Abstract

Most computer-aided engineering software provide a classical incremental computation procedure for nonlinear problems. Although little used in the literature, the Brezis-Ekeland-Nayroles (BEN) principle, an alternative step-by-step algorithm, based on the time integration of the sum of the dissipation potential and its Fenchel polar can have a global view of whole evolution. In short, the BEN principle converts a mechanical problem to a constrained optimization problem. Recently, Buliga and de Saxcé have proposed a symplectic version of the BEN principle which generalizes the Hamiltonian inclusion formalism for the dissipative systems. In the present work, this formalism is specialized to the standard plasticity in small, finite strains, in statics and dynamics. We apply it numerically to solve the classical problem of a tube problem in plane strain subjected to an internal pressure in statics and dynamics. An excellent agreement is obtained between the numerical results obtained by the BEN approach and the reference numerical solution.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

A lot of mechanical problems have non-linear behaviors because of dissipative phenomena such as plasticity, damage, etc. Their analytical solutions cannot be determined easily. As it is unlikely to carry out all kinds of experiments for the similar problems, the computer-aided engineering (CAE) software has been developed in the last 30 years. For a non-linear problem, most of the software uses the step-by-step or incremental method [1,2,3,4,5] in computational solid mechanics.

In practice, by using the step-by-step method, some simulations cannot be completely performed because the convergence frequently fails before the end of the computation and it is difficult to restart. The only solution to overcome the difficulty often lies in reducing the step size but increases the computational time. Another difficulty arises because, in an iterative method, truncation error occur at each iteration. So the computation error of the usual step-by-step method based in radial return algorithm accumulates and grows as the number of step increases. This error cannot be avoided and it may strongly affect the whole accuracy of complex simulations.

Using step-by-step methods, we are going, as it were, with the head down. This is the breakthrough we want to get. To address this issue, there is few methods in literature. We propose to start with Brezis-Ekeland-Nayroles principle (in short, the BEN principle) [6, 7]. It is based on the dissipation potential and its Fenchel transform over the time integration. In [8,9,10], the BEN principle is extended in a pure mathematical manner a few to monotone operators and doubly nonlinear equations, or reworked in order to have a discretized form. Recently, Buliga and de Saxcé [11] generalized the BEN principle to the dynamics of dissipative systems by linking two worlds together, the one of smooth functions in symplectic geometry systems and the one of non-smooth functions for dissipative systems. They applied this symplectic BEN principle to standard plasticity [12] in dynamics and deduce from it the limit case of statics. The BEN principle is a tool perfectly designed to solve complex problem of evolution of dissipative systems. In place of computing in the step-by-step way and facing the convergence problem, the BEN principle allows to work simultaneously over all steps, that allows to have a consistent view of the whole evolution.

According to the authors’ knowledge, no one has ever numerically applied the BEN principle to test its feasibility to work on all time steps simultaneously. The aim of this paper is to implement numerically the powerful BEN principle by solving a mechanical problem in statics and dynamics. When the analytical solution cannot be provided, the BEN principle solution is compared with the numerical solution of a standard finite element (FM) method solver.

The paper is divided in three parts. Firstly, we present directly the BEN principle for elastoplasticity in statics and dynamics. Then, we apply the general principle to the tube problem, using the mixed FE [13, 14] to avoid the drawbacks of the standard or displacement FE, like inaccuracy of the stress field, simulation results for elastic, elastoplastic regime in statics and dynamics. Simulation results are presented separately with different plastic criteria and behavior laws.

2 BEN Principle for Elastoplasticity

To illustrate the general formalism and to show how it allows to develop powerful variational principles for dissipative systems within the frame of continuum mechanics, we consider the standard plasticity and viscoplasticity in small deformations based on the additive decomposition of strains into elastic and plastic strains:

where S is the elastic compliance tensor. Let \(\displaystyle \varOmega \subset \mathbb {R}^{n}\) be a bounded, open set, with piecewise smooth boundary \(\partial \varOmega \). As usual, it is divided into disjoint parts, \(\partial \varOmega _0\) (called support) where the displacements are imposed and \(\partial \varOmega _1\) where the surface forces are imposed. U and E are suitable functional spaces of displacement and stress fields on \(\varOmega \). The standard duality between stress and strain fields is:

Applied to the quasi-static plasticity, the BEN principle claims that the evolution curves \({\sigma }: [0, T] \rightarrow E\) and \({u}: [0, T] \rightarrow U \) minimize:

among all curves satisfying:

-

the equilibrium equations in statics:

$$\begin{aligned} \nabla \cdot {\sigma } + {f} = {0}\quad \text {in}\quad \varOmega ,\qquad {\sigma }\cdot {n} = \bar{{f}} \quad \text {on}\quad \partial \varOmega _1 \end{aligned}$$(2) -

the equilibrium equations in dynamics:

$$\begin{aligned} \nabla \cdot {\sigma } + {f} = \rho \ddot{u} \quad \text {in}\quad \varOmega ,\qquad {\sigma }\cdot {n} = \bar{{f}} \quad \text {on}\quad \partial \varOmega _1 \end{aligned}$$(3) -

the kinematical conditions on supports:

$$\begin{aligned} {u} = \bar{{u}} \quad \text {on}\quad \partial \varOmega _0 \end{aligned}$$(4) -

and the initial conditions:

$$\begin{aligned} {\sigma } (0) = {\sigma }_0, \qquad {u} (0) = {u}_0 \end{aligned}$$(5)

The following is detailed in statics. To show the pertinence of the principle, we prove now that the stationarity condition of the variational principle restitues the expected equations governing the elastoplastic evolution problem. First, we introduce densities \(\phi \) and \(\phi ^*\) such that:

If \(\phi \) and \(\phi ^*\) are differentiable, the yielding rule and the inverse law are:

Then Eq. (1) reads:

The stationarity conditions is:

Taking into account that the stress fields satisfy a priori the initial conditions (5):

and time integrating by part leads to:

Taking into account that the displacement fields satisfy a priori the kinematical conditions (4):

and space integrating by part the second term of the former line gives:

Taking into account that the stress fields satisfy a priori the equilibrium equations (2), the expression (10) becomes:

Introducing this expression into Eq. (9) and considering arbitrary field variations, we obtain for every time:

Condition (11) means that the stress and plastic strain given by Eq. (6) fulfill the classical strain decomposition into plastic and elastic parts:

Condition (12) and (13) mean that the stress field given by the inverse law (6) verifies the equilibrium equations.

The previous framework is valid only under suitable assumptions of differentiability of dissipation potentials in viscoplasticity, for instance for Norton-Odqvist model. The case of classical plasticity is singular since the potential \(\phi \) is non-differentiable as indicator function \(\chi _K\) of the elastic domain K, equal to 0 on K and to \(+\infty \) otherwise. This pitfall can be by-passed in practice by relaxing the plasticity criterion:

thanks to a field of Lagrange multiplier \(\lambda \), with \(f_{vm}\) von Mises criterion adn \(f_T\) Tresca one. Then BEN principle specialized to classical plasticity claims that the evolution curves \({\sigma }: [0, T] \rightarrow E\) and \({u}: [0, T] \rightarrow U \) minimize:

among all curves satisfying the plasticity criterion (14), the equilibrium equations (2), the kinematical conditions on supports (4) and the initial conditions (5). Formally, the plasticity is a particular case of viscoplasticity, replacing the potential \(\phi \) by \(\lambda \,f\) and the yielding rule (6) provides the normality law:

3 The Tube Problem in Statics

The previous section provides some useful notions of the BEN principle. Thanks to the Eqs. (1, 2, 4, 5), the mechanical problem could be solved as an optimization problem. To start up, we choose a classical academic example, the thick tube subjected to an internal pressure.

To simplify, we take an axisymmetric problem. The internal and external radii of the tube are a and b respectively. The imposed internal pressure is p. For material parameters, we have Young’s modulus E, Poisson coefficient \(\nu \) and yield stress \(\sigma _Y\). Supposing that the thick tube is in plane strain and the initial fields are null, if the internal pressure increases in the monotone way from zero to limit charge, the internal wall of the tube will come to yield firstly, and successively the external wall.

One material behavior laws and two yield criteria are discussed, isotropic perfectly plastic behavior law, Tresca or von Mises criteria.

3.1 Application of the BEN Principle

Taking into account the is axisymmetry and the plane strain, the displacement u depends only the radius and is radial:

The stress and strain tensors are given in small deformations hypothesis by:

The elastic domain is:

The dissipation power by unit volume is:

where \({\sigma }\) and \({\dot{\epsilon }^p}\) are associated by the normality law. The dissipation power is:

The dissipation potential for both criteria is:

with \(\chi _K\) the indicator function of the elastic domain K. The Fenchel conjugate function is:

Applying the BEN principle, we minimize the functional (15) that reads:

among all the curves among all curves \(({\sigma }, {u}): [t_0, t_1] \rightarrow U \times E \) such that \({\sigma } (0) = {0} \), \({u} (0) = {0} \), satisfying Tresca or von Mises yield condition, the normality rule and the equilibrium equations.

3.2 Mixed Finite Element Method for Thick Tube Problem

The mixed finite element method (FEM) is proposed to discretize the functional which allow to have different discretized fields at the same time like stress, displacement, plastic multiplier etc. The mixed FEM has a better convergence in a stress field which is statically admissible specially for beam, plate and shell element, also a good accuracy of stress in plasticity. For the thick tube problem, there are three unknown fields: radial and hoop stresses, radial displacement and plastic multiplier.

3.2.1 Stress Field

As the thick tube is modeled by an axisymmetric element (\(a \leqslant r \leqslant b\)), imposing an axisymmetric element inside the thick tube with \(\alpha \leqslant r \leqslant \beta \), there are two stress connectors (radial and hoop stresses) per end of the element gathered in the vector:

In order to satisfy a priori the internal equilibrium equations in the constrained minimization problem, we choose a polynomial stress field \({\sigma }_e\) which depends on the stress parameters h of the element. The expression of the hoop stress is derived from the equilibrium equation \({\sigma }_{\theta \theta } = \frac{d}{dr}(r{\sigma }_{rr})\), that gives in matrix form:

Owing to Eqs. (20) and (22), we have the stress connectors \({g}_e\) in terms of the stress parameters h:

By eliminating the stress parameters between Eqs. (21) and (23), the stress field \({\sigma }_e\) is expressed in terms of stress connector \({g}_e\) of the element:

3.2.2 Displacement Field

For the same element occupying \(\alpha \leqslant r \leqslant \beta \), there is one displacement connector \({q}_e\) at each end:

In order to provide a strain field which has the same number of parameters as the one of the stress field, we add two intermediate equidistant nodes inside the element:

and two extra connectors \( {q}_{e,3} = {u}_r\mid _{r = \gamma }, \; {q}_{e,4} = {u}_r\mid _{r = \delta } \). The four displacement connectors are gathered in the vector:

A polynomial displacement field \(u_r\) is proposed:

By defining a cubic Lagrange interpolation, we obtain the relation between the displacement field \(u_r\) and the displacement connectors \({q}_e\):

with:

The corresponding strain field \({\varepsilon }_e\) can be expressed in terms of the displacement connectors of the element thanks to Eq. (17):

3.2.3 Plastic Multiplier Field

Introducing the plastic multipliers \({\lambda }\) which are located at the four Gauss point for each element \(\alpha \leqslant r \leqslant \beta \), the flow rule reads:

3.2.4 Discretization of the Functional

For the thick tube problem, we have three discretized fields for one element \(\alpha \leqslant r \leqslant \beta \), stress \({\sigma }_e\), displacement \({u}_r\) and plastic strain rate \({\dot{\varepsilon }}^p_e\) which depend on each connectors, stress connectors \({g}_e\), displacement connectors \({q}_e\) and plastic multipliers \({\lambda }_e\):

We have now the BEN principle equation, the application of the mixed FEM. To numerically solve the thick tube problem, it remains to obtain the discretization form of Eq. (19).

-

1.

Space integral discretization

For the space discretization, we would like to evaluated the stress and displacement fields in four Gauss point for each element where the plastic multipliers are located. So the space integral is approximated by the usual Gaussian quadrature numerical integration method on every axisymmetric element:

Thanks to the localization matrices \({M}_e, {L}_e, {P}_e\) for each unknown field, we could carry out the assembling:

The discretized form of the functional Eq. (19) is:

with:

under the constraints of:

-

equilibrium (on the boundary, the internal equilibrium being satisfied a priori):

$$\begin{aligned} g_1(t) = - p (t),\qquad g_{2\,(n+1)} (t) = 0 \end{aligned}$$(30) -

plasticity (at every Gauss point g of every element e):

$$\begin{aligned} {N}^T_{Y,e }(r_g)\, {g} - \sigma _Y \le 0, \qquad {\lambda }_g \ge 0, \qquad {N}_Y {\lambda }_g= {B}_e (r_g) \,\dot{{q}}_e - {S}\,{T}_e (r_g)\,\dot{{g}}_e \end{aligned}$$(31) -

initial conditions:

$$\begin{aligned} {g} (t_0) = {0},\qquad {q} (t_0) = {0}, \qquad {{\lambda }} (t_0) = {0} \end{aligned}$$(32)

with \({N}_{Y,e} (r_g) = {M}^T_e {T}^T_e (r_g) {N}_Y\).

-

2.

Time integral discretization

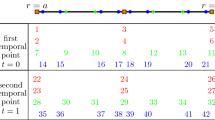

For any physical quantity a, we impose \( a_j = a (t_j), \; \varDelta a_j = a_j - a_{j - 1} \). On each step, we approximate the time rate by \( \dot{a} = \frac{\varDelta a_j}{\varDelta t_j} \). As the plasticity is independent of the time parameterization in statics, we use for convenience sake:

Considering m time step from \(t_0\) to \(t_m\) and enforcing the yield condition only at the beginning and the end of the step, we have to minimize the objective function:

under the constraints of:

-

equilibrium (on the boundary, at each time step):

$$\begin{aligned} g_{0,j} = - p (t_j),\qquad g_{2\,(n+1) - 1,j} = 0 \end{aligned}$$(35) -

plasticity (at every Gauss point g of every element e and at every time step):

$$\begin{aligned} {N}^T_{Y,e} (r_g) {g}_j - \sigma _Y \le 0, \qquad {\lambda }_{g,j} \ge 0 \qquad {N}_Y (r_g) {\lambda }_{g,j}= {B}_e (r_g) \,{L}_e \varDelta {q}_j - {S}\,{T}_e (r_g)\,{M}_e \varDelta {g}_j \nonumber \\ \end{aligned}$$(36) -

initial conditions:

$$\begin{aligned} {g}_0 = {0},\qquad {q}_0 = {0}, \qquad {{\lambda }}_0 = {0} \end{aligned}$$(37)

3.3 Implementation and Simulation Results

Matlab and its solver fmincon can find the minimum of constrained nonlinear multivariable function. The functional (34–37) is a quadrature non-linear function under linear (Tresca criterion) or quadrature (von Mises criterion) constraints.

In the program, one needs to impose a small tolerance for the equality constraint (Eq. 36) in the optimization problem because there always exists the computation error which deduces that the equality can not be satisfied exactly. For all fields in all temporal en points, their optimization depart points are 0.1.

For simulation work, the numerical values of the thick tube radius a, b, material parameters Young’s modulus E, etc. need to be provided firstly. Then one needs to specify the number of elements and number of temporal end points. And the imposed pressure for each time step also the initial condition should be fixed. Finally, Matlab solver will minimize the BEN principle functional.

Here are three examples, the elastic and elastoplastic case with Tresca or von Mises criterion which are theoretically explained in the previous section. The numerical values for the thick tube and material parameters are: \(a=100\) mm, \(b=200\) mm, \(E = 210\) GPa, \(\nu = 0.3\) and \(\sigma _Y = 360\) MPa. For the elastic case, the internal pressure is \(p=100\) MPa, and \(p=200\) MPa for the elastoplastic case.

3.3.1 Elastic Regime

In this regime, there are two fictive temporal end points, \(t=0\) and \(t=1\). When \(t=0\), all unknown fields are equal to zero (initial conditions). When \(t=1\), the internal pressure is imposed as \(p=100\) MPa. Simulation results are shown in Figs. 1 and 2. With one element (\(ne = 1\)), the convergence of radial stress is better than the one of the hoop stress (Fig. 1), because the radial stress is imposed as a constraint in the beginning of simulation. For radial displacement, convergence appears with 3 elements (Fig. 2). As the plastic multipliers are equal to zero in the elastic regime, its results are not represented here. By increasing the number of element to 3, the BEN principle result already converges to the analytical solution.

To conclude for the elastic regime, the BEN principle solution converges soon to the analytical solution while increasing the number of elements. Moreover, for one element, the convergence of stress field is faster than the one of radial displacement.

3.3.2 Elasto-Plastic Regime (Tresca Criterion)

For the elastoplastic regime, there are also two fictive temporal end points, \(t=0\) for initial conditions and \(t=1\) directly for the imposed pressure \(p=200\) MPa which makes the internal wall come to yield. The mid temporal end point for the elastic regime is not necessary. As the BEN principle is based on dissipation potential, its characteristic allows to have a better performance in plastic regime which is an advantage comparing to usual computing code.

As the analytical solution in the plastic part is not easily to obtain, the numerical solution of software Cast3M is chosen as the reference solution. Cast3M is an open-source software developed in French Alternative Energies and Atomic Energy Commission (CEA).

Simulation results are shown in Figs. 3, 4 and 5. There is a better convergence for the stress field even with one element (Fig. 3) comparing to the elastic regime. That is a big advantage in mechanical simulation while the mechanism comes to yield. For radial displacement, there is the convergence when 3 elements are modeled. The extra Fig. 5 is the plastic multiplier. As these three unknown fields are linked by the constraint of decomposition of strains, so the plastic multiplier field converges to reference one also with 3 elements.

For the elastoplastic regime, the BEN principle solution converges to reference solution while increasing the number of elements. It has a better convergence than the elastic regime. The mid-step for elastic regime is not required.

3.3.3 Elasto-Lastic Regime (von Mises Criterion)

The only difference between Tresca and von Mises criterion is the optimization constraint because of the computing of the equivalent stress. Only the results of stress field is represented here for the reason of page limit.

Simulation results are represented in Fig. 6. Comparing to the Tresca criterion, interface between elastic and plastic part of von Mises case is smaller. The convergence of displacement and plastic multiplier field with von Mises criterion is faster than the ones of Tresca. Convergence of the BEN principle while increasing the number of element is always satisfied as before.

4 The Tube Problem in Dynamics

In dynamics, we need to consider the inertia force, \(\rho \ddot{u} \ne 0\). After some paper work, the functional to minimize is same as the one in statics. Expression of displacement field is always the same. The one of stress field is modified because of the change in equilibrium equation.

4.1 Stress Field

There are two different methods to discretize the stress field.

-

Method A allows to satisfies the balance of momentum equation exactly.

-

Method B considers the equation as an optimization constraint which is satisfied in Gauss points.

4.1.1 Method A: Balance of Momentum Satisfied Exactly

The principle is same as in the case of statics. Here we use the method due to Schaefer ([15, 16]) in order to find the solution of the equilibrium equation. The general solution of:

is the sum of the general solution \({\sigma }_h \) of the homogeneous equation and a particular solution \({\sigma }_d \) of the non homogeneous equation. Following a method due to Schaefer, this last one is of the form:

where the vector potential w is solution of \( {\nabla ^2 {w} = \dot{{p}}} \). For the displacement field, we seek a radial vector potential. The previous equation reduces to:

Clearly, a solution is given by a homogeneous polynomial in r of degree five. Introducing it in the previous equation, we obtain by identification:

condition (38) reads in polar coordinates:

leads to the expression of \({\sigma }_d\):

Besides, the homogeneous stress field being defined by four connectors is same as in statics. In matrix form, the total stress field in terms of stress and displacement parameters reads:

stress connectors are linearly depending on the stress and displacement parameters:

Hence, one has: \( { {h}_e = {C}^{-1}_e ({g}_e - {D}_e \dot{{v}}_e)} \). Eliminating the stress parameters provides the stress field in terms of stress and displacement connectors:

where:

4.1.2 Method B: Balance of Momentum Satisfied in Gauss Points

We choose the same position for the radial and hoop stress field as the one of displacement.

There are four degrees of freedom for each stress:

Thus:

4.2 Spatial and Temporal Discretization

The discretized form of the functional adapts with the corresponding discretization of the stress field.

4.2.1 Method A

Performing the same assembling, the discretized form of the functional is:

with:

The Brezis-Ekeland-Nayroles claims that we have to find the minimum of (41) with respect to the path \(t \mapsto ({g} (t), {q} (t), {\lambda } (t))\) under the constrains of equilibrium, plasticity and initial conditions as in statics.

For the time discretization of any physical quantity a, we put:

On each step, we approximate the time rates at \(t = t_j\) by:

Considering m time step from \(t_0\) to \(t_m\) and enforcing the yield condition only at the beginning and the end of the step, we have to minimize the objective function:

under the constrains of:

-

equilibrium (on the boundary, at each time step):

$$g_{r=a,j} (t_j) = - p (t),\quad g_{r=b,j} (t_j) = 0 $$ -

plasticity (at every integration point g of every element e and at every time step):

$$f_{g,j}({g}, \ddot{{q}}) - \sigma _Y \le 0, \quad \lambda _{g,j} \ge 0, $$$$ {N}_Y \lambda _{g,j}= {{B}_e (r_g) \,{L}_e \dot{{q}}^T_j - {S}\,\left[ {T}_e (r_g)\,{M}_e \dot{{g}}_j + {U}_e (r_g) \,{L}_e \dddot{{q}}_j \right] } $$ -

initial conditions:

$$\begin{aligned}&{g}_0 = {0},\qquad {q}_0 = {0}, \qquad {\lambda }_0 = {0}, \qquad \dot{{g}}_0 = {0},\qquad \dot{{q}}_0 = {0},\qquad \ddot{{q}}_0 = {0}, \qquad \dddot{{q}}_0 = {0} \end{aligned}$$

4.2.2 Method B

Performing the assembling thanks to the localization matrices \({L}_e, {M}_e, {P}_e\) such that:

the discretized form of the functional is:

with:

The Brezis-Ekeland-Nayroles claims that we have to find the minimum of (43) with respect to the path \(t \mapsto ({t} (t), {q} (t), {\lambda } (t))\) under the constrains of:

-

equilibrium (on the boundary, the internal equilibrium being satisfies a priori):

$$g_{r=a} (t) = - p (t),\quad g_{r=b} (t) = 0, \quad \frac{d}{dr} \sigma _r (r_g) + \frac{1}{r_g} \left[ \sigma _r(r_g) - \sigma _\theta (r_g)\right] = \rho \ddot{u}_r(r_g) $$ -

plasticity and initial conditions are same as in the method A

By applying the same time discretization of method A, considering m time step from \(t_0\) to \(t_m\) and enforcing the yield condition only at the beginning and the end of the step, we have to minimize the objective function:

under the constrains of:

-

equilibrium (on the boundary, at each time step):

$$g_{r=a,j} = - p (t_j),\quad g_{r=b,j} = 0, \quad \frac{d}{dr} \sigma _r (r_{g,j}) + \frac{1}{r_{g,j}} \left[ \sigma _r(r_{g,j}) - \sigma _\theta (r_{g,j})\right] = \rho \ddot{u}_r(r_{g,j}) $$ -

plasticity and initial conditions are same as in the method A

4.3 Simulation Results

The program is coded in Matlab, the solver fmincon is applied to find the local minimum of the constrained functional (42, 44). Material parameters are, \(E = 210\) GPa, \(\nu = 0.3\), \(\sigma _Y = 360\) MPa, \(a = 100\) mm, \(b=101\) mm, \(\rho =7.8\,e^{-9}\) Kg/mm\(^3\). Internal pressure history is displayed in 7. The Simulation results are displayed in Figs. 8 and 9 for elastic and plastic cases.

There is a good consistence between the BEN principle solution and the analytical or numerical solution. The BEN principle requires sufficient time steps to have a better precision than the one of step-by-step (Fig. 8). The method A and B does not change the simulation results in elastic case (Fig. 8). As displayed in Fig. 9, the method A is more accurate than the method B in plastic case as the momentum equation is satisfied exactly.

5 Conclusions and Future Works

In this work, the BEN principle has numerically proven with success. It allows to transform a mechanical problem into an optimization problem under constraints, that is how the BEN principle has the ability to work simultaneously on all time steps in place of using the step-by-step method and facing the convergence problem. Comparing to an usual computing code, another advantage of the BEN principle is the convenience of implementation of special plastic criteria and material behavior laws, but it is not always a good choice to impose a refined mesh to have a better solution. By means of the simulations, the BEN principle solution has a fast convergence to the reference solution, especially for the stress field, that is a big advantage in a plastic regime.

In the future, a more effective minimization solver is necessary to solve a large optimization problem. Moreover, as this is a space-time coupling problem, the computing time is expensive. We would like to apply the Proper Generalized Decomposition (PGD) reduction method [17,18,19] to the problem in order to decrease the computation time. The main idea of the PGD method is to separate space and time and carry out the computation of each field separately. Moreover, this method allows to modify the initial problem to a parametric model which is very useful for the mechanical problem.

References

Larman, C., Basili, V.R.: Iterative and incremental developments a brief history. Computer 36(6), 47–56

Boisse, P.H., Ladevèze, P., Rougée, P.: A large time increment method for elastoplastic problems. Eur. J. Mech. A. Solids 8(4), 257–275 (1989)

Boisse, P.H., Bussy, P., Ladeveze, P.: A new approach in non? linear mechanics: the large time increment method. Int. J. Numer. Methods Eng. 29(3), 647–663 (1990)

Ladevèze, P.: Sur une famille d’algorithmes en mécanique des structures. Comptes-rendus des séances de l’Académie des sciences. Série 2, Mécanique-physique, chimie, sciences de l’univers, sciences de la terre 300(2), 41–44 (1985)

Ladevèze, P.: New advances in the large time increment method. In: New Advances in Computational Structural Mechanics, pp. 3–21. Elsevier, Amsterdam (1991)

Brézis, H., Ekeland, I.: Un principe variationnel associéa certaines equations paraboliques. Le cas independant du temps. CR Acad. Sci. Paris Sér. A 282, 971–974 and 1197–1198 (1976)

Nayroles, B. (1976). Deux Theoremes De Minimum Pour Certains Systemes Dissipatifs

Appl, A.M.S.: Extension of the Brezis-Ekeland-Nayroles principle to monotone operators. Adv. Math. Sci. Appl 18, 633–650 (2008)

Stefanelli, U.: The Brezis? Ekeland principle for doubly nonlinear equations. SIAM J. Control Optim. 47(3), 1615–1642 (2008)

Stefanelli, U.: The discrete Brezis-Ekeland principle. J. Convex Anal. 16(1), 71–87 (2009)

Buliga, M., de Saxcé, G.: A symplectic Brezis? Ekeland? Nayroles principle. Math. Mech. Solids 22(6), 1288–1302 (2017)

Halphen, B., Nguyen, Q.S.: Sur les matériaux standard généralisés. J. de mécanique 14, 39–63 (1975)

Roberts, J.E., Thomas, J.M., Ciarlet, P.G., Lions, J.L.: Mixed and hybrid methods. In: Handbook of Numerical Analysis (1991)

Brezzi, F., Fortin, M.: Mixed and Hybrid Finite Element Methods, vol. 15. Springer Science & Business Media (2012)

Schaefer, H.: Die Spannungsfuncktionen des dreidimensionalen Kontinuums und des elastischen Körpers. Z. Angew. Math. Mech. 33, 356–362 (1953)

Gurtin, M., The linear theory of elasticity. In: Encyclopedia of Physics, S. Flügge, Mechanics of Solids II, vol. VIa/2. Springer, Berlin (1972)

Chinesta, F., Keunings, R., Leygue, A.: The Proper Generalized Decomposition for Advanced Numerical Simulations: A Primer. Springer Science & Business Media (2013)

Bognet, B., Bordeu, F., Chinesta, F., Leygue, A., Poitou, A.: Advanced simulation of models defined in plate geometries: 3D solutions with 2D computational complexity. Comput. Methods Appl. Mech. Eng. 201, 1–12 (2012)

Giner, E., Bognet, B., Rdenas, J. J., Leygue, A., Fuenmayor, F.J., Chinesta, F.: The proper generalized decomposition (PGD) as a numerical procedure to solve 3D cracked plates in linear elastic fracture mechanics. Int. J. Solids Struct. 50(10), 1710–1720 (2013)

Acknowledgements

The work is funded by the Dissipative Dynamical Systems by Geometrical and Variational Methods (DDGV) and Application to Viscoplastic Structures Subjected to Shock Waves international project by the French National Research Agency (ANR) in cooperation with the Institute of General Mechanics of RWTH Aachen University.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Cao, X., Oueslati, A., Nguyen, A.D., Stoffel, M., Market, B., de Saxcé, G. (2021). Numerical Method for Quasi-static and Dynamic Elastoplastic Problems by Symplectic Brezis-Ekeland-Nayroles Non-incremental Principle. In: Pisano, A., Spiliopoulos, K., Weichert, D. (eds) Direct Methods. Lecture Notes in Applied and Computational Mechanics, vol 95. Springer, Cham. https://doi.org/10.1007/978-3-030-48834-5_10

Download citation

DOI: https://doi.org/10.1007/978-3-030-48834-5_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-48833-8

Online ISBN: 978-3-030-48834-5

eBook Packages: EngineeringEngineering (R0)