Abstract

There are some impediments to the effective use of conventional flat web steel girders such as poor web stability and low buckling strength. To overcome these kinds of problems, the idea of using steel corrugated webs to bridge girders has been introduced to get enhanced web stability and buckling strength. The existing studies on bridge girders with steel corrugated webs are focused on single corrugated web girders. According to previous researches, large forces generated on the girders result in buckling of single corrugated web. This paper focuses on Double corrugated web girders. The Double corrugated web girders can be strengthen either by providing stiffeners along with the corrugated web or by making the web as a composite one. This paper consists of buckling investigations on Double Corrugated Stiffened Steel Web Non-prismatic girders (DCSSWG) consist of two stiffened corrugated steel webs with steel flat flanges and also on Double Corrugated Composite Web Non-prismatic girders (DCCWG) having Ultra-Lightweight Cement Composite fill (ULCC) in the space between two corrugated steel webs. Buckling performance of Non-prismatic girders with Double Corrugated Stiffened Steel Webs and Double Corrugated Composite Webs having different tapered ratios are investigated using ANSYS 16.1 software. The results obtained from the study have shown that Non prismatic girders with Double Corrugated Composite Webs show more buckling strength as compared to Double Corrugated Stiffened Steel Webs for the same tapered ratio.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The corrugated steel web plates have a lot of favorable properties and recently it is used for many structural engineering applications, especially in the field of bridges. Bridge girders with corrugated webs have a number of advantages such as more out-of plane stiffness, higher buckling resistance and shear capacity, excellent strength and web stability than that of conventional flat web girders. Some examples of bridges provided with corrugated steel web girders are the Maupré Bridge constructed in France and the Hondani Bridge constructed in Japan. According to previous researches, large forces generated on the girders result in buckling of single corrugated steel webs. For improving its strength and web stability, Double corrugated webs can be provided. The present study focuses on Double corrugated web girders. The purpose of this paper is to obtain numerical modelling results on Single and Dual linearly tapered girders (Non-prismatic girders) with Double corrugated webs. A tapered girder is wider at one end than the other, giving a tapered appearance to the member and the term Tapered ratio is the ratio between maximum web height to minimum web height of tapered girders (Non-prismatic girders). The objectives of this paper are to investigate buckling performance of Single Non-prismatic girders with Double Corrugated Stiffened Steel Webs and Double Corrugated Composite Webs for different tapered ratios and also to investigate buckling performance on Dual Non-prismatic girders with Double Corrugated Stiffened Steel Webs and Double Corrugated Composite Webs for different tapered ratios of corrugated web.

2 Literature Review

Kovesdi and Dunai [1] conducted investigations on prismatic single corrugated web girders and patch load resistance was determined. It was showed that loading length, flat flange thickness and also girder span have a significant effect on patch loading resistance and buckling strength of girders. Kovesdi et al. [2] investigated Interacting stability behavior of steel I-girders with single corrugated steel webs. The results showed that interacting stability depended more on ratio of flange to corrugated web patch loading resistance of prismatic steel I-girders. Hassanein and Kharoob [3] conducted study on the single corrugated steel webs of tapered bridge girders. From the study, the increase in shear strength was found to be linear with the web thickness increment of the linearly tapered corrugated steel webs. Zevallos et al. [4] presented a study on shear performance of tapered web panels of the linearly tapered bridge girders with single corrugated steel webs. It was observed that web thickness of girders has a greater influence on their shear behaviour. Wang et al. [5] conducted study on prismatic steel I-girders with single corrugated webs for various stiffener arrangements. From the study it can be observed that strength and stability of corrugated web with vertical stiffeners was more than that of horizontal stiffeners.

Other studies [6,7,8,9,10,11] show that, a lot of parameters related to geometry (such as thickness of web and flanges, fold height-to-width aspect ratio of corrugated web, the fold width-to-thickness ratio of web, span, web corrugation angle, flange inclination angle etc.) and loading conditions (including position of the applied load [parallel, inclined fold or corner area], loading length etc.) affect behaviour of trapezoidal corrugated web girders. According to previous researches and studies large forces on the girders result in buckling failure of single corrugated webs. To strengthen it, Double corrugated web girders can be provided.

3 Numerical Study on Non-prismatic Girders

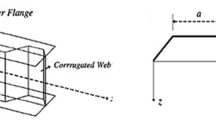

The geometric details of the corrugated web for all models considered for this study are shown in Fig. 1. For numerical study both Single (Fig. 2) and Dual (Fig. 3) Non-prismatic girders are considered. For Single Non-prismatic girders, three kinds of models were made using shell 181 elements. First one is Single Non-prismatic girder with Double Corrugated Web (DCWG), where additional stiffeners or members were not provided. Second one is Single Non-prismatic girder with Double Corrugated Stiffened Steel Web (DCSSW) and third one is Single Non-prismatic girder with Double Corrugated Composite Webs (DCCWG). Each model consists of steel flat flanges and steel corrugated webs, connected by normal welding. In case of DCSSW, additional stiffeners having same thickness of corrugated webs were provided in between the two corrugated webs as shown in Fig. 4. In case of DCCW, an extra material Ultra-Lightweight Cement Composite (ULCC) fill was provided in space between two corrugated steel webs instead of stiffeners. For Dual Non-prismatic girders, two kinds of models were made using shell 181 elements, one is with DCSSW and another one is with DCCW. Both Single and Dual girders are simply supported and 4 points loading was applied. The Properties of steel corrugated web for all models are shown in Table 1. ULCC is characterized by low density <1500 kg/m3 and high compressive strength >60 MPa. The properties of ULCC for composite webs are given in Table 2 (Figs. 2, 3 and 4).

The geometric details of corrugated steel web [1]

The length of Single and Dual Non-prismatic girders was adopted as 4500 mm and 9000 mm respectively, Thickness of flat flange is 20 mm and for corrugated web is 6 mm, Width of flange is 300 mm and height of corrugated web for each model is adopted as in Table 3 for different tapered ratios of web. The performance of Non-Prismatic girders was investigated under different tapered ratios of web. The average height of corrugated web for each model is about 500 mm. Tapered ratios of 1.5, 2, 3, and 4 was adopted for this numerical study of Single Non-prismatic girders and for Dual Non-prismatic girders tapered ratios of 2, 3 and 4 was adopted.

4 Results and Discussion

4.1 Load-Deflection Curve for Single Non-prismatic Girders

The Ultimate load and total deformation of each specimens was obtained from ANSYS 16.1. WORKBENCH. Each specimen was failed by local buckling of corrugated web. Figures 5, 6 and 7 show combined Load-Deflection curve for single Non-prismatic girders with Double Corrugated Web (DCWG), Single Non-prismatic girders with Double Corrugated Stiffened Steel Web (DCSSWG) and Single Non-prismatic girders with Double Corrugated Composite Web (DCCWG) respectively obtained for different tapered ratios of corrugated web.

From the obtained results, it can be observed that Single Non-prismatic girders with Double Corrugated Composite Web (DCCWG) show high load carrying capacity and better strength as compared to Single Non prismatic girders with Double Corrugated Stiffened Steel Web (DCSSWG) for the same tapered ratio. Figure 8 shows the final results for Single Non-prismatic girders.

4.2 Load-Deflection Curve for Dual Non-prismatic Girders

The Ultimate load and total deformation of each specimens was obtained from ANSYS 16.1. WORKBENCH. Each specimen was failed by local buckling of corrugated web. Figures 9 and 10 show combined Load-Deflection curve for Dual Non prismatic girders with DCSSW and Dual Non prismatic girders with DCCW respectively, obtained for different tapered ratios of corrugated web.

From the obtained results, it can be observed that Dual Non-prismatic girders with Double Corrugated Composite Web (DCCWG) show high load carrying capacity and better strength as compared to Dual Non prismatic girders with Double Corrugated Stiffened Steel Web (DCSSWG) for the same tapered ratio. Figure 11 shows the final results for Dual Non-prismatic girders.

5 Conclusions

The Single and Dual Non prismatic girders with Double corrugated web can be strengthen in two ways. One way is to provide Double corrugated steel web with stiffeners. Another way is to provide Ultra Lightweight Cement Composite fill along with Double corrugated steel webs. From the results obtained from this paper, it can be concluded as follows;

-

The load carrying capacity and buckling strength of Non-prismatic girders with Double corrugated web is affected by tapered ratio of web, in case of both Single and Dual girders. In all cases load-carrying capacity is gradually improved as per the increase in tapered ratio of corrugated web.

-

The strength and load carrying capacity of Single and Dual Non-prismatic girders with Double corrugated web can be improved by means of providing stiffeners or by making the web as composite one by providing ULCC fill.

-

Both Single and Dual Non prismatic girders with Double corrugated composite web exhibit more buckling strength and the rate of improvement of strength is excellent for composite web than that of stiffened steel web.

References

Kovesdi B, Dunai L (2011) Determination of the patch loading resistance of girders with corrugated webs using nonlinear finite element analysis. Comput Struct 89

Kovesdi B, Dunai L, Kuhlmann U (2012) Interacting stability behaviour of steel I-girders with corrugated webs. Thin-Walled Struct 61:132–144

Hassanein MF, Kharoob OF (2014) Shear buckling behavior of tapered bridge girders with steel corrugated webs. Eng Struct 74:157–169

Zevallos E, Hassanein MF, Real E, Mirambell E (2016) Shear evaluation of tapered bridge girder panels with steel corrugated webs near the supports of continuous bridges. Eng Struct 113:149–159

Wang S, He J, Liu Y (2019) Shear behavior of steel I—girder with stiffened corrugated web. Part I: experimental study. Thin-Walled Struct 140:248–262

Nie J-G, Zhu Li, Tao M-X, Tang L (2013) Shear strength of trapezoidal corrugated steel webs. J Constr Steel Res 85:105–115

Guo T, Sause R (2014) Analysis of local elastic shear buckling of trapezoidal corrugated steel webs. J Constr Steel Res 102:59–71

Jáger B, Dunai L, Kövesdi B (2017) Flange buckling behavior of girders with corrugated web. Part I: experimental study. Thin-Walled Struct 118:181–195

Leblouba M, Barakat S, Altoubat S, Junaid TM, Maalej M (2017) Normalized shear strength of trapezoidal corrugated steel webs. J Constr Steel Res 136:75–90

Leblouba M, Barakat S, Al-Saadon Z (2018) Shear behavior of corrugated web panels and sensitivity analysis. J Constr Steel Res 151:94–107

Wang Z-Y, Li X et al (2018) Shear response of trapezoidal profiled webs in girders with concrete-filled RHS flanges. Eng Struct 174:212–228

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Saranya Radhakrishnan, M., Binu, P. (2021). Study on Structural Performance of Non-prismatic Girders with Double Corrugated Stiffened Steel and Composite Webs. In: Dasgupta, K., Sudheesh, T.K., Praseeda, K.I., Unni Kartha, G., Kavitha, P.E., Jawahar Saud, S. (eds) Proceedings of SECON 2020. SECON 2020. Lecture Notes in Civil Engineering, vol 97. Springer, Cham. https://doi.org/10.1007/978-3-030-55115-5_18

Download citation

DOI: https://doi.org/10.1007/978-3-030-55115-5_18

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-55114-8

Online ISBN: 978-3-030-55115-5

eBook Packages: EngineeringEngineering (R0)