Abstract

A classifier that provides a technical diagnosis of complex equipment is proposed. Predicting the remaining life of the equipment is implemented to determine the time of diagnosis and inclusion of equipment in the repair program. The procedure for forming a repair program based on the forecast value of the remaining resource and financial losses associated with equipment failure is described.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The main purpose of technical diagnostics is to identify and evaluate the deviation of the current state of the unit from the normal on the basis of measuring information [1]. This information can come from sensors [2], as well as be qualitative (described linguistically in natural language) and relate to expert knowledge [3]. The results of technical diagnostics are used for predicting the technical condition in order to plan measures to maintain the equipment in the proper technical condition [4].

In the present study, it is accepted that the object state is determined by the vector of S = (s1, …, sm), where m—the total number of diagnostic parameters (a set of parameters of the diagnosed object sufficient to make a diagnosis with a given accuracy). Deviation of the identified state from the normal one (accepted as such taking into account a number of assumptions) characterizes the technical state of the diagnosed object (specific equipment unit) at the current moment [5].

The magnitude of the deviation (often referred to as a simple error) can be not only a characteristic of the type of emergency situation, such as a failure but also the basis for finding the reasons that led to it (based on expert information accumulated during the operation of the equipment).

The error can be the cause of failure (self-recovery failure)—a state in which the object either returns to the working state itself for a long period of time with the unimportant help of the operator, or the cause of sustainable failure, at which the object requires restoration—repair to return to the working state.

Based on the value of the error, the type of possible failure and its veracity are evaluated, and the reasons leading to the error are searched for. To implement this approach, it is necessary to have expert knowledge that would allow correlating the type of possible failure and the reasons that led to its occurrence. In addition, the probability of occurrence of the specified emergency situation should be assessed. Often, the researcher does not have statistical data that would allow estimating the probability of failure of this or that type (brand) of equipment.

The process of state vector formation is individual for each piece of equipment and is determined by its internal properties. Traditionally several methods are used to determine the magnitude of deviation: analysis of signal models [6]; analysis of system model response; classification; cause-and-effect networks.

When using signal models, the measuring information (signal) is presented in the form of a time series (signal values measured at certain intervals of time) and is divided into four components: trend (describes continuous regular changes of the average level), periodic (repeated at equal intervals of time fluctuations of the measured value), stochastic (the influence of random variables) and pattern (arise and characterize specific modes, situations, and perturbations) [7].

Of greatest interest is the template component, it is described by a curve, which has a unique appearance and allows to identify the moment of occurrence of a particular state (for example, malfunction) and determine from this the cause of its occurrence.

Another effective way to identify the technical state of equipment is classification [8]. The classifier allows calculating the “distance” of the current state to each class and selecting the closest one. Classifiers can be a deterministic, statistical, fuzzy, or neural network [9].

Analysis of system model response consists in its comparison with the measured state vector. The model is an ideal digital copy of an object and characterizes its functioning in a normal state. The deviation of model output from the measured state vector is a source of information for diagnosis. Such models can be synthesized for different modes, thus increasing the accuracy of technical state determination [10].

In addition, cause-effect networks (error trees) can be used to determine the error [11]. Such a network usually consists of three layers: symptoms (quantitative (measured) and qualitative (expert estimates) indicators), events (intermediate symptoms, the set of which determines a specific error, and therefore not a proper technical state), errors (the result of determining the technical state of the diagnosed object). Links between layer elements are formalized using rules of the type “IF…, THAT…” (logical in case of quantitative information and productive in case of qualitative indicators).

2 Equipment Condition Classifier

Thus, the task of diagnostics, in general, can be formulated in the following way.

This means that for any vector of state S [characterized by a set of diagnostic signs (s1, …, sm)] there is such a classifier that a diagnosis can be made \(d_{i} \in D,i = \overline{1,N} ,\) where D—a limited set of N equipment diagnoses. The availability of a classifier is a mandatory condition for implementation of the system for evaluation of the actual technical condition of equipment and the formation of repair programs based on it.

In accordance with the methodology proposed in [12] it is necessary to determine the basic (immediately after the installation of equipment, different from the passport, which characterizes the “ideal” state of a particular unit of equipment at the time of start-up) and the actual characteristics of the equipment (at any other time, which requires setting the diagnose). The difference between basic and actual characteristics is a measure of the current technical state of the equipment and is used to clarify the causes of a particular emergency situation.

The basic characteristics are removed for a certain number of modes (set for each type of equipment separately). The type of actual characteristics indicates the presence of a specific symptom and is necessary for making the diagnosis. If it is not possible to remove such characteristics, passport data can be used [13]. The use of pass-port data thus affects the accuracy of estimation of technical structure and quality of the statement of a diagnosis.

The classifier of diagnoses itself is implemented in tabular form (Table 1). Table 1 contains the following designations: > (the current characteristic is larger than the allowable deviation limit values of the base or passport characteristics), < (the current characteristic is smaller than the allowable deviation limit values of the base or passport characteristics), ∈ (the current characteristic belongs to a set of allowable deviation limit values of the base or passport characteristics). In addition, there may be signs ≥ , ≤ , = (if the corresponding inequality limit or the exact value of the diagnostic parameter included in the classifier can be strictly estimated).

In this case, the classifier is a simple rule of the form IF s1 AND … AND sm, THAT d = . It allows not only to diagnose a unit of equipment but also to determine the reasons for its occurrence if there is expert knowledge to do so.

The presence of uncertainty, which is caused by the lack of precise knowledge about the limits of change of the diagnostic parameter, provided that production rules can be obtained, reflecting the process of human reasoning of the expert in making the diagnosis leads to the fact that for making the diagnosis can be used fuzzy production rules [14] and the algorithm of fuzzy conclusion (eg, Mamdani). Such an approach will allow us to obtain a value that determines the proximity of the current situation in the object to possible diagnoses.

3 Time to Send Equipment for Repair

Choosing the time for repair of a particular piece of equipment is a very urgent and complex task [15]. On the one hand, one should not allow the failure of a piece of equipment, and on the other hand, too early withdrawal into repair, because the equipment could still function for a certain period of time. This means that it is necessary to choose a point in time when the equipment is still functioning, but its condition is close to a critical one (in this condition the equipment fails and fails).

The decision to put a particular piece of equipment into the repair (to include it into the repair program) is made on the basis of the calculation of the residual operating time τoct based on the following condition:

To forecast τoct, a regression model is built (based on pre-processed measurements of diagnostic parameters [16]). The algorithm, which implements diagnosis on the basis of calculation of τoct, can be presented in the following way.

Step 1. Input data for calculation τoct.

Step 2. Calculate the τoct.

Step 3. If the condition \(\tau_{oct} > 0\) is met at the forecast time, then conclude that the unit is operable and put the value \( r = 1\).

Otherwise, proceed to step 7.

Step 4. output the values of \(r\).

Step 5. output the calculated value of τoct, as an additional characteristic, which characterizes the time of equipment operation in the current technical condition until the moment of its failure and failure.

Step 6. Move on to step 11.

Step 7. Make a conclusion that the unit of equipment is not working and put the value \( r = 0\).

Step 8. Using the classifier obtained from Table 1, perform the classification operation, and diagnose \(d_{i} \in D\).

Step 9. Output the values τoct, \(r\).

Step 10. Print the value \(d_{i} \in D\).

Step 11. Algorithm stop.

The diagnosis of a unit of equipment \(d_{i} \in D\) obtained from the synthesized algorithm serves as an additional characteristic. By using \(d_{i} \in D\) the causes of its occurrence can be obtained (if there is additional expert knowledge about the presence of such a bond), thus reducing the labor intensity in planning repairs and forming the repair program.

Let us consider the solution of the assigned problem of diagnostics and the formation of a repair program for partially defective equipment that continues to function, but is outside the normative quality [17].

Such equipment is subject to repair, however in case of limited financial resources, and also a considerable quantity of units of the equipment is a partially defective condition, it is necessary to repair at first those units which risk breakage and the cost of repair will be the greatest among a presented set of units of the equipment.

4 The Repair Program Formation

The formation of the repair program should be based on a certain criterion [18]. The restrictions imposed on the criterion are due to the fact that not all the equipment can be repaired, as there is only a certain amount of financial resources that can be spent on repairs and bringing the equipment into the proper technical condition [19].

The moment of failure j-th unit of equipment can be determined using residual life. Therefore, it is suggested to use negative operating time as the first criterion: \(R_{j} = \left| {\tau_{oct,j} } \right|\) for the j-th unit.

The second criterion to be used in evaluating the items of equipment of candidates for inclusion in the repair program is the total financial loss \(L\). These losses are caused by equipment failure (the cost of repairing the equipment itself, the cost of repairing equipment that may fail due to functional relationship, as well as losses caused by forced downtime).

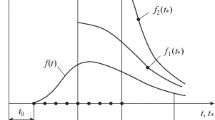

To analyze the value, it is necessary to standardize \(\overline{{R_{j} }} = R_{j} /\max \left( {R_{j} } \right)\) and \(\overline{{L_{j} }} = L_{j} /\max \left( {L_{j} } \right)\). The geometrical interpretation of the equipment located in the plane of normalized criteria is shown in Fig. 1.

If you put all units of equipment on a plot with \(R\) and \(L\) axes, you can identify many units with maximum aggregate risk, i.e. many units optimal for repair—points marked in red.

Using two criteria \(\overline{{R_{j} }}\) and \(\overline{{L_{j} }}\) it is possible to rank partially defective pieces of equipment according to the degree of expediency of repair and their proper technical condition. This is done using the criterion \(I_{j} = \overline{{R_{j} }} + \overline{{L_{j} }}\). The higher the value of criterion \(I\), the higher the expediency of repair, which means that a piece of equipment should get into the formed repair program with a higher probability.

Let \(\left\{ {x_{1} , \ldots ,x_{l} , \ldots ,x_{n} } \right\},l = \overline{1,n}\), where \(n\) the total number of pieces of equipment—a set of ordered in descending order criterion \(I\) units of equipment. Let’s denote \(c_{j}\)—the cost of repair i-th unit of equipment and \(C_{r}^{\max }\)—the maximum allowable cost of the repair program (funds allocated for the repair of the equipment). Then the repair program will include only those \(h\) units, for which the condition is fulfilled:

5 Example of the Approach Applying

Let’s show an example of a calculation using the described sequence of steps and the synthesized algorithm. The input data for the calculation were taken from [12]. The object of diagnosis is a pump unit NM-10000–210 (used to transport oil through the main oil pipelines, with flow rates up to 10,000 m3/hr).

The proposed approach is implemented as a corresponding software in the programming language R [20].

As a result of the analysis, the classifier is obtained, presented in Table 2 (software implementation of the classifier in R language is shown in Fig. 2).

The current state is determined on the basis of calculation \(\tau_{oct} = \left( {\hat{\eta }_{npe\partial } - a_{1} } \right)/b_{1} - \tau\), where \(\hat{\eta }_{npe\partial }\) corresponds to the lower boundary of the passport value of pumping unit efficiency, \(a_{1} ,b_{1}\)—coefficients of regression equation used for calculation of relative efficiency value (trend) \(\hat{\eta }_{i,p} = a_{1} + b_{1} \tau_{i}\) (\(\tau_{i}\)—operating time, [hr]).

Table 2 shows the relative head \(Q = Q_{np} /Q_{\max }\), pressure \(H\), power \(N\) и efficiency \(\eta\).

The work of the classifier was tested on simulated values of actual and passport characteristics. As a result of the check, all diagnoses and their absence are determined without errors, there are no unidentified conditions and no diagnoses made.

Two modes of operation of the equipment participated in the diagnostics (Tables 3–4, values are given in [12]).

The residual resource was also predicted using the data provided in [12] (Table 5).

As a result of calculations, the value of 675 h of residual time was obtained (in [12] this value is 668 h, which indicates a high accuracy of forecasting).

As a result of diagnostics of both modes in [12] the diagnosis №7 (frail-dimensional leakages through the impeller seal and end seals, passes the check valve) is advanced. A similar diagnosis was obtained using the synthesized classifier (example in Fig. 3).

To test the synthesized method of equipment ranking according to the degree of expediency of its inclusion into the repair program, the following array of criteria values was obtained (for convenience and clarity, the graphical interpretation in Fig. 4 is given), calculated in accordance with the above sequence of steps to obtain and predict the residual resource of the equipment.

The red color indicates those units of equipment, for which it is expedient to include in the repair program and transfer to the repair. Taking into account the available financial resources, the repair program may be limited, but it must necessarily include those items of equipment that are identified in the described way.

6 Conclusion

The sequence of calculations offered in work is a basis of a subsystem of support of acceptance at the formation of the repair programs, based on the forecasting of a residual resource and an estimation of an actual condition of the equipment of different functions. The decision of a problem of reception of the diagnosis for the equipment will allow forming the repair program more precisely as provides reception of the information on the reason for possible failure. The implemented software can be built, for example, into EAM-systems [21] to increase their efficiency.

References

Wang J., Zhang W., Shi Y., Duan S., Liu J. Industrial Big Data Analytics: Challenges, Methodologies, and Applications. https://arxiv.org/ftp/arxiv/papers/1807/1807.01016.pdf. Accessed 21 Apr 2019

Czichos, H.: Technical diagnostics: principles, methods, and applications. NCSLI Measure 9, 32–40 (2014). https://doi.org/10.1080/19315775.2014.11721681

Protalinskiy, O., Andryushin, A., Shcherbatov, I., Khanova, A.A., Urazaliev, N.: Strategic Decision Support in the Process of Manufacturing Systems Management. 1–4 (2018). https://doi.org/10.1109/MLSD.2018.8551760.

Alexandrov, O.I.: Sampling of the plan of repairs of the main equipment in the electrical power system. Energetika. In: Proceedings of CIS Higher Education Institutions and Power Engineering Associations, 60, 320–333 (2017). https://doi.org/10.21122/1029-7448-2017-60-4-320-333

Paunescu, I., Paunescu, P., Velicu, S.: Decision support in maintenance activity by using modern techniques for equipment condition monitoring. MATEC Web Conf. 112, 09001 (2017). https://doi.org/10.1051/matecconf/201711209001

Candy, J.: Signal Processing: Model Based Approach (1986)

Romberg T.M., Black J.L., Ledwidge T.J.: Signal Processing for Industrial Diagnostics. Wiley (1996)

Kravchuk, N.: Investigation of intelligent classification of current technical condition of the gas turbine engine. Technol Audit Prod Reser. 1 (2015). https://doi.org/10.15587/2312-8372.2015.38073

Andryushin, A., Arakelyan, E., Shcherbatov, I., Kosoy, A., Dolbikova, N.: Application of neural network technologies in power engineering. J. Phys. Conf. Series 1370, 012054 (2019). https://doi.org/10.1088/1742-6596/1370/1/012054

Isermann, R.: Fault Diagnosis Systems An Introduction from Fault Detection to Fault Tolerance. SERBIULA (sistema Librum 2.0) (2006)

Ibrahim, A., Kacianka, S., Pretschner, A., Hartsell, C., Karsai, G.: Practical Causal Models for Cyber-Physical Systems (2019) https://doi.org/10.1007/978-3-030-20652-9_14

Belkin A.P., Stepanov O.A.: Diagnostics of Heat and Power Equipment, 240 p. M.: Lan (2018)

Borodin, V., Andryushin, A., Protalinsky, O., Khanova, A.A.: Multiexpert Planning System for Repair Programs of Power-Generating Equipment, 1–5 (2019). https://doi.org/10.1109/MLSD.2019.8911105

Gayme, D., Menon, S., Ball, C., Mukavetz, D., Nwadiogbu, E.: Fault diagnosis in gas turbine engines using fuzzy logic. 4(4), 3756–3762 (2003). https://doi.org/10.1109/ICSMC.2003.1244473

Akinyemi, O.: Development of equipment maintenance strategy for critical equipment. Pacific J. Sci. Technol. 11, 328–342 (2010)

Andryushin, A., Shcherbatov, I., Dolbikova, N., Kuznetsova, A., Tsurikov, G.: Outlier Detection in Predictive Analytics for Energy Equipment (2020). https://doi.org/10.1007/978-3-030-32579-4_15

Yashchura A.I.: System of Maintenance and Repair of Power Equipment, 504 p. Handbook. – M.: publishing house of the NTS ENAS (2006)

Protalinsky, O., Shcherbatov, I., Stepanov, P.: Identification of the actual state and entity availability forecasting in power engineering using neural-network technologies. J. Phys. Conf. Series 891, 012289 (2017). https://doi.org/10.1088/1742-6596/891/1/012289

Baskakova, N.T., Sidoruk, I.L.: Optimization repair costs in terms of the theory of constraints with using RCM technology. Aktualnyye problemy sovremennoy nauki, tekhniki i obrazovaniya 2(1), 207–211 (2014)

Widemann, B.T.y., Bolz, C.F., Grelck, C.: The Functional Programming Language R and the Paradigm of Dynamic Scientific Programming. 182–197 (2013). https://doi.org/10.1007/978-3-642-40447-4_12

Srinivasan, V.: Sustaining Manufacturing Assets Through Smarter Utilization of Information and Communication Technologies, 478–482 (2009). https://doi.org/10.1109/COASE.2009.5234087

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Voropai, R., Shcherbatov, I., Agibalov, V., Belov, M. (2021). Repair Program Formation on the Basis of the Technical Condition Classifiers. In: Kravets, A.G., Bolshakov, A.A., Shcherbakov, M. (eds) Cyber-Physical Systems: Design and Application for Industry 4.0. Studies in Systems, Decision and Control, vol 342. Springer, Cham. https://doi.org/10.1007/978-3-030-66081-9_8

Download citation

DOI: https://doi.org/10.1007/978-3-030-66081-9_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-66080-2

Online ISBN: 978-3-030-66081-9

eBook Packages: EngineeringEngineering (R0)