Abstract

Supply chains for agricultural products have taken on great importance in recent times due to the need that exists for consumers to acquire fresh products in excellent quality conditions. In the design of supply networks for this type of product, the location of facilities and allocation decisions are among the most relevant decisions in operations management, which in many cases involve aspects of uncertainty. This research proposes to plan the distribution of multiple agro-food products taking into account the location and capacities of producers, potential location of facilities and variations in crop yields. A scenario-based optimization model for the location of multiple uncapacitated facilities is developed. The model is tested in the cassava agro-food chain in Sucre, Colombia. First, the description for the construction of the scenarios for the uncertainty associated with the yield per hectare of cassava crops is presented. Next, the mixed integer programming model (MIP) for the location of uncapacitated facilities (UFLP) is presented. The aim of the model is to minimize operational distribution costs. The results of the case study were obtained with the help of the CPLEX Solver integrated in GAMS in low computational time. A reduction of costs by almost 60% of the distribution costs is obtained.

Corporación Universitaria del Caribe.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

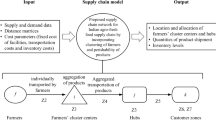

The supply chain (SC) of a typical product starts with material input, followed by production, and finally, distribution of the final product to customers [1]. In [2] define that a SC is composed of all parties involved, either directly or indirectly, with the sole function of satisfying the customer. Similarly, in [3] define the SC as a network of retailers, distributors, transporters, warehouses, and suppliers involved in the production, distribution, and sale of a product to the consumer. In [4] classify SC-related activities into four areas such as sourcing, production, inventory, and transportation/distribution. Therefore, the SC is a distribution network composed of facilities and transportation flows between these facilities. This network fulfills functions such as suppliers, factories, warehouses, distribution centers, among others. Supply Chain Management (SCM) efficiently integrates suppliers, manufacturers, warehouses, and retailers. SCM aims to ensure that products are produced and distributed in the correct quantities, at the locations, and at the time, to minimize system-wide costs while meeting service level requirements [5].

Most studies focus on SCMs dedicated to manufacturing products and services, and only a few studies focus on agricultural products in food supply chains [6]. Therefore, SCM for agricultural products has become relevant in the last decade as Agri-Food Supply Chains (ASC). Unlike other SCMs in ASCs, there is a continuous and significant change in product quality [7]. In addition, products are perishable, prices are sensitive, and high quality is demanded [8]. For SCs involving fresh foods, distribution planning is complex due to the nature and source of the product, the rival interaction between the SC, and the marketplace [9].

Location decisions are strategic and are hard to make for an efficient SC design. In addition, deciding where to locate leads to high facility costs [10]. Therefore, localization problems vary according to the particularity of the cases, the objective, and the constraints that seek to minimize, equalize, or maximize problems. In the literature, this type of problem is called Facility Location problem (FLP) [11]. One of the variants of this model is the uncapacitated FLP (UFLP), called by other names such as uncapacitated, simple, and optimal [12].

Optimization models for ASCs are deterministic or under uncertainty, depending on the type of information in the problem [13]. Several researchers present stochastic approaches to deal with uncertainty for ASC models. However, its application is limited compared to deterministic models [6]. The uncapacitated multiple-warehouse location optimization model proposed in this paper is efficient for handling stochastic interval parameters limited to a range of variance. Additionally, the model presents optimal results of a real case for the cassava supply chain in the department of Sucre, Colombia. The application of operations research in real cases generates complex problems. However, there are alternatives and solution strategies that allow obtaining optimal or efficient results. A statistical analysis of the yield behavior of cassava crops (industrial and sweet) in the last ten years is performed for the case study. The intervals are grouped according to [14], taking the class mark as the scenario value. A tree with 16 possible scenarios in the yields of sweet and industrial cassava crops is constructed. The study problem is solved using the General Algebraic Modeling System (GAMS) software with the CPLEX solver, generating optimal results in low computational times. Another differentiating factor of the study carried out in the cassava agro-food chain is to consider the crop yield with a probabilistic behavior due to its dependence on environmental factors. This type of consideration allows for early warning of food safety management [14].

The remainder of this document is structured as follows. Section 2 provides a brief review of the literature. Section 3 defines the mathematical model. Section 4 presents the elements of the cassava agro-food supply chain as a case study. Section 5 details the experimental results. Finally, the conclusions of the model, the case study, and future research lines are summarized in Sect. 6.

2 Related Literature

The FLP is a combinatorial optimization problem[15] that aims to minimize the location and service cost associated with facilities [16]. One of the variants of this problem is UFLP, which is Np-hard framed within binary optimization [17]. This variant considers that the capacity of the facility is unlimited, giving fulfillment of all customer demand [17, 18]. Some UFLP models aim to optimize transportation costs and minimize opening costs [19]. In addition, to consider more realistic situations, uncertainty is included in some parameters, such as demand [16]. Different approaches have been developed in the literature to solve this type of problem, such as mixed integer programming [20], dynamic programming [21], and quadratic programming [19]. These techniques are efficient with the simple structure of the problem and generate results in low computational times [17]. However, given the Np-hard nature, some approximate methods have been developed.

To solve the UFLP, [12] apply Tabu Search (TS) by obtaining efficient solutions on a test data set from the literature. The results are compared with optimal solutions to check the efficiency of the algorithm. Similarly, [15] apply TS and compare it with approaches such as the Lagrangian method showing better results. For real cases, [22] solve the UFLP by implementing a discrete variant of the metaheuristic called Unconscious Search (US). This approach presents three steps: construction, construction review, and local search. The results obtained show a high performance compared to other algorithms. [17] develop an improved scatter search (ISS) based on the scatter search algorithm (SS). The method presents improvements oriented to the application of different techniques of crossover and mutation of the best solutions found in the local search. The algorithm is compared with other metaheuristics such as Genetic Algorithm (GA), Particle Swarm Optimization (PSO), Artificial Bee Colony (ABC), Differential Evolution (DE), Tree-Seed Algorithm (TSA), and Artificial Algae Algorithm (AAA), showing better solutions.

2.1 Optimization Model Under Uncertainty

Network design models involving uncertainty aspects are divided into three main groups: i. conditions where the uncertainty factor is considered. ii. models based on the probabilistic approximation that represents random variables with known probability distributions. iii. scenario-based approximation [23]. In the latter approach, a discrete number of scenarios of the random parameters represents the uncertainty of the SC. Similar to [24], a scenario tree representing the possible realizations of the stochastic parameters is constructed. Each path from the root to one of the leaves represents a particular scenario; a scenario is a realization of the uncertain parameter along the stages at a given time [25]. For the probability associated with each scenario, [26] states that \(\Omega \) represents the set of all possible outcomes of the experiment. Also, probability is defined as an application such as and \(P(\Omega )=1\) y \(P(A_1\cup A_2)= P(A_1) +P(A_2)\).

3 Model Description

The uncapacitated location model for distribution planning in an agri-food supply chain presents the following assumptions. i. there are multiple products, ii. the location of producers (suppliers), distributors, processing plants, and warehouses is known. iii. the yield of products per hectare cultivated has a stochastic behavior. iv. warehouse capacities are infinite. v. flows are allowed only between two consecutive echelons in the chain, and no flows are allowed between elements of the same echelon, nor skipping echelon. vi. production and transportation costs are deterministic. The entire quantity of sweet cassava flows to the distributors through the warehouses. Finally, the shipment from the warehouses to the customers uses vehicles with a capacity of 30 tons. The index, parameters, and decision variables used in the formulation of the model are detailed below (Tables 1 and 2).

Equation (1) minimizes distribution costs in logistics operations from producers to distributors and processors through the facilities. Constrain (2) and (3) guarantees that no flow takes values above the possible quantities to be produced. Constrains (4) and (5) ensure demand compliance. Constrains (6) and (7) limit the number of facilities to be opened. Constrains (8) and (9) give viability to fixed cost generation in open facilities. Finally, constrains (10), (11) and (12) correspond to the restrictions of non-negative and binary admissible values for decision variables.

s.t.

4 Description of the Case Study

The Department of Sucre, Colombia, is agriculturally oriented. The agricultural sector is the second-largest contributor to the Gross Domestic Product (GDP). One of the most representative crops of Sucre is the cassava [27]. Cassava is a plant that supplies a high-carbohydrate tuber. Two types of cassava are grown in Sucre, industrial and sweet, most of the M-Tai and Venezuelan varieties, respectively; the latter is for human consumption. The product flow begins with the production of cassava roots during the cultivation stage. At this stage, there is seed selection, sowing, crop maintenance, and finally, harvesting. There is a great uncertainty linked to crop yields due to the variety of soils, environmental conditions, and the level of technical labor. Harvesting is generally in rural areas that are difficult to access, so it is necessary to transport the crop in tractor vehicles to the municipalities and store it in the open air. Subsequently, once the required quantity is available, the cassava roots are transported in larger trucks. Purchasing agents plan the sweet cassava process. The activities correspond to the purchase and sale of different distribution centers located mainly in Sincelejo, Corozal, Cartagena, and Barranquilla. One of the biggest problems in the SC is storage without the necessary measures to maintain product quality.

On the other hand, industrial cassava is transported to processors to obtain native starch used as raw material in various sectors. A by-product of cassava is cassava chips for animal feed production. Currently, the scheduling of cassava root harvesting and distribution activities depends mainly on the empirical experiences of producers and purchasing agents. It is difficult to achieve an optimal scheduling sequence and operation of the SC due to the limitations of human judgment. Therefore, it is necessary to formulate a multi-facility location optimization model to improve logistics operations. This model aims to minimize the total costs of the system, model the uncertainty present in the chain, and improve the food safety of the product. Therefore, it includes an echelon between producers, processing plants, and distributors. Figure 1 shows a diagram of the cassava agri-food supply chain in Colombia. The echelons demarcated by the dots are those that have direct relevance in the department of Sucre.

4.1 Identification and Determination of Uncertain Parameters

This research uses the scenario analysis methodology as shown in Sect. 2.1 to recreate the yield variability of sweet and industrial cassava crops. The analysis of sweet cassava crop yield variations for 2007–2017 is in Fig. 2(a). The average is in the range of 8 to 12 tons/ha. As time has passed, yield variations have decreased. For industrial cassava, the average is in the range from 15 tons/ha to approximately 18 tons/ha (see Fig. 2(b)). In addition, the crop has not varied considerably between the years included in this period. However, in 2012, no yield information was obtained for this crop, as reported by Agronet [28].

The yield behavior of sweet and industrial cassava crops in Sucre presents a variability associated with a degree of uncertainty. Based on this, it is necessary to build scenarios to represent the uncertainty [29]. Statistical analysis was performed in Statgraphics Centurion XVII software. Figure 2(c) shows the histogram of sweet cassava yields grouped into four intervals [30]. The height of the bars denotes the absolute frequency of the yield data, representing the probability for the scenarios. There is a higher height in the range between 8.25 and 13.5 and a class mark or midpoint of 10.875 ton. The histogram of industrial cassava yields is shown in Fig. 2(d). The interval with the highest height equivalent to 33 data points in the range 17.5–23.7 and a class mark or midpoint of 20.625. Subsequently the scenario tree is developed by taking the class marks of each interval as an event of the possible outcomes (i.e., there are four intervals for sweet cassava yield and four intervals for industrial cassava yield, leading to 16 scenarios in total, represented as\( RDYD_n\) and \(RDYI_m\); where n and m \(={1,2,3,4} \)). The probabilities are shown in Table 3.

5 Computational Results

The model is coded in GAMS software and solved with the CPLEX solver. A computer with a 2.2 GHz Intel Core I5 - 5200U processor, 8 GB of RAM, and a Windows 10 Professional operating system is used. The model considers 254 cassava producers in the Sabana and Montes de María subregions. 103 produce sweet cassava \((i) i\in L^1; L^1 \subset L \) and 151 produce industrial cassava \((j) j\in L^2; L^2 \subset L\). In addition, eight warehouses (Q) are being evaluated, with potential locations in the municipalities of San Juan de Betulia, Ovejas, Corozal, Sincelejo, San Pedro, Sincé, Galeras, and Los Palmitos. As a strategic decision, our model proposes to open a maximum of 4 warehouses. As a strategic decision, our model proposes to open a maximum of 4 warehouses. It also considers 21 processors (K) and five distributors (H), including the municipal markets of Corozal and Sincelejo, and the collection centers located in Monteria, Cartagena, and Barranquilla. The parameters and variables correspond to production costs, transportation costs, availability of area for growth, demand, and production quantities closely linked to yields in each of the scenarios. The period considered in this case study is four months (October, November, December, and January). This period corresponds to the cassava root harvest in the department of Sucre.

Yield variability of sweet and industrial cassava crops generates two conditions. The first corresponds to an average yield scenario called ESC PROME. Yield variability of sweet and industrial cassava crops generates two conditions. The first corresponds to an average yield scenario called ESC PROME. The second condition corresponds to 16 scenarios, called ESC PROB that contemplate the variability and probability associated with each one (Table 4). For ESC PROME, the objective function generates distribution costs of $ COP 36,068’981,374. A total of three warehouses are opened. The solution is obtained in 388 iterations, a relative GAP of 0.5%, and a computational time of 1.92 s.

For ESC PROB, the objective function minimizes distribution costs by COP $ 58,718’387,753 with the opening of four warehouses. The solution has 9755 iterations, a relative GAP of 0.1%, and a computational time of 22.3 s. Table 5 presents the comparison between the average scenario solution and the solution obtained under uncertainty conditions as proposed by [27]. This comparison consists of simulating what happens in a particular scenario where is present and calculating the objective function that reports evaluating the solution vector of the probabilistic scenario (ESC PROB) at. This value is compared with the one obtained by evaluating the solution vector of the average scenario in. The comparison is made for each of the scenarios in the tree.

In this sense, if scenario 13 occurs, the solution of the average scenario replaced in the objective function of scenario 13 presents a value of ESC PROM = $COP 35,569’658,879. On the other hand, the solution of the probabilistic model associated with scenario 13, if replaced in the objective function for this scenario, yields a result for ESC PROB = COP $35,112’758,888. The absolute difference GAP ABS = ESC PROB - ESC PROM is $COP 456’899,991. Therefore, for this scenario, the solution obtained in ESC PROB is 1.28% better than ESC PROM. Thus, the solution under uncertainty conditions is better than the average scenario solution.

Warehouse capacities correspond to the amount of product passing through the warehouse. The minimum capacity for establishing warehouses corresponds to the scenario where the yield per hectare is lower (Scenario 1). The maximum capacity of the warehouse corresponds to the amount of distribution in the highest yield scenario (Scenario 16). The harvest period is four months (in this study, it represents one year of production). The calculation of the daily capacities consists of dividing the annual quantity into the corresponding months. The warehouse with the highest capacity in the 16 scenarios is in the municipality of Ovejas, with a minimum capacity of 245 tons/day and a maximum capacity of 817 tons/day.

In addition, to observe the impact generated on the costs associated with the distribution of the cassava agri-food chain in Sucre, a new scenario is created that compares the current conditions of the CS. The new scenario prioritizes a producer with one hectare of land devoted to the crop with a yield of 5,625 tons/ha and a production of 5625 tons of sweet cassava. Given the current conditions, this product is sent using a tractor to the nearest town (in this case, the municipality of Sincé). Later, it is transported in a truck to the distributor (Corozal’s public market). However, the model solution recommends shipping the product through warehouse number eight, located in Los Palmitos. Then, ship the product to the Corozal market. Distribution costs are shown in Table 5. In addition, warehouse administration and management costs are considered (20% of operating costs).

6 Conclusions

This paper presents an unconstrained model for the location of agri-food supply chain facilities applied to a real case study corresponding to cassava production in the department of Sucre. The model incorporates the variations that occur in yields in tons per hectare due to the environmental conditions of the department, soil characteristics, and crop management. In addition, the model is multi-product and evaluates a chain in a department with deficiencies in the protection of environmental and mechanical risk factors of the product in the processes of packaging, storage, transportation, and post-harvest handling. The solution proposes the opening of four warehouses to provide strategic support to logistics operations in the SC. The expected costs correspond to COP $ 58,718’387,753. The results show a low computational time, a relative optimality tolerance of 10% (optcr = 0.1), and a relative gap equal to 0.001430. Based on the scenario recreated with the first cassava producer, the model generates a decrease of approximately 60% in distribution costs.

For future research, it is necessary to use scenarios to represent the individual variability of crop yields in each producer. Another uncertain factor in this type of model is the selling price. Similarly, it is necessary to include environmental parameters such as water availability and a method of post-harvest product preservation.

References

Chen, Z.-L.: Integrated production and distribution operations. In: Simchi-Levi, D., Wu, S.D., Shen, Z.J. (eds.) Handbook of Quantitative Supply Chain Analysis, pp. 711–745. Springer, Boston (2004). https://doi.org/10.1007/978-1-4020-7953-5_17

Chopra, S., Meindl, P.: Administración de la cadena de suministro. Pearson educación (2013)

Muñoz Aguilar, R.A., Roldan Zuluaga, S.: Competitividad Y Cadenas De Abastecimiento En El Sector Productivo Del Valle Del Cauca, Colombia (competitiveness and supply chain in the productive sector of Valle Del Cauca, Colombia). Revista Global de Negocios 4(1), 77–87 (2015)

Reina, M.L., Adarme, W.: Logística de distribución de productos perecederos: estudios de caso Fuente de Oro (Meta) y Viotá (Cundinamarca). Rev. Colomb. Ciencias Hortícolas 8(1), 80–91 (2017)

Simchi-Levi, D., Kaminsky, P., Simchi-Levi, E., Shankar, R.: Designing and Managing the Supply Chain: Concepts, Strategies and Case Studies. Tata McGraw-Hill Education, New York (2008)

Paam, P., Berretta, R., Heydar, M., Middleton, R.H., García-Flores, R., Juliano, P.: Planning models to optimize the agri-fresh food supply chain for loss minimization: a review. Ref. Module Food Sci. (2016)

Ahumada, O., Villalobos, J.R.: Application of planning models in the agri-food supply chain: a review. Eur. J. Oper. Res. 196(1), 1–20 (2009). https://doi.org/10.1016/j.ejor.2008.02.014

Salin, V.: Information technology in agri-food supply chains. Int. Food Agribus. Manag. Rev. 1(3), 329–334 (1998). https://doi.org/10.1016/S1096-7508(99)80003-2

Amorim, P., Günther, H.-O., Almada-Lobo, B.: Multi-objective integrated production and distribution planning of perishable products. Int. J. Prod. Econ. 138(1), 89–101 (2012). https://doi.org/10.1016/j.ijpe.2012.03.005

Daskin, M.S., Snyder, L.V., Berger, R.T.: Facility location in supply chain design. In: Langevin, A., Riopel, D. (eds.) Logistics Systems: Design and Optimization, pp. 39–65. Springer, Boston (2005). https://doi.org/10.1007/0-387-24977-X_2

Solimanpur, M., Kamran, M.A.: Solving facilities location problem in the presence of alternative processing routes using a genetic algorithm. Comput. Ind. Eng. 59(4), 830–839 (2010). https://doi.org/10.1016/j.cie.2010.08.010

Al-Sultan, K.S., Al-Fawzan, M.A.: A tabu search approach to the uncapacitated facility location problem. Ann. Oper. Res. 86, 91–103 (1999). https://doi.org/10.1023/A:1018956213524

Min, H., Zhou, G.: Supply chain modeling: past, present and future. Comput. Ind. Eng. 43(1), 231–249 (2002). https://doi.org/10.1016/S0360-8352(02)00066-9

Everingham, Y.L., Muchow, R.C., Stone, R.C., Inman-Bamber, N.G., Singels, A., Bezuidenhout, C.N.: Enhanced risk management and decision-making capability across the sugarcane industry value chain based on seasonal climate forecasts. Agric. Syst. 74(3), 459–477 (2002). https://doi.org/10.1016/S0308-521X(02)00050-1

Sun, M.: Solving the uncapacitated facility location problem using tabu search. Comput. Oper. Res. 33(9), 2563–2589 (2006). https://doi.org/10.1016/j.cor.2005.07.014

De Armas, J., Juan, A.A., Marquès, J.M., Pedroso, J.P.: Solving the deterministic and stochastic uncapacitated facility location problem: from a heuristic to a simheuristic. J. Oper. Res. Soc. 68(10), 1161–1176 (2017). https://doi.org/10.1057/s41274-016-0155-6

Hakli, H., Ortacay, Z.: An improved scatter search algorithm for the uncapacitated facility location problem. Comput. Ind. Eng. 135, 855–867 (2019). https://doi.org/10.1016/j.cie.2019.06.060

Verter, V.: Uncapacitated and capacitated facility location problems. In: Eiselt, H.A., Marianov, V. (eds.) Foundations of Location Analysis. ISORMS, vol. 155, pp. 25–37. Springer, New York (2011). https://doi.org/10.1007/978-1-4419-7572-0_2

Ramshani, M., Ostrowski, J., Zhang, K., Li, X.: Two level uncapacitated facility location problem with disruptions. Comput. Ind. Eng. 137, 106089 (2019). https://doi.org/10.1016/j.cie.2019.106089

Mousavi, S.M., Vahdani, B., Tavakkoli-Moghaddam, R.: Optimal design of the cross-docking in distribution networks: heuristic solution approach. Int. J. Eng. 27(4), 533–544 (2014). https://doi.org/10.5829/idosi.ije.2014.27.04a.04

Cortinhal, M.J., Lopes, M.J., Melo, M.T.: Dynamic design and re-design of multi-echelon, multi-product logistics networks with outsourcing opportunities: a computational study. Comput. Ind. Eng. 90, 118–131 (2015). https://doi.org/10.1016/j.cie.2015.08.019

Ardjmand, E., Park, N., Weckman, G., Amin-Naseri, M.R.: The discrete Unconscious search and its application to uncapacitated facility location problem. Comput. Ind. Eng. 73(1), 32–40 (2014). https://doi.org/10.1016/j.cie.2014.04.010

Escobar, J.W.: Rediseño de una red de distribución con variabilidad de demanda usando la metodología de escenarios. Rev. Fac. Ing. 21(32), 9–19 (2013)

Quinteros, M., Alonso, A., Escudero, L., Guignard, M., Weintraub, A.: Una aplicación de programación estocástica en un problema de gestión forestal. Rev. Ing. Sist. XX (2006)

Alonso-Ayuso, A., Escudero, L.F., Guignard, M., Weintraub, A.: On dealing with strategic and tactical decision levels in forestry planning under uncertainty. Comput. Oper. Res. 115, 104836 (2020). https://doi.org/10.1016/j.cor.2019.104836

Ramos, A., Alonso-Ayuso, A., Pérez, G.: Optimización bajo incertidumbre. Universidad Pontificia Comillas (2011)

de Económico, S.: Encuesta Nacional Agropecuaria de los periodos 2007 a 2017 (2018)

Agronet: Base Agricola EVA 2007 - 2017 (2017). http://www.agronet.gov.co/estadistica/Paginas/default.aspx. Accessed 4 Oct 2018

Govindan, K., Fattahi, M., Keyvanshokooh, E.: Supply chain network design under uncertainty: a comprehensive review and future research directions. Eur. J. Oper. Res. 263(1), 108–141 (2017). https://doi.org/10.1016/j.ejor.2017.04.009

Martínez Bencardino, C.: Estadística y muestreo. e-libro, Corp. (2012)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Mendoza-Ortega, G.P., Soto, M., Ruiz-Meza, J., Salgado, R., Torregroza, A. (2021). Scenario-Based Model for the Location of Multiple Uncapacitated Facilities: Case Study in an Agro-Food Supply Chain. In: Figueroa-García, J.C., Díaz-Gutierrez, Y., Gaona-García, E.E., Orjuela-Cañón, A.D. (eds) Applied Computer Sciences in Engineering. WEA 2021. Communications in Computer and Information Science, vol 1431. Springer, Cham. https://doi.org/10.1007/978-3-030-86702-7_33

Download citation

DOI: https://doi.org/10.1007/978-3-030-86702-7_33

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-86701-0

Online ISBN: 978-3-030-86702-7

eBook Packages: Computer ScienceComputer Science (R0)