Abstract

The impetus for the resurgence in the use of renewable resources has come not only from the sustainability concept but also from the potential for improved safety and environmental quality of biobased outputs, due to their allegedly less hazardous nature. This Chapter critically evaluates safety concerns about bioplastics as regards the release of volatile organic compounds, the presence of catalyst residues and possible green replacement strategies, migration risks from biobased food contact materials and their potential as active food packaging materials or as barriers to prevent migration from fossilbased packaging. REACH regulation opportunities for producers of biobased alternatives to substances of very high concern are also illustrated.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Before the fossil era, at the beginning of the twentieth century, a large part of the resources used by society in the production of goods was renewable. The availability and versatility of chemical building blocks from crude oil obscured the interest in wood and other natural materials. The impetus for the resurgence in the use of renewable resources has come not only from the sustainability concept but also from the potential for improved safety and environmental quality of biobased outputs due to their allegedly less hazardous nature (Chambers and Muecke 2010).

The European Green Deal is the most recent response to climate and environmental-related challenges (EU 2019). Resource-intensive sectors such as plastics are the focus of interest of policymakers, but a regulatory framework for biodegradable and biobased plastics is not ready yet. Academic research is pioneering in this respect. In the following, we will detail research evidence concerning the safety of biobased products.

Figure 10.1 outlines the twelve principles of green chemistry (Kharisov et al. 2019). Many of them are inspiring for the multiproduct biorefinery fed by food waste (FW), anyhow, in this chapter, we will focus on the possibility to avoid harmful synthetic methods and catalysts in order to reduce the product toxicity due to the presence of unsafe additives or volatile organic compounds.

1 Volatile Organic Compounds (VOCs) from Bioplastics

Volatile organic compounds (VOCs) are of concern as air pollutants. A clear definition of VOCs can be found in the Directive 2004/42/CE of the European Parliament and of the Council. “‘Volatile organic compound (VOC)’ means any organic compound having an initial boiling point less than or equal to 250°C measured at a standard pressure of 101,3 kPa” (The European Parliament and the Council of the European Union 2004). Their indoor presence was correlated to negative effects on human health and wellbeing and to the “sick building syndrome” (Cecchi 2014a; Adamová et al. 2019) characterized by allergies, eye irritation, nose and throat malfunction, and tiredness; hence the analysis of VOCs is crucial for assessing the safety of both common materials and innovative bioplastics to be used in the building sector.

As regards bioplastics the VOCs fingerprint is essential for (i) understanding the chemical processes involved in polymer synthesis, stability, and degradation, (ii) detecting toxic compounds, including volatile catalyst, antioxidants, plasticizers, and other additives (iii) detecting substances with distinct odor and taste whose potential migration from bioplastics may lead to the sensorial deterioration of packaged foods and beverages. The emissions depend on the chemical composition of the material and climate conditions. Primary emissions, greatest after the synthesis of the material, are due to nonbound VOCs that can originate from solvents, technological agents, and unreacted raw materials such as residual monomers, low molecular weight oligomers, and polymerization byproducts. Secondary emissions are due to chemically or physically bound VOCs formed during polymer decomposition, degradation, and oxidation, or reactions of the primary VOCs (Wolkoff 2003; Cecchi 2014b).

Protocols for VOC determination should detect compounds in the part per trillion to part per billion range. On-site, direct-reading methods are less precise and accurate than collection methods, which can typically achieve a more sensitive quantification limit since they involve the collection of the compound into a container or its concentration onto a sorbent for later analysis.

As regards VOC emissions from bioplastics, there is a dearth in the literature since it is allegedly felt that their biobased source guarantees their safety and the absence of any health concerns. Since the use of biobased materials for building construction and for the automotive sector has become increasingly prevalent in recent years, indoor air quality concerns related to VOC release have to be properly addressed. In fact, indoor air quality issues and the reduction of the level of indoor air contaminants within the interior of the building are the focus of interest of many building rating systems and areas of legislation (Chambers and Muecke 2010; Wei et al. 2015). European Collaborative Action ECA “Indoor Air Quality & its Impact on Man” stimulated a multidisciplinary collaboration of European scientists.

Both EPA Compendium of Methods for the Determination of Toxic Organic Compounds in Ambient Air (TO methods) and ISO standards for indoor products emission testing are available; many countries have established mandatory or voluntary assessment programs regarding the release of VOCs from construction materials and furnishing, but reference legislation that sets limits to the concentrations of pollutants in indoor air has not been issued yet. Most of the available analytical methods rely on either gas chromatography (GC) or high-performance liquid chromatography (HPLC). The ISO 16000 series of standards are of particular interest. ISO 16000-6:2011 (ISO 2011), ISO 16000-9:2006 (ISO 2006a), ISO 16000-10:2006 (ISO 2006b), ISO 16000-11:2006 (ISO 2006c) are used for VOCs determination indoors. Most ISO standards have the corresponding ASTM standard.

The emission test chamber is widely used to test VOC emissions. It is a proper chamber working at constant temperature and humidity, with a specific rate of air exchange inside, where it is possible to place the sample whose emissions are studied. The airflow containing the emissions passes through a glass or stainless steel sorbent tube, usually packed with a porous polymer stable up to 400°C, properly designed for volatiles trapping. The thermal desorption unit enables the desorption of VOCs from the sorbent cartridges; VOCs are quantitatively transferred to the gas chromatograph, where they are separated during the chromatographic run.

The test chamber equipment is very expensive, and the procedure is very time-consuming; for these reasons, academicians studied the possibility to use the Solid Phase Micro Extraction (SPME) technique for the sampling step.

Compared to several sampling techniques, SPME shows the advantages of being solvent-free, cheap, and easy to use. The low cost of the very compact and lightweight device, the possibility of automation, and the simplicity of coupling with chromatographic techniques are further advantages of the SPME sampling strategy. This environmentally and user-friendly technique allows for integrating sampling, enrichment, and transfer to the chromatographic equipment. VOCs are usually released from a sample sealed in a vial. The SPME manual device is illustrated in Fig. 10.2. The holder has a needle containing a retractable fiber that pierces the vial septum; the fiber, coated with an extracting phase, is then exposed to the sample. Volatiles are extracted at a specific temperature for a specific time because the extracted amount of each analyte is a function of temperature and time. The curve, at constant temperature, flattens with increasing adsorption time; higher reproducibility is obviously expected in this flat equilibrium region; subsequently, the fiber is retracted and transferred to the GC injection port where thermal desorption of the adsorbates occurs. The extracting phase can extract different kinds of analytes from different kinds of media. Absorbing fibres should be conditioned before use. The divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS) fiber is almost universal because it is able to adsorb analytes in a wide range of polarity. The optimization of adsorption time and temperature provides high concentration factors. If the detection relies on a mass spectrometer, VOCs can be easily determined both qualitatively and quantitatively. The identification of the constituents is usually based on the comparison of the retention times with those of authentic samples, on computer matching against commercial spectral libraries (http://webbook.nist.gov/chemistry/) (Cecchi and Alfei 2013), and by comparison of their Kovats retention indices relative to n-alkanes, calculated using straight-chain alkanes mixture, with the averaged values reported in the bibliography for chromatographic columns similar to that used (van Den Dool and Dec. Kratz 1963).

Noteworthy, sampling via SPME is independent of humidity if it is not excessively high (Harper 2000). Anyhow, partition equilibrium composition depends on analyte volatility, sampling temperature, and time because competitive adsorption may occur; hence it is essential to adjust the design of experiment in order to pinpoint the best extraction conditions. The main drawback of SPME is the fact that absolute quantity determination is not straightforward (Pawliszyn 2011): the quantity of analyte extracted by the fiber is proportional to its concentration in the sample as long as equilibrium is reached; anyhow, determination of amounts of target compounds relative to total peak area easily allows the comparison of quantities of the same compound in different samples under constant conditions.

Emissions from PLA and PLA composites were sampled via SPME and measured through gas chromatography coupled to mass spectrometry (SPME-GC-MS) (Cecchi et al. 2019; Salazar et al. 2017).

The identification and quantification of VOCs formed after extrusion and after thermoforming of some commercial types of PLA via the SPME-GC-MS apparatus was studied. The extruded film released more analytes (namely acetaldehyde, acetone,2-methyl-2-propanol, acetic acid,2,3-pentanedione,2,4-dimethyl-2-pentanol,2,3,4-trimethyl-hexane, and2,2,4,6,6-pentamethyl-heptane) and higher amounts of VOCs than thermoformed samples. After 6 months of PLA storage at ambient conditions, the presence of VOCs decreased (Salazar et al. 2017). From a commercial point of view, these results are remarkable: the detected VOCs have distinct odor and taste and their migration may lead to the sensorial deterioration of packaged foods and beverages; interestingly, VOCs in PLA samples are not produced during storage at room temperature, but only during its processing at high temperatures.

A SPME-GC-MS apparatus was used to study the volatile fingerprint of both PLA obtained from (S)-lactic acid and the same PLA compounded with ceramic food waste powder fillers, such as eggshells and mussel shells. Volatiles from biocomposites can originate from the matrix polymer or from the natural-filler or from a combination of the two (Cecchi et al. 2019).

The molecular fingerprint of VOCs from PLA and from its composites is outlined in Table 10.1. It details the odor type (Dunkel et al. 2009) and the chemical class of each VOC, its experimental and literature retention indices (van Den Dool and Dec. Kratz 1963), as well as its abundance.

Interestingly, priority air pollutants released by fossil plastics that pose a significant public health threat (such as phenylalkanes, phthalates, and bisphenol A) are missing from the volatile profile of PLA and its composites. It is rewarding to observe that VOCs known to be causative factors of hormone disruption or reproductive dysfunction are similarly missing.

The volatile profile is very simple. Fig. 10.3 shows the chromatographic profiles for raw PLA from (S)-lactic acid, PLA compounded with eggshell powder, and PLA compounded with mussel shell powder. Cis-(S,S)-lactide and trans-(R,S)- lactide are easily predicted to be released from the PLA matrix. The presence of cis-(S,S)-lactide can be taken for granted since it is the dimer of the (S)-lactic acid used to obtain PLA; anyhow, at high temperature, an inversion of configuration may occur. This explains the presence of smaller amounts of trans-(R,S)-lactide. Heptanal, nonanal, and decanal are typical food odorants that do not pose a concern to public health: they were actually found also in the volatile fraction of both fillers. Compounding PLA with mussel shells seems to reduce the VOC emission since the chromatographic volatile profile of the filler is almost flat, and the presence of the filler reduces the surface of PLA available for the emission of its volatiles. In this respect, the filler behaves as a kind of PLA matrix diluent, decreasing its emissions.

It cannot be excluded, anyhow, that at a higher temperature, PLA and its composites are not exempt from other emissions due to thermal degradation that would not occur at ambient temperature (Wojtyła et al. 2017); it was demonstrated that PLA is one of the lowest emitters if used as a 3D printer filament (Azimi et al. 2016); anyhow, the high temperature of the 3D printer nozzle may be responsible for the emission of some the toxic or irritant VOCs from the PLA filaments, even if VOCs apportionment, between PLA matrix and additives in the filament, can be difficult; the specific source of the volatiles was unsure and, actually, out of hundreds of VOCs identified, only 5 ((S,S)-Lactide, acetaldehyde, 1-butanol, formaldehyde, and decanal) were consistently detected for all PLA filaments and thereby linked to the PLA matrix (Davis et al. 2019).

The detrimental influence of increasing temperature on the VOCs emission was demonstrated for neat PLA, PBS, and their bio-composites with pineapple flour and destarched cassava flour. VOC and formaldehyde were measured via thermal extractor analysis, field and laboratory emission cell techniques, and 20 L small chamber test with sorbent tubes and GC-MS analyses (Kim et al. 2011).

The detection of VOC (volatile oligomers) via SPME-GC-MS was also used to monitor the changes in PLA matrix exposed to outdoor soil environment. Lactic acid and lactoyl lactic acid appeared in the volatile profile of PLA films not before 12 months, thereby indicating that degradation in soil is a slow process due to hydrolysis and microbial metabolism (Gallet et al. 2000).

Main volatiles from a lignin/PLA/PHB composite, identified from pyrolysis GC-MS, were sulfur compounds (Ház et al. 2018).

Naturally occurring di- and multifunctional carboxylic acids were used to cross-link epoxidized sucrose soyate; the resulting highly functional biobased epoxy resin was a VOC-free thermoset with excellent thermal and mechanical properties. Fossilbased thermosets usually release volatile solvents or monomers, used to achieve favorable properties and low viscosity during the curing process. For this reason, these fully green VOC-free thermosets can replace fossilbased ones; noteworthy, they could be degraded either thermally or in alkaline media (Ma and Webster 2015).

However, it is felt that the VOCs release from bioplastics is far from being suitably studied; hence it is a cogent research need.

2 Catalyst Residues and Green Catalysts

Intensive research efforts about catalysts used for the synthesis of bioplastics focus on a number of different criteria for green industrial applications. First of all, the catalyst should be effective with small loadings, and it should not be harmful to the environment (during biodegradation) and the health since many materials have potential application in the biomedical sector.

As regards renewable and biodegradable PLA, nontoxic, highly active green catalysts for its polymerization would be highly desirable. Actually, tin(II)octanoate, Sn(Oct)2, is the commonly used catalyst for the industrial ring-opening polymerization of lactide described in Chap. 6; its homogeneous nature impairs the complete removal of the catalyst from the final product in which it is incorporated. Its growing use is leading to an increased intake of residual tin into the environment.

Due to its known toxicity for several aquatic organisms and many adverse effects on enzymes, receptors, and whole organisms, replacement strategies in agricultural applications are of great interest. Even if Sn(Oct)2 has been approved by the U.S. FDA (Howard et al. 2019), its genotoxicity and cytotoxicity are major drawbacks in biomedical applications (Parwe et al. 2017; Tanzi et al. 1994). The remnants of tin-based catalysts hinder safe PLA application for medical devices and food handling packages (Howard et al. 2019). The development of safe catalysts for biopolymers synthesis is of great interest. Cerium trichloride heptahydrate is a nontoxic and easy to handle Lewis acid catalyst in organic reactivity; a new and efficient lactic acid polymerization by multimetallic cerium complexes yielded a poly(lactic acid) suitable for biomedical applications, in high yields up to 95% and a molecular weight ranging from 9000 to 145000 g/mol (Pastore et al. 2021).

Iron and zinc are prominent metal candidates as tin substitutes. Three biocompatible iron(II) hybrid guanidine complexes rely on a metal ion with a clear biological role to polymerize lactide to long-chain polylactide with monomer/initiator ratios of more than 5000:1 via the coordination–insertion mechanism and with an increased polymerization activity compared to Sn(Oct)2 (Rittinghaus et al. 2019). Achiral iron complexes proved to be stereoselective under mild reaction conditions for the ring-opening polymerization of lactide for the production of thermally stable and industrially relevant stereocomplexes (Marin et al. 2019).

Four new zinc guanidine complexes have been tested for the polymerization of non-purified lactide under industrially relevant conditions: PLA with molecular weights over 71,000 g/mol were achieved with a polymerization rate that compares to that of Sn(Oct)2 (Schäfer et al. 2019). Similarly, zinc L-Proline complex was used as a safe catalyst in bulk polymerization of L-lactide and gave high molecular weight PLLA (Parwe et al. 2017); zinc amido-oxazolinate complexes proved to be active and isoselective initiators for the ring-opening polymerization of rac-lactide, producing isotactic stereoblock polylactides (Abbina and Du 2014). The potential zinc complexes prompted the investigation of analogous magnesium and calcium catalysts due to their low toxicity and cost.

Divalent metals (i.e., Mg, Ca, and Zn) with monoanionic ancillary scaffolds or neutral ligands were also successfully tested (Wheaton et al. 2009; Chen et al. 2007).

Germanium is an unharmful element that is able to mimic the tin catalytic activity to yield high molar mass PLA due to their similar properties. Germanium complexes, tested in combination with zinc and copper, showed high bulk polymerization activities for lactide at 150 °C. Germanium provides the active site for the ring opening polymerization of lactide probably through the coordination–insertion mechanism (Rittinghaus et al. 2020).

The fully biobased poly(propylene succinate), with thermal stability similar to that of its fossilbased analog, was obtained starting from the biobased 1,4-butanediol and tetraisopropyl orthotitanate as a catalyst (Parcheta and Datta 2018).

Biocatalysis is regarded as both a green and sustainable technology. The spectacular advances in molecular biology and biotechnology resulted in protein engineering that has enabled the optimization of existing enzymes and the invention of entirely new biocatalytic reactions (Sheldon and Woodley 2017).

For example, bacteria have been engineered in a microbial plastic factory to produce lactate-based polyesters in a single-step metal-free system (Cheng et al. 2014). In this research field, the literature is still scarce, but it is felt that the quantum leap from conceptualization of this idea to showcase the potential of this technology is not far.

3 Migration: Risks and Opportunities from Biobased Food Contact Materials

Food contact materials (FCMs) are all items envisioned to come into contact with food (or water for human consumption) during its production, processing, transportation, storage, preparation, and serving. FCMs include packaging and containers, kitchenware, cutlery, and dishes.

The safety of FCMs must be assessed as chemicals can migrate from the materials into food or water: any potential transfer should not (i) have adverse effects on human health and on the taste and/or odor of foods, (ii) change the composition of the food in an unacceptable way. Factors that influence migration include the kind of food and its fat content, the nature of FCM, the temperature, and the duration of the contact. The migration of chemicals from the packaging into the food deserves academic and industrial attention. It is the result of diffusion, dissolution, and processes involving the mass transport phenomena, often described by Fick’s second law, of low molecular mass compounds initially present in the package into a food sample or food simulant. Migration studies are usually performed using standardized food simulants and conditions specified in European food packaging regulations (Valdés et al. 2014).

In Europe, the safety of FCM is evaluated by the European Food Safety Authority (EFSA), which provides FCMs manufacturers with opinions on substances to be used in food contact materials. The U.S. Food and Drug Administration (FDA) laws and regulations similarly aim at protecting the consumers’ health throughout the supply chain.

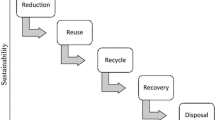

Current fossilbased polymers used as packaging materials face environmental and disposal issues. Actually, food package stability provided by fossilbased plastics during the shelf-life of the product is an advantage, but it becomes a disadvantage when the packages enter the post-use phase. Moreover, problems of food contamination due to substances migration from packaging are always the focus of attention. The world of packaging has great opportunities to develop a circular economy and industrial symbiosis. Bioplastics have been seen as an opportunity in this respect, notwithstanding their usually higher cost. Biodegradable biobased food packaging deserves attention because it could reduce material waste, elongate shelf life, and enhance food quality.

The gas and water vapor permeability are crucial properties of bioplastics in the packaging sector (they were discussed in Sect. 6.8); longshelf-life foods such as snacks and many other dry foods require high-barrier packaging, whereas fresh fruits, vegetables, and ready-to-eat meals need permeable packaging to stay fresh. Most bioplastics have lower water barrier properties due to their hydrophilicity but similar oxygen barrier characteristics as conventional plastics; hence their principal applications are breathable packagings for short shelf-life products. Still, PLA has an oxygen transmission rate at least one order of magnitude below those of the synthetic polymers used in the same field as PET and PS (Siracusa 2012; Zhao et al. 2020)

Biobased plastics have to comply with the same regulations with respect to food safety as fossilbased plastics; many biobased plastics such as biodegradable polyesters, starch, cellulose-based bioplastics, and drop-in bioplastics have been proven safe for food contact use (van den Oever et al. 2017).

Anyhow, bioplastics are not additive-free. For example, plasticizers are added to provide the necessary workability to bioplastics featuring fragility and brittleness during thermoformation and end-use application. Since bioplastics are usually less stable and have a lower diffusion barrier than conventional plastics, additional stabilizers and additives are often used to make their performance adequate and to overcome these problems. Furthermore, bioplastics are seldomly VOC-free (Ma and Webster 2015).

There is a dearth in the scientific literature as regards a comprehensive comparative evaluation of the migration behavior of chemicals from biobased and fossil-fuel based plastics. The differences between conventional and biobased plastics are not clear since the physico-chemical properties of biobased and fossil based materials might result in higher or lower migration rates of additives. Comparative studies describing the relative or absolute migration rates of the additives are scarce. The vast majority of studies describe migration from PLA and starch-based polymers (Avella et al. 2005; Conn et al. 1995). The low migration of lactic acid and its dimer, the lactide, from PLA and the fact that they do not pose serious health concerns, according to their toxicological data, made PLA one of the Generally Recognized As Safe (GRAS) substances (Conn et al. 1995) even if the development of safe catalyst candidates as tin substitutes and their use in green industrial applications is mandatory, as discussed above.

Zhu et al. (2014) described experimental results and a suitable model for the migration of the plasticizer triacetin from starch acetate into food simulants, but the authors concluded that they are still far from understanding migration on a molecular level and theoretical models covering these aspects would be desirable. The monomers of cellulose-based, starch-based, PHB, and PLA polymers are judged to be of no health concern (Clarke et al. 2012; Conn et al. 1995) at variance with the toxicological profile of many other monomers and additives used in the production of packaging materials, e.g., bisphenols (used to harden polycarbonate plastics and epoxy coatings), phthalates (used as plasticizers), vinyl chloride and acrylamide that pose serious environmental concerns and health risks to population (Plank and Trela 2018).

Since plasticizers are also needed in bioplastics, researchers tested the ability of some biobased products to mimic the role of conventional plasticizers in fully green bioplastics. For example, in an attempt to avoid the use of phthalates to mitigate the brittleness of biopolymers, oligomers of lactic acid (with a molar mass of around 1000 Da) are blended with commercial PLA to improve ductility, obtaining transparent and ductile materials, able for films manufacturing. These oligomers are proposed as innovative, and fully compatible and biodegradable plasticizers for PLA to avoid the migration of conventional plasticizers (Burgos et al. 2014). Among other possible PLA biobased plasticizers, cardanol acetate, obtained as a by-product of cashew nut extraction by the use of nontoxic and low environmental impact reagents, proved to be as effective as conventional plasticizers. In addition, plasticizer migration tests showed a lower weight loss of PLA plasticized by cardanol acetate compared to diethylhexyl phthalate plasticized PLA (Greco and Maffezzoli 2016).

Lower migration compared to fossil plastics was assessed for PLA nanocomposites with organoclays in packaging for the cosmetics industry. Total overall migration levels were well below the total legislative migration limit (10 mg/dm2), established by EU-Plastics Regulation 10/2011 (European Commission 2020), and the nanocomposite migration extracts stimulated minimal toxicity to the skin (Connolly et al. 2019).

Compliance with legislation for food packaging materials was also demonstrated for the overall migration levels in both non-polar and polar simulants of transparent nanocomposite-based packaging film comprised of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and cellulose nanocrystal methyl ester (Yu et al. 2014).

Nano-packaged foods are momentous. Mixing nanoparticles into packaging materials was used to improve their temperature, humidity, and gas barrier resistance or to introduce in active packaging antimicrobial, oxygen, or ultra-violet scavengers. Possible interaction of nanomaterials with food products and potential risks and health hazards are possible as a result of migration of nanoparticles into food materials (Adeyeye 2019). Even if the migration of nanoclay from starch-nanocomposites was reported to be of no concern (Avella et al. 2005), Houtman and colleagues demonstrated the in vitro toxicity of nanoclays with cytotoxic effects on two different cell lines (Houtman et al. 2014); cytotoxic and genotoxic effects were independently confirmed (Maisanaba et al. 2013; Sharma et al. 2010); there is a need for further testing under more standardized conditions to perform an adequate risk assessment of nanomaterials used in bionanocomposites.

3.1 Biobased Barriers to Prevent Migration from Conventional Packaging Materials

Biobased barriers to mitigate migration from common packaging materials were cleverly envisioned, devised, and tested. Cellulose-based packaging materials are very common due to their lightweight, stability, and affordable price. However, the use of recycled paper and board may result in the migration of undesirable substances into the packed goods. To reduce this kind of migration, the application of functional barriers in the packaging is crucial: biobased or biodegradable polymers proved to be effective (Walzl et al. 2019). In order to enhance the safety of fiber-based packaging, a biobased composite barrier layer was used to protect against mineral oil migration through paperboard. Starch-clay composite coatings were effective barriers against the migration of mineral oil and could hence improve the barrier properties and safety of fiber-based primary food packaging (Koivula et al. 2016). Biobased coatings, such as modified starches (cationic starch and cationic waxy starch), plant and animal proteins (gluten and gelatine), were evaluated as potential barriers to chemical contaminants from recycled paper and board for food packaging; diffusion studies into the solid food simulant poly 2,6-diphenyl-p-phenylene oxide confirmed that all the tested biopolymers slowed down migration (Guazzotti et al. 2014). Two different types of paperboard produced from primary and secondary cellulosic fibers were upgraded by coating them with alginate and chitosan; these two biodegradable biomaterials decreased (i) air permeability, (ii) water vapor transmission, (iii) permeation of volatile compounds, (iv) migration of mineral oil saturated hydrocarbons and mineral oil aromatic hydrocarbons while improving grease resistance (Kopacic et al. 2018).

As regards metal cans, tomato processing wastes were transformed into a novel bio-lacquer coating intended for metal food packaging: this way, consumers protection is achieved via the upcycling of food waste from the food chain itself; this strategy meets current demands for sustainable production (Montanari et al. 2017).

3.2 Biobased Products for Active and Smart Food Packaging

Food package is increasingly conceived not only as a simple container: actually, it is progressively perceived as adding value to the product. Smart packaging is an active research field and a key area of development in new multifunctional materials because it could be used to highlight biochemical or microbial changes in foods, to prevent food counterfeit and adulteration, to provide better food protection and preservation, marketing, and smart communication to consumers. In active packaging the sustained release to foodstuff of active agents is an intended, intentional, and favorable case of migration to obtain a deliberate interaction of the packaging with the food. Intelligent packaging systems should not release substances into the food since they are used to inform consumers about the conditions of the packaged food.

Food industry is subject to pressure from different stakeholders: producers, retailers, and customers have different priorities. By this scenario, the use of agricultural and food processing wastes in the packaging industry is getting increasing interest because it provides both reductions in environmental pollution by the packaging disposal and waste recovery. Food technology researchers are engaged with developing intelligent packing for better preservation and increased shelf life of food products. In this context, nontoxic pH indicator films produce a visual response to pH changes and represent a sensor that provides visual information to the customers concerning food deterioration. Anthocyanins from the blueberry by-product in starch-based films (Luchese et al. 2017), blueberry and blackberry pomace extracts in chitosan-based antioxidant smart films (Kurek et al. 2018) anthocyanins from red cabbage in a PVA/chitosan film are examples of intelligent food packaging (Pereira et al. 2015).

Biobased products find application as active agents for incorporation into biobased packaging, especially as antimicrobials because microbial spoilage is the major cause of senescence, gas build-up, and off-odors; rancidity, color loss/change, nutrient losses, dehydration can also be addressed (López-Gómez et al. 2009).

Gelatin and methyl cellulose were used as matrixes in antimicrobial active and edible films with citrus extract, which shows antibacterial activity (Iturriaga et al. 2012). The addition of grape seed extracts, nisin, and EDTA to soy protein isolate edible films reduced the populations of major foodborne pathogens and improved the tensile properties of the soy protein isolate edible films (Sivarooban et al. 2008). The antimicrobial activity of active films based on barley bran protein and gelatin was due to the addition of grapefruit seed extracts; the active films were used in packed salmon fish (Song et al. 2012).

Chitosan can be obtained from seafood waste utilization as detailed in Sect. 5.9. Chitosan and nano-chitosan edible coatings are food preservative with antimicrobial activity; chitosan-based films are widely studied for fishery products applications. (Yu et al. 2019); extracts of grape pomace were incorporated into chitosan edible films providing antioxidant properties and promising shelf-life extension (Ferreira et al. 2014). Gelatin and whey protein are additional FW (discussed in Chap 2) that have the potential to be used as carriers for antioxidants or antibacterial agents in coatings and films; noteworthy, the presence of lactoperoxidase in whey results in a broad spectrum antibacterial activity (Yu et al. 2019).

The use of mint extracts or pomegranate peel extracts in chitosan and polyvinyl alcohol active films increased protection against UV light and their tensile strength without significantly affecting their puncture strength and barrier properties; the extracts conferred antioxidant properties and effectiveness against Gram- positive food bacteria to the active films (Kanatt et al. 2012).

Three different concentrations of lemon extract, thymol, and lysozyme were incorporated in PLA, PCL, and LDPE; the antimicrobial activity of the resulting nine active films was tested. Antimicrobials incorporated into PLA and low-density polyethylene (LDPE) lost some antimicrobial activity due to higher processing temperature. On the other hand, the lower processing temperature of PCL prevented the degradation of antimicrobial activity. In particular, lysozyme showed higher thermal stability (Del Nobile et al. 2009).

Olive leaves extract rich in polyphenols with high antimicrobial efficiency on many food pathogens was successfully incorporated into PLA films. The antimicrobial activities against Staphylococcus aureus increased with increasing extract concentration in the film. Moreover, the amount of extract in the film positively correlated to the water vapor permeability and the water solubility; the degradation rates of films also increased, thereby conjugating antimicrobial effects and improved properties (Erdohan et al. 2013).

Antioxidant piperidine conjugated star-shaped PLLA (star-PLLA-PPD) proved to be a novel polyfunctional free radical stabilizing additive for bioplastics. A model study on the free radical scavenging ability of this active ingredient in PLA blends was carried out. The star-PLLA-PPD efficiently scavenges free radicals in the PLA matrix upon irradiation with doses generally used for food and medical device sterilization, thereby protecting molecular weight reduction when compared with the neat PLA. The migration of star-PLLA-PPD is significantly lower than piperidine, thereby confirming the importance of the new radical scavenger for bioplastics in the food packaging and biomedical sectors (Haema et al. 2017).

Biobased and biodegradable active films based on a PLA/PHB blend with lactic acid oligomers as plasticizers used carvacrol as an active agent for antimicrobial active packaging. In this case, migration of the active additive resulted in the microbiological protection of foodstuff with high-fat content. These results underlined the specific antimicrobial properties of these bio-films, suggesting their applicability in active food packaging (Burgos et al. 2017).

The potential of biocomposites for active food packaging is one of the most-studied approaches in the last years. Improved mechanical, barrier, antioxidant, and antimicrobial properties are sought with a focus on safety and risk associated with fillers and additives, migration properties, and possible human ingestion. For example, Thymus Vulgaris leaf extract was used as a stabilizer and reducing agent in the green synthesis of zinc oxide silver nanoparticles, used as an active agent in poly(3-hydroxybutyrate-co-3-hydroxyvalerate)-chitosan to fabricate a novel degradable biopolymer nanocomposite characterized by good mechanical properties and antimicrobial activity and with the lowest migration rate to improve the shelf life of poultry items (Zare et al. 2019). Biocomposites with rice straw paper incorporating 30% activated carbon enabled ethylene scavenging; ethylene is a plant hormone responsible for softening, ripening, color change, and senescence of many kinds of fruits; its environmentally-friendly scavenging is extremely important in the fresh fruit and vegetable industry since common ethylene scavengers are based on potassium permanganate that is not allowed to come into contact with foodstuff because of its toxicity and color (Sothornvit and Sampoompuang 2012).

To sum up, the production of active packaging systems releasing natural antimicrobials allowing to extend the shelf life of food products, and the development of new high-barrier packaging materials (often using cellulose nanocrystals) are among the latest multifaceted innovations. Aesthetic aspects, communication, and information will be essential issues since innovations are considered to be outstanding when it comes to lower resource use and to improvements in sustainability and safety. In this perspective, developing biobased materials and bioplastics is of great relevance.

Regulations 1935/2004/EC and 450/2009/EC pioneered the development of general requirements and specific safety and marketing issues related to active packaging materials, the intentional migration of active elements to food, criteria for the safety evaluation procedure, admissable active elements identification, and maximum release of the active component; the latter could exceed the overall migration requirements indicated in the legislation, and it should not be considered in the calculation of the overall migration limit (Dainelli et al. 2008); European Commission 2004; European Commission 2009; Llorens et al. 2012).

Consolidated texts of Regulations enable tracking of the evolution of legal acts via incorporation of successive amendments and corrigenda. Normal migration is covered by the specific legislation applicable to those materials, such as the EU Regulation 10/2011 (European Commission 2020).

Guidelines concerning the Commission Regulation (EC) No 450/2009 were provided to deal with the interpretation and application of certain features in the referred legislation, such as toxicological properties and the extent to which the original substance or breakdown products could transfer into food.

Similarly, new active packaging materials used in food-contact applications are subject to pre-market regulatory clearance by the US Food and Drug Administration if they are deemed “food additives.”

Even if smart and active packaging still remains more expensive than “traditional” packaging, new technologies and industrial development are expected to quicken cost reduction.

4 Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) Regulation for Biobased Products

Companies are gradually interested in the registration of biobased substances under European Union’s Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) Regulation (The European Parliament and the Council of the European Union 2006).

The principle is “one substance, one registration”; hence data sharing among all registrants by the joint submission of registration data to the European Chemical Agency (ECHA) is mandatory.

Persistence in the environment, bioaccumulation, and toxicity are the key targets of the hazard assessment required by the REACH regulation consolidated version for all chemicals that are produced or imported in Europe in amounts exceeding 10 tonnes per year. The regulation heavily impacts most companies (manufacturers of chemicals, importers of individual chemicals, mixtures for onwards sale or finished products from outside the EU, and downstream users) across the EU; they must identify risks and inform users about the risk management measures. ECHA’s website provides useful information about already registered substances: if the substance has already been registered for the same use by any company, it should not be registered again. REACH establishes procedures for collecting and assessing information on the properties and hazards of substances, and companies have the burden of proof. If the risks cannot be managed, according to the ECHA’s scientific committee judgment, authorities can restrict the use of substances or make it subject to prior authorization or definitively ban them. In the long run, less dangerous alternatives should replace the most hazardous substances. In principle, REACH applies to all chemicals but, by this scenario, REACH may favors manufacturers of safe biobased substitutes for substances of very high concern: in this respect, REACH may actually be an opportunity rather than the administrative obstacle it is often perceived to be.

Substances that are discarded as waste as defined in the consolidated text of Directive 2008/98/EC (“Waste Framework Directive”) (EU 2008) are exempted from REACH, but REACH applies for any substance, mixture, or article obtained from the recovery of waste and that meets the end of waste criteria: they generally need to be registered, except recovered substances already registered. However, for a recovered substance, it is sometimes possible to get an exemption from REACH registration.

Among substances exempted from registration we may find many biobased products. In fact, exemptions from registration apply to substances that present minimum risk (listed in Annex IV of the REACH Regulation) or substances for which registration is deemed inappropriate or unnecessary, often occurring in nature and not chemically modified (listed in Annex V of the REACH Regulation), to polymers, and to substances that are adequately regulated under other legislation, like substances used in food or feeding stuff or in medicinal products, where the relevant criteria are met. Even if a substance is exempted from the obligation to register it may still be subject to authorization or restriction provisions under REACH Regulation (ECHA 2016).

In particular, compost and biogas, as well as byproducts, unless they are imported or placed on the market themselves, are clearly mentioned among the exemptions from the obligation to register in Annex V of the REACH Regulation.

It is clear that biobased companies might qualify for exemptions that may lessen the registration burden. Readers are referred to the text of the REACH regulation, the only authentic legal reference.The information provided in this chapter does not constitute legal advice. The Author does not accept any liability as regards the contents of this document.

Bibliography

Abbina S, Du G (2014) Zinc-catalyzed highly isoselective ring opening polymerization of rac -lactide. ACS Macro Lett 3:689–692. https://doi.org/10.1021/mz5002959

Adamová T, Hradecký J, Prajer M (2019) VOC emissions from spruce strands and hemp shive: in search for a low emission raw material for bio-based construction materials. Materials (Basel) 12:2026. https://doi.org/10.3390/ma12122026

Adeyeye SAO (2019) Food packaging and nanotechnology: safeguarding consumer health and safety. Nutr Food Sci 49:1164–1179

Avella M, De Vlieger JJ, Errico ME et al (2005) Biodegradable starch/clay nanocomposite films for food packaging applications. Food Chem 93:467–474. https://doi.org/10.1016/j.foodchem.2004.10.024

Azimi P, Zhao D, Pouzet C et al (2016) Emissions of ultrafine particles and volatile organic compounds from commercially available desktop three-dimensional printers with multiple filaments. Environ Sci Technol 50:1260. https://doi.org/10.1021/acs.est.5b04983

Burgos N, Tolaguera D, Fiori S, Jiménez A (2014) Synthesis and characterization of lactic acid oligomers: evaluation of performance as poly(lactic acid) plasticizers. J Polym Environ 22:227–235. https://doi.org/10.1007/s10924-013-0628-5

Burgos N, Armentano I, Fortunati E et al (2017) Functional properties of plasticized bio-based poly(lactic acid)_poly(Hydroxybutyrate) (PLA_PHB) films for active food packaging. Food Bioprocess Technol 10:770–780. https://doi.org/10.1007/s11947-016-1846-3

Cecchi T (2014a) Identification of representative pollutants in multiple locations of an Italian school using solid phase micro extraction technique. Build Environ 82:655–665. https://doi.org/10.1016/j.buildenv.2014.10.009

Cecchi T (2014b) Head space – solid phase micro extraction profile of volatile organic compounds emitted from parquet samples. J Wood Chem Technol 34:211–224. https://doi.org/10.1080/02773813.2013.861849

Cecchi T, Alfei B (2013) Volatile profiles of Italian monovarietal extra virgin olive oils via HS-SPME-GC-MS: newly identified compounds, flavors molecular markers, and terpenic profile. Food Chem 141:2025. https://doi.org/10.1016/j.foodchem.2013.05.090

Cecchi T, Giuliani A, Iacopini F et al (2019) Unprecedented high percentage of food waste powder filler in poly lactic acid green composites: synthesis, characterization, and volatile profile. Environ Sci Pollut Res 26:7263–7271. https://doi.org/10.1007/s11356-019-04187-1

Chambers M, Muecke M (2010) Biobased products and the LEED® rating system. J Green Build 5:91–107. https://doi.org/10.3992/jgb.5.4.91

Chen HY, Tang HY, Lin CC (2007) Ring-opening polymerization of l-lactide catalyzed by a biocompatible calcium complex. Polymer (Guildf) 48:2257–2262. https://doi.org/10.1016/j.polymer.2007.02.030

Cheng HN, Gross RD, Smith PB (2014) Green polymer chemistry: biocatalysis and materials II. American Chemical Society, Washington, DC

Clarke K, Tchabanenko K, Pawlosky R et al (2012) Oral 28-day and developmental toxicity studies of (R)-3-hydroxybutyl (R)-3-hydroxybutyrate. Regul Toxicol Pharmacol 63:196–208. https://doi.org/10.1016/j.yrtph.2012.04.001

Conn RE, Kolstad JJ, Borzelleca JF et al (1995) Safety assessment of polylactide (PLA) for use as a food-contact polymer. Food Chem Toxicol 33:273–283. https://doi.org/10.1016/0278-6915(94)00145-E

Connolly M, Zhang Y, Brown DM et al (2019) Novel polylactic acid (PLA)-organoclay nanocomposite bio-packaging for the cosmetic industry; migration studies and in vitro assessment of the dermal toxicity of migration extracts. Polym Degrad Stab 168:108938. https://doi.org/10.1016/j.polymdegradstab.2019.108938

Dainelli D, Gontard N, Spyropoulos D et al (2008) Active and intelligent food packaging: legal aspects and safety concerns. Trends Food Sci Technol 19:S103–S112. https://doi.org/10.1016/j.tifs.2008.09.011

Davis AY, Zhang Q, Wong JPS et al (2019) Characterization of volatile organic compound emissions from consumer level material extrusion 3D printers. Build Environ 160:106209. https://doi.org/10.1016/j.buildenv.2019.106209

Del Nobile MA, Conte A, Buonocore GG et al (2009) Active packaging by extrusion processing of recyclable and biodegradable polymers. J Food Eng 93:1–6. https://doi.org/10.1016/j.jfoodeng.2008.12.022

Dunkel M, Schmidt U, Struck S et al (2009) SuperScent--a database of flavors and scents. Nucleic Acids Res 37:D291–D294. https://doi.org/10.1093/nar/gkn695

ECHA (2016) Guidance on registration. ECHA, Helsinki. https://doi.org/10.2823/969

Erdohan ZÖ, Çam B, Turhan KN (2013) Characterization of antimicrobial polylactic acid based films. J Food Eng 119:308–315. https://doi.org/10.1016/j.jfoodeng.2013.05.043

EU (2008) Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. EU, Brussels Consolidated text available at https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02008L0098-20180705. Accessed 7th Mar 2021

EU (2019) Communication from the commission to the European parliament, the European Council, The Council, The European Economic and Social Committee and The Committee of The Regions, The European Green Deal. EU, Brussels, pp 1–24. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52019DC0640. Accessed 7th Mar 2021.

European Commission (2004) Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food and repealing Directives 80/590/EEC and 89/109/EEC. Off J Eur Union L338(4):4–17 Consolidated text available at https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02004R1935-20090807. Accessed 7th Mar 2021

European Commission (2009) Commission Regulation (EC) No. 450/2009 of 29 May 2009 on active and intelligent materials and articles intended to come into contact with food. Off J Eur Union L 135:3–11

European Commission (2020) COMMISSION REGULATION (EU) 2020/1245 of 2 September 2020 amending and correcting Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food. In: Off. J. Eur. Union. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32020R1245&from=EN. Accessed 6 Mar 2021

Ferreira AS, Nunes C, Castro A, et al (2014) Influence of grape pomace extract incorporation on chitosan films properties. Carbohydr Polym 113:490–499. https://doi.org/10.1016/j.carbpol.2014.07.032

Gallet G, Lempiäinen R, Karlsson S (2000) Characterization by solid phase microextraction-gas chromatography-mass spectrometry of matrix changes of poly(L-lactide) exposed to outdoor soil environment. Polym Degrad Stab 71:147–151. https://doi.org/10.1016/S0141-3910(00)00165-8

Greco A, Maffezzoli A (2016) Cardanol derivatives as innovative bio-plasticizers for poly-(lactic acid). Polym Degrad Stab 132:213–219. https://doi.org/10.1016/j.polymdegradstab.2016.02.020

Guazzotti V, Marti A, Piergiovanni L, Limbo S (2014) Bio-based coatings as potential barriers to chemical contaminants from recycled paper and board for food packaging. Food Addit Contam Part A Chem Anal Control Expo Risk Assess 31:402–413. https://doi.org/10.1080/19440049.2013.869360

Haema K, Piroonpan T, Taechutrakul S et al (2017) Piperidine-conjugated polyfunctional star-shaped PLLA as a novel bio-based antioxidant additive for bioplastics. Polym Degrad Stab 143:145–154. https://doi.org/10.1016/j.polymdegradstab.2017.07.001

Harper M (2000) Sorbent trapping of volatile organic compounds from air. J Chromatogr A 885:129–151

Ház A, Michal J, Lisý A (2018) Compositions of volatile organic compounds emitted from natural and synthetic polymers. Earth in a trap? 2018 Anal Methods Fire Environ Sci 2018:1–6

Houtman J, Maisanaba S, Puerto M et al (2014) Toxicity assessment of organomodified clays used in food contact materials on human target cell lines. Appl Clay Sci 90:150–158. https://doi.org/10.1016/j.clay.2014.01.009

Howard IC, Hammond C, Buchard A (2019) Polymer-supported metal catalysts for the heterogeneous polymerisation of lactones. Polym Chem 10:5894–5904. https://doi.org/10.1039/c9py01472a

ISO (2006a) ISO 16000-9:2006 – indoor air — part 9: determination of the emission of volatile organic compounds from building products and furnishing — Emission test chamber method. https://www.iso.org/standard/38203.html. Accessed 6 Aug 2020

ISO (2006b) ISO 16000-10:2006 – indoor air — part 10: determination of the emission of volatile organic compounds from building products and furnishing — Emission test cell method. https://www.iso.org/standard/38204.html. Accessed 6 Aug 2020

ISO (2006c) ISO 16000-11:2006 – indoor air — part 11: determination of the emission of volatile organic compounds from building products and furnishing — Sampling, storage of samples and preparation of test specimens. https://www.iso.org/standard/38205.html. Accessed 6 Aug 2020

ISO (2011) ISO 16000-6:2011 – indoor air – part 6: determination of volatile organic compounds in indoor and test chamber air by active sampling on Tenax TA sorbent, thermal desorption and gas chromatography using MS or MS-FID. https://www.iso.org/standard/52213.html. Accessed 6 Aug 2020

Iturriaga L, Olabarrieta I, de Marañón IM (2012) Antimicrobial assays of natural extracts and their inhibitory effect against Listeria innocua and fish spoilage bacteria, after incorporation into biopolymer edible films. Int J Food Microbiol 158:58–64. https://doi.org/10.1016/j.ijfoodmicro.2012.07.001

Kanatt SR, Rao MS, Chawla SP, Sharma A (2012) Active chitosan-polyvinyl alcohol films with natural extracts. Food Hydrocoll 29:290–297. https://doi.org/10.1016/j.foodhyd.2012.03.005

Kharisov BI, Kharissova OV, Máximo C et al (2019) Greener synthesis of chemical compounds and materials. https://doi.org/10.1098/rsos.191378

Kim KW, Lee BH, Kim S et al (2011) Reduction of VOC emission from natural flours filled biodegradable bio-composites for automobile interior. J Hazard Mater 187:37–43. https://doi.org/10.1016/j.jhazmat.2010.07.075

Koivula HM, Jalkanen L, Saukkonen E et al (2016) Machine-coated starch-based dispersion coatings prevent mineral oil migration from paperboard. Prog Org Coatings 99:173–181. https://doi.org/10.1016/j.porgcoat.2016.05.017

Kopacic S, Walzl A, Zankel A et al (2018) Alginate and chitosan as a functional barrier for paper-based packaging materials. Coatings 8:235. https://doi.org/10.3390/coatings8070235

Kurek M, Garofulić IE, Bakić MT, et al. (2018) Development and evaluation of a novel antioxidant and pH indicator film based on chitosan and food waste sources of antioxidants. Food Hydrocoll. 84, 238–246. https://doi.org/10.1016/j.foodhyd.2018.05.050

Llorens A, Lloret E, Picouet PA et al (2012) Metallic-based micro and nanocomposites in food contact materials and active food packaging. Trends Food Sci Technol 24:19–29

López-Gómez A, Fernández PS, Palop A et al (2009) Food safety engineering: an emergent perspective. Food Eng Rev 1:84–104. https://doi.org/10.1007/s12393-009-9005-5

Luchese CL, Sperotto N, Spada JC, et al. (2017) Effect of blueberry agro-industrial waste addition to corn starch-based films for the production of a pH-indicator film. Int. J. Biol. Macromol. 104:11–18. https://doi.org/10.1016/j.ijbiomac.2017.05.149

Ma S, Webster DC (2015) Naturally occurring acids as cross-linkers to yield VOC-free, high-performance, fully bio-based, degradable thermosets. Macromolecules 48:7127–7137. https://doi.org/10.1021/acs.macromol.5b01923

Maisanaba S, Puerto M, Pichardo S et al (2013) In vitro toxicological assessment of clays for their use in food packaging applications. Food Chem Toxicol 57:266–275. https://doi.org/10.1016/j.fct.2013.03.043

Marin P, Tschan MJL, Isnard F et al (2019) Polymerization of rac-Lactide using achiral Iron complexes: access to thermally stable Stereocomplexes. Angew Chemie – Int Ed 58:12585–12589. https://doi.org/10.1002/anie.201903224

Montanari A, Bolzoni L, Cigognini IM et al (2017) Tomato bio-based lacquer for sustainable metal packaging. In: Acta horticulturae. International Society for Horticultural Science, Leuven, pp 159–165

Pandey A, Kumar P, Singh V (2010) Application of bioplastics in bulk packaging : a revolutionary. University of Science & Technology, Hisar

Parcheta P, Datta J (2018) Kinetics study of the fully bio-based poly(propylene succinate) synthesis. Functional group approach. Polym Degrad Stab 155:238–249. https://doi.org/10.1016/j.polymdegradstab.2018.07.025

Pastore G, Gabrielli S, Cecchi T. et al (2021) A new and efficient lactic acid polymerization by multimetallic cerium complexes: a poly(lactic acid) suitable for biomedical applications. RSC Adv 11:10592–10598. https://doi.org/10.1039/d0ra10637b

Parwe SP, Warkad SD, Mane MV et al (2017) Investigation of the biocompatibility and cytotoxicity associated with ROP initiator and its role in bulk polymerization of L-lactide. Polymer (Guildf) 111:244–251. https://doi.org/10.1016/j.polymer.2017.01.058

Pawliszyn J (2011) Handbook of solid phase microextraction. Elsevier, Ontario

Pereira VA, de Arruda INQ, Stefani R (2015) Active chitosan/PVA films with anthocyanins from Brassica oleraceae (Red Cabbage) as Time-Temperature Indicators for application in intelligent food packaging. Food Hydrocoll. 43, 180–188. https://doi.org/10.1016/j.foodhyd.2014.05.014

Plank CM, Trela BC (2018) A review of plastics use in winemaking: Haccp considerations. Am J Enol Vitic 69:307–320. https://doi.org/10.5344/ajev.2018.17041

Rittinghaus RD, Schäfer PM, Albrecht P et al (2019) New kids in lactide polymerization: highly active and robust iron guanidine complexes as superior catalysts. ChemSusChem 12:2161–2165. https://doi.org/10.1002/cssc.201900481

Rittinghaus RD, Tremmel J, Růžička A et al (2020) Undiscovered potential: Ge catalysts for lactide polymerization. Chem – Eur J 26:212–221. https://doi.org/10.1002/chem.201903949

Salazar Gonzalez R, Domenek S, Plessis C, Ducruet V (2016) Quantitative determination of volatile organic compounds formed during polylactide processing by MHS-SPME. Polym Degrad Stab 136:80–88. https://doi.org/10.1016/j.polymdegradstab.2016.12.010

Salazar R, Domenek S, Plessis C, Ducruet V (2017) Quantitative determination of volatile organic compounds formed during Polylactide processing by MHS-SPME. Polym Degrad Stab 136:80–88. https://doi.org/10.1016/j.polymdegradstab.2016.12.010

Schäfer PM, McKeown P, Fuchs M et al (2019) Tuning a robust system: N,O zinc guanidine catalysts for the ROP of lactide. Dalt Trans 48:6071–6082. https://doi.org/10.1039/c8dt04938f

Sharma AK, Schmidt B, Frandsen H et al (2010) Genotoxicity of unmodified and organo-modified montmorillonite. Mutat Res – Genet Toxicol Environ Mutagen 700:18–25. https://doi.org/10.1016/j.mrgentox.2010.04.021

Sheldon RA, Woodley JM (2017) Role of biocatalysis in sustainable chemistry. Chem Rev 118:801. https://doi.org/10.1021/acs.chemrev.7b00203

Siracusa V (2012) Food packaging permeability behaviour: a report. Int J Polym Sci 2012:11

Sivarooban T, Hettiarachchy NS, Johnson MG (2008) Physical and antimicrobial properties of grape seed extract, nisin, and EDTA incorporated soy protein edible films. Food Res Int 41:781–785. https://doi.org/10.1016/j.foodres.2008.04.007

Song HY, Shin YJ, Bin SK (2012) Preparation of a barley bran protein-gelatin composite film containing grapefruit seed extract and its application in salmon packaging. J Food Eng 113:541–547. https://doi.org/10.1016/j.jfoodeng.2012.07.010

Sothornvit R, Sampoompuang C (2012) Rice straw paper incorporated with activated carbon as an ethylene scavenger in a paper-making process. Int J Food Sci Technol 47:511–517. https://doi.org/10.1111/j.1365-2621.2011.02871.x

Tanzi MC, Verderio P, Lampugnani MG et al (1994) Cytotoxicity of some catalysts commonly used in the synthesis of copolymers for biomedical use. J Mater Sci Mater Med 5:393–396. https://doi.org/10.1007/BF00058971

The European Parliament and the Council of the European Union (2004) Directive 2004/42/CE of the European Parliament and of the Council of 21 April 2004 on the limitation of emissions of volatile organic compounds due to the use of organic solvents in certain paints and varnishes and vehicle refinishing products and amendi. Off J Eur Unio 87–96. http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2004:143:0087:0096:EN:PDF

The European Parliament and the Council of the European Union (2006) REACH Regulation. EC (2006) Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 concerning the Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH), establishing a European Chemicals Agency, amending Directive 1999/45/ EC and repealing Council Regulation (EEC) No 793/93 and Commission Regulation (EC) No 1488/94 as well as Council Directive 76/769/EEC and Commission Directives 91/155/EC, 93/67/EEC, 93/105/EC and 2001/21/ EC. J Eur Union 30.12.2006. http://ec.europa.eu/environment/chemicals/reach/reach_intro.htm. Accessed 7th Mar 2021.

Valdés A, Mellinas AC, Ramos M et al (2014) Natural additives and agricultural wastes in biopolymer formulations for food packaging. Front Chem 2:1–10. https://doi.org/10.3389/fchem.2014.00006

van Den Dool H, Dec. Kratz P (1963) A generalization of the retention index system including linear temperature programmed gas-liquid partition chromatography. J Chromatogr A 11:463–471. https://doi.org/10.1016/s0021-9673(01)80947-x

van den Oever M, Molenveld K, van der Zee M, Bos H (2017) Bio-based and biodegradable plastics - Facts and figures. Focus on food packaging in the Netherlands. Rapport nr. 1722. https://doi.org/10.18174/408350

Walzl A, Kopacic S, Bauer W, Leitner E (2019) Characterization of natural polymers as functional barriers for cellulose-based packaging materials. Food Addit Contam Part A 36:976–988. https://doi.org/10.1080/19440049.2019.1600747

Wei W, Ramalho O, Mandin C (2015) Indoor air quality requirements in green building certifications. Build. Environ. 92:10–19

Wheaton CA, Hayes PG, Ireland BJ (2009) Complexes of Mg, Ca and Zn as homogeneous catalysts for lactide polymerization. J Chem Soc Dalt Trans 25:4832–4846. https://doi.org/10.1039/b819107g

Wojtyła S, Klama P, Baran T (2017) Is 3D printing safe? analysis of the thermal treatment of thermoplastics: ABS, PLA, PET, and nylon. J Occup Environ Hyg 14:D80–D85. https://doi.org/10.1080/15459624.2017.1285489

Wolkoff P (2003) Trends in Europe to reduce the indoor air pollution of VOCs. Indoor Air 13:5–11

Yu H, Yan C, Yao J (2014) Fully biodegradable food packaging materials based on functionalized cellulose nanocrystals/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) nanocomposites. RSC Adv 4:59792–59802. https://doi.org/10.1039/c4ra12691b

Yu D, Regenstein JM, Xia W (2019) Bio-based edible coatings for the preservation of fishery products: a review. Crit Rev Food Sci Nutr 59:2481–2493

Zare M, Namratha K, Ilyas S et al (2019) Smart fortified PHBV-CS biopolymer with ZnO−Ag nanocomposites for enhanced shelf life of food packaging. ACS Appl Mater Interfaces 11:48309–48320. https://doi.org/10.1021/acsami.9b15724

Zhao X, Cornish K, Vodovotz Y (2020) Narrowing the gap for bioplastic use in food packaging: an update. Environ Sci Technol 54:4732–4732. https://doi.org/10.1021/acs.est.9b03755

Zhu J, Li X, Huang C et al (2014) Structural changes and triacetin migration of starch acetate film contacting with distilled water as food simulant. Carbohydr Polym 104:1–7. https://doi.org/10.1016/j.carbpol.2013.12.087

Author information

Authors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Cecchi, T. (2021). Assessment of the Safety of BioBased Products. In: Biobased Products from Food Sector Waste. Springer, Cham. https://doi.org/10.1007/978-3-030-63436-0_10

Download citation

DOI: https://doi.org/10.1007/978-3-030-63436-0_10

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-63435-3

Online ISBN: 978-3-030-63436-0

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)