Abstract

In the present paper, the mechanisms of electrical conductivity in a dry air atmosphere of thin ZnO films obtained from a zinc acetate solution with the addition of polyvinyl alcohol were studied. The established character of current transport in vacuum is caused by the above-barrier Schottky emission over small intercrystalline potential barriers. Heating/cooling in the air atmosphere leads to the superlinearity of the current–voltage characteristic specific for the above-barrier Schottky emission over “thick” intercrystalline barriers. The established barrier effects in the films’ conductivity are explained by the adsorption and subsequent diffusion of oxygen, which, capturing the conduction electrons, not only increases the surface locking curving of energy bands, but also increases the intercrystalline potential barriers height for electrons. The conductivity activation energy (0.43 eV) obtained from the CTD is consistent with the calculated height of intercrystalline potential barriers (0.45 eV) and is explained by the model of an inhomogeneous semiconductor with large-scale potential fluctuations.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Zinc oxide has recently been actively used to create cathodoluminophores, electroluminescent screens, acoustoelectronic amplifiers, various types of photo- and optoelectronic devices [1], as part of composite materials for electronic equipment [2]. Such a wide range of ZnO use is associated with the features of the surface and grain boundaries of the material [3,4,5]. Zinc oxide layers are used as a transparent conducting electrode in solar cells [6], as well as antireflection coatings in interference optics, in photoelectronic devices, lasers, and ultraviolet radiation LEDs [7]. The electrical conductivity changes of zinc oxide thin films in an environment, with hydrogen and oxygen-containing gases, together with their chemical resistance, non-toxicity, and low-cost fabrication make them a promising material for the active gas sensors elements [8,9,10,11]. The mechanisms of gas sensitivity of a material are usually associated with its electrical conductivity special feature. In the present work, the mechanisms of electrical conductivity in a dry air atmosphere of thin ZnO films obtained from a zinc acetate solution with the addition of polyvinyl alcohol were studied.

2 Methods

The variety of applications of thin films of zinc oxide is provided by a variety of methods for their production and subsequent processing [1, 5, 12,13,14,15]. Known methods of zinc oxide thin films forming such as atomic layer deposition technique [16, 17], magnetron sputtering in various modifications [18] require quite complex technical support. Widely used sol–gel technologies sometimes use relatively expensive and at the same time harmful reagents such as α-terpineol, 2-methoxyethanol, 2-aminoethanol.

In this work, zinc oxide films are formed by a simple method of chemical precipitation from zinc acetate solutions. ZnO films were obtained by immersing glass samples in an aqueous solution of zinc acetate with the addition of a 1% of polyvinyl alcohol (C2H4O) solution in equal proportions. The prepared solution was stirred on a magnetic stirrer and kept for several hours. The samples were obtained by reusable immersion of the substrates in the solution according to the technique described in [19]. Subsequently, the prepared films were annealed in air at 400 °C for 40–50 min.

The structure of the resulting film can be seen in the image of an electronic microscope shown in Fig. 1. The layers clearly show surface homogeneity and developed porosity.

For electrical characterization and clarification of the electrical conductivity mechanism in air, before and after several heatings to 440 K, the resistance, current–voltage characteristics, and dark current temperature dependences were measured.

3 Results and Discussion

The band gap of the obtained thin films was calculated in [19] from the absorption spectrum shown in Fig. 2 and was around 3.15–3.2 eV. In the same work, we have shown that the value of the band gap of films obtained by using polyvinyl alcohol is higher than that of films obtained by other methods used in this work. This means that the sizes of ZnO crystallites obtained in a zinc acetate solution with the addition of polyvinyl alcohol are smaller than those in ZnO films obtained from a solution without PVA. The reason is that the polymer matrix with PVA limits the size of the reaction volumes, where the synthesis of zinc oxide crystallites occurs and, therefore, inhibits the growth of ZnO crystallites.

This result slightly exceeds such value for bulk material and indicates the nanoscale level of the film crystallites formed in the bounding volumes of the PVA polymer matrix.

The electrical conductivity of ZnO films and the type of their current–voltage characteristics (CVC) turned out to be significantly dependent on external conditions. The CVC of ZnO film at room temperature tends to an exponential dependency, specific for the potential barriers influence on conductivity. Thereby, in films obtained with PVA impurities, intercrystalline potential barriers are more pronounced, and these barriers affect the current flow.

The average value of the interelectrode resistance calculated from the initial linear section of the CVC on the Fig. 3 is about 2.8 × 109 Ω. Thereby, the addition of PVA leads to the growth of films resistance. This is explained by the fact that during high-temperature annealing, PVA (which plays the role of a polymer matrix) decomposes, decomposition products evaporate, and zinc oxide films become porous with a more developed surface. The porosity of the film can be seen on Fig. 1b. Nanoscale crystallites might create a quantum well effect for carriers, which also leads to the resistance increase.

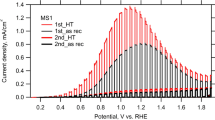

The electrical conductivity of ZnO films and the form of their current–voltage characteristics turned out to be significantly dependent on the external conditions. The cycles of heating–cooling of the films in the interval of 440–293 K were done in vacuum and in air. Curve 1 in Fig. 4 shows the CVC of the ZnO film measured in dry air atmosphere immediately after the cycle of heating the film to a temperature of 440 K and its further cooling in vacuum. CVC is almost linear, as it is seen from the figure. However, after carrying out a number of measurements on the indicated film in air atmosphere, the interelectrode resistance of the film increases by almost an order of magnitude, and its CVC becomes superlinear (see Fig. 4, curve 2). The curves reconstructed in different coordinates showed that better straightening of the CVC is observed in the coordinates ln I − U1/4 (Fig. 5, curve 1). Such coordinates are characteristic for the barrier mechanism of current flow, in particular, over-barrier Schottky emission through intercrystalline potential barriers of small thickness [20].

Curve 3 (Fig. 5) shows the CVC of ZnO film measured after heating the film to a temperature of 440 K in an air atmosphere and then room temperature cooling. This procedure leads to a further increase in the resistance of the film and an increase in the superlinearity of its CVC (Fig. 5, curve 3). It turned out that the current–voltage dependence is straightened in the coordinates ln I − U1/2 (Fig. 5, curve 2), which are characteristic for the above-barrier Schottky emission through “thick” intercrystalline barriers [20].

Mentioned results may have the following explanation. The porosity of ZnO films obtained using PVA promotes the absorption of oxygen and its diffusion along the intercrystalline boundaries. Absorbed oxygen, by capturing conduction electrons, increases the surface locking bend of energy bands and also leads to an increase in the height of the intercrystalline potential barriers for electrons. Heating the film in air (where a large amount of oxygen is available) stimulates the process of chemisorption and diffusion of oxygen, which leads to an increase in the height and thickness of the intercrystalline barriers. The consequence of these processes is an increase in the electrical resistance of the film and the transition of barriers from “thin” to “thick” barrier behavior.

This explanation is consistent with the results of the temperature–current dependences measurements (TCD) on the studied films (Fig. 6), carried out in vacuum (curve 1 and curve 2) and in a dry air atmosphere (curves 3 and 4).

It can be seen that on the TCD, measured during heating in an air atmosphere, and in the high-temperature region, there is no section with the conductivity activation energy EA = 1.1 eV, which was present on the TCD in vacuum and which was associated with desorption of molecular oxygen. When the film is heated in an air atmosphere at high temperatures, on the contrary, the growth of the current with temperature slows down, which is due to the diffusion of oxygen and an increase in the influence of intercrystalline barriers on the current transfer process.

It is characteristic that the conduction activation energy upon further cooling of the film (curve 4, Fig. 6) is EA = 0.43 eV. This is consistent with the height of intercrystalline potential barriers in zinc oxide films calculated in [21] (EA = 0.45 eV) and is explained by the model of an inhomogeneous semiconductor with large-scale potential fluctuations [22].

4 Conclusions

The established character of current transport in vacuum is caused by the above-barrier Schottky emission over small intercrystalline potential barriers. Heating/cooling in the air atmosphere leads to the superlinearity of the current–voltage characteristic specific for the above-barrier Schottky emission over “thick” intercrystalline barriers.

The established barrier effects in the films conductivity are explained by the adsorption and subsequent diffusion of oxygen, which, capturing the conduction electrons, not only increases the surface locking curving of energy bands, but also increases the intercrystalline potential barriers height for electrons. The conductivity activation energy (0.43 eV) obtained from the TCD is consistent with the calculated height of intercrystalline potential barriers (0.45 eV) and is explained by the model of an inhomogeneous semiconductor with large-scale potential fluctuations.

References

Klingshirn CF, Meyer BK, Waag A, Hoffmann A, Geurts J (2010) Zinc oxide. From fundamental properties towards novel applications. Springer, Berlin, pp 254–263

Lepikh YI, Lavrenova TI, Sadova NM, Borshchak VA Balaban AP, Zatovska NP (2018) Strukturno-fazovi peretvorennya i elektrofIzichni vlastivostI kompozitsiynih materIaliv na bazi sistemi SiO2-B2O3-Bi2O3-ZnO-BaO (Structural-phase transformations and electrophysical properties of composite materials based on the system SiO2-B2O3-Bi2O3-ZnO-BaO). Sens Electron Microsys Technol 15(4):77–84 in Ukrainian

Pronin IA, Donkova BV, Dimitrov DT et al (2014) Relationship between the photocatalytic and photoluminescence properties of zinc oxide doped with copper and manganese. Semiconductors 48:842–847. https://doi.org/10.1134/S1063782614070173

Khomchenko VS, Kushnirenko VI, Papusha VP et al (2010) Luminescent and structural properties of ZnO-Ag films. Semiconductors 44:685–690. https://doi.org/10.1134/S1063782610050246

Lyadov NM, Gumarov AI, Kashapov RN et al (2016) Structure and optical properties of ZnO with silver nanoparticles. Semiconductors 50:43–49. https://doi.org/10.1134/S1063782616010139

Lee D, Bae WK, Park I, Yoon DY, Lee S, Lee C (2011) Transparent electrode with ZnO nanoparticles in tandem organic solar cells. Sol Energy Mater Sol Cells 95(1):365–368

Liu H, Liu Y, Xiong P et al (2017) Aluminum-doped zinc oxide transparent electrode prepared by atomic layer deposition for organic light emitting devices. IEEE Trans Nanotechnol 16:634–638

Moseley PT (2017) Progress in the development of semiconducting metal oxide gas sensors. A Rev J Meas Sci Technol 28(8):082001

.Kumar R, Al–Dossary O, Kumar G, Umar A (2015) Zinc oxide nanostructures for NO2 gas–sensor applications: a review. J Nano–Micro Lett 7(2):97–120

Djurišić AB, Ng AMC, Chen XY (2010) Review ZnO nanostructures for optoelectronics: material properties and device applications. Prog Quant Electron 34:191–259

Ammaih Y, Lfakir A, Hartiti B et al (2014) Structural, optical and electrical properties of ZnO: Al thin films for optoelectronic applications. Opt Quant Electron 46(1):229–234

Semikina TV, Mamykin SV, Godlewski M et al (2013) ZnO as a conductive layer prepared by ALD for solarcells based on n-CdS/n-CdTe/p-Cu1.8S heterostructure. Semicond Phys Quant Electron Optoelectron 16(2):111–116

Krajewski TA, Luka G, Wachnicki L et al (2011) Electrical parameters of ZnO films and ZnO-based junction sobtained byatomic layer deposition. Semicond Sci Technol 26:085013–085018

Dostanko AP, Ageev OA, Golosov DA et al (2014) Electrical and optical properties of zinc-oxide films deposited by the ion-beam sputtering of an oxide target. Semiconductors 48:1242–1247. https://doi.org/10.1134/S1063782614090073

Gruzintsev AN, Volkov WT (2011) Modification of electrical and optical properties of ZnO films under ultraviolet irradiation. Semiconductors 45:1420–1424. https://doi.org/10.1134/S1063782611110121

Krajeski T, Guziewicz E, Godlewski M et al (2009) The influence of growth temperature and precursors’ doses on electrical parameters of ZnO thin films grown by atomic layer deposition technique. Microelectron J 40:293–295

Luka G, Godlewski M, Guziewicz E, Stahira P, Cherpak V, Volonyuk D (2012) ZnO films grown by atomic layer deposition for organic electronics. Semicond Sci Technol 27:074006–074013

Dave PY, Patel KH, Chauhan KV, Chawla AK, Rawal SK (2016) Examination of zinc oxide films prepared by magnetron sputtering. Procedia Technol 23:328–335

Bulyga YI, Chebanenko AP, Grinevych VS, Filevska LM (2019) Electrophysical properties of zinc oxide thin films obtained by chemical methods. Photoelectronics 28:11–18

Vereshchagin IK (1987) Electroluminescence of crystals. Moscow, Nauka, p 376, In Russian

Vorobieva NA (2015) Nanocrystalline ZnO (M) (M = Ga, In) for gas sensors and transparent electrodes. Cand. Diss., Moscow, p 180, In Russian

Bonch-Bruevich VL, Zvyakin IP, Kaiper R, Mironova AG, Everline R, Esser B (1981) Electronic theory of disordered semiconductors. Moscow, Nauka, p 383, In Russian

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Chebanenko, A.P., Filevska, L.M., Grinevych, V.S., Bulyga, Y.I., Brytavskyi, I.V., Smyntyna, V.A. (2021). The Conductivity Mechanisms of ZnO Thin Films Structured Using Polyvinyl Alcohol. In: Fesenko, O., Yatsenko, L. (eds) Nanomaterials and Nanocomposites, Nanostructure Surfaces, and Their Applications . NANO 2020. Springer Proceedings in Physics, vol 263. Springer, Cham. https://doi.org/10.1007/978-3-030-74741-1_27

Download citation

DOI: https://doi.org/10.1007/978-3-030-74741-1_27

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-74740-4

Online ISBN: 978-3-030-74741-1

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)