maintenance plan as required by Presidential Decree 207/2010 for each object of the model. Road pavement families were created from the solids generated in the previous stages. A family was created for each layer of the superstructure and the parameters relating to the characteristics of the materials used were assigned to each of them (see Fig. 6).

2.3 Pavement Monitoring via Falling Weight Deflectometer

A fundamental aspect for infrastructural monitoring is to be able to carry out checks quickly and accurately to be able to efficiently manage the resources to be allocated for maintenance work [27].

The falling weight deflectometer (FWD) is one of the most used non-destructive investigation tools in the world due to its precision and its operation that allows to simulate the loads to which roads are subject [28]. It is mounted on a trailer and towed by a vehicle specifically instrumented to monitor activities. Entire data collection process is controlled by an operator via a laptop [27]. The instrument records the temporary vertical deflection of the investigated surface by means of special sensors (geophones). The location of geophones respect to the center of fall of the mass allows to detect the deflection of the various points of the surface at a variable distance from the center of the load, thus allowing to evaluate a deflection basin. The analysis of the shape and characteristics of the deflection basin allows, through accurate back-calculation models, to determine the characteristics of the lower layers including the stiffness of the materials. Collected deflectometric data can be processed with different methods. They can be used to obtain indices, called Basin Index, which allow to obtain an initial indication of the conditions of the superstructure. Base Layer Index (BLI) provides information on the structural conditions of the base layer. Middle Layer Index (MLI) provides a high-level indication of the sub-base (foundation) layer, while Lower Layer Index (LLI) provides an indication of the condition of the sub-base layer [29].

The Fast FWD (FFWD), used for the survey, works in the same way of FWD but it allows investigations on the road pavement 5 times shorter than the original version. In the FFWD hydraulic systems for lifting the hammer mass have been replaced by an electric motor. Two investigation campaigns were carried out for the analysis of superstructure of SS n.195. During the first, on the morning of May 26th, 2020, a total of 456 beats were performed in 152 positions, 38 on each alignment. In each position 3 strokes were performed with load values between 800 kPa and 1400 kPa. The second investigation campaign was carried out on the morning of September 30th, 2020 and 108 beats were performed in 36 positions. In each position 3 strokes were performed with load values between 800 kPa and 1400 kPa. These measurements were carried out to verify the structural conditions of the base layer in cemented mix and the collected data were saved in a database.

2.4 Representation of the Survey Data

Since there were a large amount of data relating to the different layers of the pavement, it was necessary to search for a tool that would allow to represent them immediately.

A very simple geometric representation was selected, which could qualitatively provide information relating to the values detected by FFWD, by a color scheme. “Nested” families were used. Nesting a family consists in inserting it within another, in order to create a new one consisting of the union of the different geometries. A family that hosts another one is called the host family [30]. The families “Elastic modules” and “Basin Index” have been created. The families consist of cylinders: each of them represents a characteristic of the superstructure layer. For both families, a set of parameters has been defined. This set reports the value of the elastic modules and the value of BLI MLI and LLI; also text-type parameters have been defined to storage and manage qualitative information related to the structural conditions of the various layers.

2.5 Visual Programming for the Automation of the Data Entry Process

The FFWD survey data were collected in a spreadsheet in .xls format. The high amount of data and information to be connected to the BIM model would have made the process of manually compiling the schedules within Revit very long. Moreover, this process would have entailed a high probability of making mistakes and a considerable effort from a computational point of view. To solve this problem, it was decided to use the Dynamo software.

Dynamo is an open-source visual programming environment that allows construction users to process data, generate complex geometries and create automations without having to know a programming language [30]. Visual programming is an operating mode that does not involve the typing of a code list, but the connection and processing of graphic entities. The visual approach simplifies the development of applications by isolating the complexity of coding to the main users of Revit (architects, designers, engineers, companies, etc.). Nodes are the elementary entities in Dynamo, they are portions of programming code dedicated to carrying out specific operations which, combined, generate an algorithm. This process will produce a script capable of automating workflows, allowing, as in this case, direct input from an existing Excel file and the automatic compilation of parameter fields within Revit. The Dynamo work environment is accessible directly from Revit in the Manage>Visual programming section.

To reach the above target, a script has been defined in Dynamo (see Fig. 7).

It can be divided into three sections. The first (see Fig. 8), relating to the positioning of the instances on the model, reads the data from the spreadsheet and generates lists containing the coordinates of the points of the survey in the space at which various instances of the families that will contain the detected data are positioned.

The second part of the script (see Fig. 9) reads the survey data from the spreadsheet and compiles the related parameters present in the families: the procedure for acquiring values is identical to the acquisition of coordinates.

Finally, the last part of the script (see Fig. 10) associates a color coding to the different families according to the data contained in the fields of the different parameters.

This result was obtained following the creation of dictionaries. Dictionaries are a very powerful tool for creating associative sets between two lists of equal length. The first is a list of “keys” (or indexes) and the second a set of “values” (or the data that will be returned for each index). In this case study, the keys represent the list of possible conditions of road pavement according to the value assumed by the parameters that are being considered for the evaluation. The dictionaries created are two: the first relating to the indices linked to the areas of influence of the deflections: Base layer index (BLI), Middle layer index (MLI) and Lower layer index (LLI); the second relating to the elastic modules of the various layers of pavement.

Running this part of the code generates the following results (Fig. 11):

3 Conclusion

In this work the Authors pursued the goal of defining BIM procedures that could be applied to road infrastructure sector. They tried to create a workflow that could support the management phase of a road infrastructure, with a view to exploiting the potential of integrated design. The methodological approach was structured according to the logic “definition of objectives - execution of alternatives - verification of the result”, and led to the definition of practices that could be applied to any type of infrastructure, without, however, assuming that the alternative identified could be the best.

One of the aspects to which more attention was paid was to test the interoperability between the various applications used during the different phases of the work. Starting from the documentation provided by the construction company (Aleandri SPA), a great effort was made to transfer the project information from CAD formats to BIM software. The most important criticality found at the end of this phase is undoubtedly linked to the transfer formats of the documents. Although the direction in the field of BIM is to develop an open and neutral interchange format (IFC), this tool does not yet support BIM objects relating to the world of infrastructures. Moreover, during this work, shortcomings were found also for the transfer of simple geometries. The development of a tool that allows the sharing of data of an Infra-BIM model without redundancies or deficiencies seems to be still far away. However, the growing number of research activities promoted by Building Smart International as part of the new IFC standards dedicated to roads, bridges, urban and spatial planning, railways and airports, bodes well for a short time horizon.

Another important issue was the analysis of how the data deriving from infrastructure maintenance activities could be managed in an Infra-BIM model. From this point of view, the results obtained can be considered very satisfactory. The possibility of being able to define different parameters in the model to be able to dynamically associate a large amount of information makes BIM almost a necessity when it comes to infrastructural works; the visual programming tools, in fact, although not easy to use, make the data association processes a completely automatic step.

The model created in this work, although extremely simplified, allows to represent information relating to the performance characteristics of the pavement. A next step could be to associate the detected data with specific decay models in order to obtain a forecasting tool that, based on the results of the monitoring activities, allows to define which areas may be most exposed to critical issues over time, so that to obtain a better planning of maintenance interventions, savings in economic terms and adequate levels of safety during operation.

Another interesting perspective is related to the integration between BIM and territorial information systems (GIS). It is precisely in the infrastructural field that this link becomes more significant: the BIM model provides the information that is loaded onto a cartographic database. With this mechanism, a complete system of all the information deriving from the cartographic model and from the monitoring activities is created, which allows to manage maintenance activities in a highly defined and perfectly georeferenced environment.

References

Costin, A., Adibfar, A., Hu, H., Chen, S.S.: Building information modeling (BIM) for transportation infrastructure – literature review, applications, challenges, and recommendations. Autom. Constr. 2018(94), 257–281 (2018). https://doi.org/10.1016/j.autcon.2018.07.001

Singh, P., Sadhu, A.: System identification-enhanced visualization tool for infrastructure monitoring and maintenance. Front. Built Environ. 6, 76 (2020). https://doi.org/10.3389/fbuil.2020.00076

Mirza, S., Ali, M.S.: Infrastructure crisis - a proposed national infrastructure policy for Canada. Can. J. Civ. Eng. 2017, 6 (2017). https://doi.org/10.1139/cjce-2016-0468

Heaton, J., Parlikad, A.K., Schooling, J.: Design and development of BIM models to support operations and maintenance. Comput. Ind. 111, 172–186 (2019). https://doi.org/10.1016/j.compind.2019.08.001(2019)

Becerik-Gerber, B., Jazizadeh, F., Li, N., Calis, G.: Application areas and data requirements for BIM-enabled facilities management. J. Constr. Eng. Manag. 138, 431–442 (2012). https://doi.org/10.1061/(ASCE)CO.1943-7862.0000433

Pärn, E.A., Edwards, D.J., Sing, M.C.P.: The building information modelling trajectory in facilities management: a review. Autom. Constr. 75, 45–55 (2017). https://doi.org/10.1016/j.autcon.2016.12.003

Building Information Models (BIM): How It Has Changed FM. FMLink (2009)

Di Giuda, G.M., Maltese, S., Re Cecconi, F., Villa, V.: Il BIM per la gestione dei patrimoni immobiliari. Linee guida, livelli di dettaglio informativo grafico (LOD) e alfanumerico (LOI). Hoepli, (2017)

Di Giuda, G.M., Pellegrini, L., Schievano, M., Locatelli, M., Paleari, F.: BIM and post-occupancy evaluations for building management system: weaknesses and opportunities. In: Daniotti, B., Gianinetto, M., Della Torre, S. (eds.) Digital Transformation of the Design, Construction and Management Processes of the Built Environment. RD, pp. 319–327. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-33570-0_29

Dell’Acqua, G.: BIM per Infrastrutture Lineari. Ingenio, Tekna Chen (2017)

Dell’Acqua, G.: Infrastructure‐Building Information Modeling: Stato dell’Arte. Le Strade, Ottobre 2016. Casa Editrice la Fiaccola SRL (2016) http://www.lestradeweb.com/

Yabuki, N.: BIM and construction information modeling (CIM) in Japan. In: Proceedings of the International Conference on Computational Design in Engineering, Jeju, Korea, p. 325 (2012)

Japan Construction Information Technology Center, CIM Construction Information Modeling/Management, Japan

Cho, D., Cho, N.S., Cho, H., Kang, K.I.: Parametric modelling based approach for efficient quantity takeoff of NATM-tunnels. Gerontechnology 11(2), 70–75 (2012)

Yabuki, N.: Issues and implementation methods for BIM in the civil infrastructure domain. In: Teng, J.G. (ed) Proceedings of the 1st International Conference on Sustainable Urbanization (ICSU), Hong Kong, China (2010)

Fabozzi, S., Cipolletta, G., Capano, E., Asprone, D., Dell’Acqua, G., Bilotta, E.: BIM-FEM interoperability for the modelling of a traditional excavated tunnel, tunnels and underground cities: engineering and innovation meet archaeology, architecture and art. In: Proceedings of the WTC 2019 ITA-AITES World Tunnel Congress, pp. 785–794 (2019)

Acampa, G., Bona, N., Grasso, M., Ticali, D.: BIM: building information modeling for infrastructures. In: AIP Conference Proceedings, vol. 2040(1), p. 140008. AIP Publishing LLC (2018)

Dell’Acqua, G., De Oliveira, S.G., Biancardo, S.A.: Railway-BIM: analytical review, data standard and overall perspective. Ingegneria Ferroviaria 73(11), 901–923 (2018)

Guerra de Oliveira, S., Tibaut, A., Dell’Acqua, G.: Airport pavement management systems: an open BIM approach. In: Pasetto, M., Partl, M.N., Tebaldi, G. (eds.) ISAP APE 2019. LNCE, vol. 48, pp. 450–459. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-29779-4_44

Campisi, T., Acampa, G., Marino, G., Tesoriere, G.: Cycling master plans in Italy: the I-BIM feasibility tool for cost and safety assessments. Sustainability 12(11), 4723 (2020)

Aritomi, K., Shibasaki, R., Yabuki, N.: The construction management cooperated with clients using a parametric information design method. In: Luo, Y. (ed.) CDVE 2005. LNCS, vol. 3675, pp. 157–165. Springer, Heidelberg (2005). https://doi.org/10.1007/11555223_18

Rebolj, D., Tibaut, A., Čuš-Babič, N., Magdič, A., Podbreznik, P.: Development and application of a road product model. Autom. Constr. 17(6), 719–728 (2008)

Lee, S.H., Kim, B.G.: IFC extension for road structures and digital modeling. Proc. Eng. 14, 1037–1042 (2011)

Cho, G.H., Song, J.K., Ju, K.B.: Analysis of road elements for the extension geometry part of IFC model schema. In: Proceedings of the First International Conference on Civil and Building Engineering Informatics (ICCBEI2013), Tokyo, Japan, pp. 457–460 (2013)

Biancardo, S.A., Russo, F., Veropalumbo, R., Vorobjovas, V., Dell’Acqua, G.: Modeling roman pavements using heritage-BIM: a case study in Pompeii. Balt. J. Road Bridge Eng. 15(3), 34–46 (2020)

Chen, Y.: Modeling and analysis methods of bridges and their effects on seismic responses: II—implementation. Comput. Struct. 59, 99–114 (1996). https://doi.org/10.1016/0045-7949(95)00226-X(1996)

Coni, M., Mistretta, F., Stochino, F., Rombi, J., Sassu, M., Puppio, M.L.: Fast falling weight deflectometer method for condition assessment of RC bridges. Appl. Sci. 11, 1743 (2021). https://doi.org/10.3390/app11041743

Talvik, O., Aavik, A.: Use of FWD deflection basin parameters (SCI, BDI, BCI) for pavement condition assessment. Balt. J. Road Bridge Eng. 4, 196–202 (2009). https://doi.org/10.3846/1822-427X.2009.4.196-202

Horak, E.: Surface moduli determined with the falling weight deflectometer used as benchmarking tool. In: Proceedings of the 26th Southern African Transport Conference (SATC 2007) , South Africa, (2007). ISBN 1-920-01702-X, Document Transformation Technologies cc, Pretoria,

Pozzoli, S., Bonazza, M., Villa, S.W.: Autodesk Revit Architecture 2020. Guida Completa per la Progettazione BIM. Tecniche Nuove, Milano (2019). ISBN 978-88-481-4022-5

Author information

Authors and Affiliations

Contributions

Conceptualization, all; methodology and formal analysis, Luca Curreli, Francesca Maltinti, Mauro Coni, Emanuela Quaquero, Giulia Rubiu; introduction and literary review Luca Curreli, Emanuela Quaquero, Giulia Rubiu; writing-original draft preparation, Luca Curreli, Francesca Maltinti; writing-review and editing Francesca Maltinti, Emanuela Quaquero, Giulia Rubiu; visualization, all. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Maltinti, F., Curreli, L., Quaquero, E., Rubiu, G., Coni, M. (2021). Applying Building Information Modeling to Road Pavements Management. In: Gervasi, O., et al. Computational Science and Its Applications – ICCSA 2021. ICCSA 2021. Lecture Notes in Computer Science(), vol 12958. Springer, Cham. https://doi.org/10.1007/978-3-030-87016-4_11

Download citation

DOI: https://doi.org/10.1007/978-3-030-87016-4_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-87015-7

Online ISBN: 978-3-030-87016-4

eBook Packages: Computer ScienceComputer Science (R0)