Abstract

Coal gasification fine slag (CGFS) is a kind of industrial waste with more than 30% of carbon, a large surface area, and a broad pore size distribution, which provides favorable conditions for the preparation of activated carbon. In this paper, activated carbon was prepared from residual carbon of CGFS processed by flotation and modified by nitric acid. The effects of nitric acid on the pore structure, surface properties and electrochemical performance of activated carbon were investigated. The results showed that after treated with nitric acid, the content of mesoporous and surface functional groups of coal-based activated carbon increased, leading to the significant improvement of electrochemical properties and electro-adsorption performance.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Coal gasification fine slag (CGFS) is a kind of industrial waste, and China’s annual emissions are tens of millions of tons, with more than 30% of carbon. At present, the utilization of coal gasification slag mainly focuses on the separation of residual carbon and application as the admixture of building materials [1]. The residual carbon in coal gasification fine slag can be the precursor to prepare activated carbon with certain specific surface area and pore structure.

Activated carbon is divided into coal-based activated carbon, wood activated carbon, and nutshell activated carbon according to the raw materials. Coal-based activated carbon has the characteristics of wide raw materials and low price. The preparation of traditional coal-based activated carbon generally divided into two steps: (1) carbonization to remove organic matter and volatiles; (2) activation to obtain a rich pore structure [2]. Activated carbon could be directly obtained by activating the carbon of CGFS, which has low organic matter and volatiles content, and certain pore structure, making the preparation process more simplified. Therefore, the preparation of activated carbon from the residua carbon of CGFS could be an effective way to recycle solid waste.

Electrosorption, a desalination technology developed in recent years, has the characteristics of economy, energy saving and no secondary pollution [3]. Compared with other carbon-based electrode materials, activated carbon is cheap and easy to obtain, widely used in electrosorption desalination. However, due to the low specific capacitance of conventional activated carbon, it often needs to load metal oxides [4, 5] or modify by acid [6] or alkali treatment [7]. Huang et al. [7] found that after modification with nitric acid, the oxygen-containing functional groups and capacitance of activated carbon increase, and the resistance decreases, thereby improving the desalination performance. Moreover, nitric acid can also remove impurities in the gasification slag and improve the pore utilization rate.

In this work, coal-based activated carbon (CAC) was prepared from the residual carbon of CGFS processed by flotation and then was modified by HNO3 to improve its electrochemical performance. The effects of HNO3 on the pore structure and electrochemical performance of activated carbon were studied using advanced analytical techniques. The electrosorption performance of CAC for nitrate was investigated through electrosorption tests.

Materials and Methods

Materials

CGFS was obtained from a gasification slag plant in Henan province of China. The residual carbon of CGFS was prepared in our lab. Nitric acid (HNO3) and sodium nitrate (NaNO3) were purchased from Sinopharm Chemical Reagent Co., Ltd. N-methylpyrrolidone (NMP) from Macklin, Polyvinylidene fluoride (PVDF) form Arkema, conductive carbon black (Hunan Durban Activated Carbon Manufacturing Co., Ltd.) and foam nickel from Shenzhen Feixin Filter Equipment Co., Ltd. The reagents used in this work are of analytical grade. Deionized water (18.2 MΩ) was used for all experiments and acquired from Millipore.

Characterizations

The specific surface area of the samples was determined by using a Macchicker Bayer analyzer (MaxII) based on the BET method. Fourier transform infrared spectrometer (Nicolet Is5) was used to identify the chemical structure and the functional groups presented on the samples. The electrochemical properties of CAC and N-CAC electrodes were obtained by using an electrochemical comprehensive analysis system (Princeton PARSTAT4000A). Scanning electron microscope (Zeiss/auriga-bu, Germany) was used to detect the surface morphology of the samples.

Synthesis and Modification of CAC

The residual carbon of CGFS was firstly grinded to below 75 μm using a universal pulverizer. The residual carbon was activated at 800 °C for 1.5 h in a quartz tube furnace with N2 atmosphere and heating rate of 10 °C/min and then cooled to room temperature to obtain the coal-based activated carbon (CAC). The CAC was modified with a range of different concentrations of HNO3 according to the following step: CAC and HNO3 solution were mixed in a conical flask and conditioned in a thermostatic oscillator at room temperature to react for 12 h. After reaction, the modified activated carbons were separated by centrifugation, washed with deionized water until the filtrate is neutral and finally placed in a 60 °C vacuum drying oven for 12 h. The modified coal-based activated carbon with HNO3 was named as 1-N-CAC, 2- N-CAC, 4- N-CAC, 6- N-CAC, 8- N-CAC, respectively.

Electrosorption Experiments

The fabrication of carbon electrode was referenced in the reported literature [3]. Take 100 mg/L NaNO3 solution and circulate it in electro-adsorption cell at a flow rate of 25 mL/min through a peristaltic pump. Use a DC stabilized power supply to apply a 1.4 V potential at both ends of the electrode. Use a conductivity meter to record every 5 min until the conductivity value no longer drops, and then, the opposite voltage is applied to regenerate the electrode.

Results and Discussion

Electrochemical Performance Analysis

In this study, the electrochemical performance test conducted through CV, EIS and GCD on the electrochemical comprehensive analysis system produced by AMETEK Advanced Measurement Technology. In the test, platinum was used as the counter electrode, Ag/AgCl as the reference electrode, and the electrolyte was 0.5 mol/L KCl solution. The scan rate is 5 ~ 50 mV/s, and the voltage range is −0.4 ~ −0.8 V.

The cyclic voltammetry curve is usually a center-symmetric curve, and the capacitance and reversibility can be judged according to the shape. According to formula (1), the specific capacitance can be calculated

where C—specific capacitance, F/g; A—cyclic voltammetry integral area, V · A; m—mass of active material, g; k—scanning speed, V/s; ∆V—pressure difference, V (Fig. 1).

At low scanning speeds, the CV curves of CAC and N-CAC are both rectangular, but as the scanning speed increases, the polarization becomes more serious, and the CV curves appear leaf-like. There is no obvious redox peak in the CV curve, which proves that activated carbon is used for ion storage through electric double layer, and the desalination process is mainly electrostatic. Calculating the specific capacitance, cyclic voltammetry (CV) studies revealed that 8 mol/L HNO3 treated carbon had the highest specific capacitance of 7.07 F/g, lastly un-treated carbon having the capacitance of 2.16 F/g (Fig. 2), and the specific capacitance increases with the increase of the concentration of nitric acid [8].

In order to investigate the difficulty of electronic transmission, EIS test was performed within the frequency range of 10−2~105. The approximately vertical straight line in the low frequency region indicates the capacitance characteristics of the sample; the semicircular arc in the high frequency region is the impedance of the interface between the carbon particles in the activated carbon electrode. In Fig. 3, semicircular arc of the high frequency region is hardly small, indicating that the internal impedance of the electrode material is low and the electron transfer in the hole is relatively easy [9]. The inclined line in the impedance spectrum of modified activated carbon is closer to 45°, indicating that the diffusion resistance of ions in the electrolyte is lower. It may attribute to the surface of 8-N-CAC has more surface functional groups, stronger hydrophilicity, and the pore diameter is also improved, which reduces the resistance of ions in the electrolyte and the pores of the electrode material.

As shown in Fig. 3, the charging and discharging curve of 8-N-CAC are of isosceles triangle shape with good reversibility and typical double-layer capacitance characteristics. After 200 cycles, there is no obvious attenuation trend, and 8-N-CAC has good cycling performance.

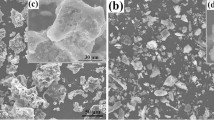

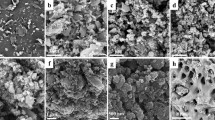

Morphological Characterizations

The SEM image shows the surface morphology of CAC and 8-N-CAC. As shown in Fig. 4a, c, CAC has certain pore structure, distributes unevenly, and the surface and pores contain a lot of impurities, resulting in poor performance. Figure 4b, d is CAC modified with 8 mol/L HNO3 (8-N-CAC). It can be seen that after modified, the surface pore structure of activated carbon changed obviously, the pore size increased, and impurities in the pores decreased. Therefore, nitric acid can not only enhance the pore structure of activated carbon, but also reduce the impurity content.

FTIR Analysis

Fourier transform infrared (FTIR) spectroscopy is shown in Fig. 5. The characteristic peak of −OH at 3500 cm−1 represents the phenolic and alcoholic hydroxyl groups on the surface of activated carbon, and the intensity of this peak increases significantly after modification. The characteristic peaks for the physical adsorption peak of CO2 on the surface of activated carbon disappear after modification. The characteristic peaks for –C = O and –COO- around 1400 and 1600 cm−1 present in both composites. The absorption peak at 1100 cm−1 is attributed to the antisymmetric stretching peak of the carboxylate exist in both CAC and 8-N-CAC. The FTIR test shows that N-CAC surface retains most of the oxygen-containing functional groups in the CAC and enhances partly [10]. These oxygen-containing functional groups can improve the wettability of the surface of the activated carbon electrode material to improve the electrosorption performance

N2 Adsorption/Desorption Isotherms and Pore Structure

In Fig. 3, the adsorption isotherms of CAC and 8-N-CAC belong to the type II according to the International Union of Pure and Applied Chemistry (IUPAC) adsorption isotherm classification. When the relative pressure (P/P0) is greater than 0.45, there is a hysteresis loop in the isotherm, which usually related to the capillary condensation in the mesoporous structure. Under low pressure, the adsorption and desorption isotherms overlap, indicating a large number of micropores in the samples. The HK model and BJH model are used to calculate the pore size distribution of CAC and 8-N-CAC. As shown in Table 1, the specific surface area dropped from 35.306 m2/g to 29.356 m2/g after modification, and total pore volume is slightly reduced. However, the average pore size increased because of the increase in mesoporous content. Nitric acid plays a role in regulating the pore structure (Fig. 6).

Electrosorption Performance

The electro-adsorption performance of CAC and 8-N-CAC was investigated. The adsorption capacity and removal efficiency of activated carbon electrode after modification get better, and electro-adsorption time gets shorter. This is because the content of mesopores in CAC is less, and there are more impurities in the pores. After HNO3 modified, oxygen-containing functional groups on CAC surface increased, the ratio of mesopores increased, the impurities in the pores reduced, thereby improving the pore utilization rate. Therefore, the electro-adsorption capacity of 8-N-CAC is significantly higher than CAC, salt removal gets more thoroughly, and the concentration of NaNO3 decreased from 100 mg/L to less than 10 mg/L (Fig. 7).

Conclusions

In this paper, coal-based activated carbon was prepared from fine carbon of coal gasification fine slag flotation. The surface properties and pore structure of HNO3 modified activated carbon were regulated. It was found that not only the microstructural characteristics of activated carbon could be changed, but also the surface physical and chemical properties of activated carbon were significantly affected. The optimal concentration of nitric acid modified activated carbon was 8 mol/L, the 8-N-CAC has highest specific capacitance of 7.07 F/g, compared to the CAC, the specific capacitance is increased by 227%. In addition, after modified by nitric acid, the pore structure of activated carbon was developed, the mesoporous content increased, the impurities in the pore reduced, the surface oxygen-containing functional groups increased, so the electro-adsorption performance of activated carbon greatly improved, the concentration of NaNO3 could be reduced from 100 mg/L to below 10 mg/L.

References

Guo F et al (2019) Fractal analysis and pore structure of gasification fine slag and its flotation residual carbon. Colloids Surf A 585:124148

Yue X et al (2017) Preparation of coal-based activated carbon electrodes by two steps of physical-chemical activation. Zhongguo Kuangye Daxue Xuebao/J China Univ Min Technol 46(4):888–894

Tang W et al (2015) Fluoride and nitrate removal from brackish groundwaters by batch-mode capacitive deionization. Water Res 84(NOV.1):342–349

Xia et al (2016) Electrosorption of fluoride on TiO2-loaded activated carbon in water. Colloids Surf A Physicochemical Eng Aspects

A XM et al (2019) Enhanced desalination performance via mixed capacitive-Faradaic ion storage using RuO 2-activated carbon composite electrodes. Electrochimica Acta 295:769–777

Villar I et al (2010) Capacitive deionization of NaCl solutions with modified activated carbon electrodes. Energy Fuels 24(MAY-JUN.):3329–3333

Huang W et al (2014) Desalination by capacitive deionization process using nitric acid-modified activated carbon as the electrodes. Desalination 340:67–72

Chuan-Xiang Z et al (2009) Influence of pore structure of coal-based activated carbons on electric double layer capacitance. J China Univ Min Technol

B OSA et al (2020) Enhanced electrosorption capacity of activated carbon electrodes for deionized water production through capacitive deionization. Sep Purif Technol 247

Xue-Yan T, Zhen-Qian C (2018) Change of physico-chemical proterties of activated carbons modified with acid-base. Build Energy Environ

Acknowledgements

The authors acknowledge the financial support of the Key scientific research projects of colleges and universities in Henan Province (No. 21A610011) and High-level Talent Introduction and Training Project of Zhengzhou University (No. 22180012).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Ma, M., Chai, W., Cao, Y. (2021). Structure and Electrochemical Property of Coal-Based Activated Carbon Modified by Nitric Acid. In: TMS 2021 150th Annual Meeting & Exhibition Supplemental Proceedings. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-65261-6_2

Download citation

DOI: https://doi.org/10.1007/978-3-030-65261-6_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-65260-9

Online ISBN: 978-3-030-65261-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)