Abstract

During the electrospinning process, the most crucial and impactful factors affecting the quality of the PCL membrane on collectors include humidity, temperature, syringe pump speed. Additionally, some buffers may generate toxic gas that must be immediately evacuated from the environment, and the high voltage part of the device is dangerous that must be safely isolated from the users. Therefore, designing a complete electrospinning system that generates high-quality membranes and safety to use becomes vital. We designed a complete electrospinning system that includes: a protecting glass chamber equipped, an electronic controller to supervise and display environmental parameters. The chamber was built from profiled aluminum and glass, and a fume hood ventilator was used to suck gas out of the chamber. A controller system consisting of hardware design and firmware programming was implemented to measure temperature and humidity in electrospinning chamber; to control factors affecting the nanofiber membrane such as drum collector speed, syringe pump, temperature, and humidity. The zero-crossing technique was used to control temperature and speed of fume hood fan. Furthermore, the PID controller was applied to regulate the rotational movement of drum collector. We successfully built the complete electrospinning system. The temperature and humidity ranges varied from −40 to +125 °C and 0–100% RH, respectively. Rotational speed of the aluminum drum was from 0 to 2000 rpm. And the volume error of the electrical syringe pump on the average is 0.60% and the speed is from 0.1 to 20 ml/h.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Nanosized fibers have been playing a vital role in manufacturing practical applications related to both microfiber and nanofiber, including protective clothing, pharmaceutical products, tissue engineering, and regenerative medicine, and have granted great interest from scientists, researchers, and nanotechnologists [1]. Electrospinning is an advanced and special nanotechnology, which produces different polymer material, including natural and synthetic polymer. This technology bases on a high-voltage environment to produce nanofibers, and these super smooth fibers are crucial due to their resemblance to the extracellular matrix in human tissue. Apart from the high-voltage part, the electrospinning machine required a controller for factors that affected the generated fibers such as the pumping speed of electrical syringe pump, the position between the pump (positive electrode of the high-voltage source) and the receiver (negative electrode of the high-voltage source), the air exchange to vacuum the poisonous solvent, spinning speed of the Drum Collector receiver (−), the internal light of the fume hood, and the measurement of environmental parameters, including internal temperature and humidity.

1.1 Some Methods to Treat Wound Healing

Wound healing has become much more effective for skin reproduction thanks to the advancement in tissue technology and the production and research of saving cells by biological scaffold, which is created by biologically compatible material [2]. The biological scaffold is actually a support for the formation of tissues and usually implanted with high growth factors. The newly produced tissues of the scaffold are rapidly replaced by a great number of new tissues. Therefore, the scaffold of the implanted tissues has the ability to be taken advantage of for synthesizing tissues; then, it will be injected into a test-tube to eliminate the lost tissues in particular. The meaning of this direct implant into the wound using the patient’s own tissues is to reproduce the lost tissues. The process is illustrated in Fig. 1. Furthermore, antibacterial substances can be included on the surface of the biological scaffold in order to prevent bacteria from penetrating into the wound surface.

This image illustrates the usage of the bandage applied electrospinning technology in treating open wound [3]

1.2 Basic Component of Electrospinning Machines

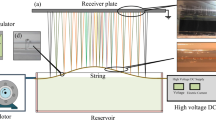

Traditional electrospinning and its modifications have received massive interest from the science community, especially in the biomedical field [4]. Methods such as multijet electrospinning, needleless electrospinning, electro-blowing, coaxial electrospinning, force spinning, etc. award researchers with a low-cost, flexible, and convenient set-up. A fundamental electrospinning system consists of three main parts: an emitter, a collector, and a solution controlling pumping system [5]. This system has yielded a simple and economical assay to do electrospinning with various and composite materials, bringing enormous potential to the tissue engineering field in Vietnam (Fig. 2).

2 Design an Electrospinning System Consists of a Fume Hood Controller

2.1 Mechanical Design

The mechanical design includes a drum collector, ground facility, and electrical control panel box. Considering the rotating drum collector, the external and internal diameter is 100 mm and 15 mm, respectively. The length of the drum is at 200 mm while that one of the shafts is 45 mm. Additionally, the electrical syringe pump owns 3 pinheads which are composed of a 1.8-degree step motor with decelerating gearbox at the rate of 1:3.71, a lead-screw bar with equal 1-cm distance among the teeth, and bearings and sliders (Figs. 3 and 4).

2.2 Hardware Development

Control Panel Board

The control panel board consisted of a 3 × 4 button matrix and a Rotate Encoder rotating button, which were used to input values such as pumping speed of the electrical syringe pump, driving speed of the slider to maneuver the relative position between the pinhead and the drum collector, and manage the rotating speed of the drum collector, the lamp, and vacuum fan. An MCU controller collected the input values from users and displayed them on Text LCD 20 × 4, and simultaneously, sent orders to command the MCU. A display screen also took charge in keeping track of the temperature, humidity, practical speed of Drum Collector, and remaining solution releasing time of the electrical syringe bump (Figs. 5 and 6).

Main Board Control

Central controlling board was in charge of regulating the speed of the Drum Collector from 10 to 2000 rounds/min based on Control Feedback (PID) algorithm. To control the temperature inside the chamber, and fan speed to vacuum the internal air out to external environment, we adjusted voltage AC220V by applying Zero-crossing method with the help of Dimer and One Pulse Mode function of ARM Cortex M4. Default setup and users’ setup values were stored on an EEPROM for the purpose of further usage. There was also an additional function inside the central controlling board to monitor on-screen time of users and exhibited the time in real life through the RTC system inside the ARM STM32F407VET6.

Another function of the central controller was to measure the temperature and humidity inside the chamber using SHT30 sensor, and actual speed of the drum collector by encoder, which was for users to follow aspects that may influence the quality of electrospinning fibers.

The Main Control Unit supported users to communicate with the computer in order to trace the calibrated parameters by the device. Furthermore, the improvement of the central controller is on the way for the purpose of remote electrospinning production in the future.

Microcontroller STM32F407VET6 also interacted with a Slaver MCU through serial to conduct the electrical syringe pump and the slider (Fig. 7).

Control Syringe Pump and Slider

The electrical syringe pump and slider controller exploited the Slaver MCU (STM32F030F4P6–ARM Cortex M0) to regulate pumping speed of the electrical syringe pump from 0.1 to 20 ml/h with all the available sizes on the market in Vietnam. Meanwhile, the slider lead-screw transmission system played as a manipulator to adjust the relative distance between electrical syringe pump and Drum Collector (Figs. 8 and 9).

3 Firmware Development

3.1 The Operation of the Control Panel Board

Once begun, the program started building peripheries such as GPIO, UART, KeyPad and LCD20×4. The loop program analyzed whether the flags of Update Display LCD blocks were set; if they were, the program began processing them and updated new values on the LCD.

Knob Rotate Encoder was in charge of confirming if users had input the values into the buttons or not; if they did, the buttons would execute corresponding orders. Vice versa, the buttons would skip the action and check ongoing tasks, known as Check RxTxUART. This task would investigate if there was data received from Main Board Control, then the data would be transferred to UART Break program. When the collected data was correct, the bufferFrame would copy them, then deleted the values in ReceiveFrame. The remaining data in bufferFrame would be assigned to CheckRxTxUART to handle.

The last task in Loop program is to verify KeyPad4×3. If users input new values on LCD20×4 screen, these values would be updated onto the storage. On the contrary, the program would return to Update Display LCD to do the verification and operate aforementioned tasks.

Whenever the panel board’s MCU receives any data frame from the mainboard’s MCU, the program of the panel board’s MCU will go to the UART Interrupt Subroutine in order to process the received data frame. The program will evaluate to find out the right frame, then it will be copied to the BufferFrame and delete the ReceiveFrame. Otherwise, the wrong receive frame will be deleted and waiting for the new coming data frame (Fig. 10).

3.2 The Description of How the Main Board Control Operated

At the beginning, the program constructed Initial GPIOs for the system and internal Real Time Clock of STM32F407VET6 to keep track of the electrospinning shooting time. In the meantime, EEPROM was in use to save the setup of the machine and Kp, Ki, and Kd of PID were also activated to control the Motor Servo of Drum Collector. Then the Timer counter, System tick and UART were all initialized to do timing job for the controller and Initial Moving Average to measure the speed of Servo motor. Moreover, the Servo and Stepper motor were under the control of Initial H-Bridge.

In the first main loop, infrared light and fume hood fan availability would be examined; and if there were an order from the Control Panel Board, the program proceeded according to parameters input by users. On the other hand, the program skipped the previous step and perform the next algorithm, Control Slaver MCU.

The function of the Slaver MCU was to regulate the Syringe Pump Controller and Slider for the Electrospinning device. The orders went through the path from Control Panel Board to Main MCU and continued going to Slaver MCU. If there were no orders, the program advanced to CheckRxTxUART.

CheckRxTxUART was where all of the information received from Control Panel Board was processed; if there was any Frame orders transmitted from Control Panel Board, the receiving process would occur in Interrupt UART program, and ReceiveFrame would be copied into BufferFrame and treated in Main loop program; or else, the program would jump to the next part.

Control Servo motor was a program section where the speed of Drum Collector and Motor servo were under the control of closed loop based on PID algorithm through determining the number of pulses read back from the encoder and checking feedbacks from updating PWM values to control H-Bridge; the frequency, which was applied to take over servo motor, was 15 kHz.

Read Temperature and Humidity function traced them temperature and humidity inside the electrospinning chamber so that users could adopt the most suitable environmental parameters for electrospinning membrane. The activation of this function happened while in the “Run” process, remaining temperature, humidity, actual speed of Drum Collector, and Electrospinning shooting time would be grafted with TranferFrame and transmitted to Control Panel Board to display on LCD screen. The system would automatically move to Read and Write EEPROM when the former function stopped.

Read and Write EEPROM had the ability to store the used controlling parameters; if users found them to be productive of high quality of electrospinning membrane, they would input these parameters in “Save” so that the setup be stored into EEPROM. When users wished to apply saved parameters, they chose “Read” function to read the parameters from EEPROM; the MCU would read these values and send them to Control Panel Board.

If Main MCU receives any transmit frame from Control Panel Board, Program will come to subroutine for process Data.

Whenever the mainboard’s MCU receives any data frame from the panel board’s MCU, the program of the mainboard’s MCU will go to the UART Interrupt Subroutine in order to process the received data frame. The program will evaluate to find out the right frame, then it will be copied to the BufferFrame and delete the ReceiveFrame. Otherwise, the wrong receive frame will be deleted and waiting for the new coming data frame (Fig. 11).

3.3 The Control Syringe Pump and Slider Procedures

When the program started, Initial GPIOs had charge of Syringe Pump and Slider, Initial Timer, and System Tick to do timing for the shooting speed of Syringe Pump and transferring speed of Slider. Initial UART adopted the orders from Main MCU to manage Initial Syringe Pump and Slider.

When we accessed the main loop, the initial task was CheckRxTxUART for receiving orders from main board to run the electrical syringe pump and slider; if there was no signals from main MCU, the controller would proceed to Slider Execute.

Slider Execute implemented the duty to adjust the relative positions between Syringe Pump and Drum Collector if it obtained the order from main MCU; if not, SyringePump Execute would be called.

SyringePump Execute was a function to administer the speed of the syringe to shoot out an appropriate amount of solution in the electrospinning application. The main MCU delivered order to the slaver MCU to regulate the syringe pump; however, when there was no orders, the program would move on to the next task: CheckTxRxUART.

Whenever the slaver’s MCU, which using for controlling the Syringe Pump and Slider, receives any data frame from the mainboard’s MCU, the program of the slaver’s MCU will go to the UART Interrupt Subroutine in order to process the received data frame. The program will evaluate to find out the right frame, then it will be copied to the BufferFrame and delete the ReceiveFrame. Otherwise, the wrong receive frame will be deleted and waiting for the new coming data frame (Fig. 12).

4 Result of Experiment

The result is shown in Fig. 13 which is able to control the speed of Drum Collector from 10 to 2000 rounds/min and fume hood fan speed. The temperature and humidity has an active range from −40 to 125 °C with the precision up to ±0.3 °C and 0–100% with ±2% error (Following the SHT31’s manufacturer datasheet).

4.1 Testing Methodology

We chose the 12 cc syringe with 15.8 mm diameter and pumping time is an hour for each experiment; the measurement is operated twice per experiment based on the following formula. The experiment was set up by using the caliper of Mitutoyo Manufacturer (Model: CD-6″BS, with the accuracy, is ±0.002 mm). Firstly, the caliper was fixed position to the syringe clamp of Syringe Pump, then the machine ran 2 times with 1 time per 1 h. Secondly, the data was recorded after each time. Finally, we using the below formula to calculate the volume result (Table 1).

- R1:

-

the first measurement.

- R2:

-

the second measurement.

- Rtb:

-

Result Volume.

The Volume is evaluated in accordance with the following formula:

- V:

-

is the volume of the solution inside the cylinder.

- R:

-

is the radius of the cylinder.

- D:

-

is the distance of the piston shifting in an hour.

From (1), (2), we can conclude the substantial Volume by quantifying distance D of the electrical syringe pump as in Table 1.

Error calculation formula:

The maximum and average error value are 2.9% and 0.60%, respectively based on the formula:

5 Conclusion

Overall, the system has proven its functionality in terms of controlling the speed of the drum collector and fume hood fan. The relative distance between the electrical syringe pump and drum collector has also been adjusted and managed by our algorithm. Furthermore, the system also has the ability to isolate the high voltage for the purpose of user’s safety. Finally, our device is able to take fully charge of humidity and temperature, which is under the control of infrared light, inside the electrospinning chamber.

References

Chou S-F, Carson D, Woodrow KA (2015) Current strategies for sustaining drug release from electrospun nanofibers. J Control Release 220:584–591

Mano J et al (2007) Natural origin biodegradable systems in tissue engineering and regenerative medicine: present status and some moving trends. J Roy Soc Interface 4(17):999–1030

Auger FA, Lacroix D, Germain L (2009) Skin substitutes and wound healing. Skin Pharmacol Physiol 22(2):94–102

Keirouz A, Chung M, Kwon J, Fortunato G, Radacsi N (2020) 2D and 3D electrospinning technologies for the fabrication of nanofibrous scaffolds for skin tissue engineering: a review. Wiley Interdisc Rev Nanomed Nanobiotechnol 12(4):e01626

Chimene D, Alge DL, Gaharwar AK (2015) Two-dimensional nanomaterials for biomedical applications: emerging trends and future prospects. Adv Mater 27(45):7261–7284

Call CC (2010) The study of electrospun nanofibers and the application of electrospinning in engineering education. Texas A & M University

Do TM, Ho MH, Do TB, Nguyen NP, Van Toi V (2018) A low cost high voltage power supply to use in electrospinning machines. In: International conference on the development of biomedical engineering in Vietnam. Springer, Berlin, pp 95–100

Acknowledgements

This research is funded by Vietnam National University Ho Chi Minh City (VNU-HCM) under grant number C2020-28-08.

Conflicts of Interest

The authors have no conflict of interest to declare.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Switzerland AG

About this paper

Cite this paper

Viet, T.N., Thai, D.M., Phuc, P.T., Van Toi, V. (2022). Design and Fabrication of a Complete Electrospinning System. In: Van Toi, V., Nguyen, TH., Long, V.B., Huong, H.T.T. (eds) 8th International Conference on the Development of Biomedical Engineering in Vietnam. BME 2020. IFMBE Proceedings, vol 85. Springer, Cham. https://doi.org/10.1007/978-3-030-75506-5_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-75506-5_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75505-8

Online ISBN: 978-3-030-75506-5

eBook Packages: EngineeringEngineering (R0)