Abstract

Monitoring the structural performance of engineering structures has always been pertinent for maintaining structural health and assessing the life cycle of structures. Structural Health Monitoring (SHM) and Structural Damage Detection (SDD) fields have been topics of ongoing research over the years to explore and verify different monitoring techniques and damage detection and localization procedures. In an attempt to compare performances of different methods, benchmark datasets are valuable resources since the data is made available to researchers enabling side-by-side comparisons. This paper presents a new experimental benchmark dataset generated from tests on a large-scale laboratory structure. The primary goal of the authors was to explore brand-new damage detection and quantification methodologies for efficient monitoring of structures. For this purpose, a large-scale steel grid structure with footprint dimensions of 4.2 m × 4.2 m was constructed in laboratory environment and it has been used as a test bed by the authors. The structural members of the structure are all IPE120 hot-rolled steel cross sections. The simulation of structural damage was simply loosening the bolts at one of the beam-to-girder connections, which is a slight change of rotational stiffness at the joint of the steel grid structure. The authors shared the dataset for 1 undamaged and 30 damaged conditions and published it on a public website as a new benchmark problem for structural damage detection at http://www.structuralvibration.com/benchmark/ so that other researchers can use the data and test algorithms. The authors also shared one of the damage detection tools they used, One-Dimensional Convolutional Neural Networks (1D-CNNs). The application codes, configuration files, and accompanied components of the 1D-CNNs package are available for viewers at http://www.structuralvibration.com/cnns/.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Benchmark problem

- Structural Damage Detection

- Structural Health Monitoring

- Damage localization

- Damage quantification

- Damage identification

- Steel structures

1 Introduction

The traditional way of monitoring civil infrastructure is based on visual inspections [1, 2]. Along with the computing and sensing technologies, dynamic response of structures has started to be used for condition evaluation [3,4,5,6,7,8,9,10,11] and serviceability assessment [12,13,14,15,16,17,18,19,20] of engineering structures. Structural Health Monitoring (SHM) and Structural Damage Detection (SDD) have emerged as research fields targeting efficient monitoring of structures [21,22,23,24,25,26,27,28,29] for which Machine Learning (ML) and Deep Learning (DL) algorithms have been implemented [30,31,32,33,34,35,36,37,38] to facilitate and optimize the identification and localization processes. Before the researchers apply newly developed damage detection and damage quantification methods on real structures, it is important that they verify the methodologies experimentally in laboratory. Yet, building a laboratory structure, arranging the logistics for data collection and processing, is not always easy. This is why benchmark datasets are made available to researchers to benefit from existing data. Benchmark datasets are useful resources for comparing the performances of various damage detection/localization/quantification procedures. Such datasets are convenient because the data becomes accessible to all, and since everybody uses the same data, the performance comparisons are systematic and more efficient.

In this paper, the authors are presenting a new experimental benchmark dataset generated by tests on a large-scale laboratory structure. The primary goal of the authors was to explore and test brand-new damage detection and quantification methodologies on the laboratory structure. It was later decided to share the dataset in a benchmark format so that other researchers can use the data and test their own methodologies. The One-Dimensional Convolutional Neural Networks (1D-CNNs) code package was also published on a website about the same time, by the authors.

The benchmark structure used to simulate the damage conditions was an inclined steel grid structure with footprint dimensions of 4.2 m × 4.2 m (Fig. 1). By loosening the bolts at the beam-to-girder connections, 31 different damage conditions were created on the benchmark structure. Acceleration data was carefully collected for each damaged and undamaged condition. The collection of the acceleration recordings formed the Benchmark dataset, providing SHM and SDD researchers with a new test bed for verifying newly developed vibration-based damage detection algorithms.

The steel frame consists of hot-rolled members (4 columns, 25 filler beams, 8 girders and brace elements to stabilize the columns). While the length of the 20 typical filler beams is 77 cm, the 5 cantilevered filler beams are about 1 m long (Fig. 1). The length of the girders is 4.6 m. As per grandstand specifications, there is a 20° inclination on the structure. All structural members are IPE120 cross sections (Fig. 2). Based on the structural drawings, a finite element model is created in Abaqus using C3D20R quadratic brick elements with 27 integration points (using 210 GPa for modulus of elasticity of steel), and the resulting first four governing bending mode shapes and corresponding modal frequencies are determined (Fig. 2). The measured frequencies per modal testing are processed in MEScope software and the values are shown in Fig. 2.

The total number of joints where the filler beams are being connected to the main girders is 30 (Fig. 3). One accelerometer was assigned for each joint and data was collected under various dynamic excitations without moving accelerometers between tests. Brüel & Kjær (model 8344) and PCB (model 393B04) accelerometers were used to record acceleration data, along with other dynamic testing equipment such as SmartAmp 2100E21-400 power amplifier, a dual 16-channel data acquisition system (DT9857E-16), and a modal shaker (Model 2100E11). Based on the type of dynamic excitation, a modal impact hammer or a shaker was utilized to create dynamic excitations as inputs.

For structural damage, the reference condition was considered as the undamaged state when all bolts are fully tightened (Fig. 4). Thirty additional conditions were individual bolt loosening at each joint shown in Fig. 3 (corresponding to 30 independent damage conditions). Loosening the bolts might be considered as a very slight damage, may be no damage at all. The authors wanted to consider bolt loosening as a damage based on the idea that when the damage detection methodology is sensitive enough to recognize and locate this slight damage condition and quantify it, this would be an indication of success for the methodology.

2 The Benchmark Website

The Benchmark dataset includes accelerations for each damage condition. The website address for the Benchmark dataset is:

-

http://www.structuralvibration.com/benchmark/

The main page of the Benchmark website includes links for additional information on the overview of the dataset package; grandstand simulator; instrumentation; damage scenarios; dataset descriptions; and downloading links (Fig. 5a). Users can navigate through the menu options on the left side of the main window. In addition to the Benchmark dataset, the damage detection tool used by the authors, One-Dimensional Convolutional Neural Networks (1D-CNNs) application codes and accompanied files are shared on this website:

-

http://www.structuralvibration.com/cnns/

Similarly, through the menu on the left side of the main window, the users can access information on back-propagation, and 1D-CNN package which includes the C++ Windows Console application; Matlab code; CDF files; configuration file; and downloading links (Fig. 5b).

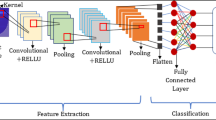

After successful use of the original 2D version applications of CNNs [39,40,41,42,43,44,45,46,47], the 1D-CNNs were also proven to be an accurate and reliable tool used in various fields [48,49,50,51]. They are implemented as a damage identification/localization tool with the built-in adaptive architecture, merging the steps of feature extraction and classification into one compact unit. The first civil/structural engineering application of 1D-CNNs was conducted on the Benchmark structure, by the authors. The procedure runs directly on the raw acceleration signal, making the methodology available for real-time use.

The authors have conducted extensive analytical and experimental research on the Benchmark structure, mostly focusing on damage detection methods. Some of the publications produced based on the work on the Benchmark structure are [52,53,54,55,56], followed by a patent on the 1D-CNN SDD methodology [57]. Based on the success of the 1D-CNNs on the Benchmark structure as a damage detection and localization tool, the authors tested 1D-CNNs on other structures. For example, on another benchmark structure [58], 1D-CNNs showed excellent performance on identifying and quantifying the damage [59, 60]. In addition, the 1D-CNN code was also successful on damage identification on bearings as a rotating machine element [61, 62].

3 Benchmark Dataset Description

The Benchmark dataset comprises two datasets to be downloaded (Dataset A and Dataset B). One dataset is for training and the other one is for testing purposes. The datasets include 31 TXT files (a total of 62 TXT files). Among the 31 files in one dataset, 30 files are dedicated to the damaged (untightened bolts) condition for each joint shown in Fig. 3. One additional TXT file is for the undamaged condition of the Benchmark structure. For each damaged condition, the accelerations were recorded for 256 s at each joint subjected to a white noise shaker excitation at a sampling frequency of 1024 Hz. This results in signals containing 256 × 1024 = 262,144 samples. For one dataset, this procedure was repeated 31 times, therefore resulting in 31 TXT files. The data collection process was done twice, resulting in two different datasets: Dataset A and Dataset B.

The naming of the TXT files is explained below:

Dataset A

-

zzzAU.TXT: Undamaged condition

-

zzzAD1.TXT: Damage at Joint 1

-

zzzAD2.TXT: Damage at Joint 2

-

…

-

zzzAD30.TXT: Damage at Joint 30

Dataset B

-

zzzBU.TXT: Undamaged condition

-

zzzBD1.TXT: Damage at Joint 1

-

zzzBD2.TXT: Damage at Joint 2

-

…

-

zzzBD30.TXT: Damage at Joint 30

Each TXT file contains 31 columns

-

Column 1: timestamp.

-

Column 2: Signal measured at Joint 1.

-

Column 3: Signal measured at Joint 2.

-

…

-

Column 31: Signal measured at Joint 30.

4 Conclusions

A new experimental Benchmark dataset generated from dynamic tests on a large-scale laboratory structure is presented in this paper. The Benchmark structure is a large-scale steel grid structure with footprint dimensions of 4.2 m × 4.2 m. It was constructed in a laboratory and has been used as a test bed for several publications by the authors. All structural members are hot-rolled steel IPE120 cross sections. For the structural damage detection studies, the damage was introduced at the joints of beam-to-girder connections by loosening the bolts. Even though bolt loosening is a slight change of rotational stiffness at the joints of the steel structure, the authors were able to detect, locate, and quantify it in their studies. The authors posted the dataset for 31 structural damage conditions on a public website as a new benchmark problem for structural damage detection at http://www.structuralvibration.com/benchmark/. The authors also shared the damage detection tool they used: One-Dimensional Convolutional Neural Networks (1D-CNNs). The 1D-CNNs package (application codes and accompanied files) is posted at http://www.structuralvibration.com/cnns/. The authors would appreciate feedback from other researchers on the Benchmark data and the 1D-CNNs package.

References

Agdas, D., Rice, J.A., Martinez, J.R., Lasa, I.R.: Comparison of visual inspection and structural-health monitoring as bridge condition assessment methods. J. Perform. Constr. Facil. (2016). https://doi.org/10.1061/(asce)cf.1943-5509.0000802

Gattulli, V., Chiaramonte, L.: Condition assesment by visual inspection for a bridge management system. Comput. Civ. Infrastruct. Eng. (2005). https://doi.org/10.1111/j.1467-8667.2005.00379.x

Živanović, S., Pavic, A., Reynolds, P.: Finite element modelling and updating of a lively footbridge: the complete process. J. Sound Vib. 301, 126–145 (2007). https://doi.org/10.1016/j.jsv.2006.09.024

Zarei, J., Tajeddini, M.A., Karimi, H.R.: Vibration analysis for bearing fault detection and classification using an intelligent filter. Mechatronics. 24, 151–157 (2014). https://doi.org/10.1016/j.mechatronics.2014.01.003

Yan, R., Gao, R.X., Chen, X.: Wavelets for fault diagnosis of rotary machines: a review with applications. Signal Process. 96, 1–15 (2014). https://doi.org/10.1016/j.sigpro.2013.04.015

Raghavan, A., Cesnik, C.E.S.: Review of guided-wave structural health monitoring. Shock Vib. Dig. (2007). https://doi.org/10.1177/0583102406075428

Pavic, A., Reynolds, P., Prichard, S., Lovell, M.: Evaluation of mathematical models for predicting walking-induced vibrations of high-frequency floors. Int. J. Struct. Stab. Dyn. 03, 107–130 (2003). https://doi.org/10.1142/S0219455403000756

Pacas, M., Villwock, S., Dietrich, R.: Bearing damage detection in permanent magnet synchronous machines. In: 2009 IEEE Energy Convers. Congr. Expo., pp. 1098–1103. IEEE, New York (2009). https://doi.org/10.1109/ECCE.2009.5316091

Mao, Z., Todd, M.D.: A Bayesian recursive framework for ball-bearing damage classification in rotating machinery. Struct. Health Monit. 15, 668–684 (2016). https://doi.org/10.1177/1475921716656123

Díaz, I.M., Pereira, E., Reynolds, P.: Integral resonant control scheme for cancelling human-induced vibrations in light-weight pedestrian structures. Struct. Control Health Monit. (2012). https://doi.org/10.1002/stc.423

Chen, H.-P., Ni, Y.-Q.: Structural Health Monitoring of Large Civil Engineering Structures. John Wiley & Sons, Ltd, Chichester, UK (2018). https://doi.org/10.1002/9781119166641

Royvaran, M., Avci, O., Davis, B.: An overview on floor vibration serviceability evaluation methods with a large database of recorded floor data. In: Conf. Proc. Soc. Exp. Mech. Ser. (2021). https://doi.org/10.1007/978-3-030-47634-2_10

Ngoan, D.T., Mustafa, G., Osama, A., Onur, A.: Stadium vibration assessment for serviceability considering the vibration duration. In: Proceedings, Annu. Conf. - Can. Soc. Civ. Eng. (2017)

Muhammad, Z., Reynolds, P., Avci, O., Hussein, M.: Review of pedestrian load models for vibration serviceability assessment of floor structures. Vibration. (2018). https://doi.org/10.3390/vibration2010001

Chaabane, M., Ben Hamida, A., Mansouri, M., Nounou, H.N., Avci, O.: Damage detection using enhanced multivariate statistical process control technique. In: 2016 17th Int. Conf. Sci. Tech. Autom. Control Comput. Eng. STA 2016 – Proc. (2017). https://doi.org/10.1109/STA.2016.7952052

Celik, O., Do, N.T., Abdeljaber, O., Gul, M., Avci, O., Catbas, F.N.: Recent issues on stadium monitoring and serviceability: a review. In: Conf. Proc. Soc. Exp. Mech. Ser. (2016). https://doi.org/10.1007/978-3-319-29763-7_41

Celik, O., Catbas, F.N., Do, N.T., Gul, M., Abdeljaber, O., Younis, A., Avci, O.: Issues, codes and basic studies for stadium dynamics. In: Proc. Second Int. Conf. Infrastruct. Manag. Assess. Rehabil. Tech., Sharjah, UAE (2016)

Catbas, F.N., Celik, O., Avci, O., Abdeljaber, O., Gul, M., Do, N.T.: Sensing and monitoring for stadium structures: a review of recent advances and a forward look. Front. Built Environ. 3, 38 (2017). https://doi.org/10.3389/fbuil.2017.00038

Alabbasi, S., Hussein, M., Abdeljaber, O., Avci, O.: A numerical and experimental investigation of a special type of floating-slab tracks. Eng. Struct. (2020). https://doi.org/10.1016/j.engstruct.2020.110734

Alabbasi, S., Hussein, M., Abdeljaber, O., Avci, O.: Investigating the dynamics of a special type of a floating-slab tracks. In: COMPDYN Proc. (2019). https://doi.org/10.7712/120119.6962.19626

Carden, E.P., Fanning, P.: Vibration based condition monitoring: a review. Struct. Health Monit. (2004). https://doi.org/10.1177/1475921704047500

Abdeljaber, O., Avci, O., Do, N.T., Gul, M., Celik, O., Necati Catbas, F.: Quantification of structural damage with self-organizing maps. Conf. Proc. Soc. Exp. Mech. Ser. (2016). https://doi.org/10.1007/978-3-319-29956-3_5

Y.Y. Li, Hypersensitivity of strain-based indicators for structural damage identification: a review, Mech. Syst. Signal Process. (2010). doi:https://doi.org/10.1016/j.ymssp.2009.11.002

Mansouri, M., Avci, O., Nounou, H., Nounou, M.: Iterated square root unscented Kalman filter for state estimation - CSTR model. In: 12th Int. Multi-Conference Syst. Signals Devices, SSD 2015 (2015). https://doi.org/10.1109/SSD.2015.7348243

Farrar, C.R., Worden, K.: Structural Health Monitoring: A Machine Learning Perspective. Wiley, Hoboken, NJ (2012). https://doi.org/10.1002/9781118443118

Quek, S.T., Tran, V.A., Hou, X.Y., Duan, W.H.: Structural damage detection using enhanced damage locating vector method with limited wireless sensors. J. Sound Vib. 328, 411–427 (2009). https://doi.org/10.1016/j.jsv.2009.08.018

Mansouri, M., Avci, O., Nounou, H., Nounou, M.: Iterated square root unscented Kalman filter for nonlinear states and parameters estimation: three DOF damped system. J. Civ. Struct. Health Monit. 5 (2015). https://doi.org/10.1007/s13349-015-0134-7

Ghahari, S.F., Abazarsa, F., Avci, O., Çelebi, M., Taciroglu, E.: Blind identification of the Millikan Library from earthquake data considering soil-structure interaction. Struct. Control Health Monit. (2016). https://doi.org/10.1002/stc.1803

Mansouri, M., Avci, O., Nounou, H., Nounou, M.: A comparative assessment of nonlinear state estimation methods for structural health monitoring. In: Conf. Proc. Soc. Exp. Mech. Ser. (2015). https://doi.org/10.1007/978-3-319-15224-0_5

Ghahramani, Z.: Probabilistic machine learning and artificial intelligence. Nature. (2015). https://doi.org/10.1038/nature14541

Kiranyaz, S., Avci, O., Abdeljaber, O., Ince, T., Gabbouj, M., Inman, D.J.: 1D convolutional neural networks and applications: a survey. Mech. Syst. Signal Process. 151 (2021). https://doi.org/10.1016/j.ymssp.2020.107398

Avci, O., Abdeljaber, O., Kiranyaz, S., Hussein, M., Gabbouj, M., Inman, D.J.: A review of vibration-based damage detection in civil structures: from traditional methods to machine learning and deep learning applications. Mech. Syst. Signal Process. (2021). https://doi.org/10.1016/j.ymssp.2020.107077

Kubat, M.: An Introduction to Machine Learning. Springer, New York (2017). https://doi.org/10.1007/978-3-319-63913-0

Rafiei, M.H., Adeli, H.: A novel machine learning-based algorithm to detect damage in high-rise building structures. Struct. Des. Tall Spec. Build. (2017). https://doi.org/10.1002/tal.1400

Avci, O., Abdeljaber, O., Kiranyaz, S., Inman, D.: Control of plate vibrations with artificial neural networks and piezoelectricity. In: Conf. Proc. Soc. Exp. Mech. Ser. (2020). https://doi.org/10.1007/978-3-030-12676-6_26

Abdeljaber, O., Avci, O., Inman, D.J.: Active vibration control of flexible cantilever plates using piezoelectric materials and artificial neural networks. J. Sound Vib. 363 (2016). https://doi.org/10.1016/j.jsv.2015.10.029

Avci, O., Abdeljaber, O., Kiranyaz, S.: Structural damage detection in civil engineering with machine-learning: current state of the art. In: Conf. Proc. Soc. Exp. Mech. Ser. (2021)

Avci, O., Abdeljaber, O., Kiranyaz, S.: An overview of deep learning methods used in vibration-based damage detection in civil engineering. In: Conf. Proc. Soc. Exp. Mech. Ser. (2021)

Dai, J., Qi, H., Xiong, Y., Li, Y., Zhang, G., Hu, H., Wei, Y.: Deformable convolutional networks. In: Proc. IEEE Int. Conf. Comput. Vis. (2017). https://doi.org/10.1109/ICCV.2017.89

Milosevic, N.: Introduction to Convolutional Neural Networks. Apress, New York (2020). https://doi.org/10.1007/978-1-4842-5648-0

Tan, M., Le, Q.V.: EfficientNet: rethinking model scaling for convolutional neural networks. In: 36th Int. Conf. Mach. Learn. ICML 2019 (2019)

Niepert, M., Ahmad, M., Kutzkov, K.: Learning convolutional neural networks for graphs. In: 33rd Int. Conf. Mach. Learn. ICML 2016 (2016)

Zhang, Y., Gao, J., Zhou, H.: Breeds classification with deep convolutional neural network. In: ACM Int. Conf. Proceeding Ser. (2020). https://doi.org/10.1145/3383972.3383975

Kalash, M., Rochan, M., Mohammed, N., Bruce, N.D.B., Wang, Y., Iqbal, F.: Malware classification with deep convolutional neural networks. In: 2018 9th IFIP Int. Conf. New Technol. Mobil. Secur. NTMS 2018 – Proc. (2018). https://doi.org/10.1109/NTMS.2018.8328749

Lopez Pinaya, W.H., Vieira, S., Garcia-Dias, R., Mechelli, A.: Convolutional neural networks. In: Mach. Learn. Methods Appl. to Brain Disord. (2019). https://doi.org/10.1016/B978-0-12-815739-8.00010-9

Kim, Y.: Convolutional neural networks for sentence classification. In: EMNLP 2014–2014 Conf. Empir. Methods Nat. Lang. Process. Proc. Conf. (2014). https://doi.org/10.3115/v1/d14-1181

Krizhevsky, A., Sutskever, I., Hinton, G.E.: ImageNet classification with deep convolutional neural networks. Commun. ACM. (2017). https://doi.org/10.1145/3065386

Ince, T., Kiranyaz, S., Eren, L., Askar, M., Gabbouj, M.: Real-time motor fault detection by 1-D convolutional neural networks. IEEE Trans. Ind. Electron. (2016). https://doi.org/10.1109/TIE.2016.2582729

Kiranyaz, S., Ince, T., Gabbouj, M.: Real-time patient-specific ECG classification by 1-D convolutional neural networks. IEEE Trans. Biomed. Eng. 63, 664–675 (2016). https://doi.org/10.1109/TBME.2015.2468589

Kiranyaz, S., Gastli, A., Ben-Brahim, L., Alemadi, N., Gabbouj, M.: Real-time fault detection and identification for MMC using 1D convolutional neural networks. IEEE Trans. Ind. Electron. (2018). https://doi.org/10.1109/TIE.2018.2833045

Kiranyaz, S., Ince, T., Gabbouj, M.: Personalized monitoring and advance warning system for cardiac arrhythmias. Sci. Rep. 7 (2017). https://doi.org/10.1038/s41598-017-09544-z

Abdeljaber, O., Avci, O., Kiranyaz, S., Gabbouj, M., Inman, D.J.: Real-time vibration-based structural damage detection using one-dimensional convolutional neural networks. J. Sound Vib. 388, 154–170 (2017). https://doi.org/10.1016/j.jsv.2016.10.043

Abdeljaber, O., Younis, A., Avci, O., Catbas, N., Gul, M., Celik, O., Zhang, H.: Dynamic testing of a laboratory stadium structure. In: Geotech. Struct. Eng. Congr. 2016 - Proc. Jt. Geotech. Struct. Eng. Congr. 2016 (2016). https://doi.org/10.1061/9780784479742.147

Avci, O., Abdeljaber, O., Kiranyaz, S., Inman, D.: Structural damage detection in real time: implementation of 1D convolutional neural networks for SHM applications. In: Niezrecki, C. (ed.) Struct. Heal. Monit. Damage Detect. Vol. 7 Proc. 35th IMAC, A Conf. Expo. Struct. Dyn. 2017, pp. 49–54. Springer International Publishing, Cham (2017). https://doi.org/10.1007/978-3-319-54109-9_6

Avci, O., Abdeljaber, O., Kiranyaz, S., Hussein, M., Inman, D.J.: Wireless and real-time structural damage detection: a novel decentralized method for wireless sensor networks. J. Sound Vib. (2018)

Avci, O., Abdeljaber, O., Kiranyaz, S., Inman, D.: Convolutional neural networks for real-time and wireless damage detection. In: Conf. Proc. Soc. Exp. Mech. Ser. (2020). https://doi.org/10.1007/978-3-030-12115-0_17

Kiranyaz, S., Avci, O., Jaber, O.A.Q.A.: Real-time structural damage detection by convolutional neural networks. US16031519. https://patents.google.com/patent/US20190017911A1/en (2019)

Dyke, S.J., Bernal, D., Beck, J., Ventura, C.: Experimental phase II of the structural health monitoring benchmark problem. In: Proc. 16th ASCE Eng. Mech. Conf. (2003)

Abdeljaber, O., Avci, O., Kiranyaz, M.S., Boashash, B., Sodano, H., Inman, D.J.: 1-D CNNs for structural damage detection: verification on a structural health monitoring benchmark data. Neurocomputing. (2017). https://doi.org/10.1016/j.neucom.2017.09.069

Avci, O., Abdeljaber, O., Kiranyaz, M.S., Boashash, B., Sodano, H., Inman, D.J.: Efficiency validation of one dimensional convolutional neural networks for structural damage detection using a SHM benchmark data. In: 25th Int. Congr. Sound Vib. 2018, ICSV 2018 Hiroshima Call., p. 2018

Abdeljaber, O., Sassi, S., Avci, O., Kiranyaz, S., Ibrahim, A.A., Gabbouj, M.: Fault detection and severity identification of ball bearings by online condition monitoring. IEEE Trans. Ind. Electron. (2019). https://doi.org/10.1109/TIE.2018.2886789

Avci, O., Abdeljaber, O., Kiranyaz, S., Sassi, S., Ibrahim, A., Gabbouj, M.: One dimensional convolutional neural networks for real-time damage detection of rotating machinery. In: Conf. Proc. Soc. Exp. Mech. Ser. (2021)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Society for Experimental Mechanics, Inc

About this paper

Cite this paper

Avci, O., Abdeljaber, O., Kiranyaz, S., Hussein, M., Gabbouj, M., Inman, D. (2022). A New Benchmark Problem for Structural Damage Detection: Bolt Loosening Tests on a Large-Scale Laboratory Structure. In: Grimmelsman, K. (eds) Dynamics of Civil Structures, Volume 2. Conference Proceedings of the Society for Experimental Mechanics Series. Springer, Cham. https://doi.org/10.1007/978-3-030-77143-0_2

Download citation

DOI: https://doi.org/10.1007/978-3-030-77143-0_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-77142-3

Online ISBN: 978-3-030-77143-0

eBook Packages: EngineeringEngineering (R0)