Abstract

This chapter considers the two-echelon supply chain network design with unreliable facilities when nodes related to facilities in both echelons fail under disruptions. A new mixed-integer programming (MIP) model is proposed for a reliable facility location with possible customer reassignment in different probabilistic scenarios. The maintaining of the materials flow between different echelons of the network is investigated under network disruptions. The performance of global optimization is investigated by comparing this approach with independent and non-integrated optimization. The objective function of the problem seeks to minimize expected costs, including fixed and service costs in the supply chain, such that maintaining the demand flow in both echelons of the network interconnects them. The medium- and large-sized problems are solved using a custom-designed Lagrangian dual decomposition algorithm. Our computational results show that the proposed algorithm is efficient for the given problems, efficiently overcomes the computational complexity of the problems, and provides good-quality solutions within an acceptable time.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Facility location problems involve the study of determining locations of |J| facilities with the finite or infinite capacity among |I| demand points, and making assignment decisions to serve a set of clients. The objectives of location and allocation are to achieve a trade-off between first-stage setup costs and second-stage service and transportation costs. Facility location problems have extensively been studied; various types of facilities (e.g., factories, warehouses, stores, airports, hospitals, and emergency departments) have been examined (Rohaninejad et al. 2017). In classical facility location problems, it is assumed that clients always get service from the facilities and the facilities are always available. Considering realistic situations, these assumptions are not likely valid.

Every year, many companies are faced with unexpected events in their supply chain networks. From time to time, network performance can be disrupted for various reasons; for example, natural disasters, power outages, changes of ownership, operational risks, and strike actions. The strategic nature of supply chain decisions differentiates them from operational-level decisions, such as machine scheduling and short-term material requirement planning. Hence, uncertainties in a supply chain can impose heavy costs on the system by completely stopping the flow of the network for a lengthy period. In this paper, this default assumption is used to design a reliable network, whose facilities are unreliable. Continuous changes in the network structure (i.e., first-stage decisions) are impossible and without justification in facility location problems with facility disruptions. Designing optimal supply chains when facilities are subject to random disruptions is an appropriate response to dealing with this type of uncertainty, which is located in the class of provider-side uncertainty (randomness in facility capacity or reliability of facilities, etc.).

Considering reliability in facility location problems makes it possible that a system continues to function with the minimal loss when its components fail. Reliable design of a facility location problem considers a change in second-stage decisions by reassigning client demand to other facilities far from their regularly assigned facilities or arranging backup facilities for failed facilities. The reliable uncapacitated facility location problem (RUFLP), was first studied by Snyder and Daskin (2005). They formulated the problem as a linear MIP, called “implicit formulation” (IF), which employed Lagrangian relaxation for efficient solutions. A similar study was presented by Berman et al. (2007), who relaxed the assumption of identical failure probabilities, which was a basic assumption of the model presented by Snyder and Daskin (2005). Then, they developed several exact and heuristic approaches. Other studies, such as Cui et al. (2010) and Shen et al. (2011), have formulated the RUFLP with non-identical failure probabilities. In addition to a scenario-based model of the problem, Shen et al. (2011) also provided a mixed-integer nonlinear programming model and provided several approximation algorithms that can produce near-optimal solutions. Cui et al. (2010) proposed a compact mixed-integer programming (MIP) model and a continuum approximation (CA) model to study the problem and used Lagrangian relaxation to solve the models. In a reliable capacitated facility location problem (RCFLP), Aydin and Murat (2013) developed a model for the RCFLP and presented a novel hybrid method, namely swarm intelligence-based sample average approximation (SIBSAA), to solve their model. Peng et al. (2011) presented an RCFLP to minimize the nominal cost (when no disruptions occur) and at the same time reducing the disruption risk by applying the p-robustness criterion, in which bounds the cost in disruption scenarios. Li et al. (2013a) investigated reliable facility location problems, while the failure of the facilities was correlated. Fan et al. (2018) proposed a reliable location model for a nexus of interdependent infrastructure systems. Their model aims to locate the optimal facility locations in multiple heterogeneous systems to balance the trade-off between the facility investment and the expected nexus operation performance. Afify et al. (2019) are proposed an evolutionary learning technique to near-optimally solve Reliable p-Median Problem and Reliable Uncapacitated Facility Location Problem considering heterogeneous facility failure probabilities, one layer of backup and limited facility fortification budget.

Multi-echelon supply chain design has been extensively studied in classical facility location problem. To the best of the authors’ knowledge, there have been a few studies on the multi-echelon in reliable facility location problems. These studies assumed that facility disruption occurs only at one echelon of the network. For example, Razmi et al. (2013) proposed a scenario base mixed-integer linear programming (MILP) model for redesigning a reliable single product, single period, and two-echelon logistics network. In this paper, we consider the two-echelon reliable facility location with unreliable facilities when nodes related to facilities in both echelons fail under disruptions. The analysis of problems that involve single-echelon supply chains and decisions made under that assumption may lead to many errors. In other words, the single-echelon perspective on a supply chain of goods and services lacks the required accuracy and efficiency in cases, in which the network itself is part of a larger network and interacts with other echelons and layers of the network. Decisions, actions, and reactions at each echelon of the supply chain can have significant effects on other echelons. For this reason, we intend to study the RFLP by taking into account all the echelons of the supply chain. Rohaninejad et al. (2018) first considered the RCFLP in a multi-echelon manner with the possibility of disruption in all echelons. They presented the new scenario-based formulation to maintain the materials flow between different echelons of the network under facilities disruptions. In continue of their study, this paper examines whether the design of reliable multi-echelon facility location problems with a global optimization approach (i.e., integrated optimization in all echelons) is more effective than independent and non-integrated optimization. The answer is to provide an insight for the owners of the supply chain, in which “how effective is the cooperation between the owners of each echelon of the network?”

A review of the literature on the RFLP regarding complexity shows that the RUFLP is NP-hard (Li et al. 2013b). The RCFLP, which involves the addition of capacity constraints, is NP-hard as well because the RCFLP reduces to the RUFLP when the capacities of the facilities tend towards infinity. In another hand, using the implicit formulation provided by Snyder and Daskin (2005) to provide low-complexity formulation has some drawbacks. This type of formulation has limitations when it is extended to problems with different failure probabilities for facilities, partial allocation of client demand to facilities, the possibility of partial disruption of facilities, facility capacity constraints and multi-echelon networks. Tracking demand flows across different network echelons is not possible or not easy in multi-echelon networks by implicit formulation. So using the scenario-based formulation is in priority. The scenario-based approach is flexible and can be used for our considered problem; however, there might be numerous scenarios, (in our case, if \(J\) facilities are assumed that each of them can fail independently, there are \({2}^{J}\) failure scenarios) and the complexity of the model increases exponentially by increasing the number of scenarios. Therefore, due to the complexity of the model, a custom-designed Lagrangian dual decomposition algorithm is proposed for this problem.

The literature on the RFLP presents various solution procedures: heuristic or approximation procedures (Shen et al. 2011; Rohaninejad et al. 2015; Aboolian et al. 2013); Lagrangian relaxation algorithms (Snyder and Daskin 2005; An et al. 2015); continuum approximation (Li and Ouyang 2010); exact methods (Rohaninejad et al. 2018; Hatefi and Jolai 2014) and metaheuristic algorithms (Aydin and Murat 2013; Peng et al. 2011).

The remaining sections are organized as follows. The problem definitions are defined in Sect. 2. Section 3 presents a new MILP model of the problem. Section 4 illustrates the proposed solution method. Section 5 provides the computational results. Finally, Sect. 6 outlines the conclusion and some suggestions for future research.

2 Problem Definition

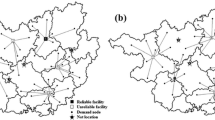

In this paper, we consider a two-echelon reliable facility location problem (TE-RFLP). While considering a two-echelon instead of single-echelon RFLP, we assume that there is the possibility of a failure of facilities at both echelons of the network. In the TE-RFLP, we assume that facilities at the first echelon of the chain are clients at the second echelon of the chain and vice versa. In other words, the client demand at the second echelon of the supply chain is equal to the coefficient of the total client demand at the first echelon assigned to it as a facility at the first echelon. Demand in the first echelon is predetermined; however, the demand in the second echelons is uncertain and dependent on the first echelon. Therefore, it is necessary to examine two-echelon systems from an integrated perspective to enhance the reliability of the whole system. Figure 1 depicts a schematic representation of the relationship between the echelons in a supply chain. This figure shows that potential sites at each echelon are potential clients at a higher echelon. As well, actual sites (openings) at each echelon are actual clients at a higher echelon. In this figure, it is clear that the flow of demand is interdependent at all echelons. It is assumed, that the flow of demand may be discontinued from one echelon to a higher echelon, and demand is supplied from outside the network by paying a higher cost (i.e., penalty cost). In other words, all open facilities need to supply their client demand from inside the network (its higher echelons), or from the outside network by paying a penalty cost.

In the TE-RFLP, the facilities have two operational levels, namely active and inactive. In an active mode, the facilities are fully available and inactive facilities cannot provide any services to the clients and are out of reach. The aim of solving this problem is to design a reliable network for a two-echelon supply chain to minimize the expected total fixed costs and service costs (including the expected transportation costs and costs incurred for failing to meet client demand). Other assumptions of the problem are as follows:

-

The potential sites for establishing facilities are predefined and discrete.

-

There is no relationship between facilities at an echelon.

-

The problem is a single-product model.

-

The allocation of a demand node to more than one facility node is not allowed. In other words, partial or fractional allocation of demand to a facility is not allowed.

-

There is a fixed cost to establish a facility.

-

There is a transportation cost to allocate a demand node to a facility node.

-

There is a penalty cost for supplying demand from outside the network.

-

The maximum number of facilities that can be established in each location is one.

-

The network is two-echelon and all facilities in each echelon are the same (e.g., all facilities are wholesalers or retailers).

-

The problem parameters (e.g., demand in the first echelon, distance, and failure probabilities) are specified.

3 Notation and Formulation

The indices, parameters and variables of the proposed model are as follows:

Model indices:

- i:

-

Client index.

- j:

-

Potential site index.

- l:

-

Echelon index; (l = 1, 2).

- s:

-

Scenario index \(s\in S\)

Model parameters:

- \({d}_{i}\):

-

Demand quantity of client \(i\) in the first echelon.

- \({s}_{l,j}\):

-

Fixed cost of opening facility j in echelon l.

- \({c}_{l,i,j}\):

-

Transportation cost per unit demand of client i in echelon l that is serviced by facility j.

- \({h}_{l,i}\):

-

Penalty cost per unit of client i demand in echelon l if its demand is not met.

- \({\beta }_{j}\):

-

Conversion coefficient of demand volume from the first echelon to the second echelon for facility j in the first echelon (1 ≤ β_j ≤ 2).

- \({I}_{l}\):

-

Total number of clients in echelon l.

- \({J}_{l}\):

-

Total number of potential sites in echelon l.

- \({q}_{s}\):

-

Probability of scenario s.

- \({b}_{l,j,s}\):

-

1 if facility j in echelon l is active and functional under scenario s; 0, otherwise.

- G:

-

A positive large number.

Model variables:

- \({y}_{l,j}\):

-

1 if facility \(j\) at echelon \(l\) is opened; 0, otherwise

- \({X}_{l,i,j,s}\):

-

1 if client \(i\) assigned to facility \(j\) at echelon \(l\) under scenario \(s\); 0, otherwise

- \({Z}_{l,i,s}\):

-

1 if demand of client \(i\) at echelon \(l\) is not met under scenario \(s\); 0, otherwise

- \({u}_{i,j,s}\):

-

A positive variable specifies the demand of client \(i\) provided by facility \(j\) at second echelon under scenarios

- \({v}_{i,s}\):

-

A positive variable specifies the demand of client \(i\) at second echelon that is not met under scenarios

The mathematical model of the TE-RFLP based on the scenario-based formulation is as follows:

Objective function (1) consists of the total expected cost of facility fixed charge, transportation, and unmet demands penalty. Constraints (2) and (3), which refer to the first and second echelons respectively, ensure that all actual client demand is supplied from inside or outside the network. Since not all the second-echelon clients will necessarily become actual clients in Constraint (3), inequality is used instead of equality. For this reason, Constraint (3) is not enough to establish the demand flow in the second echelon; we need to add Constraint (4) to the model. Constraint (4), which refers to the second echelon (\(l=2\)) of the supply chain, has conditions similar to Constraint (2). However, the right side of this constraint ensures when a facility in the first echelon becomes a client in the second echelon, its demand in the second echelon is a function of the number of orders it accepted in the first echelon. The combination of Constraints (5) and (6) with Constraint (4) prevents a partial assignment (i.e., assigning a part of the client’s demand to a facility). Constraint (7) prevents assignment to a facility that has not been opened.

4 Lagrangian Dual Decomposition

Lagrangian dual decomposition (LDD) is a classical method for combinatorial optimization. This method is an important special case of the Lagrangian relaxation algorithm, in which the original problem decomposes to two or more combinatorial optimization problems. In this algorithm, we assume that there is a minimization problem as follows:

By decoding the problem, it can be found:

s.t.

We introduce a vector of Lagrange multiplier \(\lambda\). The Lagrangian is now.

And the dual objective is as follows:

Equation (12) is a lower bound for the original problem and the tightest lower bound can be shown by:

We solve each sub-problems of the relation (13) for the current \(\lambda\) separately and then update the \(\lambda\) for improve the sub-gradient level.

4.1 Custom Designed LDD

To solve the proposed model, we decompose the model based on the \(N\) subsets (\({e}_{n};n=1,\dots ,N\)) of scenarios, so that \({\bigcup }_{n=1}^{N}{e}_{n}=S\). For creating each subset with the similar importance and weight, we first sort all scenarios based on their probability value (\({q}_{s}\)) in a list, then for each subset, we select one scenario from the first of the list and then one another scenario from the end of the list. We repeat this procedure until the subset is filled (i.e., the number of members reaches a predefined value), and then the next subset will create until all possible scenarios assign to a subset. Then, to do the LDD method, we introduce the new first stage variables \({y}_{l,j}^{n}\) for each subsets of scenarios (\({y}_{l,j}^{1},{y}_{l,j}^{2}, \dots , {y}_{l,j}^{N}|l=\mathrm{1,2};j=1, \dots ., {J}_{l}\)). Finally, we add the non-anticipative constraints \({y}_{l,j}^{1}={y}_{l,j}^{2}= \dots = {y}_{l,j}^{N}\) so that establish these constraints by equations as follows:

where \({k}^{1}=1-N\) and \({k}^{n}=1\) for \(n=2,\dots ,N\).

Then, we relax the non-anticipative constraints and set the \(\lambda\) as a vector of Lagrangian multi-players that are related to these constraints. The objective function of Lagrangian relaxation for each set of scenarios are as follows:

where

.

Now, we can decompose the problem to \(N\) subproblem with minimization of Relation (17) for each \(n\in \{1,\dots ,N\}\). Also, the feasible solution space of the problem will be divided based on each subset of scenarios.

4.2 Updating the Lagrangian Multiplayer

The Lagrangian multipliers \({\lambda }_{l,j}\) are updated at per iteration using standard sub-gradient optimization by Fisher (Fisher 2004). So, given the initial value of multiplayer (\({\lambda }_{l,j}^{(0)}\)), a sequence value of multiplayer in iteration (t\({\lambda }_{l,j}^{(t)}\)) is generated by:

\({y}_{l,j}^{n}\) is optimal to the previous iteration and \({\beta }^{\left(t\right)}\) is a positive scaler step size.

In Eq. (19), \({Z}_{UB}^{*}\) is the best upper bound so far. \({Z}_{LB}\) is the lower bound at the current iteration. Also, \({\Delta }^{(t-1)}\upepsilon (\mathrm{0,2}]\) and we start with \({\Delta }^{(0)}=2\) and \({\Delta }^{(t)}\) is halved if the improvement in the Lagrangean lower bound is not more than 0.2% in \({L}_{\text{max}}\) consecutive iterations.

4.3 Generate the Upper Bound

Gradient method, a feasibility procedure is applied to generate an upper bound for the Lagrangian problem. So, after obtaining the lower bound, we propose a simple heuristic method to find a feasible solution at per iteration of the Lagrangian procedure, but possibly not an optimal solution. Since the non-anticipative Constraints (14) are relaxed, therefore, the \({y}_{l,j}^{n}\) are not equal in different subsets of scenarios. So, we generate a feasible solution in three steps as follows.

-

Step (1) Fixing the value of \({y}_{l,j}\) to 1 if they are 1 in minimum 50% of the optimal solution related to each subset of scenarios; 0, otherwise.

-

Step (2) Fixing the value of \({X}_{l,i,j,s}\) and their dependent variables (\({Z}_{l,i,s}, {u}_{i,j,s},{v}_{i,s}\)) for each \(i\le {I}_{l}\) and \(s\) to their optimal value if Constraint (7) is not violated after inserting the value of \({y}_{l,j}\).

-

Step (3) Solve the simplified original model for finding the optimum value of remained variables in the feasible state.

If the value of the new feasible solution is better than the incumbent upper bound, then the new value becomes the incumbent upper bound.

4.4 Pseudo Code of the Algorithm

The step-by-step pseudo code of the proposed algorithm is outlined in Fig. 2.

5 Computational Results

In this section, the credibility of the presented mathematical model and the performance and effectiveness of the presented heuristic algorithm are evaluated and compared with each other. The mathematical model and the LDD method are coded in the GAMS 24.1.2 software and solved by the CPLEX solver for the MIP models and run on a PC with 4 GHz processor and 8 GB of RAM. To compare the results of the proposed MIP formulation and LDD method two Relative Percentage Deviation criteria that called RPD is used. These performance measures are calculated based on the deviation of solutions to the best solution that achieved by MIP model and LDD. The RPD criterion for solution method A is calculated as follows (Note that the index A denotes a solution method.):

Also, to demonstrate the effectiveness and quality of LDD algorithm, we use three criteria (i.e., \(\mathrm{GAP}1\), \(\mathrm{GAP}2\), \(\mathrm{GAP}3\)). The gap between the lower bound (LB) and the upper bound (UB) is calculated by:

The distances between the upper bound (UB) and the optimal solution (OP) are denoted as GAP2, and between the lower bound (LB) and the optimal solution (OP) are denoted as GAP3. The distances are calculated by:

5.1 Generating Random Instances of the Problem

This section describes the testing of the proposed algorithms on 12 data sets that are generated randomly. The data set consists of 25–325 nodes for small to large instances. In each case, demands \({d}_{i}\) in the first echelon are drawn from a normal distribution with (\(\mu =100\); \(\delta =30\)) and rounded to the nearest integer. Fixed costs \({s}_{l,j}\) for \(l=1\) are drawn from U[30,000; 80,000] and rounded to the nearest integer. Fixed costs \({s}_{l,j}\) for \(l=2\) are drawn from U[120,000; 200,000] and rounded to the nearest integer. Penalty costs \({h}_{l,i}\) are drawn from U[1000; 3000] and rounded to the nearest integer.

Also, for each instance with \(\sum_{l}{I}_{l}\) clients and \(\sum_{l}{J}_{l}\) facilities, the locations of clients and facilities are determined randomly within a square, whose length and width are equal to \(\partial =\left(\sum_{l}{I}_{l} +\sum_{l}{J}_{l}\right)\left(2.8-0.01\left(\sum_{l}{I}_{l} +\sum_{l}{J}_{l}\right)\right)\). Transportation costs \({c}_{l,i,j}\) are set equal to the Euclidean distance between \(i\) and \(j\). The full failure probability of facilities in the first echelon is equal to 0.15 and in the second echelon is equal to 0.12. The scenarios of each instance are generated simply by taking into account all the possible combinations of active and inactive facilities. The probability of each scenario is computed by multiplying the probabilities of facilities according to their situation in an active or inactive scenario.

Ultimately, each instance is labelled with \((a;b;c)\), where \(a\) indicates the number of clients in the first echelon; \(b\) indicates the number of potential sites in the first echelon (potential clients in the second echelon) and \(c\) indicates the number of potential sites in the second echelon. The size of these parameters influences both the solution quality and the efficiency of the proposed procedures. To find the best trade-off between the algorithm speed and solution quality, the runtime of the solution methods is limited to 3600 s.

5.2 Numerical Examples

In this subsection, we present the results of the numerical examples to show the validity of the proposed mathematical model and the efficiency of the presented solution method. Table 1 shows a comparison of the optimal results obtained by the scenario-based MIP model and the proposed LDD algorithm. This table shows that the proposed LDD algorithm can provide the optimal solution in all cases, which the scenario-based formulation is provided with a feasible solution in predefined time restriction (i.e., 3600 s).

When the size of the problem increases, the scenario-based formulation loses its effectiveness; solving problems of sp100;10;2 and larger is not possible with this formulation in predefined time restriction. Instead, the LDD can obtain a feasible solution for larger-sized problems. Therefore, considering the average difference of 0% between the best upper bound of the LDD algorithm and the optimal solution of the scenario-based formulation can be found by the LDD algorithm has the reasonable performance for larger-sized problems. This algorithm can also reduce the total solution time of sp18;5;2 to sp100;8;2 cases from 7910 to 294 s. Finally, concerning the inefficiency of the scenario-based formulation for large-sized problems, we can propose the LDD algorithm as a suitable alternative to the scenario-based formulation and an efficient algorithm for two-echelon reliable uncapacitated facility location problems.

Table 2 shows the criteria related to the performance of the LDD algorithm. The table shows that the LDD algorithm allows using of the scenario-based model for larger-sized problems. On the other hand, according to the gap criterion, we are confident that the LDD algorithm can provide high-quality solutions (i.e., optimal or most closely optimal solution) in problems. The Gap 1 criterion is less than 5% in the 8 first samples and also less than 10% in the10 first samples {sp18,5;2 to sp200;20;5}. Therefore, we can recommend the use of the LDD algorithm to solve the scenario-based model of the TE-RFLP, especially for medium-sized problems.

Figures 3 and 4 show the comparative graphs of the results obtained from the LDD algorithm by changing the size of scenario’s subsets, for the criteria of the best upper bound (UB) and lower bound (LB) values and also the CPU time. These graphs are shown for sp100;8;2. In this examination, we consider five levels for the size of the scenario’s subsets, including \(\left\{\frac{|S|}{2},\frac{|S|}{3},\frac{|S|}{4},\frac{|S|}{5},\frac{|S|}{6}\right\}\). These figures show the complexity of the problem is increased and the gap between the upper and lower bounds is decreased by increasing in the size of the subset. Based on these figures, creating a trade-off between the quality and complexity is so important by selecting the optimal size of subsets.

Table 3 shows the performance results of the LDD algorithm under the influence of changes in the failure probabilities of the facilities in the sp100,8;2. Based on this table results, the LDD algorithm shows sustainable performance under different scenarios of the failure probability and provided an optimal or near-optimal solution in many cases. In the LDD algorithm, except for \({\mathrm{p}}_{1}={\mathrm{p}}_{2}=0.9\), where we see a significant drop in quality (RPD = 28.67%), we do not notice any significant changes in the performance of this method in other failure probabilities. The average RPD, regardless of \({\mathrm{p}}_{1}={\mathrm{p}}_{2}=0.9\), is 1.61%.

Our models are based on the assumption of integrated optimization at all echelons. Establishing this assumption requires cooperation between the owners of all echelons of the network. Table 4 examines how effective is this cooperation. This table shows the results obtained from solving the model in the two approaches: the integrated optimization and hierarchical optimization. Each echelon is independently optimized from other echelons in the hierarchical approach. At first, the lowest echelon of the network (i.e., echelon 1) is optimized and its results are fixed. Next, the second echelon is optimized and its results are fixed. According to the results of Table 4, the priority of the integrated approach to the hierarchical approach is evident. The average RPD criterion in this approach is 15.8% better than the hierarchical approach.

6 Conclusions

We developed a new mixed-integer programming (MIP) model based on the scenario-based formulation for two-echelon reliable facility location problems. However, the computational complexity of the scenario-based model made it less applicable for medium- and large-sized problems. Therefore, we were able to develop the use of this formulation for larger-sized problems by providing a Lagrangian dual decomposition algorithm. The computational results showed that the proposed algorithm was an efficient method for the scenario-based formulation in medium- and large-scale problems that provided a high quality of solutions with reasonable running time and resilience to change the failure probabilities of facilities. Also, the computational results showed that the adoption of an integrated approach to make a decision and simultaneous optimization at all echelons are much more effective than hierarchical optimization. Therefore, interaction and collaboration between owners of different echelons of the network are strongly recommended.

Future studies can focus on developing exact solution methods to solve the problem. Also, in multi-echelon systems, different types of relationships between echelons can be studied. For example, the failure probability of a facility or the cost of providing demand from a facility depends on the planned level of reliability in the other echelons of the network. For this reason, the lower reliability of the system in an echelon increases the costs of providing demand and the probability of failure in a lower echelon, and vice versa. It is also recommended to develop the implicit formulation for the problem with the aim of reduction in the complexity of the problem in future studies.

References

Aboolian R, Cui T, Shen ZJM (2013) An efficient approach for solving reliable facility location models. INFORMS J Comput 25(4):720–729

Afify B, Ray S, Soeanu A, Awasthi A, Debbabi M, Allouche M (2019) Evolutionary learning algorithm for reliable facility location under disruption. Expert Syst Appl 115:223–244

An S, Cui N, Bai Y, Xie W, Chen M, Ouyang Y (2015) Reliable emergency service facility location under facility disruption, en-route congestion and in-facility queuing. Transp Res Part E Logist Transp Rev 82:199–216

Aydin N, Murat A (2013) A swarm intelligence based sample average approximation algorithm for the capacitated reliable facility location problem. Int J Prod Econ 145(1):173–183

Berman O, Krass D, Menezes MB (2007) Facility reliability issues in network p-median problems: strategic centralization and co-location effects. Operat Res 55(2):332–350

Cui T, Ouyang Y, Shen ZJM (2010) Reliable facility location design under the risk of disruptions. Operat Res 58(4-part-1):998–1011

Fan H, Ma J, Li X (2018) A reliable location model for heterogeneous systems under partial capacity losses. Transp Res Part C Emerg Technol 97:235–257

Fisher ML (2004) The Lagrangian relaxation method for solving integer programming problems. Manage Sci 50(12_supplement):1861–1871

Hatefi SM, Jolai F (2014) Robust and reliable forward–reverse logistics network design under demand uncertainty and facility disruptions. Appl Math Model 38(9–10):2630–2647

Li X, Ouyang Y (2010) A continuum approximation approach to reliable facility location design under correlated probabilistic disruptions. Transp Res Part B Methodol 44(4):535–548

Li X, Ouyang Y, Peng F (2013a) A supporting station model for reliable infrastructure location design under interdependent disruptions. Transp Res Part E Logist Transp Rev 60:80–93

Li Q, Zeng B, Savachkin A (2013b) Reliable facility location design under disruptions. Comput Oper Res 40(4):901–909

Peng P, Snyder LV, Lim A, Liu Z (2011) Reliable logistics networks design with facility disruptions. Transp Res Part B Methodol 45(8):1190–1211

Razmi J, Zahedi-Anaraki A, Zakerinia M (2013) A bi-objective stochastic optimization model for reliable warehouse network redesign. Math Comput Model 58(11–12):1804–1813

Rohaninejad M, Navidi H, Nouri BV, Kamranrad R (2017) A new approach to cooperative competition in facility location problems: mathematical formulations and an approximation algorithm. Comput Oper Res 83:45–53

Rohaninejad M, Amiri AH, Bashiri M (2015) Heuristic methods based on MINLP formulation for reliable capacitated facility location problems. Int J Indus Eng Prod Res 26(3):229–246

Rohaninejad M, Sahraeian R, Tavakkoli-Moghaddam R (2018a) Multi-echelon supply chain design considering unreliable facilities with facility hardening possibility. Appl Math Model 62:321–337

Rohaninejad M, Sahraeian R, Tavakkoli-Moghaddam R (2018b) An accelerated Benders decomposition algorithm for reliable facility location problems in multi-echelon networks. Comput Ind Eng 124:523–534

Shen ZJM, Zhan RL, Zhang J (2011) The reliable facility location problem: Formulations, heuristics, and approximation algorithms. INFORMS J Comput 23(3):470–482

Snyder LV, Daskin MS (2005) Reliability models for facility location: the expected failure cost case. Transp Sci 39(3):400–416

Acknowledgements

The research has been supported by the Ministry of Education, Youth and Sports within the dedicated program ERC CZ under the project POSTMAN with reference LL1902.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Rohaninejad, M., Hanzálek, Z., Tavakkoli-Moghaddam, R. (2020). Lagrangian Dual Decomposition for Two-Echelon Reliable Facility Location Problems with Facility Disruptions. In: Golinska-Dawson, P., Tsai, KM., Kosacka-Olejnik, M. (eds) Smart and Sustainable Supply Chain and Logistics – Trends, Challenges, Methods and Best Practices. EcoProduction. Springer, Cham. https://doi.org/10.1007/978-3-030-61947-3_25

Download citation

DOI: https://doi.org/10.1007/978-3-030-61947-3_25

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-61946-6

Online ISBN: 978-3-030-61947-3

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)