Abstract

Camels are an indispensable element in the lives of people living in arid regions of Sudan for many reasons. In addition, it is an excellent source of meat and dairy in difficult areas to produce food. While camel milk is actually used for human consumption, it is rarely used to make cheese. Among the reasons for this is that this type of milk is difficult to coagulate compared to other livestock milks. The objective of the present study was to produce white cheese (jibna-beida) from raw camel milk, and a mixture of camel milk and cow milk (1:1), and to evaluate the quality and safety of the product. For manufacture of cheeses, the milk samples were inoculated with 5% starter culture and 10% citric acid were added to the mixture. The microbiological analyses indicate that the total bacterial count and yeast and moulds counts for cheeses ranged 11 × 105 and 15 × 106–8 × 102 and 2 × 103–6 × 102 (c.f.u/ml), respectively. The chemical analyses indicated relative increase calcium in cheese made from the mixture of camel milk and cow milk (449.50 ± 0.70 mg/100 g) compared to that made from pure camel milk (325.50 ± 0.70 mg/100 g). Moreover, potassium contents in mixed camel milk cheese exceeded that of pure camel milk cheese. The sensory analysis indicated that the cheese manufactured by utilization starter culture was highly preferred compared to other cheeses. The study concluded that blending camel milk with cow milk enhanced the nutritional value, microbiological safety and organoleptic properties of cheese. The study recommends understanding the mechanism of enzymatic coagulation of camel milkto improve quality and yield of camel milk cheese.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

13.1 Introduction

Sudan is appraised the second in numbers of camel population on the planet. Camels in Sudan are concentrated in two primary areas; the Eastern where camels are found in the Butana plains and the Red Sea slopes and the Western districts in Darfour and Kordofan (El-Amin and Wilcox 1992; Eisa and Mustafa 2011). These Camels vary in their potential in milk and meat production; and hustling capacities. Majority of camels (>90%) in Sudan belongs to pack camels; these are characterised by heavy belt and classified as dual purpose animals (for milk and meat production). The Rashaidi camel is found in eastern Sudan (Kasala and Gedaref states) and described as dairy camel.

The number of camels in Sudan is assessed to be more than 4.6 million heads (MARF 2010).The actual camel milk production in Sudan is assessed to be 59,000 tons per year. However, the capability of camel milk creation in Sudan is assess to be 1,700,000 tons per year. Commercialization of camel milk is a relatively new trend in the Sudan. The production of milk is the main reason for sustainability of the current rearing management system which is practiced by camel’s owners or laborers. Majority of the milk production is purchased with value which is multiple times higher contrasted with cow’s milk (Amasai et al.b 2013). The camel female produces 8–14 calves during her life span and could reach 20 under improved management conditions.

Camel milk has a significant part in human sustenance in the hot locales and arid countries. Most the camel milk in the Sudan is smashed new and some of the time harsh (matured) (Gariss) or with tea (Sbanes). Handling and assembling of camel milk in to drain items like spread, ghee, cheddar, frozen yogurt, and so on., not found aside from in some restricted exploration. It was presumed that the creation framework and dairy creation of camel in Sudan deplorably got little consideration .and sometimes sour (fermented) (Gariss) or with tea (Sbanes). It was presumed that the production system and dairy creation of camel in Sudan deplorably got little consideration.

13.2 Camel Milk Composition

Camel milk is a complete food, that is, it covers the nutritional needs of the whole organism, but not for humans, but for young suckling camels, and despite this it is considered a food of high nutritional and healthy value for humans, even if it is not a complete food. Scientists and researchers have been interested in studying the components and composition of camel milk, and the results of the studies showed variation and a clear difference in the values of the analysis, due to the different production conditions such as environmental, geographical and seasonal factors, summer and winter, the abundance of water and the type of feed provided to camels in each study, as well as according to the methods of analysis and methods of sampling. . Looking at the entirety of the published studies, as reported by the scientific review study of the scholars Hajj and Kanhal, and published in the International Journal of Dairy Research for the year 2010, the average values of the nutritional analysis of camel coffee were as follows:

Protein (3.1%): The protein content of camel’s milk varies according to the difference in the type of breed to which it belongs, and according to the season in which the grazing is carried out. Studies have shown that the camel breed “Majahim” contains higher amounts of protein than that of other breeds. The amount of protein decreases in the summer while it rises in the spring. Perhaps one of the most prominent features of camel milk protein is that it contains large quantities of the protein known as casein, which represents more than half of the protein types in milk (50–80% of the protein intake), while the other type known as Whey protein represents the least part. The rest of it. One of the characteristics of casein protein that gives camel milk an additional advantage is that it is the easiest type to digest and the least sensitizing to the intestine of a nursing infant, when compared to other types of protein such as those found in cow’s milk, which makes camel milk closer and more similar to human milk than cow’s milk, and safer. Anti-allergy. Looking at the quality of the amino acids that make up the protein of camel milk, studies have shown similarity between the types of amino acids in both camel and cow’s milk, with a slight difference being the lower content of the first amino acids glycine and cysteine compared to the second. As for the other component of the protein, the whey protein, it is present in smaller quantities than it is in cow’s milk protein.

Fat (3.5%): The fat content in camel milk ranges between 1.2–6.4%, with an average of 3.5%. The difference in the fat content of camel milk is associated with the protein content in it, and the fat content is significantly lower in cases of dehydration and thirst for camels, and the decrease reaches 74% from the original content. The white color of camel’s milk is less yellow compared to cow’s milk, which is more yellowish, due to the low amount of carotene compounds in the first compared to the second. Camel milk contains more long-chain fatty acids than cow’s milk fat, as well as contains more unsaturated fatty acids, up to 43%, and less saturated acids compared to cow’s milk. This makes camel milk a suitable choice for heart patients, high fats and cholesterol. On the other hand, camel milk contains varying amounts of cholesterol, which are higher or lower at times compared to cow’s milk, according to different care factors.

Lactose (4.4%): The milk sugar content is the least affected by grazing conditions, the prevailing climate and the nature of the forage, and the most stable, unlike other nutrients. Looking at the nutritional composition tables, we find that the lactose content in camel milk (4.4%) is less than It is similar to cow’s milk (5.26%), which makes camel milk safer and more beneficial for patients suffering from lactose intolerance, which is a disease that spreads in a number of countries of the world, especially East Asian countries, and results in intestinal disorders after consuming milk. . This disease occurs as a result of the absence of the enzyme lactase that degrades galactose in the intestine due to genetic defects in patients with it.

Salts (0.79%): Like other components of milk, the amount of mineral salts varies according to strain and environmental conditions. Camel milk is a distinctive source of chloride, due to the high content of this mineral in the plants on which the camel depends for its food. In general, the content of camel milk is high in trace salts such as zinc, iron, copper, manganese and major such as sodium, potassium and chloride, while the content of camel milk is similar. With cow’s milk in calcium, phosphorous and magnesium. Looking at the behavior of camels, the researchers found that they tend to eat salt-loving pastoral plants, as a natural way to compensate for the loss of salts from their body as a result of sweating and exposure to heat for long periods of time, which makes the milk taste sweet and slightly salty.

Vitamins: Camel milk, like other types of milk, contains varying amounts of vitamins (C), (E), (D) and (A) and some vitamins (B) complex, but in contrast it is distinguished from other types of milk because it contains excess quantities of vitamin C. This vitamin is known to prevent oxidative stress and contribute to building connective tissues and strengthening immunity against diseases. Therefore, camel milk can contribute greatly to providing desert dwellers with their need of this vitamin, which rural and urban people used to obtain from vegetables and fruits, and that the presence of vitamin C in this relatively large quantity also contributes to prolonging the shelf life of milk and raising its resistance to perceptual corruption resulting from Air oxidation of fats. In addition to this vitamin, camel milk contains more vitamins of pantothenic acid, folic acid, cobalamin (B12) and niacin (B3) compared to that of cow’s milk. In contrast, camel milk has lower amounts of vitamins A and riboflavin (B2). According to American dietary recommendations, one cup of camel milk meets 15.5% of an adult’s body’s need for vitamin Cobalamin (B12), 8.25 per cent for riboflavin (B2), 5.25 percent for vitamin A, and 10.5 percent for Both vitamins C, thiamine (B1), and pyridoxine (B6).

13.3 Camel Milk Products

Camel milk is just appropriate for drinking (Yagil et al. 1984). However different items delivered from Dromedary camel milk incorporate soft cheese (El-Zubeir and Jabreel 2008; Inayat et al. 2003) fermented milk (Elayan et al. 2008; Farah et al. 1990), yoghurt (Hashim et al. 2008), ice cream (Abu-Lehia 1989) and butter (Farah et al. 1989).

Technical development and scientific interest in camel milk have contributed to the development of many food products from camel, and these products have become the focus of consumer interest. Given what modern science reveals about its benefits, and then the benefits of its products, and the level of health and nutritional awareness among consumers. Despite this, camel milk products remain more limited and less widespread, for the simple reason that is the low quantities of production compared to other types of milk, such as cows and sheep. In addition to a number of factors inherent in it that hinder the development of food products such as cheese and others, including:

-

1.

The length of cheese for protein: This makes the time required for cheese 3–5 times the time required for cow’s milk cheese. This is mainly due to the aforementioned difference in the content and nature of camel milk proteins mentioned under the protein item represented by the casein protein responsible for cheese.

-

2.

Weak curd: This is due to the relatively low total solids in camel milk (11.9%) compared with its counterparts in cow and sheep milk, especially for casein protein. This property is also due to the small size of the fat grains in camel milk compared to cow’s milk.

-

3.

Weakness of the effect of rennet (the enzyme cheese) that causes cheesiness: studies have shown that the thrombus resulting from camel’s milk cheese is weak and inconsistent, which negatively affects the organoleptic properties of the products derived from it.

-

4.

Low amount of cheese production: the amount of soft cheese resulting from camel milk cheese is about half less than that of cow’s milk, whereas a kilogram of cow’s milk produces about a quarter of a kilogram of cheese. Camel milk produces half of this amount (about 120 grams), which makes camel milk an economically unfeasible source for cheese.

Camel milk has been utilized for production of various products such as yoghurt having a thin, flow able and very soft texture (Hashim et al. 2008).

Ice cream was accounted for to be delivered effectively from camel milk utilizing a blend of 12% fat, 11% milk solids not fat (MSNF) and 37% all out solids (Abu-Lehia 1989). The invade of camel milk frozen yogurt was found to fundamentally rely upon the fat and MSNF levels in the blend (Abu-Lehia 1989). For instance the expansion in fat and MSNF content in the blend prompts an expansion in thickness.

These camel milk products were made at laboratory scale, yet some are normally created at a larger scale in the pastoral areas during the pinnacle period of milk production or when milk production is over that required for human and youthful calf use. These products are as yet not very much grew enough to arrive at a commercial scale, additionally a need to inspect buyer adequacy of these products.

13.4 Camel Milk Cheese

Camels have been used for thousands of years as a means of transporting people and transporting goods across the desert, but seeing them as mere `` ships of the desert “is a diminution of their true value. The basic principle in cheese making is to coagulate the milk to form curds and whey. Modern methods of cheese-making and the coagulation process are assisted by the addition of yeast, which is a bacterial seed that produces lactic acid, and rennet, a substance extracted from calves that contains flocculation enzymes, and these enzymes ensure the acceleration of the rate of separation of liquids from solids.

Apparently, camel milk is technically more hard to process compared to milk from other dairy animals. Only a few rare cheeses are manufactured by acidic separation and heating of milk proteins (Yagil 1982). There have been various endeavors to produce cheese from camel milk, however a large portion of these preliminaries were fruitless and yielded contradictory outcomes. The issues related with production of cheese include:

-

1.

Long coagulation time. Camel milk shows an a few fold longer rennet coagulation time and bovine milk (Farah et al. 1990). This was credited to the differences in the size of casein particles.

-

2.

Weak curd due to the low total solids content of the coagulum, especially casein (El-Zubeir and Jabreel 2008; Mehaia 2006; Ramet 2001) and/or the small size of the camel fat globules (2.99 mm), or might be due to low elasticity and high fragility of the cheese gel texture (Ramet 2001).

-

3.

Rennet action.

-

4.

Lower cheese yield. % because of higher recovery of proteins, fat, and other milk solids (Mehaia 2006).

A few factors have been accounted for to improve camel milk coagulation, including the expansion of calcium chloride (El-Zubeir and Jabreel 2008). Utilizing camel gastric enzyme extracts (Siboukeur et al. 2005) and rennet rather than bovine rennet brought about in improved camel milk coagulation. This could be ascribed to the pepsin content in the rennet preparation utilized.

The addition of yoghurt culture or other lactic acid bacteria with rennet to camel milk was accounted for to encourage camel milk coagulation expanding the lactic acid content and improving curd firmness (Gassem and Abu-Tarboush 2000; Mehaia 2006), while the addition of yoghurt culture or other lactic acid bacteria alone to camel milk did not coagulate the milk.

Other investigations announced that diminishing pH to 5.6 and expanding temperature to up 420C brought about a decrease in camel milk coagulation time (Farah et al. 1990; Siboukeur et al. 2005). The system behind the decrease of camel milk coagulation time when bringing down the pH could be because of the improvement of the charge balance cycle and compliance changes happening in the optional period of coagulation (Mehaia 2006). However, expanding the temperature builds the pace of accumulation of the micelles and the arrangement of a gel network through the hydrophobic connections. Expanding the convergence ration of rennet up to multiple times was additionally answered to quicken camel milk coagulation (Larsson-Raznikiewicz and Mohamed 1986; Ramet 1989). The need for high rennet concentration to coagulate camel milk could be could be because of the presence of explicit protease inhibitors in camel milk and/or a specific casein micelle structure restricting access of the protease to the k-CN substrate, notwithstanding, these theories should be affirmed (Ramet 2001). Fermented milk products often contain probiotics, which promote gut health.

13.5 Technology of Cheese Making

Cheese manufacture is fundamentally a dehydration process in which the milk protein (casein), fat and colloidal salts of are concentrated 6 to 12 times with removal of great amount on milk water (90%) milk and mostly all of the lactose, whey proteins and soluble milk salts. It is an easy and simple and does not require much effort, all that the manufacturer needs is preparing the ingredients to start preparing the cheese.

Cheese is formed as a result of curdling milk; where it is transformed from a known liquid state to a semi-cohesive protein (casein). The concentration is achieved by coagulating the casein by the action of enzymes blown (enzyme resonance), or by acidity formed by the action of added precursors, or by acidity and heat with the separation of the yellow liquid known as the grit, when the clot is cut, stirred, heat treated and compressed. Basic cheese compounds are transformed from proteins, lipids and carbohydrates into simple, easily digestible compounds as a result of the biochemical reactions that take place during the cheese settlement process.

The cheeses that can be consumed after being kept shall be soft, semi-dry, dry or very dry. They may be covered with a waxy layer or wrap with plasticine. Ripening is done by milk bacteria, added initiator bacteria, and / or fungi (mold) growing inside and / or on the cheese surface.

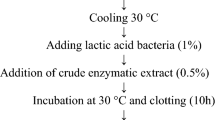

13.6 Cheese Preparation

Mahgoub (2015) prepared white cheese using raw camel milk, and a mixture of camel milk and cow milk (1:1). The temperature of milk was brought down to 40 °C. Three types of cheese were prepared; the first type was addition of 10% citric acid to pure camel, the second type was addition 10% citric acid to a mixture of camel milk and cow milk (1:1), third type was addition 5% starter culture to a mixture of camel and cow milk (1:1) two methods were then used to manufacture soft white cheese from pure camel milk and mixture of camel and caw (1:1) (Fig. 13.1) One method utilized addition of 10% citric acid solution to one portion of milk till pH came down to 5.5. The starter culture was then added at the rate of 5% to second portion. After about an hour rennet was then added to both portions of milk at the rate of 0.15 ml/litre of milk. The milk was allowed to coagulate for five hours. After curd formation the coagulum was cut and whey was drained off. The coagulum so obtained was cut and scalding was done by gradually raising the temperature of the curd to 38 °C within 30 minutes. The curd was moulded and pressed for 2–3 hours at room temperature (25 °C). Cheese was removed from mould, packaged in packaging, sampled and stored at 4 °C for further revaluation.

13.7 Chemical Composition of Cheese

The chemical characteristics of white cheese prepared from camel and cow milk are presented in (Table 13.1). Most of the tested chemical components of both camel milk and cow’s milk were comparable.

These samples included: cheese made using 10% citric acid for pure camel milk (PCM), mixture camel milk and cow milk (MCCM) with citric acid, (MCCM1) using 5% starter culture for mixture of camel milk and cow milk (MCCM2). The moisture content was 55.00% for PCM, this result is in line with those found by Haider et al. (2004) which was 55.64–58.8% for pure camel milk cheese, while it was 61.42% and 67.49%, in MCCM1 and MCCM2, respectively. On the other hand, these results were higher than those results reported by Shahein et al. (2014) which were 54.67% for mixture camel (60%) and cow milk (40%) cheese.

The ash values were 2.36% for PCM, these results were higher than those reported by Derar et al. (2014) which were 1.46% for pure camel cheese while they were 2.52% and 2.67%, in MCCM1 and MCCM2, respectively. However these results were lower than that result reported by Shahein et al. (2014).which was 2.80–3.10%.

The protein contents in PCM, MCCM1 and MCCM2 were 35.55%, 31.55% and 25.70%, respectively. These results were higher than those reported by Haider et al. (2004) which was 21.30%, while these results were lower than that reported by Awad elsid (1996) which was 47.98%.

The fat (%) in PCM, MCCM1 and MCCM2 were 1.85%, 1.97% and 1.73% respectively, these results were extremely lower than those reported by Yonas et al. (2014) which were 12.90% and 13.40%. The variation in fat content in this study could be attributed to several factors like breed, individuality of animal, type of feed, health and age of the animal when the milk was taken.

The Lactose (%) in PCM, MCCM1 and MCCM2 was 2.49%, 2.47% and 2.37%, respectively. However, these results are in line with that found by Haider et al. (2004) which was 2.55%.

Total solid (%) were 45.00%, 38.58% and 32.51%, in PCM, MCCM1 and MCCM2, respectively. These results are in line with those found by Haider et al. (2004) and Shahein et al. (2014) and Yonas et al. (2014) which were 44.36%, 34.03% and 39.90%, respectively.

The pH value was 5.52, 4.39 and 4.39% in PCM, MCCM1 and MCCM2, respectively. These results were in close agreement with those reported by Yonas et al. (2014) which were 4.87 and 5.27 and also Haider et al. (2004) which were 4.90 and 5.80. The variation of pH values of various cheese samples could be attributed to the variation in composition and properties of milk.

The acidity (lactic acid%) was 3.19, 2.99, and 2.79%, in the PCM, MCCM1 and MCCM2, respectively. These findings are in close agreement to those obtained by Zakaria et al. (2012) who found that acidity in cheese (Jibna-beida) produced in Sudan from cow milk ranged between 1.58% and 2.10%. The high acidity of the cheese samples could be due to extended period of storage of cheese.

The mineral contents of PCM, MCCM1 and MCCM2 are also shown in Table 13.2. The major salt constituents were Calcium (Ca) Sodium (Na) and potassium (K) their concentrations were, 325.50, 299.5 and 449.50 mg/100 g, respectively, for Calcium (Ca), 48.50, 64.50 and 64.50 mg/100 g for Sodium (Na) and 16.50, 14.83 and, 12.50 mg / 100 g for potassium. The results indicated relative increase in calcium in MCCM2 as compared with those of PCM and MCCM2. On the other hand; the results indicated relative decrease of potassium in PCM as compared with those of MCCM1 and MCCM2.

13.8 Sensory Evaluation of White Cheese

Sensory characteristics of cheeses are considered one the most important attributes determining the consumers’ choice. Before and during ingestion itself, the consumer can perceive several sensory features of cheese, which are generally grouped under appearance, flavour and texture. All such attributes determine the eating quality of cheeses and consequently their acceptability. There is a wide diversity of cheese types worldwide, each one with a unique sensory profile. It reflects the characteristics of the milk feedstock, the cheese making conditions and the physical and chemical changes throughout ripening Jerónimo and Malcata (2013). The results of sensory evaluation of various cheeses are shown in Figs. 13.2, 13.3 and 13.4. The results show that the cheese samples prepared by using starter culture were more preferred on the basis of appearance, flavour and texture as compared to cheeses obtained by direct acidification using citric acid. However, all cheeses were accepted by the panelists (Figs. 13.5, 13.6, 13.7 and 13.8) (Table 13.3).

13.9 Conclusions

Making cheese from camel milk is a difficult task. The present was a trial to prepare camel milk at the laboratory level. Because of the difficulty of camel milk curdling, it was blended with cows milk (1:1) of was also mixed study confirmed possibility of production of cheese from camel milk with acceptable quality. The manufactured cheese was analyzed chemically, microbiologically and subjected to sensory analysis. From the obtained results, mixing camel milk with cow milk increased and improved the microbiological and chemical quality as well as the organoleptic properties of cheese. Fresh soft white cheese made from camel milk inoculated with starter culture was highly acceptable. The study recommends understanding the mechanism of enzymatic coagulation of camel milk to improve quality and yield of camel milk cheese. In addition, hygienic conditions must be available while making cheese.

References

Abu-Lehia IH (1989) Physical and chemical characteristics of camel milk fat and its fractions. Food Chem 34:261–271

Amasaib EO, Mohamed HE, Ishagl A, El-Zubeir IEM. 2013. The status of camel milk production in Sudan. Proceedings of International Camel Conference (Conference for sustainability for camel population and production

Derar AMA, El Zubeir IEM (2014) Compositional content of white cheese manufactured from mixtures of camel and sheep milk during storage. J. Food Nutr. Disor 3:3

Eisa MO, Mustafa AB (2011) Production systems and dairy production of Sudan camel (Camelus dromedarius): a review middle-east. J Sci Res 7(2):132–135. 2011 ISSN 1990-9233 © IDOSI Publications, 2011

Elamin FM, Wilcox CJ (1992) Milk composition of Majaheim camels. J Dairy Sci 75:3155–3157

Elayan AA, Sulieman AE, Saleh FA (2008) Effect of Gariss and Gariss containing Bifidobacteria in rats fed on a cholesterol-enricheddiet. Asian J Biochem 3:43–47

El-Zubeir IEM, Jabreel MSO (2008) Fresh cheese from camel milk coagulated with Camifloc. Int J Dairy Technol 61:90–95

Farah Z, Streiff T, Bachmann MR (1989) Manufacture and characterization of camel milk butter. Milchwissenschaft 44:412–414

Farah Z, Streiff T, Bachmann MR (1990) Preparation and consumer acceptability tests of fermented camel milk in Kenya. J Dairy Res 57:281–283

Gassem MA, Abu-Tarboush HM (2000) Lactic acid production by Lactobacillus delbrueckii ssp. bulgaricus in camel’s and cow’s wheys. Milchwissenschaft 55:374–378

Haider K, Izhar HA, Muhammad A (2004) Evaluation of cheese by processing camel milk. Pakistan J Zool 36:323–326

Hashim IB, Khalil AH, Habib H (2008) Quality and acceptability of a set yoghurt made from camel milk. J Dairy Sci 92:857–862

Inayat S, Mohammad AA, Khaskheli M, Alamdar SM (2003) Study of the effect of processing of the chemical quality of soft unripened cheeses. Pakistan Journal of Nutrition 2(2):102–105

Jerónimo E, Malcata FX (2013) Handbook of cheese in health: production, nutrition and medical sciences. Wageningen Academic publisher, Dordrecht, pp 39–50

Larsson-Raznikiewicz M, Mohamed MA (1986) Why difficult to make cheesefrom camel milk. In proceedings of the 22nd international dairy congress, theHague. D. Reidel Publishing Company, Dordrecht, p 113

Mehaia MA (2006) Manufacture of fresh soft white cheese (Domiati-type) from dromedary camels milk using ultrafiltration process. J Food Technol 4:206–212

Ramet JP (1989) Use of bovine calf rennet to coagulation raw camel milk. World Animal Review 61:11–17

Ramet, JP (2001) The technology of making cheese from camel milk (Camelus dromedary). Animal Production and Health Paper. No. 113. Rome, Italy: F.A.O

Shahein MR, Hassanein AM, Abeer FZ (2014) Evaluation of soft cheese manufacture from camel and buffalo milk, World Journal of Dairy and Food Sciences 9(2):213–219. ISSN 1817-308X © IDOSI Publications, https://doi.org/10.5829/idosi.wjdfs.2014.9.2.8681

Siboukeur O, Mati A, Hessas B (2005) Improving the coagulability of camel’s milk’s by using gastric enzyme coagulation extracts (Camelus dromedarius). Cahiers Agricultures 14:473–478

Yagil R (1982) Camels and camel milk animal production and health report. FAO, Rome

Yagil R, Saran A, Etzion Z (1984) Camels’ milk: for drinking only? Comp Biochem Physiol 78A:263–226

Yonas H, Eyassu S, Zelalem Y (2014) Physicochemical properties and consumer acceptability of soft unripened cheese made from camel milk using crude extract of ginger (Zingiberofficinale) as coagulant African Journal of Food Science 8(2):87–91. https://doi.org/10.5897/AJFS2013.1102 ISSN 1996-0794 ©2014 Academic Journals http://www.academicjournals.org/AJFS.

Zakaria A, Salih, Abdel Mone im E, Sulie man, Elamin A, Elkhalifa Ali O Ali (2012) Chemical and Microbiological characteristics of white cheese (Jibna-beida) produced in Sudan. Food and Public Health 2(6):259–264

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Mahgoub, S., Sulieman, A.M.E. (2022). Production and Quality Assessment of Camel Milk Cheese. In: Elhadi Sulieman, A.M., Adam Mariod, A. (eds) African Fermented Food Products- New Trends. Springer, Cham. https://doi.org/10.1007/978-3-030-82902-5_13

Download citation

DOI: https://doi.org/10.1007/978-3-030-82902-5_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-82901-8

Online ISBN: 978-3-030-82902-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)