Abstract

Agri-food production must increase while food waste needs to be reduced for improving the position of farmers. To do so it is necessary to sustainably manage agri-food supply chains beginning with the crop planning decisions. Although the centralized approach has usually been adopted for this purpose, it can lead to unfair solutions due to inequitable distribution of profits among farmers causing their unwillingness to collaborate in the implementation of decisions made. To solve this, in this paper a novel centralized multi-objective mathematical programming model is proposed to support the sustainable crop planning definition for a region that jointly optimize three objectives aligned to the sustainability aspects: supply chain profits maximization (economic objective), waste minimization (environmental objective) and unfairness among farmers minimization (social objective), being the last two objectives novel in the crop planning literature. It has also shown the conflicting nature of the three objectives finding trade-offs among them. Other novelties of this proposal are: (1) anticipation of operative decisions (such as harvest, transport, sale, clearance sale, waste and unmet demand) when defining the crop planning, (2) possibility of clearing the oversupply of crops as a means of increasing the farmers’ profits and reducing waste, and (3) the modelling of a agri-food supply chain characterized by the lack of intermediaries between farmers and retailers, fostering the freshest product delivery and farmers’ power position. The model is solved by applying the weighted sum method concluding that the crop waste generated along the chain and the unfairness among farmers can be considerably reduced by little decreasing the optimal SC profits.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

According to the Food and Agriculture Organization (FAO) the agri-food production must increase by 60% by 2050 to meet the demand of a growing population while reducing food waste which amounts for a third of production (Azevedo et al. 2018). To achieve these objectives, at least the production and distribution planning and inventory management should be done sustainably (Banasik et al. 2018).

Existing models to support decision making in agri-food supply chains (AFSC) mainly focus on economic and environmental aspects (Seuring and Müller 2008) by minimizing emissions or water consumption (Djekic et al. 2018; Fang et al. 2018; Anastasiadis et al. 2018). However, the importance of considering social sustainability when managing AFSC has been recognised (Pourhejazy and Kwon 2016). It is necessary to develop new mathematical programming models to sustainably manage AFSC that can adjust to the new context arising in the sector.

One current trend in fresh agri-food sector is to operate with short AFSC characterized by the reduction of intermediaries and use of transport, and the proximity sales predominance, which improves the local social and economic benefits (Pérez-Mesa et al. 2019) and diminishes the environmental impact due to the reduction of travelling distances and gas emissions. For that, a direct relationship between farms and retailers, who represent the end consumers’ demand (Esteso et al. 2018a, b), is established. This additionally improves the competitiveness of small farmers by removing the gains obtained by intermediaries.

Until recently, and to maintain the freshness and quality of products, retailing workers collected all fresh products from shelves at the end of each day, stored them in a refrigerated storage, and reorganized and placed the fresh products again on shelves at the beginning of the following day. This way of operating implied a high cost related to the existence of a refrigerated storage at retailers, to the energy consumption, and to the workers costs. However, the new agri-food context aims to improve the freshness of products delivered reducing at the same time these operation and inventory costs derived from handling fresh products at the retailer. For that, all products received at a retailer in one period need to be sold to avoid the possibility of storing fresh products from one period to the following not incurring, therefore, in handling and storage costs between periods. This way of operating implies the need of increasing collaboration among farmers and developing more exact demand forecasts with the aim of adjusting supply to demand, as well as to create mechanisms to sell the excess of supply in order to minimize waste. Some examples of these mechanisms are the clearance sales of products at the end of the day, promotions, or the change of location of products in the shop.

In this context, a commonly adopted approach to balance the supply and demand of crops in AFSCs that leads to the best results for the supply chain as a whole (Stadtler 2009) is the centralized decision-making. This approach implies members of the supply chain to accept and implement decisions made. However, the centralized decision-making usually originates inequalities in the distribution of profits among members of the supply chain (Moon et al. 2018; Zaraté et al. 2019). Supply chain members may not be inclined to collaborate if they feel there is injustice in the distribution of profits, being impossible to implement the centralized decisions. In addition, authors such as Ajmal et al. (2018) identify the fairness feeling as one of the core social factors that drive the sustainability of organizations. Therefore, ensuring fairness in the distribution of profits among farmers contributes, not only to the social pillar of sustainability, but also to the implementation of centralized decisions, and therefore to the maximization of profits, the minimization of waste and unmet demand, promoting the sustainability of the supply chain.

It draws attention that despite the extensive research adopting a centralized decision-making, we have only found one paper dealing with the unfairness in the agricultural sector. For that, Li et al. (2015) introduced in their centralized model to define a crop rotation scheduling for an investor that offer contracts to small farmers, some constraints limiting the difference in profits obtained among farmers. However, these authors did not try to reduce the unfairness by optimizing its value.

To fill this gap, in this paper a centralized model is proposed in which the unfairness in the distribution of profits among farmers is minimized that is aligned with the with the following specific objective of the Common Agricultural Policy (CAP): Improve farmers’ position in the value chain (European Commission 2018) through the development of tools for a mutually beneficial cooperation, that allows the integration of the producers and consumers needs in a practical approach, minimizing the margins obtained by intermediaries, and contributing to an equitable distribution among farmers and to the sustainability.

For that, this paper proposes a novel multi-objective model to support the sustainable perishable crop planning of an AFSC operating in this agri-food context and accounting objectives aligned to sustainability aspects: profits maximization, and the minimization of waste and unfairness among farmers. The detailed description of the novelties of this study can be consulted at the end of Sect. 3.

The rest of the paper is structured as follows: Sect. 2 describes the problem under study. A literature review of optimization models addressing similar problems is made in Sect. 3. Section 4 proposes the multi-objective model designed to address the problem. Section 5 analyses the main results of the model and Sect. 6 outlines main conclusions and future research lines.

2 Problem description

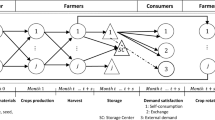

One current trend in the agri-food sector is to reduce the intermediaries between farms and retailers to improve the power position of farmers, reduce transport, storage, and operation costs and to increase the freshness of the product delivered. In this context, the AFSC under study is characterized by the lack of intermediaries between farms and retailers, so it is comprised by a set of farming locations and retailers directly linked that produces and commercializes multiple perishable crops (Fig. 1).

At the farmers’ stage the crop planning problem is addressed that consists in selecting the crops to be planted by farmers and defining the area allocated to each of them (Dury et al. 2012). In order to synchronize supply and demand, it is necessary to anticipate jointly with planting decisions more operative ones, such as the time periods and quantities to harvest and their transport through the AFSC with the aim of satisfying demand not only in the right quantity but also at the right time and freshness.

On their part, retailers sell products to end consumers. Retailers avoid storing fresh products from one period to the following one in order to sell fresher products and to eliminate costs related to the handling and storage of products. Therefore, to balance supply and demand at the retailer level is also essential to minimize the generation of waste and unmet demand. Therefore, in cases of oversupply, a new demand for the excess of product can be generated by using a clearance sale strategy (Sebatjane and Adetunji 2021). Products not sold or cleared are finally wasted.

It is important to note, that the problem under study and the considered assumptions are derived from real problems and practices identified in the framework of an European project (RUC-APS 2016) being most of them also supported by previous research. Therefore, the following assumptions are considered in our problem that are in concordance with real-life practices:

-

Each farmer disposes one location with a determined available planting area (Ahumada et al. 2012).

-

Farmers define the area to be planted in their location with each crop per period (Dury et al. 2012). Periods in which it is possible to plant each crop are known.

-

The total area planted with all crops cannot exceed the available area at the location (Nguyen et al. 2019).

-

Due to technical reasons, a minimum area needs to be planted per crop and period when it is decided to do so (Tan et al. 2017).

-

Harvest periods for each crop depend on the planting period. The quantity of product to be harvested, or yield of the crop plant, depends on its planting and harvest date (Zaraté et al. 2019).

-

All matured product has to be harvested when it is mature so no product can be left on the plant (Ahumada and Villalobos 2011b).

-

Farmers have all the necessary resources (such as machineries) to carry out the planting, cultivation and harvesting of crops.

-

Products need to be transported to retailers in the same period of their harvest (Ahumada and Villalobos 2011b).

-

Harvested products that are not transported to retailers, are wasted at the farming location.

-

Trucks are used to transport products from farming locations to retailers. Trucks are rented so a fixed cost is related to their use (Blanco et al. 2010). There is also a variable cost dependent on the distance between locations and the crops transported (Jonkman et al. 2019).

-

To use one truck a minimum percentage of the cargo capacity needs to be loaded.

-

Due to the high perishability of crops, products transported to retailers are sold (Darby-Dowman et al. 2000) or wasted (Mason and Villalobos 2015) in the same period of their arrival. Consequently, no inventory is allowed between periods, and therefore, no handling nor holding costs are considered.

-

If there is an excess of supply, waste can be reduced by looking for new demand for the clearance sale of crops with lower prices. Demand for cleared products is limited by a percentage of demand.

-

A minimum level service is ensured when meeting the demand of each crop (Flores et al. 2019).

-

If supply is lower than demand, unmet demand is produced and penalized in the economic objective function (Forrester et al. 2018).

-

The crop planning objectives are aligned to the three pillars of sustainability: maximize AFSC profits, minimize crop waste, and minimize economic unfairness among farmers.

-

Farmers perceive unfairness when there is a difference between the profit per hectare obtained by farmers and the mean profit per hectare for the farming region.

When facing the above problem farmers use to make crop planning decisions individually increasing the production of the most profitable crops of the previous season. This leads to the existence of some crops with overproduction and others with under production in the next season resulting in high levels of waste and unmet demand, respectively. Coordination among farmers’ decisions is necessary to balance supply and demand reducing, therefore, waste and unmet demand (Prima Dania et al. 2018), and consequently benefiting farmers, consumers, and the environment (Suthar et al. 2019).

For this purpose, a centralized decision-making approach in a multi-farmer context is usually adopted. It is noteworthy that centralized approaches can produce economic inequalities among farmers also known as economic unfairness (Li et al. 2015), leading to the unwillingness of farmers to collaborate. Therefore, when implementing a centralized decision-making in a multi-farmer context, it is necessary to take this aspect into account.

In this paper a centralized multi-objective model is proposed that aims to support the crop planning, harvest and transport decisions at the farm level, as well as the sale, clearance sale, and waste decisions, at the retailer level. The proposed model aims to optimize three objectives aligned to the three pillars of sustainability, which are: (1) maximization of AFSC profits (economic), (2) minimization of products’ waste (environmental), and (3) minimization of economic unfairness among farmers (social).

In this context, this paper seeks to answer the following research questions (RQ):

-

RQ1.

Which optimization model can be developed to support the crop planning decisions for a multi-farmer and multi-retailer agri-food supply chain with the described characteristics?

-

RQ2.

Are the defined objectives (maximization of AFSC profits, minimization of waste, minimization of economic unfairness among farmers) in conflict among them?

-

RQ3.

Is it possible to find a satisfactory solution for all the objectives (maximization of AFSC profits, minimization of crops’ waste, minimization of economic unfairness among farmers) despite their conflicting character?

-

RQ4.

Has the clearance sale of the excess of supply a positive impact on the supply chain profits, waste and economic unfairness among farmers?

3 Literature review of crop planning and harvest models

In this section, mathematical programming models addressing the crop planning problem while considering the crops demand are analysed to identify the already modelled features and gaps in literature related to the problem under study.

Note that it is not intended to provide in-depth details of all features of reviewed models, but only those closely linked to the problem under study. The used framework to analyse selected models was divided into six dimensions related to the described problem: (1) problem type; (2) number of products; (3) horizon, (4) model type, (5) objectives, and (6) modelling approach. The results of this analysis are displayed in Tables 1 and 2, where differences between existing models and the proposed in this paper are also highlighted. In addition, conclusions reached after analysing these tables and relevant specific characteristics of analysed models are explained hereunder.

Most models addressing the crop planning problem do not take into account decisions related to the harvest (32% of models), transport (24% of models) or sales (15% of models) of products. Moreover, the joint modelling of these decisions is only considered in 11% of models. Considering these decisions is necessary to determine the commercialization of products and to anticipate the future balance between supply and demand of products at end consumers. Indeed, few papers model what happens when an imbalance between supply and demand is produced such as the generation of waste (3% of models) or unmet demand (9% of models). It is remarkable that none of the analysed models consider the possibility of clearing the oversupply of crops in order to reduce waste and costs associated to the management of perishable products at retailers, which is arising as a new and important trend in the agri-food sector. This paper aims to fill this gap by modelling the possibility of clearing the oversupply of crops. Therefore, the modelling of the crop’s clearance sale as well as the joint modelling of crop planning, harvest, transport, sales, waste, and unmet demand decisions are novelties for the crop planning literature.

Approximately half of analysed models consider a one period planning horizon and only support decisions related to the crop planning problem. However, given the perishability of crops and the impact that crop planning decisions have on the future supply of crops, it is important to take into account the multi-period approach when addressing the harvesting and distribution decisions jointly with the cropping plan ones to satisfy the market demand. This aspect is even more crucial when limited capacity of resources per period exist for implementing more operative decisions being necessary to efficiently plan their use. For this reason, in this paper, a multi-period horizon is contemplated.

Most models (71% of models) optimize only one objective when addressing the crop planning problem, considering only one aspect of sustainability. Meanwhile the rest of papers consider more than one objective related to the same (12% of models) or different (17% of models) aspects of sustainability. It is remarkable that only one paper optimizes objectives related to the three aspects of sustainability. The 85% of models optimize economic objectives such as the maximization of profits (41% of models), expected profits (24% of models), gross margin (9% of models), net value (3% of models) or the minimization of economic risk (12% of models), working capital (6% of models) or costs (6% of models). The 29% of models optimize environmental objectives such as the minimization of land use (15% of models), environmental risks (6% of models), water consumption (9% of models), fertilizers and pesticides use (3% of models), or the maximization of water productivity (3% of models) and vegetation coverage (3% of models). Finally, the 9% of models consider social objectives such as the minimization of unmet demand (3% of models), or the maximization of crop production (3% of models), employment (3% of models) or food safety (3% of models). The model proposed in this paper optimizes three objectives related to the three aspects of sustainability, which are the maximization of supply chain profit (economic objective), minimization of waste (environmental objective) and minimization of economic unfairness among farmers (social objective). According to the literature revised, these last two objectives are modelled for the first time, in the crop planning literature, in this paper.

The analysed papers propose centralized models to support the mentioned decision-making processes. However, unless all lands belong to the same farmer, obtained solutions would be difficult to implement in a real agri-food supply chain since the centralized decision making usually produces inequalities among the supply chain members (Ertogral and Wu 2000) leading to the unwillingness of farms to collaborate. In order to reduce such inequalities, and therefore to make the obtained centralized solution implementable and interesting for farmers, this paper minimizes the economic unfairness among farmers.

As mentioned before, it is remarkable that none of the analysed models considered the reduction of waste and unfairness among farmers as objectives nor constraints of the model while these aspects are fundamental for the Sustainable Development Goals (SDG) set by the United Nations (2019).

In short, the main novelties of our proposal as regards the revised literature are: (1) modelling of an agri-food context characterized by the lack of intermediaries between farmers and retailers, shortening the supply chain, increasing the freshness of products delivered and improving the farmers’ position, (2) joint modelling of more operative decisions such as harvest, transport, sales, clearance sales, waste, and unmet demand decisions when defining the crop planning, (3) possibility of clearing the oversupply of crops assessing their impact on the improvement of the supply chain profits and generated waste, (4) modelling of a multi-objective approach aligned to the three dimensions of sustainability: the profits maximization (economic dimension), the waste minimization (environmental dimension), and the minimization of the economic unfairness among farmers (social objective) as a mean also to foster the implementation of centralized decision, (5) determination of the conflict between these objectives and (6) identification of trade-offs among them.

4 Multi-objective model formulation

This section aims to formulate an optimization model to support the crop planning problem in an AFSC with the characteristics described in previous sections, giving answer to the Research Question 1: Which optimization model can be developed to support the crop planning decisions for a multi-farmer and multi-retailer agri-food supply chain with the described characteristics?

The nomenclature used to formulate the model is exposed in Table 3, where \(c\) refers to crops, \(p\) to planting periods, \(t\) to time period, \(l\) to farming locations, \(r\) to retailers and \({PT}_{cp}\) to the set of periods \(t\) in which crop \(c\) planted in period \(p\) can be harvested.

4.1 Objective functions

Three conflicting objectives represent the three aspects of sustainability: economic, environmental, and social.

The economic objective, called \(Z_{EC}\), maximizes the supply chain profits (1). Profits are comprised by sales, clearance sales, costs derived from planting, cultivating, harvesting, and transporting product, and economic penalizations for unmet demand.

The environmental objective, called \(Z_{ENV}\), minimizes crop waste at farming locations and retailers (2).

Finally, the social objective, called \(Z_{SOC}\), minimizes the economic unfairness among farmers. Farmers perceive unfairness when there is a difference between the profit per hectare that they obtain and the mean profit per hectare obtained in the region. Therefore, the economic unfairness is calculated as the absolute difference between the mean farming profits per hectare and the profit per hectare for each farming location (3). The overall profit of farming locations (4) and the profit for each farming location \(l\) (5) are composed by their sales of crops to retailers, transport costs, and planting, cultivation and harvest costs.

4.2 Constraints

Set of constraints (6) indicates that planted area at all planting periods for all crops cannot exceed the available area per location.

Set of constraints (7) defines that, when it is decided to plant a crop in one period, the planted area should be ranged between a minimum area defined due to technical reasons and a maximum area defined by the location area.

Set of constraints (8) establishes that the harvest depends on the area planted and the yield of each crop. It is also assumed that all crop ready for harvest in a period is harvested, not being possible to keep mature product on the plant.

Set of constraints (9) indicates that crops need to be transported to retailers at the same period of their harvest due to products’ perishability. In case some crops are not transported, they will be wasted at farming location at the same period of their harvest.

Set of constraints (10) defines that, a minimum capacity of trucks used to transport product should be filled. In addition, the transported quantity cannot exceed the capacity of the used trucks.

Set of constraints (11) indicates that the transported product is immediately available at the market and must be used in that same period. Thus, crops available in the market can be both sold or cleared at the same period of their harvest. In the case in which crops are not sold nor cleared, they are wasted at the market in this same period. Therefore, it is not allowed to stock crops for the next period.

Set of constraints (12) ensures that only demanded products are sold at their sale price. If there is not enough product to satisfy the demand, unmet demand will be produced.

Set of constraints (13) defines that, if there is an excess of crops supply, crops can be cleared at a lower price. In this case, the quantity of crop to be cleared cannot exceed a determined proportion of crop demand.

Set of constraints (14) ensures that unmet demand cannot be produced when crops are cleared.

Set of constraints (15) indicates that a minimum service level should be satisfied per crop throughout the planning horizon.

Finally, set of constraints (16) shows the nature of decision variables.

4.3 Resolution methodology

To solve the model, it is necessary to linearize the objective \(Z_{SOC}\) since it has been defined as a non-linear equation. Then, a multi-objective resolution method needs to be applied.

4.3.1 Linearization of objective \(Z_{SOC}\)

As seen in Sect. 4.1. Objectives, the objective \(Z_{SOC}\) is defined by a non-linear equation. This objective consists of reducing the economic unfairness among farmers. This unfairness indicator is calculated for each farmer as the difference between the mean profit per hectare obtained in the farming region and the profit per hectare obtained by the farmer.

If these calculated unfairness for all farmers were aggregated, the obtained global unfairness would be equal to zero. This is because some of the farmers will obtain more profits per hectare than the mean while other will obtain less profits per hectare than the mean, so these positive and negative deviations would be compensated. To solve this, and to find a solution with a minimum deviation of the profits per hectare obtained by farmers over the mean, such deviations are evaluated in terms of absolute values, thus reducing both positive and negative deviations.

The need of considering an absolute value converts Eq. (3) into a non-linear equation. This makes it necessary to linearize the equation to be able to solve the proposed model. To linearize this absolute difference, it has been replaced by a new continuous decision variable called \(D_{l}\) that represents the absolute difference between the profit per hectare obtained by each farming location and the average profit per hectare obtained at the farming region. Such substitution is shown in Eq. (17).

On the other hand, the value for the variable \(D_{l}\) is calculated as the difference between the mean profit per hectare obtained in the farming region and the profit per hectare obtained by the farmer. To obtain an absolute value for this calculus, both Eqs. (18) and (19) are considered.

4.3.2 Weighted sum method

The weighted sum method is used to create a single objective function (Sarker and Ray 2009) by assigning weights to each objective and aggregating their results. The sum of weights assigned to objectives should be equal to one (\(w_{EC} + w_{ENV} + w_{SOC} = 1\)). The closer the weight assigned to an objective is to one, the stronger impact of this objective in the global objective function. The objectives’ values should be scaled so they acquire values between zero and one (20). For that, the objectives’ values are divided into their maximum value (\(Z_{max}\)) obtained by maximizing each single objective.

After applying the weighted sum resolution method, the resulting model is formulated as follows:

Subject to: Eqs. (4)–(16), (18)–(19)

Note that \(Z_{EC}\), \(Z_{ENV}\), \(Z_{SOC}\) are calculated through Eqs. (1), (2), and (17) respectively.

5 Experimental design: application to the Argentinean tomato case study

The aims of the numerical tests defined in this section are threefold: (1) to validate de proposed multi-objective model, (2) to give response to the Research Questions defined in Sect. 2, and (3) to analyse the computational efficiency of the model.

5.1 Input data

The model is applied to the Argentinean tomato case study in which a set of farmers located in La Plata should define the crop planning for three tomato varieties (round, pear, and cherry). Demand and prices data are obtained from the Buenos Aires Central Market webpage (www.mercadocentral.gob.ar/). The rest of data is gathered from interviews with Argentinian farming experts from the Universidad de la Plata inside the European Project RUC-APS.

A 1-year time horizon with weekly periods is considered. The planting/harvest calendar for all crops is shown in Fig. 2 where three planting seasons are defined. When one crop is decided to be planted, a minimum area of 0.3 hectare should be planted. The yield of crops depends on the crop, the planting and the harvest periods, being ranged from 2933 to 13,475 kg/ha week for round tomatoes, from 2688 to 12,750 kg/ha week for pear tomatoes, and from 277 to 4268 kg/ha week for cherry tomatoes. Farming cost related to the planting, cultivation and harvest of crops is estimated to be 1473 €/kg for round tomatoes, 1473 €/kg for pear tomatoes, and 1272 €/kg for cherry tomatoes.

The considered AFSC is composed by ten farmers and one retailer. The available area for planting at each farm as well as costs related to the transport of crops to the retailer are displayed in Table 4. Transporting costs differ from one farmer to other since they are dependent on the distance between farmers and the retailer. In addition, it is assumed that there is a fixed cost related to the use of trucks equal to 300 €. Trucks have a capacity of 8000 kg, and it is assumed that a minimum cargo equivalent to the 85% of the truck capacity should be filled in order to use a truck.

Demand has been generated by randomly varying the last year supply of tomatoes according to the Buenos Aires Central Market (www.mercadocentral.gob.ar/). Demand data has only been generated for harvesting periods since the demand for the rest of periods is met by external supplies A minimum service level of 85% should be met for each crop. In case there is oversupply of crops, a 1% of the crops’ demand can be cleared at a lower price. Penalties related to waste and unmet demand are assumed to be equal to the price of crops.

5.2 Experimental results

In this subsection, different set of scenarios were solved with the proposed model to give response to the defined Research Questions. The original data instance exposed in Sect. 5.1 and provided by partners from the European project RUC-APS was used for all executions.

5.2.1 Objectives’ conflict

This subsection aims to give response to the Research Question 2: Are the defined objectives (maximization of AFSC profits, minimization of waste, minimization of economic unfairness among farmers) in conflict among them?

Before using a multi-objective approach, it is necessary to determine if the proposed objectives are in conflict. This is because, if the objectives were demonstrated not to be in conflict, the model could be solved by considering a single objective, making its resolution simpler.

To prove that the considered objectives are in conflict, a partial correlation analysis of non-dominated solutions obtained with the proposed model was made as proposed in Esteso et al. (2018b). The non-dominates solution (Pareto optimal solutions) were obtained by applying a lexicographic optimization proposed by Mavrotas (2009) to the model (Table 5). This method consists in solving the model by optimizing only one objective, and to repeat this process with the rest of objectives by fixing the values obtained by previous objectives. This process is repeated as many times as necessary in order to obtain non-dominated solutions for all combination of objective. For example, in a model with two objectives (O1 and O2), the optimal value for O1 would be obtained, and then the optimal value for O2 would be obtained for the case in which O1 is equal to its optimal value. To obtain another non-dominated solution, the process would be repeated by first optimizing the objective O2, and then the objective O1 by fixing the value of O2 to its optimal value.

A partial correlation analysis (Table 6) is made to study the relations between the values obtained for the considered objectives, and to determine if the objectives are in conflict.

The values of the supply chain profit (\({Z}_{EC}\)) and generated waste (\({Z}_{ENV}\)) positively correlated in such a way that, when profits increased, the quantity of harvest finally wasted also increased. This proves the conflict between economic and environmental objectives.

On the other hand, the analysis shows a moderated and positive correlation between the supply chain profit (\({Z}_{EC}\)) and the economic unfairness among farmers (\({Z}_{SOC}\)). So, when supply chain profits increase, the economic unfairness among farmers increase too. Thus, economic, and social objectives are in conflict.

In the case of the environmental and social objectives, a low positive correlation is obtained between their values. This denotes that there is no clear correlation between the generated waste (\({Z}_{ENV}\)) and the economic unfairness among farmers (\({Z}_{SOC}\)) values, so improving one of them does not necessarily imply the improvement the other objective. Therefore, optimizing the environmental objective does not imply the optimization of the social objective, thus considering that these objectives are in conflict.

Therefore, from the partial correlation analysis made on the non-dominated solutions obtained for the proposed model through a lexicographic optimization it is concluded that the considered objectives are in conflict, giving answer to the Research Question 2.

5.2.2 Impact of objectives

This subsection aims to give response to the Research Question 3: Is it possible to find a satisfactory solution for all the objectives (maximization of AFSC profits, minimization of crops’ waste, minimization of economic unfairness among farmers) despite their conflicting character?

To determine so, the model is solved for 18 scenarios in which different weights distributions are assigned to the model’s objectives. Each Scenario is named as a-b-c where a, b and c are the weights assigned to the profit maximization, waste minimization, and unfairness minimization, respectively. Figure 3 shows the results for each scenario in terms of the objective functions, the percentage of harvest that is wasted, the percentage of demand that is not met and the total area planted.

The maximum profit obtained is 840,000 €, while the minimum quantity of waste that can be generated when meeting the defined level service is 500,000 kg and the minimum unfairness is equal to zero (Fig. 2a). When only the economic objective is optimized, a great unfairness is obtained among farming locations making farmers reluctant to collaborate in the implementation of the defined crop planning. In addition, more than 50% of harvested products would be wasted in this Scenario.

However, near to optimal profits can be obtained while considerably reducing waste and unfairness among locations. For example, Scenario 30–30–40 decreases profit by 10% from the optimal profit while waste and unfairness are reduced by 50% and 96% respectively. For that, the three objectives should be simultaneously optimized. As shown in Fig. 2a, profits remain up to 700,000 € for all cases in which more than 30% of weight is assigned to this objective, waste are lower than a million kg when its weight is higher than 50% and the unfairness is very low for assigned weights superior to 30%. Because of that, it seems that Scenarios in which the weight distribution is close to such percentages can obtain solutions with good values for the three objectives. This is the case of the Scenario 30–40–30, which obtains 760,000 € in profits, 1,600,000 kg of waste and 6200 €/ha of unfairness.

The distribution of values among scenarios is similar for the total waste, the proportion of harvest wasted, and the area planted (Fig. 2a–c). Meanwhile the percentage of unmet demand increases as waste and planted area diminish (Fig. 2b, c). This means that the quantity of harvest increases with the planted area. A small part of this harvest reduces the unmet demand while the rest of product is wasted. In addition, five Scenarios (60–20–20, 20–40–40, 20–60–20, 20–20–60, 40–40–20) reach solutions with percentage of waste lower than 30%, that is the real mean indicator in the agri-food sector, being this a great improvement for real supply chains. Two of these Scenarios (20–20–60, 40–40–20) also reduce the unfairness among farmers, obtaining unfairness values between 3700 and 4200 €/ha.

The simple fact of considering the minimization of the economic unfairness among farmers in the global objective function, considerably reduces this factor as can be seen in Fig. 4. In those scenarios in which a 10% of the weight is assigned to this social objective, the economic unfairness is reduced by up to 78% with respect to the scenario with the greatest unfairness (100–0–0). In the rest of scenarios, in which a weight greater than 10% is assigned to the objective related to unfairness, it is observed that unfairness is reduced between 83 and 100% with respect to the 100–0–0 scenario. Therefore, it can be concluded that the results obtained through the proposed model can contribute to the achievement of the Sustainable Development Goal “10. Reduced inequalities” from the United Nations.

On the other hand, the proposed model and obtained results contribute to the achievement of the Sustainable Development Goal “12. Responsible consumption and production”. More specifically, this paper contributes to the responsible production by proposing a centralized decision-making process that tries to adjust demand to supply (and therefore, to production) in which the waste generated is also minimized along the AFSC. In this way, decision-makers could choose to implement in the real AFSC, a solution obtained by the proposed model that obtains good economic results while adjusting the production to demand as much as possible.

Therefore, it is concluded that near to optimal solutions can be obtained for the AFSC profits while highly improving the waste or products generated and the economic unfairness among farmers. Therefore, it is possible to find a satisfactory solution for all objectives despite their conflicting character.

5.2.3 Impact of clearance sales

This subsection aims to give response to the Research Question 4: Has the clearance sale of the excess of supply a positive impact on the supply chain profits, waste and economic unfairness among farmers?

To determine so, the model is solved for 11 scenarios in which different quantities of product can be cleared. The total quantity of product that can be cleared is the equivalent to a percentage of the demand, defined by the parameter \({e}_{crt}\). The scenarios have been created by assigning different values to \({e}_{crt}\) ranging between 0 and 100%. In this way, if \({e}_{crt}\) is equal to 0%, clearance sales are not allowed. Whereas if \({e}_{crt}\) is equal to 100%, the created demand for cleared products is equal to the demand of products.

All scenarios have been run for a balanced weight distribution among the considered objectives (33–33–33). Figure 5 shows the results for each scenario in terms of the objective functions, the percentage of harvest that is wasted, the percentage of unmet demand and the total area planted.

Results show that the supply chain profits increase as a greater quantity of product is allowed to be cleared. However, at the same time it is observed that the planted area increases as the possibility of clearance sales increase, so the model not only tries to sell the excess of supply but also decides to plant more, to obtain more production and thus be able to have a greater amount of sales.

On the other hand, results for unmet demand remain more or less stable in all scenarios, so between the 4 and 5.5% of demand cannot be met. This means that as planted area increases, and production grows, a small part of production goes to reducing unmet demand while the rest goes to cover the demand created for clearance sales.

Despite the increase in production dure to the increase in the planted area, it is observed how the percentage of harvested product that has finally been wasted has decreased significantly, going from 36% in the case in which clearance sales are not allowed (\(e_{crt} = 0\% \forall c,r,t\)), to 21% in the case in which the amount equivalent to the demand for the product can be cleared (\(e_{crt} = 100\% \forall c,r,t\)). Therefore, clearance sales represent a sustainable solution for reducing waste in agri-food supply chains.

Unfortunately, these results are linked to a tendency to worsen the economic unfairness perceived by farmers. However, some of the scenarios obtain an interesting trade-off between the supply chain profits, the percentage of crop wasted, and the unfairness among farmers. An example is the case in which clearance sales are limited to 40% of the demand for products. In this scenario, obtained products are 15% greater than in the scenario in which clearance sales are not allowed, while the percentage of harvested product that is finally wasted is reduced from 36 to 26%, the percentage of unmet demand is reduced from 5 to 4.2%, and unfairness increases in approximately 2000 €/ha (being this the second-best value obtained in this experimentation).

Therefore, and giving response to the Research Question 4, after this experimentation, it can be concluded that the clearance sales of the excess of supply has a positive impact on the supply chain profits and the waste generated along the supply chain. On the contrary, experimentation has shown that unfairness among farmers has worsened in all the scenarios in which clearance sales were allowed. Despite this, interesting trade-offs between the supply chain profits, generated waste and unfairness among farmers can be obtained when clearance sales are allowed.

5.3 Computational efficiency

The proposed model was implemented in MPL® 5.0.8 and solved by using the solver Gurobi™ 8.1.1 in a computer with an Intel® Xeon® CPU E5-1620 v2(C) @3.70 GHz processor, with an installed capacity of 32 GB and a 64-bits operating system. Microsoft Access Database was used to store input data and obtained results.

Optimal solutions have been found for all Scenarios with a mean resolution time of 2 min and 46 s. The multi-objective model counts with 4852 constraints, 90 binary variables, 520 integer variables, and 5415 continuous variables.

6 Conclusions and future research lines

A multi-objective model to centrally define the sustainable crop planning of a supply chain is designed. The model optimizes three objectives aligned to the three aspects of sustainability: maximization of profits (economic), and minimization of waste (environmental) and of economic unfairness between farming locations (social), being the optimization of the last two objectives and the joint optimization of all of them novelties of this paper. The modelling of the possibility of clearing the crops’ oversupply in a new agri-food context, and the anticipation of operational decisions when defining the crop planning are other novelties of the paper. A single global objective function is comprised by applying the weighted sum method.

The model is executed for different set of scenarios to solve the exposed Research Questions. First, it is shown that the considered objectives are in conflict by means of a partial correlation analysis performed on non-dominated solutions. Then, the model is executed for a set of scenarios defined by considering different weight distribution between the objectives. With this experimentation it is found that near to optimal profits can be obtained while considerably reducing the quantity of waste and the economic unfairness among farming locations for certain balanced combination of weights. As it has been shown, this model and its results contribute to the achievement of the following Sustainable Development Goals from the United Nations: (10) Reduced inequalities, and (12) Responsible consumption and production.

Finally, the impact of clearance sales of the excess of supply on the sustainability of AFSC is analysed by executing the model for 11 scenarios in which different quantities of product can be cleared. Results show that clearance sales positively impact on AFSC profits and on waste reduction while negatively impact on the unfairness among farmers, and interesting trade-offs between these factors can be obtained.

In the future, the uncertainty inherent to the agri-food sector could be included in the model. Some parameters that could be considered as uncertain are demand, prices, yield of plants, or demand of cleared products. In addition, other uncontrollable factors that highly impact on AFSC performance such as the climatic events could be included in the model.

On the other hand, the weighted sum method employed in this paper needs the subjective definition of the weights assigned to objectives. This approach obtains a unique optimal solution for such distribution of weights. However, other approaches like the ε-constraint method could be used to obtain non-dominated solutions without the subjectivity of decision makers. A system to choose between the obtained non-dominated solutions should be developed.

Availability of data and materials

The instance of data used in this study can be found at https://cigip.webs.upv.es/docs/CropPlanningData.ods

Code availability

Not applicable.

References

Adekanmbi O, Olugbara O (2015) Multiobjective optimization of crop-mix planning using generalized differential evolution algorithm. J Agric Sci Technol 17:1103–1114

Ahumada O, Villalobos JR (2011a) Operational model for planning the harvest and distribution of perishable agricultural products. Int J Prod Econ 133:677–687. https://doi.org/10.1016/j.ijpe.2011.05.015

Ahumada O, Villalobos JR (2011b) A tactical model for planning the production and distribution of fresh produce. Ann Oper Res 190:339–358. https://doi.org/10.1007/s10479-009-0614-4

Ahumada O, Villalobos JR, Mason AN (2012) Tactical planning of the production and distribution of fresh agricultural products under uncertainty. Agric Syst 112:17–26. https://doi.org/10.1016/j.agsy.2012.06.002

Ajmal MM, Khan M, Hussain M, Helo P (2018) Conceptualizing and incorporating social sustainability in the business world. Int J Sustain Dev World Ecol 25:327–339. https://doi.org/10.1080/13504509.2017.1408714

Albornoz VM, Sáez JL, Véliz MI (2017) Delineation of rectangular management zones and crop planning under uncertainty in the soil properties. Commun Comput Inf Sci 695:117–131. https://doi.org/10.1007/978-3-319-53982-9_7

Albornoz VM, Véliz MI, Ortega R, Ortíz-Araya V (2020) Integrated versus hierarchical approach for zone delineation and crop planning under uncertainty. Ann Oper Res 286:617–634. https://doi.org/10.1007/s10479-019-03198-y

Alfandari L, Lemalade JL, Nagih A, Plateau G (2011) A MIP flow model for crop-rotation planning in a context of forest sustainable development. Ann Oper Res 190:149–164. https://doi.org/10.1007/s10479-009-0553-0

Alfandari L, Plateau A, Schepler X (2015) A branch-and-price-and-cut approach for sustainable crop rotation planning. Eur J Oper Res 241:872–879. https://doi.org/10.1016/j.ejor.2014.09.066

Anastasiadis F, Tsolakis N, Srai J (2018) Digital technologies towards resource efficiency in the agrifood sector: key challenges in developing countries. Sustainability 10:4850. https://doi.org/10.3390/su10124850

Azevedo S, Silva M, Matias J, Dias G (2018) The influence of collaboration initiatives on the sustainability of the cashew supply chain. Sustainability 10:2075. https://doi.org/10.3390/su10062075

Banasik A, Bloemhof-Ruwaard JM, Kanellopoulos A et al (2018) Multi-criteria decision making approaches for green supply chains: a review. Flex Serv Manuf J 30:366–396. https://doi.org/10.1007/s10696-016-9263-5

Blanco V, Carpente L, Hinojosa Y, Puerto J (2010) Planning for agricultural forage harvesters and trucks: model, heuristics, and case study. Netw Spat Econ 10:321–343. https://doi.org/10.1007/s11067-009-9120-0

Catalá LP, Durand GA, Blanco AM, Bandoni JA (2013) Mathematical model for strategic planning optimization in the pome fruit industry. Agric Syst 115:63–71. https://doi.org/10.1016/j.agsy.2012.09.010

Cid-Garcia NM, Ibarra-Rojas OJ (2019) An integrated approach for the rectangular delineation of management zones and the crop planning problems. Comput Electron Agric 164:104925. https://doi.org/10.1016/j.compag.2019.104925

Cid-Garcia NM, Bravo-Lozano AG, Rios-Solis YA (2014) A crop planning and real-time irrigation method based on site-specific management zones and linear programming. Comput Electron Agric 107:20–28. https://doi.org/10.1016/j.compag.2014.06.002

Darby-Dowman K, Barker S, Audsley E, Parsons D (2000) A two-stage stochastic programming with recourse model for determining robust planting plans in horticulture. J Oper Res Soc 51:83–89. https://doi.org/10.1057/palgrave.jors.2600858

Djekic I, Sanjuán N, Clemente G et al (2018) Review on environmental models in the food chain—current status and future perspectives. J Clean Prod 176:1012–1025. https://doi.org/10.1016/j.jclepro.2017.11.241

dos Santos LMR, Costa AM, Arenales MN, Santos RHS (2010) Sustainable vegetable crop supply problem. Eur J Oper Res 204:639–647. https://doi.org/10.1016/j.ejor.2009.11.026

Dury J, Schaller N, Garcia F et al (2012) Models to support cropping plan and crop rotation decisions: a review. Agron Sustain Dev 32:567–580. https://doi.org/10.1007/s13593-011-0037-x

Ertogral K, Wu SD (2000) Auction-theoretic coordination of production planning in the supply chain. IIE Trans 32:931–940. https://doi.org/10.1080/07408170008967451

Esteso A, Alemany MME, Ortiz A (2018a) Conceptual framework for designing agri-food supply chains under uncertainty by mathematical programming models. Int J Prod Res 56:4418–4446. https://doi.org/10.1080/00207543.2018.1447706

Esteso A, Alemany MME, Ortiz Á, Peidro D (2018b) A multi-objective model for inventory and planned production reassignment to committed orders with homogeneity requirements. Comput Ind Eng 124:180–194. https://doi.org/10.1016/j.cie.2018.07.025

European Commission (2018) Key policy objectives of the future CAP. https://ec.europa.eu/info/food-farming-fisheries/key-policies/common-agricultural-policy/future-cap/key-policy-objectives-future-cap_en#nineobjectives. Accessed 18 July 2020

Fang Y, Jiang Y, Sun L, Han X (2018) Design of green cold chain networks for imported fresh agri-products in belt and road development. Sustainability 10:1572. https://doi.org/10.3390/su10051572

FAO Sustainability Pathways. http://www.fao.org/nr/sustainability/food-loss-and-waste/en/. Accessed 29 Jan 2020

Filippi C, Mansini R, Stevanato E (2017) Mixed integer linear programming models for optimal crop selection. Comput Oper Res 81:26–39. https://doi.org/10.1016/j.cor.2016.12.004

Flores H, Villalobos JR (2018) A modeling framework for the strategic design of local fresh-food systems. Agric Syst 161:1–15. https://doi.org/10.1016/j.agsy.2017.12.001

Flores H, Villalobos JR, Ahumada O et al (2019) Use of supply chain planning tools for efficiently placing small farmers into high-value, vegetable markets. Comput Electron Agric 157:205–217. https://doi.org/10.1016/j.compag.2018.12.050

Forrester RJ, Rodriguez M, Forrester R, Rodriguez M (2018) An integer programming approach to crop rotation planning at an organic farm. UMAP J 38:5–25

Hasuike T, Kashima T, Matsumoto S (2018) Multiobjective crop planning considering optimal matching between retailers and farmers with contract. J Adv Mech Des Syst Manuf 12:1–16. https://doi.org/10.1299/jamdsm.2018jamdsm0071

Hong Y, Berentsen P, Heerink N et al (2019) The future of intercropping under growing resource scarcity and declining grain prices—a model analysis based on a case study in Northwest China. Agric Syst 176:102661. https://doi.org/10.1016/j.agsy.2019.102661

Jarin S, Khatun MK, Shafie AA (2016) Multi-objective constrained algorithm (MCA) and non-dominated sorting genetic algorithm (NSGA-ii) for solving multi-objective crop planning problem. ARPN J Eng Appl Sci 11:4079–4086

Jaya Brindha G, Gopi ES (2019) Maximizing profits in crop planning using socio evolution and learning optimization. Stud Comput Intell 828:151–174. https://doi.org/10.1007/978-981-13-6569-0_8

Jonkman J, Barbosa-Póvoa AP, Bloemhof JM (2019) Integrating harvesting decisions in the design of agro-food supply chains. Eur J Oper Res 276:247–258. https://doi.org/10.1016/j.ejor.2018.12.024

Li J, Rodriguez D, Zhang D, Ma K (2015) Crop rotation model for contract farming with constraints on similar profits. Comput Electron Agric 119:12–18. https://doi.org/10.1016/j.compag.2015.10.002

Mason AN, Villalobos JR (2015) Coordination of perishable crop production using auction mechanisms. Agric Syst 138:18–30. https://doi.org/10.1016/j.agsy.2015.04.008

Mavrotas G (2009) Effective implementation of the ε-constraint method in multi-objective mathematical programming problems. Appl Math Comput 213:455–465. https://doi.org/10.1016/j.amc.2009.03.037

Mellaku MT, Reynolds TW, Woldeamanuel T (2018) Linear programming-based cropland allocation to enhance performance of smallholder crop production: a pilot study in Abaro Kebele, Ethiopia. Resources. https://doi.org/10.3390/resources7040076

Moon I, Jeong YJ, Saha S (2018) Investment and coordination decisions in a supply chain of fresh agricultural products. Oper Res. https://doi.org/10.1007/s12351-018-0411-4

Najafabadi MM, Ziaee S, Nikouei A, Ahmadpour Borazjani M (2019) Mathematical programming model (MMP) for optimization of regional cropping patterns decisions: a case study. Agric Syst 173:218–232. https://doi.org/10.1016/j.agsy.2019.02.006

Nguyen T-D, Venkatadri U, Nguyen-Quang T et al (2019) Optimization model for fresh fruit supply chains: case-study of dragon fruit in Vietnam. AgriEngineering 2:1–26. https://doi.org/10.3390/agriengineering2010001

Pérez-Mesa JC, Piedra-Muñoz L, García-Barranco MC, Giagnocavo C (2019) Response of fresh food suppliers to sustainable supply chain management of large European retailers. Sustainability 11:3885. https://doi.org/10.3390/su11143885

Pourhejazy P, Kwon O (2016) The new generation of operations research methods in supply chain optimization: a review. Sustainability 8:1033. https://doi.org/10.3390/su8101033

Prima Dania WA, Xing K, Amer Y (2018) Collaboration behavioural factors for sustainable agri-food supply chains: a systematic review. J Clean Prod 186:851–864. https://doi.org/10.1016/j.jclepro.2018.03.148

Radulescu M, Radulescu CZ (2013) Simulation and optimization for crop planning under risk. In: Proceedings—8th EUROSIM congr model simulation, EUROSIM 2013, pp 409–414. https://doi.org/10.1109/EUROSIM.2013.117

Rǎdulescu M, Zbǎganu G, Rǎdulescu CZ (2008) Crop planning in the presence of production quotas (invited paper). In: Proceedings—UKSim 10th Int Conf Comput Model Simulation, EUROSIM/UKSim2008, pp 549–554. https://doi.org/10.1109/UKSIM.2008.40

Rǎdulescu M, Rǎdulescu CZ, Zbǎganu G (2014) A portfolio theory approach to crop planning under environmental constraints. Ann Oper Res 219:243–264. https://doi.org/10.1007/s10479-011-0902-7

Ren C, Li Z, Zhang H (2019) Integrated multi-objective stochastic fuzzy programming and AHP method for agricultural water and land optimization allocation under multiple uncertainties. J Clean Prod 210:12–24. https://doi.org/10.1016/j.jclepro.2018.10.348

RUC-APS (2016) Enhancing and implementing knowledge based ICT solutions within high risk and uncertain conditions for agriculture production systems. In: Proj. 691249 funded by Eur. Union’s Res. Innov. Program. under H2020 Marie Skłodowska-Curie Actions. www.ruc-aps.eu

Santos LMR, Munari P, Costa AM, Santos RHS (2015) A branch-price-and-cut method for the vegetable crop rotation scheduling problem with minimal plot sizes. Eur J Oper Res 245:581–590. https://doi.org/10.1016/j.ejor.2015.03.035

Sarker RA, Quaddus MA (2002) Modelling a nationwide crop planning problem using a multiple criteria decision making tool. Comput Ind Eng 42:541–553. https://doi.org/10.1016/S0360-8352(02)00022-0

Sarker R, Ray T (2009) An improved evolutionary algorithm for solving multi-objective crop planning models. Comput Electron Agric 68:191–199. https://doi.org/10.1016/j.compag.2009.06.002

Sebatjane M, Adetunji O (2021) Optimal lot-sizing and shipment decisions in a three-echelon supply chain for growing items with inventory level- and expiration date-dependent demand. Appl Math Model 90:1204–1225. https://doi.org/10.1016/j.apm.2020.10.021

Seuring S, Müller M (2008) From a literature review to a conceptual framework for sustainable supply chain management. J Clean Prod 16:1699–1710. https://doi.org/10.1016/j.jclepro.2008.04.020

Stadtler H (2009) A framework for collaborative planning and state-of-the-art. Or Spectr 31:5–30. https://doi.org/10.1007/s00291-007-0104-5

Suthar RG, Barrera JI, Judge J et al (2019) Modeling postharvest loss and water and energy use in Florida tomato operations. Postharvest Biol Technol 153:61–68. https://doi.org/10.1016/j.postharvbio.2019.03.004

Tan Q, Zhang S, Li R (2017) Optimal use of agricultural water and land resources through reconfiguring crop planting structure under socioeconomic and ecological objectives. Water (switzerland). https://doi.org/10.3390/w9070488

United Nations (2019) The sustainable development goals report 2019. United Nations Publ issued by Dep Econ Soc Aff 64

Villa G, Adenso-Díaz B, Lozano S (2019) An analysis of geographic and product diversification in crop planning strategy. Agric Syst 174:117–124. https://doi.org/10.1016/j.agsy.2019.05.006

Zaraté P, Alemany M, del Pino M, et al (2019) How to support group decision making in horticulture: an approach based on the combination of a centralized mathematical model and a group decision support system. In: Lecture Notes in Business Information Processing, pp 83–94

Acknowledgements

The authors also acknowledge the support of Mariana del Pino, farming expert from the Universidad de la Plata.

Funding

We acknowledge the support of the Project 691249, RUCAPS: “Enhancing and implementing knowledge based ICT solutions within high risk and uncertain conditions for agriculture production systems”, funded by the European Union’s research and innovation programme under the H2020 Marie Skłodowska-Curie Actions.

Author information

Authors and Affiliations

Contributions

AE: methodology, software, validation, writing-original draft, writing—review and editing, visualization, funding acquisition; MMEA: conceptualization, methodology, validation, writing—original draft, writing—review and editing, supervision, funding acquisition, funding administration; AO: conceptualization, methodology, validation, resources, writing—original draft, writing—review and editing, supervision, funding acquisition, funding administration; SL: investigation, validation, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Esteso, A., Alemany, M.M.E., Ortiz, A. et al. Optimization model to support sustainable crop planning for reducing unfairness among farmers. Cent Eur J Oper Res 30, 1101–1127 (2022). https://doi.org/10.1007/s10100-021-00751-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10100-021-00751-8