Abstract

To achieve the operational objectives of intercity trains, in particular, reducing the station dwell time, it is necessary to improve the boarding and alighting efficiency. The vehicle layout considerably influences the boarding and alighting efficiency. In this paper, a method to simulate pedestrian dynamics is proposed. The effects of three layout factors on the efficiency are investigated; furthermore, the regression curves of different factors and cumulative high density maps are considered for analysis. The results show that when the door width ranges from 800–1900 mm, the relationship between this width and the boarding and alighting efficiency is a quadratic function. When the hall width ranges from 1300–2100 mm, the relationship between this width and the efficiency is a power function. When the aisle width ranges from 650–950 mm, the relationship between this width and the efficiency is a cubic function.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The operating purpose of intercity trains is to satisfy the increase in the quantity and quality of passenger transport demand. Under a situation involving a large capacity and multisite stops, the key to achieve the operational objectives is to shorten the time taken by the station dwell time. Because the dwell time is mainly affected the time taken by the passengers to board and alight, improving the boarding and alighting efficiency is crucial to improve the traffic capacity and service quality. Bernhard Ruger once indicated that by optimizing the vehicle layout design of trains, the dwell time can be reduced by 1/3rd [1], thereby demonstrating the importance of the train vehicle layout. Thus, this paper focuses on the impact of the passenger room layout on the efficiency.

To effectively reduce the train dwell time, an increasing number of scholars have focused on the boarding and alighting efficiency from the perspective of the train vehicle layout. In 2013, Nigel G. Harris [2] found that the door width showed a nonlinear change at approximately 1.4 m. In 2014, Taku Fujiyama [3] noted that a wider door, corresponded to a lower efficiency. In 2014, Jungtai Kim et al. [4] observed that a door width of 1.6 to 2 m was the most suitable. In 2017, Roselle Thoreau [5] proposed that the optimal door width should between 1.7 and 1.8 m. These researchers used actual experimental platforms to study the effects of the vehicle layout on the boarding and alighting efficiency. In 2019, Qiu H [6] used the simulation method for this investigation and observed that a wide aisle and reasonable seat pitch can promote a proper evacuation. In addition, a normal train door width has no effect on an evacuation. Qiu Hanzhao [7] proposed an experimental method to verify the effectiveness of using LEGION to simulate the evacuation process of train passengers. It shows that the simulation results are not different from the real environment. This paper is based on this research, using the method to simulate the pedestrian dynamics, which the boarding and alighting efficiency can be investigated. The findings can help reduce the labor, material and financial resources.

This paper mainly includes five parts: the first part is the introduction section; the second part describes the simulation experiment scenario of the passenger boarding and alighting based on LEGION; the third part describes the research on the influence of the factors on the boarding and alighting efficiency, and the last two parts correspond to the discussion and conclusions.

2 Passenger Boarding and Alighting Simulation Scene Developed Using LEGION

2.1 Simulation Model Construction and Parameter Input

In this paper, the TP03 vehicle of the intercity emu designed by TANGSHAN Co. Ltd. was taken as the basic research object, and the experimental simulation model was built based on the control variables such as the platform and passenger attributes of the Beijing Tianjin intercity railway operation background. To analyze the most significant passenger congestion effect, an experimental scenario with a 1:1 passenger ratio was selected to study the boarding and alighting efficiency under the rated passenger load scenario. The initial number of passengers in the vehicle was set as 96.

The input parameters of the passenger sex, age and speed were defined according to the survey results of Liu Dongdong [8] (Table 1).

The boarding and alighting behavior of the passengers involves not only the instantaneous boarding and deboarding, but the entire process. According to the passenger boarding and alighting process, the interior space is divided into four areas, including the entrance, stagnant zone, interior walking space and personal space of the passengers. To board a bus, the passengers pass through these areas in turn, and they deboard in reverse. The main facilities in this process include the door, hall and aisle. Based on the ergonomic standards of human factors, the layout parameters of the mainstream intercity train passenger vehicle and the research scope of the domestic and foreign scholars, the specific research scope of the three factors is determined, as shown in Table 2.

2.2 Establishment of Analysis Area and Determination of Analysis Indicators

To analyze the experimental results, three pairs of upper and lower analysis lines were set 130 mm from the door (thickness of the vehicle body), and the movement time of the passengers was determined. According to the definition of the passenger boarding and alighting provided by Buchmueller [9], the passenger boarding and alighting time range in this study was defined as starting with the first passenger passing through the analysis line and ending with the last passenger passing through the analysis line.

As an important part of the train dwell time, we selected the total boarding and alighting time \( T \), mean boarding time \( \overline{{T_{b} }} \), and mean alighting time \( \overline{{T_{a} }} \) as the experimental indexes to measure the efficiency of the multiplication and reduction.

The total time can be calculated as

\( T^{last} \) is the last time point, determined by analyzing the time point of a line passenger; \( T^{first} \) is the first time point, determined by analyzing the time points of the line passengers.

The mean disembarkation time is calculated as

\( T_{a}^{last} \) is the last time point obtained using the downlink analysis of the passengers; \( T_{a}^{first} \) is the first time point obtained by considering the downlink passenger time point; \( N_{a} \) denotes the total number of alighting passengers.

The mean boarding time can be calculated as

\( T_{b}^{last} \) is the last time point through the upline of the analysis passenger; \( T_{b}^{first} \) is the first passenger time point through the upline analysis; \( N_{b} \) denotes the total number of passengers on board.

3 Influence of the Passenger Vehicle Layout Factors on the Boarding and Alighting Efficiency

3.1 Analysis of the Influence of the Door Width on the Boarding and Alighting Efficiency

The quadratic curve fits the relationship between the door width and \( \overline{{T_{a} }} \), \( \overline{{T_{b} }} \) and \( T \) (Fig. 1). The left figure shows the quadratic curve of the door width, \( \overline{{T_{a} }} ({\text{R}}^{2} = 0.9499) \), and \( \overline{{T_{b} }} ({\text{R}}^{2} = 0.9185) \), and the right figure shows the quadratic curve of the door width and \( T({\text{R}}^{2} = 0.9741) \).

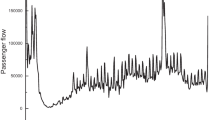

When the door width is 800 mm, the efficiency is the lowest; with the widening of the door, the efficiency is constantly improved, and when the door width ranges from 1300 to 1400 mm, the efficiency is the highest thereby reducing gradually. To explain the phenomenon, we selected the cumulative high density maps of the door width of 800, 1300 and 1900 mm for analysis, as shown in Fig. 2. As shown in the figure, the relatively high density (red area) inside the train is 1900 mm, and the lowest is 800 mm (blue area); the highest density at the entrance is 800 mm, and the lowest is 1900 mm.

3.2 Analysis of the Influence of the Hall Width on the Boarding and Alighting Efficiency

The power curve fits the relationship between the hall width and \( \overline{{T_{a} }} \), \( \overline{{T_{b} }} \) and \( T \). The left figure of Fig. 3 shows the power curves of the hall width, \( \overline{{T_{a} }} ({\text{R}}^{2} = 0.9374) \) and \( \overline{{T_{b} }} ({\text{R}}^{2} = 0.9155) \), and the right figure shows the power curves of the hall width and \( T({\text{R}}^{2} = 0.7199) \).

When the hall width is 1300–2100 mm, the three curves present a continuous downward trend. We selected the cumulative high density map of the extreme and intermediate values for analysis, as shown in Fig. 4. It is observed that when the hall width is 1300 mm, the density of the detention area is slightly high; when the hall width is 2100 mm, the density of the detention area is the lowest.

3.3 Analysis of the Influence of the Aisle Width on the Boarding and Alighting Efficiency

The cubic curve fits the relationship between the aisle width and \( \overline{{T_{a} }} \), \( \overline{{T_{b} }} \) and \( T \). The left part of Fig. 5 shows the cubic curve of the aisle width, \( \overline{{T_{a} }} ({\text{R}}^{2} = 0.9308) \) and \( \overline{{T_{b} }} ({\text{R}}^{2} = 0.8619) \), and the right figure shows the cubic curve of the hall width and \( T({\text{R}}^{2} = 0.7994) \).

The aisle width is within the range of 650–950 mm, and the three curves exhibit a downward trend later becoming stable. To explain the phenomenon, we selected the cumulative high density maps for the aisle widths of 450, 650, 800 and 950 mm for the analysis, as shown in Fig. 6. As can be seen from the figure, as the aisle widens, the density in the train decreases continuously.

4 Discussion

The door width is affected by the hall and aisle widths. When the door width is 800 mm, it plays a leading role in limiting, while when the door width is 1900 mm, the capacity of the aisle plays a leading role in the limiting. A door width of approximately 1300 mm exhibits good coordination with the other facilities (see Fig. 2).

The detention area, which is the buffer zone for the boarding and alighting, affects the total boarding and alighting time. In the range of 1300–2100 mm, a wider hall corresponds to a higher boarding and alighting efficiency (see Fig. 4).

The possible reasons for the findings shown in Fig. 6 are as follows. When the aisle width is 450 mm, only one person can pass through. The disembarking passengers enter the aisle while coordinating within the aisle. Because the passage is extremely narrow, people cannot effectively avoid one another, and the interior of the carriage is critically blocked. In this case, the densities of the passenger personal space area and passenger walking area are high. When a large number of passengers get off the bus, the aisle with a width of 450 mm cannot meet the passengers’ boarding and alighting requirements. When the aisle width is 650 mm, a conflict occurs in the middle of the aisle, and although the passengers can avoid it, the coordination time is extremely large. When the aisle width is 800 mm, the downlink passenger flow may collide with the uplink passenger flow when it arrives at the joint of the hall and aisle, resulting in a high density in the hall and low boarding and alighting efficiency. When the aisle width is 950 mm, the passengers can exit the aisle and enter the hall smoothly. At this point, the aisle capacity matches that of the door and the hall, and the passengers can promptly complete the boarding and alighting process.

5 Conclusion

To study the influence of the three factors on the boarding and alighting efficiency, we built a passenger boarding and alighting simulation model. By changing the values of the variables, the passenger boarding and alighting time at different levels of each factor was output. This study provides a reference for the train vehicle layout design in door width, hall width and aisle width. The optimal value of the door width ranges from 1300 to 1400 mm; the optimal value of the hall width is 2100 mm; and the optimal value of the aisle width is 950 mm.

Further studies will be aimed at analyzing more train vehicle layout factors and more values of the passenger ratio.

References

Rüger, B., Tuna, D.: Optimizing railway vehicles in order to reducing passenger change over time. J. XIII naučno-stručna konferencija o železnici. 9(10), 25–28 (2008)

Harris, N.G., Graham, D.J., Anderson, R.J., Li, H.: The impact of urban rail boarding and alighting factors. In: Transportation Research Boarding Meeting, London, pp. 1–13 (2014)

Fujiyama, T., Thoreau, R., Tyler, N.: The effects of the design factors of the train-platform interface on pedestrian flow rates, pp. 9–95. Springer International Publishing (2014)

Jungtai, K., Moo, S.K., Jae, S.H., Yong, H.C., Taesik, K.: An analysis of boarding and alighting times for urban railway vehicles. J. Korean 17(3), 210–215 (2014)

Thoreau, R., Holloway, C., Bansal, G.: Train design features affecting boarding and alighting of passengers: Train design affecting boarding and alighting. J. Adv. Transp. 50(8), 1–10 (2017)

Qiu, H., Fang, W.: Train vehicle structure design from the perspective of evacuation. J. Chin. Mech. Eng. 32(1), 88–100 (2019)

Qiu, H., Fang, W.: Effect of high-speed train interior space on passenger evacuation using simulation methods. J. Phys. A. 528, 378–392 (2019)

Liu, D., Zhao, B., Li, L.: Investigation and analysis of pedestrian characteristic parameters at Beijing South Railway Station. J. Architectural Sci. 27(5), 61–66 (2011)

Buchmueller, S., Weidmann, U., Nash, A.: Development of a dwell time calculation model for timetable planning. WIT Trans.State Art Sci. Eng. 1, 105–114 (2010). G. Version 1

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Wang, C., Fang, W., Chen, Y., Li, C. (2020). Effect of Intercity Train Vehicle Layout on Boarding and Alighting. In: Stanton, N. (eds) Advances in Human Aspects of Transportation. AHFE 2020. Advances in Intelligent Systems and Computing, vol 1212. Springer, Cham. https://doi.org/10.1007/978-3-030-50943-9_19

Download citation

DOI: https://doi.org/10.1007/978-3-030-50943-9_19

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-50942-2

Online ISBN: 978-3-030-50943-9

eBook Packages: EngineeringEngineering (R0)