Abstract

The paper presents the results on the physical and numerical simulation of the propagation of a shear wave in soft biological tissues. The shear wave velocity and Young’s modulus were experimentally determined on a Verasonics acoustic system (Verasonics, Inc., Kirkland, WA, USA) in calibrated polymer CIRS Model 049 Elasticity QA Phantom. The method of shear wave elasticity imaging (SWEI) allows one to determine the viscoelastic characteristics of an object under investigation by measuring the speed of a shear wave launched in a medium. The numerical analysis of the generation of the acoustic radiation force is realized in the toolbox k-Wave. The results of physical and numerical simulations of determining the velocity of shear waves in soft tissues are compared.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

14.1 Introduction

Ultrasonography has been widely used for diagnosis since it was first introduced in clinical practice in the 1970s. Based on the propagation of mechanical waves and more particularly on high frequency compressional waves aka ultrasound, it allows the construction of morphological images of organs but lacks a fundamental and quantitative information on tissue elastic properties. Since then, new ultrasound modalities have been developed, such as Doppler imaging, which provides new information for diagnosis. Elastography was developed in the 1990’s to map tissue stiffness, and reproduces/replaces the palpation performed by clinicians. Ultrasound elastography techniques can be classified based on the type of the external force that induces the tissue deformation. In general, four types of excitation sources are used to induce the deformation in the tissue: static excitation, natural physiological excitation, transient excitation, and harmonic excitation. For example, the shear wave elasticity imaging (SWEI) technique was introduced by Sarvazyan et al. in 1998 [1]. In SWEI, one or more focused or unfocused ultrasound beams are applied for a short period of time to generate tissue deformation. In turn, this deformation produces shear waves. Next, the shear wave speed is estimated from the measured particle displacements, and quantitative shear elasticity parameters are then obtained from the estimated shear wave speed. In clinical practice, SWEI has been used to quantitatively measure the stiffness of liver tissue and determine the stage of liver fibrosis. Other clinical applications for SWEI include quantitative assessment of tissue mechanical properties in thyroid, breast, kidney, and prostate [2, 3].

14.2 Verasonics Research System—Physical Simulation of Shear Waves

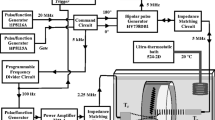

The Verasonics acoustic system (Verasonics, Inc., Kirkland, WA, USA) is a universal ultrasonic device designed for prototyping and debugging various algorithms of medical acoustics. The system allows you to work with almost any medical ultrasonic sensors, for example, L7-4, C5-2, and P4-2, which allows you to simulate the algorithms of various expert commercial ultrasound systems. The main advantage of the Verasonics system is its openness, that is, the ability to widely change the parameters of ultrasonic waves, for example, the number of emitted and receiving channels from 64 to 256, the carrier frequency from 1 to 15 MHz, the ultrasound power up to 1000 W, and program them depending on tasks and objects of research. Received echoes are recorded by the device and are available for post-processing in the form of arrays of numerical data. The whole scenario of sending pulses, receiving and processing data, and imaging is programmed by the user in the MATLAB software environment.

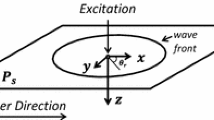

In the Laboratory of Biomedical Technologies, Medical Instrument Engineering, and Acoustic Diagnostics (MedLab), Department of Acoustics, Nizhny Novgorod University on the Verasonics ultrasound system, the shear wave elasticity imaging (SWEI) method was implemented [4]. This method allows one to determine the viscoelastic characteristics of an object under investigation by measuring the speed of a shear wave launched in a medium. For this, a focused ultrasonic “pushing” pulse is applied to a given point, which creates a disturbance. Under the influence of a radiation force, a shear wave begins to propagate from this point, resulting in a displacement of particles of the medium along the path of its propagation. To track the displacements, and hence, the propagation of the shear wave, one unfocused “reference” pulse is sent to the pushing pulse to scan the unperturbed medium. After a focused pulse, several unfocused “imaging” pulses, similar to the reference one, with a certain interval, which scan the medium at the time of wave propagation, are fed into the medium (see Fig. 14.1).

Subsequently, when processing the obtained data, the medium displacement ξ (x, t) is recorded as a function of time t at various distances x from the focus point of the pushing pulse. Different x values correspond to different curves. Each function has a maximum corresponding to the front of the shear wave, due to which the time of arrival of the front to a certain point is determined. This allows us to calculate the shear wave velocity V, which is converted into Young’s modulus E according to formula

where ρ is the density of soft biological tissue.

As mentioned earlier, the received echo signals are recorded by Verasonics and are available for post-processing in the form of arrays of numerical data, which are recorded in a separate file. This allows you to display after processing various data necessary for the study, in contrast to commercial expert ultrasound systems, which can only display information about shear wave velocity and Young’s modulus of the medium. To this end, while working with the Verasonics system, several programs were developed in the MATLAB software environment for processing source data. One of the programs allows one to obtain the values of the displacement of the medium ξ (x, t) at a given point and graphically displays the form of this function. The following program allows you to get the values of the shear wave velocity in the studied object. These programs are combined into an interface that combines the functional of obtaining the medium displacement ξ (x, t) at a given point and the shear wave velocity (see Fig. 14.2).

14.3 Numerical Simulation of Shear Waves

To numerically solve the problem of the propagation of shear waves in soft biological tissues, the k-Wave software package for the MATLAB medium was used. It combines the MATLAB optimization for working with matrix operations and a set of tools that allow you to simulate the propagation medium through parameters such as density and speed of sound in a given environment. The numerical model is based on the transition to k-space, where spatial gradients are calculated using the FFT scheme, and time gradients are calculated using the adjusted k-spatial difference scheme [5].

Numerical modeling of a physical experiment allows predicting the measurement result with high accuracy, and therefore, to solve the problem of computer simulation of media with given parameters, a large number of algorithms, software modules, and independent packages, both paid and with a free license, have been developed. Their main difference from each other is the numerical methods used and the approximations allowed for their application. Modern computer technology allows calculation with high accuracy, but makes high demands on the hardware of the machine, so it becomes important to choose an algorithm that effectively uses the power of computing modules with the lowest possible load, while ensuring the necessary and sufficient accuracy.

To solve this problem, it is convenient to use k-Wave—a software package (tool- box) for the MATLAB environment. It combines MATLAB optimization for working with matrix operations and a set of tools that allows you to simulate the propagation medium through such parameters as the density and speed of sound in a given environment. The combination of these factors allows us to simulate 2D and 3D spaces, while maintaining a high computational speed. The numerical model is based on the transition to k-space, where spatial gradients are calculated using the FFT scheme, and time gradients are calculated using the adjusted k-spatial difference scheme. The temporal scheme is accurate in the limit of propagation of a linear wave in a homogeneous medium without losses and significantly reduces numerical scattering in a more general case [6].

The solution to the problem of modeling the SWEI method can be divided into stages, which are an analysis of the initial conditions necessary for the model to work, and the use of these data to simulate a specific stage of the method. The first step is to decide on the initial conditions for the simulation, i.e., the choice of the propagation medium through the density ρ and the speed of sound in medium C. Based on these data, a numerical simulation of the focusing of an ultrasonic beam, which is a source of radiation force, is carried out. According to the pressure data obtained from the simulation results, the radiation force is calculated. From this, shear wave propagation can be modeled. The last step is to visualize the results.

The simulation subtasks involve the following steps: first, the environment in which the simulation is performed (it can be either a linear medium or a nonlinear space) is set, then a sensor is placed (in this case, it is a model of a standard linear L7-4 linear sensor for ultrasound studies), and simulation of wave propagation in the medium. In the case of a linear sensor, the emitter is a phased array of 128 elements. Within the framework of a given numerical model, these are 128 point sources. But to obtain a shear wave, it is necessary to focus the emitters to the point where the wave from each emitter comes in one phase. This is achieved by means of a quadratic phase incursion on each radiator; for zero, we consider the center of the sensor (see Fig. 14.3a). To simulate a shear wave, the source is located in the region of the focusing spot and consists of eight elements located in the shape of a rhombus (see Fig. 14.3b).

The result of this algorithm allows you to calculate the distribution of acoustic pressure, which allows you to evaluate the geometric dimensions of the focusing spot and also serve as input to calculate the amplitude and velocity of the shear wave.

The shear wave velocity and Young’s modulus were experimentally determined on a Verasonics system in calibrated polymer CIRS Model 049 Elasticity QA Phantom Spherical with spheres 10 and 20 mm in diameter located at different depths. The spheres in phantoms were of four types with different values of Young’s modulus (Type I–IV), indicated in the accompanying documents. These elements were in a polymer medium (matrix), the elastic characteristics of which were also known. The advantage of phantoms is that they are made of Zerdine polymer material, the characteristics of which are independent of changes in external temperature and applied pressure.

The shear wave velocity is calculated based on the position of the pressure peak characterizing the location of the wavefront. In Fig. 14.4 shows an example of calculating the shear wave velocity using the formula

where S is the distance between the peaks determined for two times t1 and t2

Table 14.1 presents a comparison of the results of numerical and physical modeling

A comparison of the results shows that the higher the concentration of the polymer substance in the phantom, the closer the results of numerical and physical modeling. In addition, the results of numerical simulations are consistently larger than physical ones. This effect occurs due to the strong heterogeneity of the studied physical environment.

References

Sarvazyan, A.P., Rudenko, O.V., Swanson, S.D., Fowlkes, J.B., Emelianov, S.Y.: Shear wave elasticity imaging: a new ultrasonic technology of medical diagnostics. Ultrasound Med. Biol. 24, 1419–1435 (1998)

Safonov, D.V., Rykhtik, P.I., Shatokhina, I.V., Romanov, S.V., Gurbatov, S.N., Demin, IYu.: Shear wave elastography: comparing the accuracy of ultrasound scanners using calibrated phantoms in experiment. Sovremennye Tehnologii v Med. 9, 51–59 (2017)

Ultrasound Elastography for Biomedical Applications and Medicine, ed. by Ivan Z. Nenadic. Hoboken, NJ: Wiley (2019)

Khalitov, R.S., Gurbatov, S.N., Demin, IYu.: The use of the verasonics ultrasound system to measure shear wave velocities in CIRS phantoms. Phys. Wave Phenom. 24, 73–76 (2016)

Treeby, B.E.: Modeling nonlinear wave propagation on nonuniform grids using a mapped k-space pseudospectral method. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 35, 2208–2213 (2013)

Prieur, F., Catheline, S.: Simulation of shear wave elastography imaging using the toolbox “k-Wave”. Proc. Mtgs. Acoust. (POMA). 29, 20002 (2016)

Acknowledgements

This work was supported by a grant from the Russian Science Foundation №. 19- 12-00256.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Gurbatov, S., Demin, I., Lisin, A., Pronchatov-Rubtsov, N., Spivak, A. (2021). Shear Wave Propagation in Soft Biological Tissues: A Comparison of Numerical and Physical Modeling. In: Altenbach, H., Eremeyev, V.A., Igumnov, L.A. (eds) Multiscale Solid Mechanics. Advanced Structured Materials, vol 141. Springer, Cham. https://doi.org/10.1007/978-3-030-54928-2_14

Download citation

DOI: https://doi.org/10.1007/978-3-030-54928-2_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-54927-5

Online ISBN: 978-3-030-54928-2

eBook Packages: EngineeringEngineering (R0)