Abstract

Heavy metals such as cadmium, chromium, lead, mercury, arsenic, nickel, zinc, and copper are critical pollutants of freshwater reservoirs due to their toxic, non-biodegradable characteristics and persistent nature. The rapid industrialization is the major cause for the contamination of heavy metals into the water body. Heavy metals are easily absorbed by flora like smaller plants and fauna like fishes of the aquatic system and higher plants also owing to their high solubility in water. The accumulation of heavy metals in the human body is persistent through the food chain.

The existing techniques for the removal of heavy metals include ion-exchange, membrane filtration, adsorption, electrochemical chemical precipitation. The more advanced processes include nanotechnology assisted treatments, membrane adsorption, and advanced oxidation processes. Invariably, each method is burdened with one or other issues and challenges. The issues and challenges of a particular process depend upon multiple factors like the quantity of pollutant, concentration level of pollutant, management of secondary pollutant, global removal facility, the requirement of the limit of concentration in the treated water and cost of treatment. The opportunities for employment of various techniques to remove the hazardous heavy metals from water in general and challenges therein have been enunciated in this chapter.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Wastewater

- Contamination

- Heavy metal

- Remediation

- Conventional technique

- Sludge

- Global management

- Challenge

- Advance technique

- Cost-effectiveness

- Nanomaterial

- Bio-adsorbent

- Future trend

14.1 Introduction

The ever increasing industrialization and rising of societal living standards of mankind influence the available water sources. The discharge of heavy metals through the industrial effluent to the aquatic environment has to be controlled. The removal of toxic heavy metals from aqueous solutions has become a challenge for the twenty-first century. Substantial amounts of hazardous heavy metal ions from the development activities in various industries such as chemical manufacturing, mining, metallurgical, and nuclear energy are discharged into the natural water environment. This discharge causes severe intimidation to the water environments (Vilardi et al. 2018; Yin et al. 2018). Owing to the high permeability, hazardous metal ions are accumulated in the cells of the human body through a slow but continuous process. The persistent accumulation of the heavy metals into cells of human and other species causes long-term damage to their body (Wang et al. 2015; Wang et al. 2018).

Heavy metals are likely to be accumulated in living organisms as they are not biodegradable and are highly soluble in water. The persistent accumulation of these obnoxious metal ions in the body of human causes the disease and disorder therein. Therefore, they are to be removed from the industrial effluents before they are discharged into the aquatic environment. Environmental regulations have become stricter in recent time. Hence, the practiced techniques for the removal of heavy metals are required to be revamped for producing a superior standard of treated water in the effluent. The techniques with cost-effectiveness and environmentally benignity are required to treat the water-bearing heavy metals. The increasing awareness and concern about the environment at the beginning of the twenty-first century motivated the research communities to develop alternative technologies for the treatment of water-bearing heavy metals inexpensively. The widely used treatment processes for heavy metal ions from water include ion exchange, distillation, electrodialysis, reverse osmosis, chemical precipitation assisted with coagulation and flocculation (Azimi et al. 2017). The conventional technologies for heavy metals removal from the industrial effluents are not adequate for the stricter regulation imposed by the regulatory authorities. The generation of secondary pollutants i.e. metal bearing sludge almost in every case creates the secondary problem. Globally disposal of this metal bearing sludge is extremely difficult. No single technique can precipitate the heavy metals to low levels of solubility without processing by another technique and using additional reagents. The use of additional steps significantly increases the volume of sludge.

There are conventional techniques (Fu and Wang 2011) which are being used for the removal of heavy metals. Various researchers have worked with the conventional techniques including chemical precipitation (Wang et al. 2005), adsorption (Srivastava et al. 2011; Zamboulis et al. 2011), ion exchange (Motsi et al. 2009; Ostroski et al. 2009), membrane filtration (Ersahin et al. 2012), reverse osmosis (Bódalo-Santoyo et al. 2003), coagulation and flocculation (Zhang et al. 2003), flotation and extraction (Rykowska et al. 2008), irradiation (Batley and Farrar 1978), electrochemical treatment techniques (Walsh and Reade 1994), advanced oxidation processes and bio-adsorption processes (Dave et al. 2010; Kavamura and Esposito 2010). The chemical precipitation technique is widely used by the utilization of the chemical reaction of respective chemicals with target heavy metals to form the precipitates. The chemical reagents are categorized into three classes such as inorganic, organic chelating reagents and organic polymers (Pan et al. 2009).

Lime precipitation is reported as the most effective conventional means for removal of heavy metals with a metal concentration higher than 1000 mg/L (Barakat 2011). The adsorption with new modified adsorbents and membrane filtration are also extensively used to treat these contaminations. On the other hand, photo-catalysis is a more recent and promising process to obtain cleaner water but is more expensive in comparison to other processes. Many other techniques can be used for the treatment of heavy metals from wastewater. The choice of the best technique for this purpose depends on factors such as pH, the concentration of metals in the wastewater, the possibility of ultimate performance in comparison with alternative processes, impact on the surrounding area after its employment as well as economic obligations viz. the cost of both investment and operation. Moreover, appropriateness of the application, simplicity of the process, and cost-effectiveness are the salient issues that contribute in the selection of the most appropriate technology for the treatment of heavy metals from industrial wastewater and surface water. Global management of the sludge containing concentrated heavy metals is the most critical challenge to be addressed. Novel nanomaterials having outstanding adsorption capacities, environment friendly performance and serene stability have emerged as a very important advancement in the removal techniques of heavy metal ions (Savage and Diallo 2005). Consequently, the promising nanotechnology with the exploration of very specific properties of nanomaterials has recently emerged for the treatment of wastewater (Lu and Astruc 2018). The cost, efficiency, and toxicity to the eco-system are to be combined to estimate the economic viability of nanotechnology for this purpose.

Another, very advanced process for the capturing of heavy metal ions is involved with the synthesis and use of metal-organic frameworks. The coordination chemistry between various inorganic metals (as precursors) and organic ligands helps in the synthesis of metal-organic frameworks. The inorganic precursors include various transition and heavy metals such as titanium(III), iron(III), copper(II), zirconium(IV), cobalt(II), cadmium(II), aluminium(III), zinc(II) and magnesium(II). On the other hand, various functional groups of organic compounds such as imidazole, p-phthalic acid, amines, benzoic acid, pyridine, sulfonates, phosphates, and carboxylates are used as organic ligands for the preparation of metal-organic frameworks (Wu et al. 2018). The capacity of metal-organic frameworks for the adsorption of heavy metals is likely to be higher in comparison to the other adsorbents due to some unique properties of them. The well-defined and diversified structures of metal-organic frameworks provide the high porosity, large surface area, the required characteristics of a novel adsorbent (Ricco et al. 2015; Yang and Yin 2017).

Recently, biological treatments are considered as an environmentally benign technology for the remediation of hazardous heavy metals. Extracellular polysaccharides produced during microalgal growth have emerged as the biological adsorbents for toxic components. The polysaccharides containing various positive and negative functional groups that facilitate the binding of metal cations or anionic metal radicals present in the wastewater based on the pH level of it. E.S. Priya et al. reported that the aquatic macrophytes provide very interesting results in the field of phytoremediation (Sanmuga Priya and Senthamil Selvan 2017). They have great potential for the accumulation of hazardous heavy metals inside their cellular structures up to 100,000 times greater than the amount present in the general water bodies. So, they are used for the removal of heavy metals from a variety of sources (Mishra and Tripathi 2008). Water hyacinth is one of the most commonly used macrophytes because of its fast growth rate and large uptake of nutrients and heavy metals (Rai 2009). The dried roots and the whole plant are used as the bio-adsorbent for removal of heavy metals. Other plant tissues were used by various researchers for the removal of heavy metals (Jadia and Fulekar 2009). The principles of various conventional and comparatively more advanced techniques are discussed in this chapter. Several opportunities and challenges for application of these techniques are elaborated.

14.2 The Available Techniques

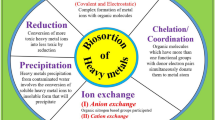

Wastewater effluents from various industries, such as metal-plating processes, mining operations, tanneries, pulp, and paper industries are contaminated by heavy metals. The prevalent metals that are discharged to the aquatic environment from these activities include mercury, nickel, cadmium, iron, chromium, and lead. The existing physicochemical methods like various types of filtration by membranes, chemical precipitation, ion exchange, adsorption, and electrochemical processes are presently used for the heavy metals remediation. Each of the methods is limited by one or more drawbacks such as the production of a large amount of sludge, difficulty in removal of sludge, use of an excessive quantity of hazardous chemicals and technical constraints. Many of the methods are widely used in large scale for the decades with certain merits and demerits and termed as the conventional methods. Others methods which are employed in the developed countries and still are required to be researched for the cost-effectiveness and better yield are termed as the advanced techniques. The basic principle, procedural details, and applicability to a particular type of heavy metal contamination and cost-effectiveness of both the conventional and advanced techniques are discussed in the following sub-sections and depicted in Fig. 14.1.

14.2.1 The Conventional Techniques

The conventional techniques for the removal of heavy metals from water are the techniques that have been widely used for the past several decades. The techniques are characterized by low cost but less efficiency and generation of a larger amount of secondary pollutants. The global management of secondary pollutant is an added problem. The conventional techniques are well experimented and limited by the further improvement. Some of the conventional methods are elaborated in the following sub-sections:

14.2.1.1 Chemical Precipitation

Chemical precipitation is a chemical process by which heavy metal ions soluble in surface water or industrial wastewater are separated. The undesired soluble ions of heavy metals present in water are converted to insoluble ions in the aqueous medium, settled down as precipitation and discarded. Therefore, the heavy metal ions are coagulated to tiny solid particles. The ionic state of the heavy metal ions is changed by the chemical reaction with the help of appropriate chemicals. The solubility of heavy metal ions is reduced by the addition of counter-ions supplied by the chemicals. The technique involves the shifting of the ionic equilibrium to produce insoluble precipitates before sedimentation. It is mostly used for the removal of heavy metals as cations. It is mostly applicable to the wastewater that contains also phosphorous compounds, hardness and organic hazards such as aromatic amines and phenols (Atlow et al. 1984). The conversion to insoluble ions is always followed by one or more unit operations to separate the coagulated ions into solids. The unit operation such as coagulation, flocculation, sedimentation, and filtration are quite often used to assist the chemical precipitation. Sometimes the metal ions are reduced by the use of chemicals so that they can be transformed to the ionic state for precipitation (Wang et al. 2005).

The heavy metals are discharged in large quantity in the wastewater from the metal plating industry. The soluble salts of various heavy metals like cadmium, chromium, copper, nickel, lead, zinc and others are present in the wastewater in higher concentrations. Chemical precipitation technique is the most inexpensive for removal of high concentration of heavy metals ions and therefore widely used for this purpose. The alternative processes for high concentrated heavy metals removal are ion exchange, electro-precipitation and reverse osmosis. But the capital cost is higher for all three alternatives. Operational energy cost is very high for both the electro-precipitation and reverse osmosis. But, advantages of theses alternative processes remain in their capacity to be better adapted to metal recovery and recycling of metals. On the other hand, chemical precipitation is simple in operation and the investment cost is low. The major issues of chemical precipitation are its operating costs arising from a large expense on a high amount of chemical utilization and the disposal cost of the precipitated sludge.

The chemicals used for precipitation are hydroxides, sulfide and carbonate salts of sodium and potassium. The heavy metals to be removed must be either reduced or oxidized to a state of valence that can then be insoluble and precipitated accordingly. The precipitation of tiny insoluble ions is facilitated by coagulation and flocculation. The concentration of flocculent, coagulant and pH of water have major influence on the precipitation. Ferric chloride has a strong capacity to form larger flocs leading to the removal of metals. Contrary, polyaluminium chloride is generally used as an agent for the neutralization of charge of ions (Zhang et al. 2003).

14.2.1.2 Membrane Filtration

Membrane filtration is considered as another conventional technique to remove inorganic heavy metals from water streams. The membrane filtration used for simultaneous removal of suspended solids, organic compounds along with heavy metals. Based on the working principle and size of the membrane pores, membrane filtration is classified as ultrafiltration, nanofiltration and reverse osmosis. Each of the types of filtration process is used depending upon the characteristics of wastewater containing heavy metals. The various membrane filtration processes are classified with regard to sizes of both the pores of the membrane and that of the particles of the solute. The pore size of the ultrafiltration membrane is in the range of 5–20 nm and it is used for the separation of coagulated heavy metals ions from water solution. The particles in the size range of 1000–100,000 Da can be separated by the ultrafiltration technique (Vigneswaran et al. 2004). Various ultrafiltration membranes are also used for the removal of metals when their concentrations remain in the range of 10–112 ppm. The operational pressure for ultrafiltration ranges from 2 to 5 bar. The advantages of ultrafiltration include the requirement of a lower pumping cost due to lower resistance to water permeation and a smaller footprint as the packing density of membrane fibers is high.

The ultrafiltration technique has been enhanced by the employment of polymers in the fabrication of membrane materials. Polymer-supported ultrafiltration technique uses polymeric ligands that are water-soluble. The binding of metal ions to membrane materials is facilitated by the formation of macromolecular complexes (Rether and Schuster 2003). The requirement of energy for the ultrafiltration becomes lower by the use of polymer-supported ultrafiltration. The reaction kinetic becomes faster and metal selectivity increases. The ultrafiltration assisted with water-soluble metal-binding polymers is a hybrid approach with higher selectivity for the recovery of heavy metals from the water. The other modification of ultrafiltration technique with the same advantages as that in polymer-supported ultrafiltration is the complexation-ultrafiltration. In this approach, the heavy metal cations are first complexed with a macro-ligand for enlargement of the metal ions to a size which is larger than the size of the membrane pores (Petrov and Nenov 2004; Trivunac and Stevanovic 2006). The polymeric ligands are water-soluble and make powerful complex to remove trace amount of heavy metals from surface water and industrial wastewater using the membrane processes. Nanofiltration is useful for the separation of the smaller particle size (nano size) of heavy metals ions. The pressure drop is larger compared to ultrafiltration and hence, the cost of separation is more. The membrane fouling problem is bigger in nanofiltration.

Semi-permeable membranes are used in reverse osmosis. The heavy metal ions are retained and the water is passed through the semi-permeable membrane with the application of high pressure. The particles of the heavy metals ions that are even smaller than the size of nano-levels are separated in reverse osmosis. The membrane is semi-permeable that permits the passage of water but not that of metal ions. The technique is used to separate different kinds of ions, molecules, even the microorganism like bacteria along with heavy metal ions from water solution. The principle of reverse osmosis is like diffusion operation and the separation efficiency depends upon the variables such as the concentration of metal ions, trans-membrane pressure, and flux of water.

14.2.1.3 Ion-Exchange

The cations and anions of heavy metals present in the water can be removed by the technique of ion exchange. The exchangers are made of a polymeric substance by cross-linking the chains of one or more monomers. The polymeric chains are so entangled that they form a solid matrix with the attachment of various functional groups by covalent bonds. They consist of a cross-linked polymer matrix (resin) in which various charged functional groups are attached by covalent bonds (C. Sherrington 1998). The exchanger resins are so hard that they are insoluble not only in water but also in various organic solvents. The exchangers with functional groups containing cations and anions as counter-ions are known as cation exchangers and anion exchangers, respectively. One of the widely used polymer matrices is polystyrene where 3–8% of divinylbenzene is incorporated with polymer matrix of polystyrene to get the strong structural stability (Kunin et al. 1962). The incorporation of more proportion (12–16%) of divinylbenzene in the polystyrene matrix provides a more stable and harder grade of ion-exchange resin that can be employed for remediation of contaminants present even in an adverse environment. They are capable to resist their degradation against the strongest oxidizing agents like ozone and chlorine. The physical stability of highly cross-linked ion exchangers is also higher. The ion-exchangers for the separation of anions form cations are fabricated with a particle size of 20–50 mesh. The smaller particles of resins (200–400 mesh) are advantageous in the affinity-based separation of heavy metal ions. The particle size of 50–100 mesh is adequate while separation by ion-exchange is facilitated with complexation of target ions by suitable complexing agents.

Ion exchange resins are classified as acidic, basic and neutral considering the attached functional groups to the polymer matrix. The various functional groups are sulphonate for strongly acidic, carboxylate for weakly acidic, quaternary ammonium for strongly basic and secondary and tertiary amines for weakly basic ion exchangers. The acidic exchangers easily dissociate over a wide range of pH and consequently, they are the best type of exchangers. The weak acidic exchangers have more capacity when the pH of water is in the alkaline region. Some amphoteric exchangers can work as both cationic and anionic exchangers depending upon the pH of the water. The amphoteric exchangers are also called as zwitterionic ion exchangers (Nesterenko and Haddad 2000). The amino-carboxylic exchangers and the carboxylic cation exchanger with a carboxylic functional group have been recently used for separation of nickel(II) from the mixture of nickel(II) and manganese(II) in aqueous solution (Kononowa et al. 2000). The heavy metal ions in the water and wastewater are separated based on the difference in their affinity to the ion exchange resin. Moreover, types of the ionic species attached to the polymeric resin decide the effectiveness of the ion exchange technique (Fritz 2005). The affinity series is the decisive factor in the formation of the types of ion-exchangers and are considered for the selection of ion exchangers for a particular heavy metal ion to be separated.

14.2.1.4 Adsorption

Adsorption is a solid-liquid or a solid-gas interaction with the objective of separation of target component from either the liquid or gas phase. The target solute present in either liquid or gas phase is adsorbed to the solid surface of the adsorbent and separated from the liquid or gas stream, respectively. Adsorption is a surface phenomenon which is limited to distance of one molecule deep on the adsorbent surface. The extent of adsorption depends upon the nature of both adsorbent and the target molecule known as the adsorbate. It also depends on the available surface. Hence, the size of the adsorbent particles is important. The smaller is the size of adsorbent, the more is the available surface area and hence, the higher rate of adsorption. Activated charcoal is the most widely used chemical adsorbent. The adsorbents of the nanoparticle size of different inorganic substances are synthesized and used as the modified adsorbent. On the other hand, some adsorbents are synthesized from organic bio-sources. Adsorption is a reversible process and the temperature has a significant role in the equilibrium. The solute molecules are adsorbed on the surface of the adsorbent and are oriented in a definite manner. The de-sorption technique is used to remove the solute from the surface of the adsorbent so that adsorbent can be reused and solute can be recovered. Adsorbents may be classified as inorganic or bio-adsorbent based on their sources.

14.2.1.4.1 Inorganic Adsorbent

Zeolites are the most effective and widely used inorganic adsorbents and ion-exchange media for removal of heavy metal ions. Commercially known NaP1 zeolites (Na6Al6 Si10O32, 12H2O) contains enormous sites of Na+ to exchange various cations of water. The zeolites are synthesized inexpensively by the process of hydrothermal activation. The fly ash containing silicon and aluminum is mixed with the caustic soda solution of 1–2 M (Moreno et al. 2001). Alvarez-Ayuso et al. used synthesized NaP1 zeolites to remove various heavy metals like copper(II), chromium(III), zinc(II), nickel(II) and cadmium(II) from wastewater of electroplating industries (Álvarez-Ayuso et al. 2003). The single layers of zeolites are assembled on the supports of mesoporous characteristic to fabricate the effective inorganic adsorbent, NaP1 (Yantasee et al. 2003). The support ceramics are prepared in the templated synthesis using the surfactants. The nanoporous ceramic oxides are formed. The adsorbent so formed is characterized by the large active surface (1000 m2.g−1) and numerous adsorption sites. The sites are functionalized accordingly to enhance selectivity to the heavy metals that are targeted. Savage and Diallo reported that the diphenyl dithiocarbamate is another important inorganic adsorbent for capturing the heavy metals (Savage and Diallo 2005). It is more efficient and provides higher capacity in comparison with widely used activated carbon. It is more applicable to the polluted water contaminated by multiple heavy metals (Savage and Diallo 2005). The efficacy of diphenyl dithiocarbamate as an adsorbent for the treatment of four common heavy metals in different operational conditions is summarized in Table 14.1.

Several research works are going on for the modification of inorganic adsorbents. The modification is based on the inclusion of magnetic property, the inclusion of polymeric property, size and shape of the adsorbent particles. The sizes of the particles are maintained in the nanoscale so that the available surface area for adsorption is very high. The examples of such modified nano-adsorbents are magnetic multi-wall carbon nanotubes, magnetic zeolite-polymer composite, graphene nanosheets, nanocrystalline titanium dioxide, and others. The removal efficiencies for various heavy metals by using these modified nano-adsorbents at various operational conditions are depicted in Table 14.2.

14.2.1.4.2 Bio-adsorbent

Both the dead and live cells of organisms are employed as bio-adsorbents to remove heavy metals from wastewater. The bio-sorbents are loaded with the positive and negative functional groups that facilitate the binding of heavy metal ions in different electronic states. The various functional groups are hydroxyl, carboxyl, amine, sulfate and phosphate ions. The currently practiced technologies for the remediation heavy metals are precipitation, adsorption, reduction, coagulation, and membrane filtration. However, they have several limitations. They are not applicable very well in treating heavy metals with high concentrations with the exception of chemical precipitation. The bio-sorbents which are wastes in the agricultural sector and various industries are used at present for removal of heavy metals. Regeneration of metal-treated bio-adsorbent and reuse of it is an important matter for the cost-effectiveness of this technique. Desorption of metals from adsorbed biomaterials is usually accomplished by eluting with different stripping agents such as water, acid, and base in different concentrations.

Agricultural wastes, especially algal biomass and activated carbon produced from such waste are used as low-cost adsorbents (Babel and Kurniawan 2003; Ahalya et al. 2005; Vijayaraghavan et al. 2005). Various functional groups such as carboxylic, sulfonic and hydroxyl groups in the extracellular polysaccharides produced from marine algae is observed to be responsible for impressive metal uptake (McKay et al. 1999; Davis et al. 2003). Javadian et al. proposed wet algal biomass as bio-adsorbent in the separation of metal ions from water (Javadian et al. 2013). On the other hand, S. Zakhama et al. used dried algal biomass for this purpose in batch and continuous reactors (Zakhama et al. 2011). El-Sikaily et al. used algal biomass to remove hexavalent chromium from wastewater (El-Sikaily et al. 2011). Soltmann et al. studied the biosorption of heavy metals with immobilized or encapsulated algal biomass, macro (Fucus) and microalgae (Spirulina etc.) in the three different silica sols for the removal of copper, nickel, chromium, and lead in drinking water (Soltmann et al. 2010). Daniel et al. reported the bio-adsorption of heavy metals (cadmium and copper) from industrial wastewater by using algal and bacterial biomass (Daniel et al. 2005). The application of live algae and bacteria for the adsorption purpose were found more promising than the immobilization of biomass.

14.2.1.5 Electrochemical Process

Two types of electrochemical processes are generally used in the remediation of heavy metals. In the electroplating process, the soluble heavy metal ions are electroplated on the electrode and thereby separated from the water. The electric potential is applied across the electrodes. On the other hand, an electro-coagulation is an electrochemical technique for remediation of metal ions that are suspended or made suspended by altering the pH of the solutions. An electrical current is passed through the solution and the suspended ions are coagulated so that they can be easily precipitated and removed. The electro-coagulation process is effective for the removal of both the suspended and dissolved heavy metals. The electrochemical technique is currently the most effective process for treating wastewater from metal extraction process industries containing a high concentration of metal ions. The pH of water solution and the current density passing through the water are two important factors. Electrochemical process is considered as a potential technique for its versatility and environmental benignity.

The heavy metal cations are neutralized with ions of negative electrical charge passed through the water solution. As soon as the cations are neutralized in electro-coagulation, they become destabilized and precipitate down. The electrochemical technique is simple, fast, very easy to operate and environmentally benign. The treated water is potable, completely free from heavy metal ions. The amount of sludge generated is very less as no precipitating agent or chemical is added. There is a very minimum chance of secondary contamination of treated water as nothing is added to the water except the electrical current in this technique. Various researchers have reported that the electro-coagulation technique can successfully remove the heavy metals as well as other soluble ionic species (Rincón and Motta 2014; Nouri et al. 2010).

14.2.1.6 Electrodialysis

Electrodialysis technique is an extraction process of heavy metals assisted with electrochemical activity. This technique is considered as a potential method to separate metals from fly ashes. The variables of this process are type and concentration of electrolytes, pH of water, the temperature of operation, and the time of the process. The remediation of heavy metals from contaminated water stream can be achieved with high current efficiencies and reasonable stack resistance (Gering and Scamehorn 1988). Electrodialysis is a combination of membrane separation and electrical potential assisted process in which ionized heavy metal ions in the aqueous solution are transported through an ion-exchange membrane. The driving force for the transportation of metal ions is an electric potential. The thin polymeric membranes with both the anionic or cationic characteristics are used. Water containing metal ions passes through a stack of cation exchange and anion exchange membranes placed in the electrodialysis cell. The anions and the cations travel toward the anode and the cathode, respectively while passing through both types of ion-exchange membranes (Chen 2004). Tzanetakis et al. reported the electrodialysis of two contaminants such as cobalt and nickel (Tzanetakis et al. 2003). Two cation-exchange membranes such as perfluorosulfonic membrane (Nafion 117) and sulfonated polyvinyl difluoride membrane are extensively employed for the separation of heavy metals from surface water and wastewater.

14.2.2 Advanced Techniques

The advanced techniques for the remediation of metal ions from water are referred to the comparatively new processes. The processes are potential but much improvement is required to be efficient concerning cost-effectiveness and efficacy. They are not extensively used for heavy metal removals. Such techniques are discussed in the following sub-sections.

14.2.2.1 Nanotechnology Assisted Treatments

The prospect for the applications of novel-nanomaterials for the removal of heavy metal ions is current research topic to have more efficient practical applications. The novel-nanomaterials with large specific surface area, much more surface-active sites due to the presence of various functional groups, have an excellent capacity for removal of heavy metal ions. They have two unique properties that make them particularly attractive for the purpose (Savage and Diallo 2005). Firstly, they have a much larger surface area per unit mass. Secondly, they are functionalized with various negative and positive functional groups to increase their affinity towards a target heavy metal ion. The research community is exploiting the unique properties of nanoparticles to provide high capacity and selectivity for metal cations and anions. Nanomaterials for heavy metal removal are categorized as inorganic and organic nature. Qi et al. studied the efficiency of chitosan nanoparticles in the size range of 40–100 nm prepared by ionic gelation of chitosan and tripolyphosphate (Qi and Xu 2004). Inorganic nanomaterials are composed of an inorganic core surrounded by small organic or inorganic molecules and polymers. Moreover, magnetic nanomaterials containing magnetic core have the great advantage of easy separation by the use of a magnetic field. Alternatively, the agricultural wastes such as bagasse, rice husk, the shell of the coconut and peanut and mycelial microorganisms such as Dictyophora indusiata and Bacillus, fly ash, clay and mineral slag like coal are reported for the synthesis of the nano-organic adsorbents. The bio-material based nano-adsorbent is preferable due to non-toxicity, economical viability and environmental compatibility. The carbon-based nanomaterials like graphene and carbon nanotubes have the limitation for their application due to the high cost for their synthesis. Therefore, the conversion of agricultural waste to carbon-based nanomaterials for the removal of heavy metals is becoming a promising alternative nano adsorbent to activated carbon. Both the agricultural waste-based nanomaterial such as cellulose and chitosan-based nanomaterial offer enormous opportunities for the remediation of heavy metals from water.

14.2.2.2 Advanced Oxidation Process

The inorganic nano-catalysts like semiconductors and metal oxides have gained considerable attention in the remediation of contaminants from wastewater. Nanosize photocatalysts (Dutta et al. 2014) electrocatalysts (Dutta et al. 2014) and Fenton reagents as catalysts (Kurian and Nair 2015) are being used in practical purposes in the developed country for removal of heavy metals through their oxidation (Ma et al. 2015). In a developing country, the advanced oxidation process ate yet to apply in the industrial level as removal of pollutants by this method is expensive. The cost of semiconductor materials and also the cost of energy for excitation of the catalytic materials for the generation of oxidizing species are very high. In recent years, inexpensive solar energy is used for the excitation of the photocatalysts. Although the installation cost for solar energy conversion for the purpose is substantially high. This photocatalytic process has the ability for rapid and efficient breakdown of heavy metal compounds. The interface between catalyst and electrolyte is irradiated by the light (solar) energy greater than that of the bandgap of the semiconductor. The electron-hole pairs (e/h+) are generated in the conduction and the valence band of the semiconductor or photocatalyst, respectively (Herrmann 1999). These charge carriers (electrons and holes) migrate to the surface of the semiconductor and oxidize the compounds of heavy metals in the solution having suitable redox potential. The semiconductors or photocatalysts such as titanium dioxide, zinc oxide, cerium dioxide, cadmium sulfide and zinc sulfide have been extensively explored for the research in this direction. The titanium dioxide has emerged as the best photocatalysts with maximum quantum yields. Zhang et al. have reported the principle and mechanism of photocatalytic reaction using titanium dioxide as catalyst (Zhang and Itoh 2006). The hydroxyl ions (-OH) are used to trap the holes and leads to the generation of strong oxidizing hydroxyl radicals. In contrast, adsorbed oxygen species are likely to trap electrons and leads to the generation of superoxide species (O−2). The superoxide species are very reactive, but they are unstable.

14.2.2.3 Membrane Adsorption

The membrane adsorption technique is the integrated process of two separation techniques such as membrane filtration and adsorption with the synergistic effects. Membrane adsorption technology was developed in the mid-1980s (Avramescu et al. 2003; Avramescu et al. 2008). The polymeric membrane is applied for the adsorption of hazardous pollutants like heavy metal ions. Membranes are used for the dual purposes of membrane filtration and adsorption of contaminants on the active sites incorporated on the surface of the membrane. This technique can be applied for the very effective removal of both the metal cations and anionic species like phosphates and nitrates. The novel nanoparticles are incorporated in the membrane to boost the effectiveness of the membrane filtration. The functional groups on the surface of the nanoparticle adsorbents facilitate in the adsorption of heavy metal cations. The pH of water solution is a key variable for the process efficiency. The solubility of the metal ions in water solution is decisive by the pH. The pH maintains the concentration of the counter-ions on the surface of the adsorbent. Moreover, the extent of ionization of target solute (heavy metals) in the aqueous solution is also maintained by the pH level of the aqueous solution. The adsorbent with functional groups is attached to the surface of the pores of the polymeric membrane. The target heavy metals ions are selectively adsorbed to the appropriate functional groups. The heavy metal ions are bound to the binding sites of adsorbent and thereby are removed from the water stream. The rate of adsorption is substantially high as a very short distance (a distance of a molecule) between the solutes and binding sites of the membrane adsorbents is pertinent for the adsorption process (Zheng et al. 2015).

14.3 Challenges

The remediation of heavy metals is a challenge from the implementation of mainly four considerations such as efficiency, recyclability, environmental benignity and cost (Lu and Astruc 2018). The cost of the treatment of the effluent water containing heavy metals is very expensive for the smaller throughput. The benefits of the regeneration of adsorbent by desorption, recovery of catalyst and recycling of the streams are achieved in lesser amount for smaller installation and the treatment process is not economically viable (Barakat 2011). The existing treatment strategies need costly chemicals. The cost of unit operations for the treatment processes is high. A substantial amount of supervision and maintenance are involved in the existing techniques for heavy metals remediation. The processes like chemical precipitation, electrochemical coagulation have more capacity, are inexpensive but generate a higher amount of sludge. Management of sludge containing heavy metals is very much likely to be unsolvable. On the other hand, processes like electroplating and electro-dialysis produce lower sludge, but the consumption of electricity is higher. Membrane filtration has the drawbacks of membrane fouling and lower flux.

The interaction between metal ions and active sites of biomass is essential for the implementation of adsorption techniques. The use of ion-exchange resins is both effective and convenient. But, it is too expensive to be used by developing countries. On the other hand, reverse osmosis employs tiny organics to generate tri-halomethane during disinfection of water using chlorine. The Environmental Protection Agency strictly confines the allowable limit of compounds like tri-halomethane in drinking water due to possible chronic exposure that causes cancer.

The use of synthetic coagulants that are used for removal of heavy metals is also restricted. The tri-halomethane seriously leads to several issues concerned with the central nervous system of human beings. The application of nanomaterials for the removal of heavy metals from water has certain merits and demerits. The high efficiency is one of the merits, and high cost, potential health risk and generation of a secondary pollutant are some of the demerits. Hence, the search for innovative and highly efficient nanomaterials with lower cost and lesser health hazards is important (Lu and Astruc 2018). Even the novel nanomaterials still face various challenges in their use for separation of heavy metals from contaminated wastewater. The nanosize of novel-nanomaterials is very prone to be clumped leading to the fouling and/or blocking of the membrane in the real applications. The blocking reduces the adsorption capacity very rapidly. Moreover, the nanoparticles may not be used in a packed column as it creates high pressure due to their nano-level sizes. Therefore, they are either implanted in or layered on the surface of support materials. Then the advantages of the nanoparticles are largely reduced. The characteristics of the surface of the promising nanomaterials very often diminish with time and nanomaterial compounds sometimes easily oxidized with the exposure of air and/or water. The production of nanomaterials in industrial scale is limited as they are unstable and proper storage is both difficult and expensive. Therefore, it is necessary to develop in each of the aspects like capacity, efficiency, selectivity, and stability of nanomaterials to separate heavy metal ions from water even under complex environment. It can be accomplished through the optimization of the surface properties and subsequent geometric arrangements of nanoparticles through compatible synthesis scheme.

The desorption techniques are to be more efficient for the recycling of bio-adsorbents to achieve cost-effectiveness. The advanced oxidation process is expensive due to the high cost of photocatalyst and irradiation. The challenge for the application of membrane adsorption is to develop a mathematical model for the optimization of the parameters concerning both filtration and adsorption processes (Table 14.3).

14.4 Conclusions

The existing treatment processes of wastewater to eliminate hazardous heavy metals are not substantially potential. The generation of sludge for chemical precipitation, membrane fouling for membrane filtration, consumption of high electricity for both the electrochemical and the electrodialysis, lack of adequate desorption agent and/or technique in case of adsorption are among the problems of conventional processes. No unique method is available for the remediation of the heavy metals in solo step as metals are in different ionic states. In the present stricter environmental obligation, green methods for the preparation of novel-nanomaterials must be explored at length. The nanomaterials have broad application prospects for the separation of heavy metals from aqueous solution. The design of integrated treatment processes for the removal of the heavy metals along with other pollutants will be practicable in principle. Several recently developed novel adsorbents such as nanosheets of porous boron nitride, porous graphene, metal organic framework and carbon nanotubes are to be developed for improving the selectivity, stability, capacity, and regenerability of these adsorbents. The membrane adsorption technique may be useful with the solution of the optimization problem.

References

Abu-El-Halawa R, Zabin SA (2017) Removal efficiency of Pb, cd, cu and Zn from polluted water using dithiocarbamate ligands. J Taibah Univ Sci 11(1):57–65. https://doi.org/10.1016/j.jtusci.2015.07.002

Ahalya N, Kanamadi RD, Ramachandra TV (2005) Biosorption of chromium (VI) from aqueous solutions by the husk of Bengal gram (Cicer arientinum). Electron J Biotechnol 8(3):258–264. https://doi.org/10.2225/vol8-issue3-fulltext-10

Álvarez-Ayuso E, Garcı́a-Sánchez A, Querol X (2003) Purification of metal electroplating wastewaters using zeolites. Water Res 37(20):4855–4862. https://doi.org/10.1016/j.watres.2003.08.009

Atlow SC, Bonadonna-Aparo L, Klibanov AM (1984) Dephenolization of industrial wastewaters catalyzed by polyphenol oxidase. Biotechnol Bioeng 26(6):599–603. https://doi.org/10.1002/bit.260260607

Avramescu ME, Gironès MR, Borneman Z, Wessling M (2003) Preparation of mixed matrix adsorber membranes for protein recovery. J Membr Sci 218(1):219–233. https://doi.org/10.1016/S0376-7388(03)00178-9

Avramescu ME, Borneman Z, Wessling M (2008) Particle-loaded hollow-fiber membrane adsorbers for lysozyme separation. J Membr Sci 322(2):306–313. https://doi.org/10.1016/j.memsci.2008.06.013

Azimi A, Azari A, Rezakazemi M, Ansarpour M (2017) Removal of heavy metals from industrial wastewaters: a review. ChemBioEng Rev 4(1):37–59. https://doi.org/10.1002/cben.201600010

Babel S, Kurniawan TA (2003) Low-cost adsorbents for heavy metals uptake from contaminated water: a review. J Hazard Mater 97(1):219–243. https://doi.org/10.1016/S0304-3894(02)00263-7

Barakat MA (2011) New trends in removing heavy metals from industrial wastewater. Arab J Chem 4(4):361–377. https://doi.org/10.1016/j.arabjc.2010.07.019

Batley GE, Farrar YJ (1978) Irradiation techniques for the release of bound heavy metals in natural waters and blood. Anal Chim Acta 99(2):283–292. https://doi.org/10.1016/S0003-2670(01)83569-8

Bódalo-Santoyo A, Gómez-Carrasco JL, Gómez-Gómez E, Máximo-Martín F, Hidalgo-Montesinos AM (2003) Application of reverse osmosis to reduce pollutants present in industrial wastewater. Desalination 155(2):101–108. https://doi.org/10.1016/S0003-2670(01)83569-8

Chen G (2004) Electrochemical technologies in wastewater treatment. Sep Purif Technol 38(1):11–41. https://doi.org/10.1016/j.seppur.2003.10.006

Daniel C, Alfano D, Venditto V, Cardea S, Reverchon E, Larobina D, Mensitieri G, Guerra G (2005) Aerogels with a microporous crystalline host phase. Adv Mater 17(12):1515–1518. https://doi.org/10.1002/adma.200401762

Dave N, Chan MY, Huang PJJ, Smith BD, Liu J (2010) Regenerable DNA-functionalized hydrogels for ultrasensitive, instrument-free mercury (II) detection and removal in water. J Am Chem Soc 132(36):12668–12673. https://doi.org/10.1021/ja106098j

Davis TA, Volesky B, Mucci A (2003) A review of the biochemistry of heavy metal biosorption by brown algae. Water Res 37(18):4311–4330. https://doi.org/10.1016/S0043-1354(03)00293-8

Dutta AK, Maji SK, Adhikary B (2014) γ-Fe2O3 nanoparticles: an easily recoverable effective photo-catalyst for the degradation of rose bengal and methylene blue dyes in the waste-water treatment plant. Mater Res Bull 49:28–34. https://doi.org/10.1016/j.materresbull.2013.08.024

El-Sikaily A, El Nemr A, Khaled A (2011) Copper sorption onto dried red alga, Pterocladia capillacea and its activated carbon. Chem Eng J 168(2):707–714. https://doi.org/10.1016/j.cej.2011.01.064

Ersahin ME, Ozgun H, Dereli RK, Ozturk I, Roest K, van Lier JB (2012) A review of dynamic membrane filtration: materials, applications, and future perspectives. Bioresour Technol 122:196–206. https://doi.org/10.1016/j.biortech.2012.03.086

Fu F, Wang Q (2011) Removal of heavy metal ions from wastewaters: a review. J Environ Manag 92(3):407–418. https://doi.org/10.1016/j.jenvman.2010.11.011

Gering KL, Scamehorn JF (1988) Use of electrodialysis to remove heavy metals from water. Sep Sci Technol 23(14–15):2231–2267. https://doi.org/10.1080/01496398808058452

Herrmann JM (1999) Heterogeneous photocatalysis: fundamentals and applications to the removal of various types of aqueous pollutants. Catal Today 53(1):115–129. https://doi.org/10.1016/S0920-5861(99)00107-8

Jadia C, Fulekar MH (2009) Phytoremediation of heavy metals: recent techniques. Afr J Biotechnol 8(6):921–928. http://www.academicjournals.org/AJB

Javadian H, Ahmadi M, Ghiasvand M, Kahrizi S, Katal R (2013) Removal of Cr (VI) by modified brown algae Sargassum bevanom from aqueous solution and industrial wastewater. J Taiwan Inst Chem Eng 44(6):977–989. https://doi.org/10.1016/j.jtice.2013.03.008

Kavamura VN, Esposito E (2010) Biotechnological strategies applied to the decontamination of soils polluted with heavy metals. Biotechnol Adv 28(1):61–69. https://doi.org/10.1016/j.biotechadv.2009.09.002

Kunin R, Meitzner EA, Oline JA, Fisher SA, Frisch N (1962) Characterization of amberlyst 15. Macroreticular sulfonic acid cation exchange resin. I&EC Prod Res Dev 1(2):140–144. https://doi.org/10.1021/i360002a016

Kurian M, Nair DS (2015) Heterogeneous Fenton behavior of nano nickel-zinc ferrite catalysts in the degradation of 4-chlorophenol from water under neutral conditions. J Water Process Eng 8:e37–e49. https://doi.org/10.1016/j.jwpe.2014.10.011

Lu F, Astruc D (2018) Nanomaterials for removal of toxic elements from water. Coord Chem Rev 356:147–164. https://doi.org/10.1016/j.ccr.2017.11.003

Ma H, Wang H, Na C (2015) Microwave-assisted optimization of platinum-nickel nanoalloys for catalytic water treatment. Appl Catal B Environ 163:198–204. https://doi.org/10.1016/j.apcatb.2014.07.062

McKay G, Ho YS, Ng JCY (1999) Biosorption of copper from waste waters: a review. Sep Purif Methods 28(1):87–125. https://doi.org/10.1080/03602549909351645

Mishra VK, Tripathi BD (2008) Concurrent removal and accumulation of heavy metals by the three aquatic macrophytes. Bioresour Technol 99(15):7091–7097. https://doi.org/10.1016/j.biortech.2008.01.002

Moreno N, Querol X, Ayora C, Pereira CCF, Janssen-Jurkovicová M (2001) Utilization of zeolites synthesized from coal fly ash for the purification of acid mine waters. Environ Sci Technol 35(17):3526–3534. https://doi.org/10.1021/es0002924

Motsi T, Rowson NA, Simmons MJH (2009) Adsorption of heavy metals from acid mine drainage by natural zeolite. Int J Miner Process 92(1):42–48. https://doi.org/10.1016/j.minpro.2009.02.005

Nesterenko PN, Haddad PR (2000) Zwitterionic ion-exchangers in liquid chromatography. Anal Sci 16(6):565–574. https://doi.org/10.2116/analsci.16.565

Nouri J, Mahvi AH, Bazrafshan E (2010) Application of electrocoagulation process in removal of zinc and copper from aqueous solutions by aluminum electrodes. Int J Environ Res 4(2):201–208. https://doi.org/10.22059/ijer.2010.10

Ostroski IC, Barros MASD, Silva EA, JDantas JH, Arroyo PA, Lima OCM (2009) A comparative study for the ion exchange of Fe (III) and Zn (II) on zeolite NaY. J Hazard Mater 161(2):1404–1412. https://doi.org/10.1016/j.jhazmat.2008.04.111

Pan B, Pan B, Zhang W, Zhang L, Lv Q, Zheng S (2009) Development of polymeric and polymer-based hybrid adsorbents for pollutants removal from waters. Chem Eng J 151(1):19–29. https://doi.org/10.1016/j.cej.2009.02.036

Petrov S, Nenov V (2004) Removal and recovery of copper from wastewater by a complexation-ultrafiltration process. Desalination 162:201–209. https://doi.org/10.1016/S0011-9164(04)00043-8

Qi L, Xu Z (2004) Lead sorption from aqueous solutions on chitosan nanoparticles. Colloids Surf A Physiochem Eng Asp 251:183–190. https://doi.org/10.1016/j.colsurfa.2004.10.010

Rai PK (2009) Heavy metal phytoremediation from aquatic ecosystems with special reference to macrophytes. Crit Rev Environ Sci Technol 39(9):697–753. https://doi.org/10.1080/10643380801910058

Rether A, Schuster M (2003) Selective separation and recovery of heavy metal ions using water-soluble N-benzoyl thiourea modified PAMAM polymers. React Funct Polym 57:13–21. https://doi.org/10.1016/j.reactfunctpolym.2003.06.002

Ricco R, Konstas K, Styles MJ, Richardson JJ, Babarao R, Suzuki K, Scopece P, Falcaro P (2015) Lead (II) uptake by aluminum-based magnetic framework composites (MFCs) in water. J Mater Chem A 3(39):19822–19831. https://doi.org/10.1039/C5TA04154F

Rincón GJ, Motta EJL (2014) Simultaneous removal of oil and grease, and heavy metals from artificial bilge water using electro-coagulation/flotation. J Environ Manag 144:42–50. https://doi.org/10.1016/j.jenvman.2014.05.004

Rykowska I, Wasiak W, Byra J (2008) Extraction of copper ions using silica gel with the chemically modified surface. Chem Pap 62(3):255–259. https://doi.org/10.2478/s11696-008-0020-4

Sanmuga Priya E, Senthamil Selvan P (2017) Water hyacinth (Eichhornia crassipes)–an efficient and economical adsorbent for textile effluent treatment–a review. Arab J Chem 10:S3548–S3558. https://doi.org/10.1016/j.arabjc.2014.03.002

Savage N, Diallo MS (2005) Nanomaterials and water purification: opportunities and challenges. J Nanopart Res 7(4):331–342. https://doi.org/10.1007/s11051-005-7523-5

Sherrington DC (1998) Preparation, structure, and morphology of polymer supports. Chem Commun 21:2275–2286. https://doi.org/10.1039/A803757D

Soltmann U, Matys S, Kieszig G, Pompe W, Bottcher H (2010) Algae-silica hybrid materials for biosorption of heavy metals. J Water Resour Prot 2:115–122. https://doi.org/10.4236/jwarp.2010.22013

Srivastava V, Weng CH, Singh VK, Sharma YC (2011) Adsorption of nickel ions from aqueous solutions by nano alumina: kinetic, mass transfer, and equilibrium studies. J Chem Eng Data 56(4):1414–1422. https://doi.org/10.1021/je101152b

Trivunac K, Stevanovic S (2006) Removal of heavy metal ions from water by complexation-assisted ultrafiltration. Chemosphere 64(3):486–491. https://doi.org/10.1016/j.chemosphere.2005.11.073

Tzanetakis N, Taama WM, Scott K, Jachuck RJJ, Slade RS, Varcoe J (2003) Comparative performance of ion exchange membranes for electrodialysis of nickel and cobalt. Sep Purif Technol 30(2):113–127. https://doi.org/10.1016/S1383-5866(02)00139-9

Vigneswaran R, Aitchison SJ, McDonald HM, Khong TY, Hiller JE (2004) Cerebral palsy and placental infection: a case-cohort study. BMC Pregnancy Childbirth 4(1):1. https://doi.org/10.1186/1471-2393-4-1

Vijayaraghavan K, Jegan J, Palanivelu K, Velan M (2005) Biosorption of copper, cobalt, and nickel by marine green alga Ulva reticulata in a packed column. Chemosphere 60(3):419–426. https://doi.org/10.1016/j.chemosphere.2004.12.016

Vilardi G, Ochando-Pulido JM, Verdone N, Stoller M, Di Palma L (2018) On the removal of hexavalent chromium by olive stones coated by iron-based nanoparticles: equilibrium study and chromium recovery. J Clean Prod 190:200–210. https://doi.org/10.1016/j.jclepro.2018.04.151

Walsh FC, Reade GW (1994) Electrochemical techniques for the treatment of dilute metal-ion solutions. In: Sequeira CAC (ed) Studies in environmental science, vol 59. Elsevier, pp 3–44. https://doi.org/10.1016/S0166-1116(08)70546-6

Wang LK, Vaccari DA, Li Y, Shammas NK (2005) Chemical precipitation. In: Physicochemical Treatment Process (ed) Handbook of environmental engineering. Humana Press, p 3. https://doi.org/10.1385/1-59259-820-x:141

Wang C, Liu X, Chen JP, Li K (2015) Superior removal of arsenic from the water with zirconium metal-organic framework UiO-66. Sci Rep 5:16613. https://doi.org/10.1038/srep16613

Wang X, Liu Y, Pang H, Yu S, Ai Y, Ma X, Song G, Hayat T, Alsaedi A, Wang X (2018) Effect of graphene oxide surface modification on the elimination of Co (II) from aqueous solutions. Chem Eng J 344:380–390. https://doi.org/10.1016/j.cej.2018.03.107

Wu Y, Pang H, Yao W, Wang X, Yu S, Yu Z, Wang X (2018) Synthesis of rod-like metal-organic framework (MOF-5) nanomaterial for efficient removal of U(VI): batch experiments and spectroscopy study. Sci Bull 63(13):831–839. https://doi.org/10.1016/j.scib.2018.05.021

Yang JC, Yin XB (2017) CoFe2O4@MIL-100(Fe) hybrid magnetic nanoparticles exhibit fast and selective adsorption of arsenic with high adsorption capacity. Sci Rep 7:40955 Article number: 40955. https://doi.org/10.1038/srep40955

Yantasee W, Lin Y, Fryxell GE, Busche BJ, Birnbaum JC (2003) Removal of heavy metals from aqueous solution using novel nanoengineered sorbents: self-assembled carbamoylphosphonic acids on mesoporous silica. Sep Sci Technol 38(15):3809–3825. https://doi.org/10.1081/SS-120024232

Yin L, Song S, Wang X, Niu F, Ma R, Yu S, Wen T, Chen Y, Hayat T, Alsaedi A, Wang X (2018) Rationally designed core-shell and yolk-shell magnetic titanate nanosheets for efficient U(VI) adsorption performance. Environ Pollut 238:725–738. https://doi.org/10.1016/j.envpol.2018.03.092

Zakhama S, Dhaouadi H, M’Henni F (2011) Nonlinear modelization of heavy metal removal from aqueous solution using Ulva Lactuca algae. Bioresour Technol 102(2):786–796. https://doi.org/10.1016/j.biortech.2010.08.107

Zamboulis D, Peleka EN, Lazaridis NK, Matis KA (2011) Metal ion separation and recovery from environmental sources using various flotation and sorption techniques. J Chem Technol Biotechnol 86(3):335–344. https://doi.org/10.1002/jctb.2552

Zhang FS, Itoh H (2006) Photocatalytic oxidation and removal of arsenite from water using slag-iron oxide-TiO2 adsorbent. Chemosphere 65(1):125–131. https://doi.org/10.1016/j.chemosphere.2006.02.027

Zhang P, Hahn HH, Hoffmann E (2003) Different behavior of iron (III) and aluminum (III) salts to coagulate silica particle suspension. Acta Hydrochim Hydrobiol 31(2):145–151. https://doi.org/10.1002/aheh.200300483

Zheng G, Ye H, Zhang Y, Li H, Lin L, Ding X (2015) Removal of heavy metal in drinking water resource with cation-exchange resins (type 110-H) mixed PES membrane adsorbents. J Hazard Toxic Radioact Waste 19(2):04014026. https://doi.org/10.1061/(ASCE)HZ.2153-5515.0000229

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Manna, M.S., Bhaumik, C. (2021). Opportunities and Challenges in Heavy Metal Removal from Water. In: Inamuddin, Ahamed, M.I., Lichtfouse, E., Altalhi, T. (eds) Remediation of Heavy Metals. Environmental Chemistry for a Sustainable World, vol 70. Springer, Cham. https://doi.org/10.1007/978-3-030-80334-6_14

Download citation

DOI: https://doi.org/10.1007/978-3-030-80334-6_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-80333-9

Online ISBN: 978-3-030-80334-6

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)