Abstract

Aggregate generated from concrete is one of the most considered recycled materials used in the U.S. for construction that requires earthwork. However, recycled concrete aggregate (RCA) is known to produce tufa. This study focuses on understanding the composition of the precipitated tufa material from RCA as well as the factors that affect the precipitation process. The precipitation experiments were conducted using PWP (Plummer–Wigley–Parkhurst) reaction vessel using a synthetic metastable RCA solution. Based on the identified parameters, a parametric study was also conducted to evaluate the effectiveness of the suggested mitigation method in the literature to remove and replace fine particles from RCA. Additionally, as part of this parametric study, the effects of contact time and blending with natural virgin aggregate (V.A.) were investigated as alternative mitigation methods. Minteq A2 and geochemical modeling were utilized to calculate the total solid-phase formation under equilibrium conditions from 100% RCA, 100% V.A., and different blends of the two materials. It is shown that the total ionic strength, availability of carbonate and bicarbonate ions, and saturation conditions of Ca and SO4 ions control the mineralogy of the tufa precipitation. Depending on the mechanism, it was found that the calcium carbonate or calcium sulfate minerals can be the dominant forms of precipitation in RCA tufa. Other minor elements contributing to RCA tufa formation were found to be Na, K, Cl, and Si. The parametric study showed that the RCA tufa potential is not dependent on the particle size fractions of RCA but can be reduced by blending RCA with V.A. or decreasing the contact time between water and RCA particle by creating a highly permeable layer of RCA.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Evaluating the potential of tufa precipitation from recycled concrete aggregate (RCA) as well as other recycled materials has been an interest to several researchers in the past. Specific studies, mainly in the 1990s, were conducted to evaluate the potential of tufa precipitation from RCA to clog the underdrain drainage systems (particularly the geotextile used in these systems). These studies were conducted both in the laboratory as well as in the field utilizing various test sections [1, 2]. Although the contents of these studies are extensive, in general, these studies were highly fragmented and often failed to provide conclusive results and scientific justifications for the observed behaviors.

For instance, based on case studies by Snyder and Bruinsma [2] and Sadecki [1] on test sections and stockpiles created using different fractions of RCA (fine and coarse fractions), the fine fraction (<4.75 mm) within RCA was held responsible for the high release of calcareous constituents and considered as the main source for tufa precipitation in underdrain systems. Aside from the use of a methodology (i.e., submerging and dissolution in hydrochloric acid as an indication of tufa formation) that would have limitations to differentiate between the tufa and the RCA particles, these past studies have not considered several important parameters during their evaluation of the data. These parameters include (but not limited to) (1) the difference in permeability of fine and course fractionated RCA and change in contact time between water and solid particles, (2) the occurrence of suffosion, and (3) the occurrence of rainfall runoffs that was not percolated through the material, which can affect the measured concentrations of ions. Based on recommendations of these studies, some of the current federal and state highway specifications either restrict or prohibit the use of RCA [3,4,5] or suggest practices to mitigate tufa precipitation from RCA used in base/subbase layers [6, 7]. These suggested mitigation methods include (i) eliminating fines or reducing the fines to less than 5%, (ii) replacing the fine fraction with fine crushed stone, and (iii) blending RCA with V.A.

Laboratory studies focusing on the leaching behavior of RCA and the role of different fractions on tufa formation have also shown disagreeing results. Name et al. [8] and McCulloch et al. [9] explained a special procedure for collecting RCA tufa precipitation by cycles of bubbling leachate solution from RCA with carbon dioxide (CO2) and drying and filtering the leachate. The study concluded that the potential of precipitation increases with an increase in fines content of RCA. However, the research did not provide any information on the saturation condition of different ions, pH, or even the mineralogical composition of collected solids. Additionally, the observations noted were often not supported in other parametric studies conducted on RCA leaching characteristics [10, 11]. The overall summary of the previous studies indicates that these studies did not determine the effects of blending and contribution of different fractions on the release of any element that may participate in potential calcareous (and non-calcareous) tufa formations from RCA.

Abbaspour and Tanyu [12] suggested a procedure to induce tufa from RCA over a porous media (nonwoven geotextile) using the Plummer–Wigley–Parkhurst (PWP) reaction vessel [13] and studied the governing mechanisms on precipitation process and composition of RCA tufa. The focus of this work is to identify the affecting parameters that contribute to the precipitation of tufa from RCA based on induced precipitation tests and to use these parameters in order to evaluate the validity of the mitigation methods previously suggested in the literature (i.e. removal of fine fraction and blending). The paramteric study was conducted using bench-scale leachate extraction and equilibrium geochemistry.

2 Materials and Methods

2.1 Materials

Recycled concrete aggregate used in this study was collected right after it was produced (within a week after being crushed and stockpiled) from a plant in northern Virginia. After collection, it was aged throughout a period of 1 year in the laboratory. The demolished concrete for RCA production in this plant comes from various sources such as curb and gutter, sewage pipes, and buildings and is classified as well-graded silty sand (SW-SM) based on Unified Soil Classification System. Detailed information on sampling procedure, mineralogical makeup, chemical composition, and the physical and index properties, of RCA aterial used in this study are explained in detail by Abbaspour et al. [14].

The V.A. used for this study was collected from a material production quarry in northern Virginia (similar to RCA). Geological composition of the source rock that is used to produce the aggregate is determined to be diabase, which is considered inert in comparison to other carbonic rocks (e.g., dolostone or limestone) with respect to leaching and tufa precipitation. The quarry produces this material to be used for base application and the average gradation of samples collected for the current study is in the range of what is referred by the Virginia Department of Transportation (VDOT) as 21 aggregates (VDOT 2007). Index properties of the V.A. used in this study are listed in Table 1 and the material is classified as SW-SM in accordance with USCS classification. Mineralogical composition and total metal content of the material are also shown in Table 1.

2.2 Methods

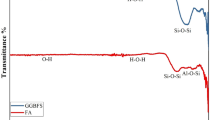

Leachate samples for this study were extracted using long-term and short-term batch water leach test procedures as suggested by Hageman [15] and in accordance with ASTM standard D3987. Both methods follow a similar procedure in sample preparation and testing steps except for the agitation time (18 h for long-term test and 5 min for short-term test). The liquid to solid ratio is 1:20 and ASTM type II de-ionized (DI) water was used in both methods. Detailed descriptions of the procedures followed for testing, sample preparation, filtration, and preservation can be found in Abbaspour et al. [14]. Liquid and solid samples that were used to generate the leachate were evaluated for their chemical properties and characteristics. The mineralogical composition of solid samples was determined using quantitative X-Ray diffraction method (QXRD) [16]. Liquid samples were evaluated for pH, redox potential (Eh), electric conductivity (EC), and total leached concentrations (TLC) of major, minor, and trace elements using inductive coupled plasma mass spectrometry (ICP-MS). MINTEQA2 software is used for geochemical modeling in this study. MINTEQA2 is a geochemical equilibrium software developed by USEPA in the late 1980s and is an official tool for USEPA to evaluate the equilibrium composition of aqueous solutions in the laboratory and natural waters [17].

Solid and Leachate Sample Preparation. In order to evaluate the RCA tufa characteristics based on thermodynamic equilibrium chemistry and geochemical modeling, RCA samples were obtained with three gradations as listed below:

-

Unfractionated (as-is) samples: RCA samples with gradation close to the as-is gradation without the oversize fraction (>19 mm)

-

Fine fraction samples: RCA samples smaller than 4.75 mm

-

Course fraction samples: RCA samples larger than 4.75 mm and smaller than 19 mm.

For the parametric study on the effect of fraction contribution on RCA tufa potential, leachate samples from these three gradations were extracted using a long-term extraction method, as achieving the solid-liquid equilibrium was necessary for geochemical analyses. In order to study the effect of blending, two different blends of RCA-V.A. with different proportions (40–60 and 20–80% by weight) were prepared and leachate samples were compared to as-is 100% RCA and 100% V.A. results. The effect of contact time (agitation time) was evaluated by comparing the total leach concentrations between RCA leachate extracted using long-term and short-term methods as explained above.

Induced Precipitation Tests. Two different induced precipitation tests were conducted using PWP reaction vessel and prepared metastable RCA leachate. The reaction vessel included a 1,000-ml beaker, magnetic stirrer, and perforated vinyl coil connected to a commercially prepared CO2–N2 (50–50%) gas tank. Details, measurements, applied conditions of both test and procedure followed to prepare the metastable solution is explained in great detail by Abbaspour and Tanyu [12]. The first induced test included continuous stirring and bubbling with CO2 (as suggested by Nam et al. [8]) and the second test was conducted under pure evaporation conditions (no bubbling-no stirring). Leachate characteristics including ion concentrations, temperature, pH–Eh–EC, and alkalinity by titration were monitored during both tests. Four geotextile samples were submerged with a different time period during each test and were studied using a stereo-microscope with a built-in camera after each test.

3 Results and Discussions

3.1 Characterization of Potential RCA Tufa Based on Induced Precipitation Tests

Figure 1 shows sample images of precipitated crystals from both tests. The mineralogy and morphology of the precipitated crystals reveal that the precipitated tufa is dominated by polymorphs of calcium carbonate (calcite/aragonite) during the first test (Fig. 1a, b), as the leachate was continuously bubbled and stirred. However, during the second test (pure evaporative test), the dominant precipitation was found to be in the form of calcium sulfate polymorphs (gypsum/selenite) as can be seen in Fig. 1c, d.

Measurements of the total alkalinity and pH during the first test showed high activity of bicarbonate ion, which means that bicarbonate ions were readily available to react with Ca and hydronium ions (as suggested by Plummer et al. [13]) to form calcium carbonate crystals. Whereas, in the second test, the bicarbonate and carbonate ion activities were extremely affected and limited by the diffusion rate of atmospheric carbon dioxide into a supersaturated solution. With the initiation of each test, crystal growth was observed over geotextile fibers (which acted only as a platform for nucleation and growth) and continued throughout the entire test. With the increase in immersion time, crystals started to form clusters over geotextile samples. More details about the use of PWP test setup to precipitate tufa from RCA can be found in Abbaspour and Tanyu [12].

The minor minerals observed from both tests (not shown here) include halite (NaCl), sylvite (KCl), and quartz low (SiO2) with a total quantity less than 5% by weight of overall precipitation (as collected in the bottom of the vessel). Analyses on the ion activates showed that in addition to precipitation mechanism (abundance of CO2 vs. pure evaporation), the most important parameters in determining the composition and formation of RCA tufa are total ionic strength of the solution, ionic activities of Ca, S (as SO42–), Na, K, Cl, and Si ions [12]. The pH of RCA leachate is only important when the leachate is extracted (10 < pH < 12). However, once the solution is equilibrated with atmospheric CO2, the equilibrium pH value is in the range of 8–8.5, which is in agreement with previous field reports [11].

3.2 Effect of Particle Size on Potential of Tufa Precipitation

The effect of particle size on release behavior and contribution of each of fine and coarse fractions on the potential of tufa precipitate formation is investigated by measuring and comparing the TLC of several elements, especially elements that participate in RCA tufa formation. Therefore, the TLC of Ca, S (as SO42–), Si, K, Na, and Cl were obtained from fine and coarse RCA fractions and normalized by dividing these values by the measured TLC of the same elements from unfractionated samples. The results of the statistical analyses carried out on the normalized data are shown in Fig. 2 in the form of Whisker diagrams for elements that were found to contribute to RCA tufa precipitation. As it is clear from this figure, statistically, data do not show any noticeable effect of particle fraction on the release of major elements or the potential of tufa formation. A similar observation was made for pH and solution ionic strength measured for the leachate samples extracted from different fractions (not shown here). However, other elements with minimal contribution to the tufa precipitation may show some particle size dependency, but it should be kept in mind that the precipitated minerals of K, Na, Cl, and Si only take up less than 5% of the total residue precipitation.

3.3 Effect of Blending RCA with V.A. on Potential of Tufa Precipitation

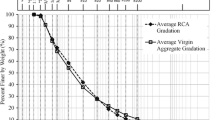

The TLC of major and minor elements contributing to the tufa formation from 100% V.A. and different blends of RCA/V.A. are depicted in Fig. 3. The release of K, Cl is basically zero from V.A., and Na and Si release is also very low (not shown here). As it was expected, V.A. is not a source of Ca2+ nor SO42–. The TLC of Ca and S are affected by blending RCA and V.A. and are reduced in comparison to 100% RCA; however, a note should be taken that these reductions in released TLC are not linearly correlated to the TLC of Ca and S from 100% RCA and V.A. samples. Based on the dominant ion activities, calcium carbonate, and calcium sulfate polymorph are still expected to be the dominant minerals in any potentially formed tufa. Although the formation of tufa from different blends was not simulated in the laboratory, the effect of blending RCA with V.A. at different proportions on potential tufa formation is estimated by calculating the equilibrium amount of any possible solid-phase formation using geochemical analyses and comparing these amounts with the calculated equilibrium amounts for 100% RCA as well as V.A. (Fig. 4).

The geochemical modeling shows that the potential of tufa precipitation reduces with the blending of RCA and V.A. material simply because of the TLC of major elements and consequently, the ionic activities of Ca2+ and SO42–. The selected V.A. material was diabase in nature, which is considered as inert with respect to releasing calcareous constituents as opposed to calcitic rocks (e.g., limestone and dolostone) which can be a source of Ca release themselves.

3.4 Other Parameters Affecting the Potential of Tufa Precipitation

One of the important parameters that is not addressed in any of the previous studies related to RCA leaching behavior and tufa precipitation potential is the effect of contact time between effluent (percolating water through RCA layer) and the solid matrix (RCA material). Contact time between effluent and solid waste is an important and determinative factor affecting the leaching behavior of any waste and reclaimed substances [18]. The effect of contact time can be different on the release of various elements; however, determining the effect of the contact time on elements contributing to the tufa precipitations (e.g., Ca and S) can be of great importance.

The effect of different contact time on the release concentration of different elements was investigated by comparing the measured TLC of certain elements obtained using long-term and short-term batch tests. Table 2 shows the calculated ratio between the measured TLC of elements contributing to the formation of RCA tufa precipitation. Except for Cl, release concentrations of all other elements are affected by agitation time, especially Ca and S releases decrease by 33% and 44%, respectively. When compared to decrease in total ionic strength in leachate extracted from both procedures (Average ISshort-term/ISlong-term of 0.64 with a standard deviation of 0.12), it can be concluded that the potential for tufa precipitation decreases with a decrease in contact time (about 36% when agitation time decreases from 18 h to 5 min).

Si release shows a major reduction when the agitation time is reduced from 18 h to 5 min (average of 81%) indicating the noticeable effect of transport by diffusion inside the solid pores (kinetics as limiting rate step) on leachability of Si from RCA [14]. However, since Si and Cl have minimal contribution to the tufa formation from RCA, the observed behavior will not affect the solid-phase precipitation from RCA. The effect of contact time between effluent and RCA can be interpreted as the permeability of the RCA layer. The higher the permeability of an RCA layer, the lower the contact time between the effluent and the solid matrix, and consequently, lower potential for tufa formation.

4 Conclusions and Practical Implications

An experimental study is conducted to evaluate the composition and affecting parameters on RCA tufa. In the next step, a parametric study was conducted based on the leaching concentrations of elements contributing to the RCA tufa formation to evaluate the effects of particle size, blending with V.A. and contact time on the potential of leaching out tufaceous constituents from RCA and precipitate formation. Based on the presented results and discussions, the following conclusions may be made:

-

Based on induced tufa precipitation tests and depending on the precipitation process, calcite or gypsum (or polymorphs of them) may be the most abundant forms of RCA tufa precipitation. Calcite is dominant when CO2 is abundant in the system (bubbled) and gypsum is the dominant form in the case of pure evaporation.

-

Release of Ca and SO42– is not particle size-dependent, and the effect of fine and coarse fractions on the potential of tufa precipitation cannot be concluded based on the statistical analyses.

-

Blending RCA with virgin aggregate, in general, reduces the potential for solid-phase formation from leachate samples.

-

Contact time was found to have a limited effect on the TLC of elements contributing to the tufa formation and, consequently, to the potential tufa precipitation. Therefore, constructing a base course/subbase layer with higher permeability will lead to a decrease in contact time between effluent and solid matrix and the potential precipitate deposition (for instance, by changing the gradation).

References

Sadecki RW, Busacker GP, Moxness KL, Faruq KC, Allen LG (1996) An investigation of water quality in runoff from stockpiles of salvaged concrete and bituminous paving. Minnesota Department of Transportation, Saint Paul, Minnesota

Snyder M, Bruinsma J (1996) Review of studies concerning effects of unbound crushed concrete bases on PCC pavement drainage. Transp Res Record: J Transp Res Board 1519:51–58

VDOT (2007) Road and Bridge Specifications. Virginia Department of Transportation, Richmond, VA

MDOT (2012) Standard specifications for construction. Michigan Department of Transportation, Lansing, MI

MSHA (2013) Special Provision Inserted-Section 900.03-Recycled Materials. Presented at the

FHWA (2004) Transportation applications of recycled concrete aggregate. Federal Highway Administration and U.S. Department of Transportation, Washington D.C.

MnDOT (2016) Standard specifications for construction. Minnesota Department of Transportation, Saint Paul, Minnesota, U.S.A

Nam BH, Behring Z, Kim J, Chopra M (2014) Evaluate the use of reclaimed concrete aggregate in french drain applications. Florida Department of Transportation, Tallahassee, FL

McCulloch T, Kang D, Shamet R, Lee SJ, Nam BH (2017) Long-term performance of recycled concrete aggregate for subsurface drainage. J Perform Constructed Facil 31. In-press

Bestgen JO, Cetin B, Tanyu BF (2016) Effects of extraction methods and factors on leaching of metals from recycled concrete aggregates. Environ Sci Pollut Res 23:12983–13002

Chen J, Tinjum J, Edil T (2013) Leaching of alkaline substances and heavy metals from recycled concrete aggregate used as unbound base course. Transp Res Record: J Transp Res Board 2349:81–90

Abbaspour A, Tanyu BF (2019) Tufa precipitation from Recycled Concrete Aggregate (RCA) over geotextile: mechanism, composition, and affecting parameters. Constr Build Mater 196:317–329

Plummer LN, Wigley TML, Parkhurst DL (1978) The kinetics of calcite dissolution in CO2-water systems at 5–60° C and 0.0–1.0 atm CO2. Am J Sci 278:179–216

Abbaspour A, Tanyu BF, Cetin B (2016) Impact of aging on leaching characteristics of recycled concrete aggregate. Environ Sci Pollut Res 23:20835–20852

Hageman PL (2004) Use of short-term (5-Minute) and long-term (18-Hour) leaching tests to characterize, fingerprint, and rank mine-waste material from historical mines in the Deer Creek, Snake River, and Clear Creek Watersheds in and around the Montezuma Mining District, Colorado

Raudsepp M, Pani E (2003) Application of Rietveld analysis to environmental mineralogy. In: Environmental aspects of mine wastes. Mineralogical Association of Canada, Québec, Canada, pp 165–180

US EPA: MINTEQA2. https://www.epa.gov/exposure-assessment-models/minteqa2

Huang K, Inoue K, Harade H, Kawakita H, Ohto K (2011) Leaching behavior of heavy metals with hydrochloric acid from fly ash generated in municipal waste incineration plants. Trans Nonferrous Metals Soc China 21:1422–1427

Acknowledgements

The financial support for the study described in this manuscript was provided by the National Science Foundation (NSF) and Virginia Department of Transportation (VDOT) and Virginia Center for Transportation Innovation and Research (VCTIR). However, the conclusions and recommendations are those of the authors and do not reflect the opinions or policies of NSF, VDOT, and VCTIR.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Abbaspour, A., Tanyu, B.F. (2021). Parameters Affecting Tufa Precipitation from Recycled Concrete Aggregate. In: Reddy, K.R., Agnihotri, A.K., Yukselen-Aksoy, Y., Dubey, B.K., Bansal, A. (eds) Sustainable Environment and Infrastructure. Lecture Notes in Civil Engineering, vol 90. Springer, Cham. https://doi.org/10.1007/978-3-030-51354-2_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-51354-2_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-51353-5

Online ISBN: 978-3-030-51354-2

eBook Packages: EngineeringEngineering (R0)