Abstract

The results of experimental investigations of the compressed masonry elements strength reinforced by expanded steel sheets are presented. These experiments make it possible to evaluate the efficiency of using this type of indirect reinforcement for brick structures that work on compression. Experimental investigations have shown that the use of high-tech reinforcement products—expanded steel sheets for the reinforcement of masonry is technically possible and economically feasible. With the same power of indirect reinforcement by meshes or sheets, the strength of elements reinforced with expanded steel sheets is on average 40% higher than analogues reinforced with welded mesh of BpI wire. Ease of manufacture and high strength make it possible to predict the widespread use of these reinforcement products in the future.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Natural stone structures were built in the Stone Age. To this day, partially preserved buildings made of natural stone, built in the Stone Age from large depths and slabs—dolmens. With the development of society and the improvement of the means of production instead of large heavy stones began the use of convenient for manual masonry hewn stones. Later, the material for the stone structures began to be artificial coarsely formed blocks of clay, followed by raw bricks and fired bricks.

Nowadays, there is a steady trend to increase the use of brick structures in construction, due to such characteristics of brick structures as high strength, fire resistance, durability, low operating costs, architectural expressiveness, accessibility for all consumers.

However, despite all the advantages of stone structures, there are situations when they can not meet the requirements that apply to them [1].

So, at construction of apartment houses the question of increase of illumination of the room quite often arises. In such cases, increase the area of window openings, thereby reducing the area of the openings. And if this house is also multi-storey, then there is a problem of increasing the strength of such a structure, because the brickwork of the walls, especially the first floor, will not withstand the actual load.

If we consider public buildings made of brick, then their construction also causes similar problems.

As a rule, on the ground floor of a public building a completely different planning solution is used than in a residential building. Such a building should have a large and spacious lobby or hall. The number of floors of such a building can be significant. To implement such a project, it is necessary that the load instead of load-bearing walls is perceived by separate columns, the cross-sectional area of which is controlled by the requirements for the spatial planning solution. And again there is a question of bricklaying strength increase for a given cross-sectional area of the element.

In such cases (but others are possible) to increase the strength of masonry, it is possible to use its indirect reinforcement [2, 4, 9, 10]. The vast majority of stone structures in operation work on compression—central or off-center. In this type of work, the destruction of the masonry is due to the loss of stability formed after its cracking of the columns, so the strength of the masonry, even with a very strong solution, is always less than the compressive strength of the brick.

Indirect reinforcement is used to increase the load-bearing capacity of compressed masonry elements. In addition, such reinforcement ensures the joint work of individual parts of buildings, significantly increases the seismic resistance of masonry structures [6,7,8].

1.1 Experimental Research of Masonry Strength Indirectly Reinforced by Expanded Steel Sheets

Experimental studies of the bearing capacity and deformability of indirectly reinforced masonry elements have been carried out at the National University «Yuri Kondratyuk Poltava Polytechnic» for the introduction of expanded steel sheets reinforcement in construction practice.

The experimental part of the work consisted of testing masonry columns reinforced by expanded steel sheets on central compression in order to further comparison the experimental data with the data obtained for analogues (twins), which are reinforced with welded meshes.

1.2 Characteristics of Test Specimens and Test Equipment

In accordance with the purpose and objectives of the study, in the Reinforced Concrete and Masonry Structures laboratory were made 3 groups of test specimens.

The test specimen of the first group (C1) was a prismatic non-reinforced masonry column with cross section \(b \times h = 380 \times 380{\kern 1pt} \,{\text{mm}}\), working height 770 mm. This sample was made to determine the strength of non-reinforced masonry.

The test specimens of the second group (C2-1, C2-2, C2-3, C2-4, C2-5) were reinforced masonry columns with cross section \(b \times h = 380 \times 380\,{\kern 1pt} {\text{mm}}\), working height 770–850 mm.

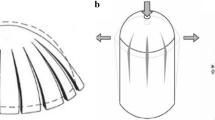

Samples of the second group were reinforced with meshes C1, C2, C3, C4 made from wire BpI Ø 4 and 3 mm (Fig. 1a), the size of the mesh cell was 60 and 120 mm, and the step of the grids in the central part of the samples was \(S = 310\,{\text{mm}}\) or \(400\,\,{\text{mm}}\).

The coefficient of indirect reinforcement by meshes is determined by the formula

where nx, ny; Asx, Asy; lx, ly – respectively, the number of bars, area and their length in the appropriate directions (within the brickwork);

A—the cross-sectional area of the element;

S—step of meshes.

The test specimens of the third group (C3-1, C3-2, C3-3, C3-4, C3-5) were in the form of reinforced masonry columns with cross section \(b \times h = 380 \times 380\,{\text{mm}}\), working height 690–850 mm.

Samples of the third group were reinforced by expanded sheets marks PVL 202, PVL 204, PVL 082 (Fig. 1b) according to [3].

The coefficient of expanded steel sheets indirect reinforcement was estimated by expression

where \(P_{M}\)—weight of expanded steel sheet 380 × 380 mm;

\(\rho_{m} = 7,85\,g/{\text{mm}}^{3}\)—density of steel;

A—the cross-sectional area of the element;

S—step of meshes.

Step of the expanded steel sheets S = 230, 310, 400 mm was selected so that the corresponding samples of the 2nd and 3rd groups in terms of indirect reinforcement power \(\mu_{S,xy} \cdot \sigma_{y}\) were about the same (were “twins”). Thus, 5 pairs of prototype twins were created.

For all test specimens, clay brick of plastic molding with a strength of M75 produced by the Poltava plant “Ceramics” was used.

The mortar for masonry was prepared using sand from the Poltava quarry (with a coarse modulus up to 1.0 mm) and Portland cement M400 from the Balaklia Cement Plant. At the time of testing, the strength of the mortar was M80.

Control samples were taken made to control the strength of brick, mortar, BpI wire and steel sheets. Evaluation of the strength of brick, mortar, wire, sheet steel was performed according to standard methods, in accordance with regulatory requirements (Table 1).

The test specimens (brick columns) were subjected to a short-term load on the central compression. The tests were performed on a 500-ton hydraulic press type PG-500. Transportation and installation of experimental samples on the bottom plate of the press was performed by a crane-beam.

The installation of experimental samples in the press was reduced to the coincidence of the dimensional axes with the axis of the hinges and ended with the clamping of the sample between the plates (traverses) of the experimental equipment. Symmetrically located and centered brick columns were subjected to uniform pressure of the slab of the experimental mechanism.

To measure the compression deformation of the brickwork on the two adjacent flat boards of the samples were installed mechanical indicators of the watch type brand 6 PAO-LISI with a division price of 0.01 mm. In addition to this function, the indicators allow you to “center” the research samples so that the line of force application applications with the geometric axis of the sample.

Loading of test specimens was carried out in stages, the value of which in fractions of the expected destructive load Nu was 0,1Nu. After each stage of the load, the instrument readings were recorded twice: the first time immediately after the application of the load, the second time—after 5–10 min of exposure under load.

During the test process, the log of observations was recorded by devices at each stage of loading, the appearance and nature of the development of cracks, the destructive load were recorded.

To avoid premature destruction of the masonry from crumpling under the supports of the press, the supporting parts of the samples were reinforced with metal clamps.

The criterion for the destruction of the sample was taken as the inability of the test column to perceive the increasing load (Fig. 2).

2 Results of Experimental Research

2.1 The Change in the Stress State and its Effect on the Nature of the Destruction of the Test Specimens

Experiments have shown that at low load levels (N/Nu = 0.1–0.4) the stress state of reinforced masonry is close to non-reinforced. Deformations of a laying are proportional to force N, formation of longitudinal cracks (cracks of separation) is not observed.

As the load increases, structural changes occur in the masonry material (caused by its inhomogeneity), which lead to an increase in transverse deformations of the masonry. The development of these deformations is actively hindered by indirect (transverse) reinforcement, as a result of which tangential stresses \(\tau_{iy}\) occur on the contact-reinforcement contact planes, which cause tensile deformations of the mesh rods or plates. Given that the perimeter of the solution “mortar—plate” is much larger than the perimeter of the contact “mortar—bar”, the expanded steel sheets are much more actively involved in tensile work.

At the load level N/Nu = 0.4–0.99, the stress state of the masonry becomes triaxial (ie, \(\sigma_{1} > \sigma_{2} = \sigma_{3}\) for sheet reinforcement \(\sigma_{1} > - \sigma_{2} = - \sigma_{3}\)).

Due to the formation of a three-axis stress state (clamp effect [5, 7, 8]), the stresses in the masonry significantly exceed the corresponding values characteristic of non-reinforced masonry under uniaxial compression.

In the boundary stage N/Nu = 0.9–0.99 the process of viscoplastic deformation takes place, the characteristic features of which are the formation of new and opening of existing vertical cracks, the appearance of local places of destruction of brick and mortar (Fig. 3b,c). The fracture process is slow and the ultimate load as a result of stress redistribution is perceived by the sample for 3–8 min.

The process of samples destruction with indirect reinforcement is much slower than samples without reinforcement (where it can be sudden).

Experiments show that even a slight transverse reinforcement of the test specimens leads to a significant increase in the strength of the reinforced masonry.

Comparing the experimental strength of mesh-reinforced elements with analogues where expanded steel sheets was used, it can be argued that the reinforcement of expanded steel sheets masonry is more effective than grids with the same reinforcement strength. For example, the increase in the strength of the masonry of the sample C3-1 is 47% greater than that of the sample C2-1, reinforced with mesh.

We explain the best effect from the use of expanded steel sheets by the significant influence of tangential stresses \(\tau_{ij}\) acting on the contact “mortar—sheet surface”, increasing the tensile deformation of sheet steel and the completeness of the stress diagram (Table 2).

3 Conclusions

The experimental investigations showed that due to the formation of the triaxial stress state (clamp effect) the stresses in the masonry significantly exceed the corresponding values characteristic of non-reinforced masonry under uniaxial compression. The process of destruction of samples with indirect reinforcement is much slower than samples without reinforcement (where it can be sudden).

Even a slight transverse reinforcement of the prototypes leads to a significant increase in the strength of the reinforced masonry. Comparing the experimental strength of mesh-reinforced elements with analogues where expanded steel sheets was used, it can be argued that the reinforcement of expanded steel sheets masonry is more effective than meshes with the same reinforcement strength.

The use of high-tech reinforcing products expanded steel sheets for reinforcing masonry is technically possible and economically feasible. This is explained by the fact that with the same power of indirect reinforcement by grids or sheets, the strength of elements reinforced with expanded steel sheets is on average 40% higher than analogues reinforced with welded mesh of BpI wire.

The economic effect of using expanded steel sheets compared to non-reinforced brickwork is more than 10%.

Ease of manufacture and high strength make it possible to predict the widespread use of these reinforcement products in the near future.

References

EN 1996–1–1 Eurocode 6 (2005) Design of masonry structures - Part 1–1: General rules for reinforced and unreinforced masonry structures

Pinchuk N, Fenko O, Kyrychenko V (2018) The stress-strain state computer modelling of reinforced masonry under local loading. Int J Eng Technol 7(3.2):316–321. https://doi.org/10.14419/ijet.v7i3.2.14427

TU 5262–001–23082253–96 Technical conditions. Expanded steel sheets, p 16

Pavlikov A, Kochkarev D, Harkava O (2020) Analysis of eccentrically loaded members of circular cross section by nonlinear deformation model. In: Proceedings of the 2nd International Conference on Building Innovations. ICBI 2019. Lecture Notes in Civil Engineering, (73), pp 171–181

Pinchuk N, Byba V (2020) Experimental investigation of masonry and reinforced masonry walls under local loading. In: Proceedings of the 2nd International Conference on Building Innovations. ICBI 2019. Lecture Notes in Civil Engineering, (73), pp 205–213 (2020).https://doi.org/10.1007/978-3-030-42939-3_22

Sementsov SA (1959) Local and extra-center compression of concrete and masonry. Struct Mech Calculation Struct 1(1):11–19

Shapoval SL (2005) Stress-strain state and strength of brickwork at local compression: Dis. … Cand. tech. Sciences: 05.23.01 Poltava National Technical Yuri Kondratyuk University. Poltava: PNTU

Baryliak B, Pavlikov A, Harkava O (2020) General method of structural analysis of reinforced concrete columns under axial load and biaxial bending. In: Proceedings of the 2020 Session of the 13th fib International PhD Symposium in Civil Engineering, pp 179–186

Pavlikov A, Kosior-Kazberuk M, Harkava O (2018) Experimental testing results of reinforced concrete beams under biaxial bending. Int J Eng Technol 7(3.2):299–305 (2018)

Dharek MS, Raghunath S, Ashwin CP (2021) Experimental behaviour of unreinforced and reinforced concrete block masonry walls under uniaxial compression. Materials Today: Proceedings, ISSN 2214-7853 (2021). https://doi.org/10.1016/j.matpr.2021.01.398

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Pavlikov, A., Pinchuk, N., Kachan, T. (2022). Strength of Masonry Indirectly Reinforced by Expanded Steel Sheets. In: Onyshchenko, V., Mammadova, G., Sivitska, S., Gasimov, A. (eds) Proceedings of the 3rd International Conference on Building Innovations. ICBI 2020. Lecture Notes in Civil Engineering, vol 181. Springer, Cham. https://doi.org/10.1007/978-3-030-85043-2_29

Download citation

DOI: https://doi.org/10.1007/978-3-030-85043-2_29

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-85042-5

Online ISBN: 978-3-030-85043-2

eBook Packages: EngineeringEngineering (R0)