Abstract

In this work, we propose the use of Coherent Optical Time-Domain Reflectometry (C-OTDR) in order to discriminate the medium surrounding one or more Co2+-doped fiber sections. The proposed approach can be used to perform vibration measurements along the whole fiber by means of C-OTDR measurements at 850 nm, as well as liquid detection in selected positions by active thermometry at 1550 nm. By pumping the fiber with a modulated optical pump, the induced fiber temperature modulation is monitored through C-OTDR, as the latter is sensitive to optical phase changes occurring along the sensing fiber. As the induced phase modulation (i.e. the C-OTDR signal) is affected by the thermal conductivity of the surrounding medium, the latter can be retrieved from the phase signal. In our tests, a 5 Hz modulation frequency was chosen to discriminate between air, water, and acetone.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Recently, distributed acoustic sensors have emerged as one of the most promising technologies for distributed measurements of acoustic disturbance and vibrations along an optical fiber [1,2,3]. The principle of operation relies on Rayleigh scattering in optical fibers, occurring naturally due to inhomogeneities of the fiber itself. When a short optical pulse of coherent light is sent through an optical fiber, the interference between the contributions due to the single scatterers within the pulse leads to an apparently random variation of the backscattered power, which is detected at the pulse launching end as a function of the time. Any external perturbance acting on the fiber, modifies the position of the scatterers in the perturbed region, leading to a change in the backscattered intensity. Tracking these changes among consecutive acquisitions, one may capture any event occurring along the fiber. This technique is commonly referred to as coherent-OTDR (C-OTDR), or in some cases phi-OTDR (the latter is especially used when the phase, rather than intensity, of the backscattered signal is employed for quantitative measurements). The C-OTDR method is simpler and more cost-effective than other distributed sensing technologies, and therefore it is of interest to extend its applicability beyond vibration measurements [4].

In this work, we demonstrate that a conventional C-OTDR setup can be also used to distinguish any external medium surrounding the fiber is some specific points, based on its thermal properties [5]. The only condition is that, in those points, the fiber is subjected to periodical heating through an external source. This heating can be realized by injecting current in a metal-coated fiber, or, more elegantly, by pumping light into the core of a specialty fiber embedding some metal absorbing light and converting it to heat [6].

In this work, we propose the use of short sections of Cobalt-doped fibers absorbing light at 1550 nm optical wavelength. Therefore, our sensing scheme relies on the use of a single-mode optical fiber, along which one or more sections of Co2+-doped fibers are spliced. The sensing fiber is interrogated using 850 nm pump pulses for C-OTDR measurements [7], while being optically heated through a pump light at 1550 nm. The heating light is modulated at low frequency (5 Hz), thus inducing a periodic phase modulation in the specialty fiber, which is detected through C-OTDR measurements. The amount of phase modulation is dependant on the external medium, and in particular from its capability to remove heat from the fiber. In out tests, we show that the proposed approach is able to distinguish between air, water and acetone in two separate sections of the sensing fiber.

2 Experimental Results

The C-OTDR sensor used for the tests is schematically shown in Fig. 1. The setup implements an intensity-based heterodyne C-OTDR scheme, with the addition of an 850 nm/1550 nm wavelength division multiplexing (WDM) splitter. Heating is performed by a 1550-nm DFB diode laser, with a nominal output power of 40 mW. The driving current of the laser was adjusted in order to directly modulate the optical power at 5-Hz frequency and 13% modulation depth. The sensing fiber was composed by a 160 m-long standard single mode fiber (SMF), followed, in the first test, by a single 10-cm section of Co2+-doped fiber, manufactured by CorActive HighTech, Inc. (ATN-FB series), whose absorption at 1550 nm was 50 dB/m.

A first test was carried out, aimed to demonstrate the capability of the system of carrying out simultaneous vibration and liquid detection measurements. The vibration was induced by wrapping a 5 m portion of the fiber around a PVC pipe, put in vibration using a magnetostrictive actuator bolted to the upper border of the pipe. The actuator was driven with a sinusoidal wave with a peak-to-peak current of 4 A, and a frequency of 100 Hz. For this test, the Co2+-doped fiber section was surrounded by air. The C-OTDR measurements were carried out setting a pulse duration of 50 ns (corresponding to a spatial resolution of 5 m), a pulse repetition period of 2 µs, and a number of averages equal to 1024. The combination of pulse repetition period and number of averages, resulted in an acquisition rate of ≈488 traces/s. The number of acquired traces was set to 512, corresponding to an overall acquisition time of ≈1 s. In Fig. 2a, we show the C-OTDR signals in the frequency domain, clearly revealing the region where the vibration was applied (z ≈ 62 m).

Furthermore, the 5-Hz signal induced by optical heating is observed at the Co2+-doped fiber position (z ≈ 163 m). We also note that, some energy at 100-Hz is visible not only at the vibrated position, but also in correspondence with the Co2+-doped fiber. This can be explained by the fact that, the signal received by the Co2+-doped fiber is strongly amplified by the Fresnel reflection at the end of the sensing fiber, thus even a small phase modulation induced on it by the mechanical vibration, is captured at the detection stage.

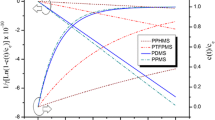

The next test was carried out in order to demonstrate the capability of our sensor to discriminate the medium surrounding the Co2+-doped specialty fibers. For this test, we have added another piece of 10-cm long Co2+-doped fiber, at a distance of 10-m from the first one. The new measurements were carried out after increasing the number of averages up to 8192, resulting in an effective acquisition rate of ≈61 Hz. We have carried out 100 consecutive measurements, where, for each measurement the amplitude of the 5-Hz spectral component of the signal detected at each Co2+-doped section was determined. The amplitude of the detected signal was calculated as the ratio between the 5-Hz spectral component of the C-OTDR signal at the monitored section, divided by the mean signal at the same section. The average and standard deviation of the detected signals are reported in Fig. 3, for three different surrounding media (air, water and acetone).

The experimental results show that, while the single measurement is not able to distinguish the surrounding liquid, averaging over several measurements (100, in the present case) provides a signal increasing with its thermal conductivity, being the largest when the fiber is immersed into water. The physical reason is that, as the thermal conductivity increases, the surrounding medium is more efficient to dissipate away the heat conveyed by optical heating, resulting in a deeper temperature modulation. Figure 3 also reveals that the uncertainty of the measurements was quite large: this should be mostly attributed to the detection scheme used for the tests; in fact, C-OTDR sensors are strongly affected by fading and laser phase noise, which was quite large in our setup because of the relatively poor coherence of our laser source (3-MHz linewidth).

3 Conclusions

We have proposed and demonstrated a novel scheme for simultaneous vibration and liquid detection measurements. Vibrations are detected through a C-OTDR scheme operating at 850-nm wavelength, while liquid detection is done in selected positions based on active thermometry at 1550-nm wavelength. The advantage of the proposed method is that liquid detection can be performed in more points simultaneously, with limited additional cost with respect to a conventional C-OTDR scheme.

References

Qin Z, Zhu T, Chen L, Bao X (2011) High sensitivity distributed vibration sensor based on polarization-maintaining configurations of phase-OTDR. IEEE Photonics Technol Lett 23:1091–1093

Mompó JJ, Martín-López S, González-Herráez M, Loayssa A (2018) Sidelobe apodization in optical pulse compression reflectometry for fiber optic distributed acoustic sensing. Opt Lett 43:1499–1502

Muanenda Y, Oton CJ, Faralli S, Di Pasquale F (2016) A cost-effective distributed acoustic sensor using a commercial off-the-shelf DFB laser and direct detection phase-OTDR. IEEE Photonics J 8:1–10

Hartog AH (2017) An Introduction to distributed optical fiber sensors. CRC Press.

Coscetta A, Catalano E, Cerri E, Cennamo N, Zeni L, Minardo A, A C-OTDR sensor for liquid detection based on optically heated Co2+-doped fibers. IEEE Sens J. https://doi.org/10.1109/JSEN.2020.2991224.

Davis MK, Digonnet MJF (2000) Measurements of thermal effects in fibers doped with cobalt and vanadium. J Lightwave Technol 18:161–165

Coscetta A, Catalano E, Cerri E, Zeni L, Minardo A (2020) Theoretical and experimental comparison of a distributed acoustic sensor at 850- and 1550-nm wavelength. Appl Opt 59:2219–2224

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Coscetta, A., Catalano, E., Cerri, E., Cennamo, N., Zeni, L., Minardo, A. (2021). Distributed Acoustic Sensor for Liquid Detection Based on Optically Heated CO2+-Doped Fibers. In: Di Francia, G., Di Natale, C. (eds) Sensors and Microsystems. AISEM 2020. Lecture Notes in Electrical Engineering, vol 753. Springer, Cham. https://doi.org/10.1007/978-3-030-69551-4_14

Download citation

DOI: https://doi.org/10.1007/978-3-030-69551-4_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-69550-7

Online ISBN: 978-3-030-69551-4

eBook Packages: EngineeringEngineering (R0)